System components

1. Both Recessed Horizontal and Slim Flush Tracks consist of 3 parts,

the track housing, the track, and the locking strip.

2. End pulley assembly - This can either be installed when the

housing is installed or at the time the mechanism is installed.

3. Track protector: It is important to protect the track while the

concrete deck is being poured. This can be done either by using

10 mill plumbing tape or using an optional track protector that is

available for recessed horizontal track (X0865).

Installation Guidelines

1. The installed tracks must start flush with the inside of the cover

box, which must be a minimum of 12 inches from the end of the

pool and extend 18 inches beyond the other end of the pool.

The tracks must form a perfect rectangle. The track lengths, the

distance between the tracks and the diagonals each must be

equal.

2. The tracks must be installed exactly at finished deck grade. It is

strongly recommended that the deck be kept level from the

pool to the track housings. Start the slope outside of the tracks.

Note: the deck around the cover housing boxes should be flat

for a minimum of 4” before starting any slope if a standard lid is to

be used.

3. The housing must have the track, a spacer (standard spacer or

optional plastic protector) and top protection in place before

pouring deck.

4. There are several ways that the tracks can be installed. In each

case track supports / mounting feet must be no further than 5’

apart.

a. Set in place using the mounting feet kit (A3031 for Slim

Flush Track. A1531 for Recessed Horizontal Track)

b. Mounted on top 2x4 stakes, which are left in the deck

permanently. Attach housing to the stakes with self

tapping screws or by drilling holes in the housing and

using drywall or deck screws.

c. Set into piles of concrete or gunite approximately every 4

feet. If this method is used, care must be taken to make

sure that no cement is left higher than the bottom of the

side of the channel. Otherwise it will have to be chipped

down before the deck is poured.

5. Regardless of how the tracks are installed, it is recommended that

a string line be left in place until after the pour.

6. The standard installation is with straight track; however, optional

curved pieces of recessed horizontal track are available if flush

deck lid is to be used. In this case, the deck is lowered 2” between

the tracks and the box is installed 2” lower.

7. It is recommended that a minimum width of 5 to 6 inches of

concrete be poured on each side of the housing. Rebar or

concrete wire under the housing will help eliminate the concrete

cracking and separating from the housing.

8. It is recommended that you put a strike joint off the end of your

track to control the shrinkage crack.

9. To avoid concrete flaking when the protector is removed, go down

each side with a 1/8-radius edger. For proper cover operation,

concrete must be as close to the top of the housing as is possible

10. Some builders find that it is easier to keep the tracks clean if they

install Deck-O-Drain channel between the end of the housing and

the end of the deck. However, this is optional.

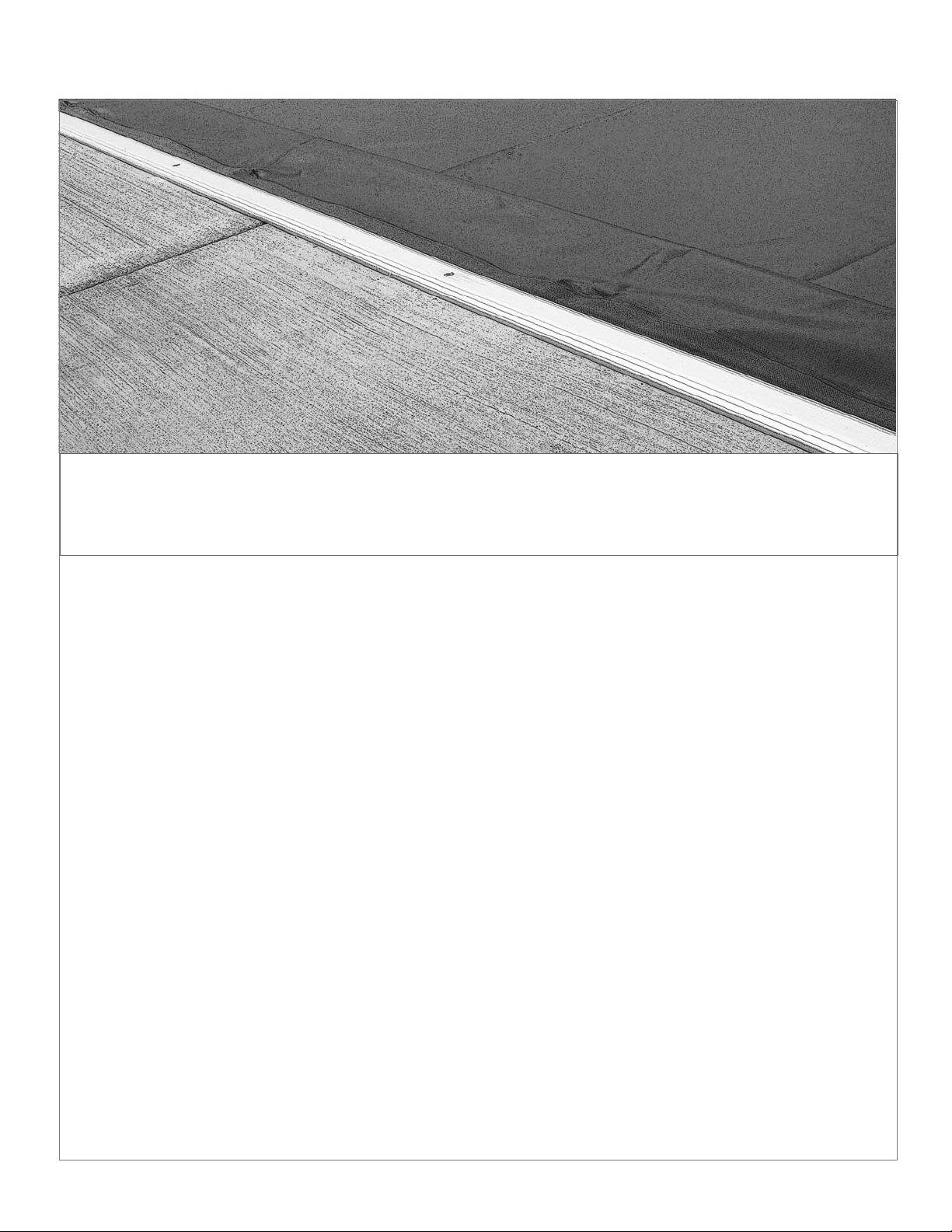

(4.a.) Track staked in place, ready for pour

(4.b.) Housing in place mounted on gunite piles ready

for deck pour.

Slim Flush Track with

Track, Housing and Spacer

(6) OPTION: Recessed horizontal track sloped into the

box. Purchase set of curved tracks for housing end of

track. Bend begins 15” in front of housing. Make sure

top of track is minimum of 1” lower than bottom of lid.

Recessed Horizontal

track with Track,

Housing and Spacer

(4.a.) Track staked in place using the optional

mounting feet, ready for pour

© Latham Pool Products, Inc. 2019. All rights reserved.