1.8M SERIES 1194 ANTENNA SYSTEM

TABLE OF CONTENTS

SECTION I GENERAL INFORMATION....................................................................... 5

1.0 INTRODUCTION ....................................................................................... 5

1.1 UNPACKING AND INSPECTION ............................................................. 5

1.2 FREIGHT DAMAGE.................................................................................. 5

1.3 MATERIAL - MISSING OR DAMAGED.................................................... 5

1.4 MECHANICAL INSTALLATION TOOLS .................................................. 6

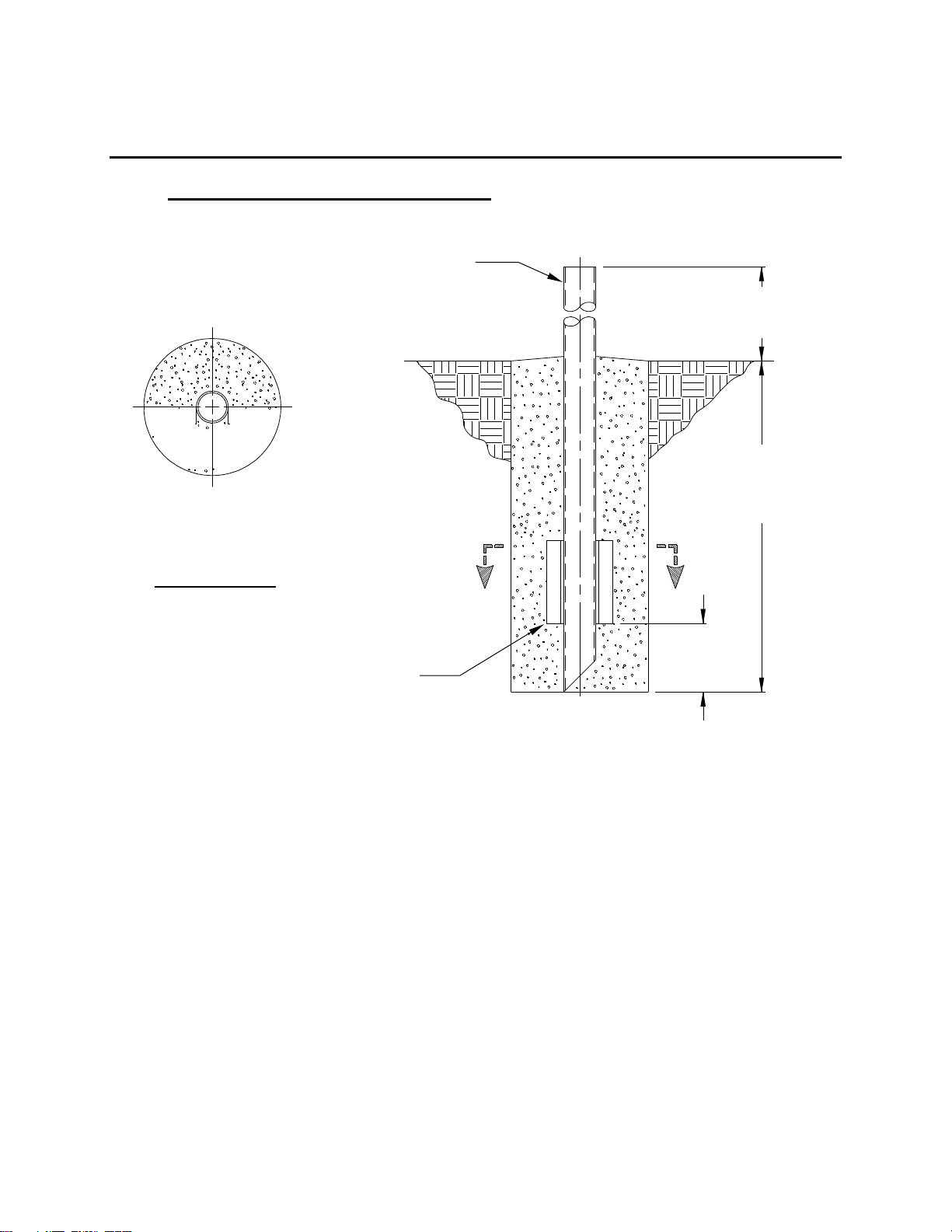

1.5 FOUNDATION INTERFACE ..................................................................... 6

1.6 SUGGESTED MAST & FOUNDATION..................................................... 7

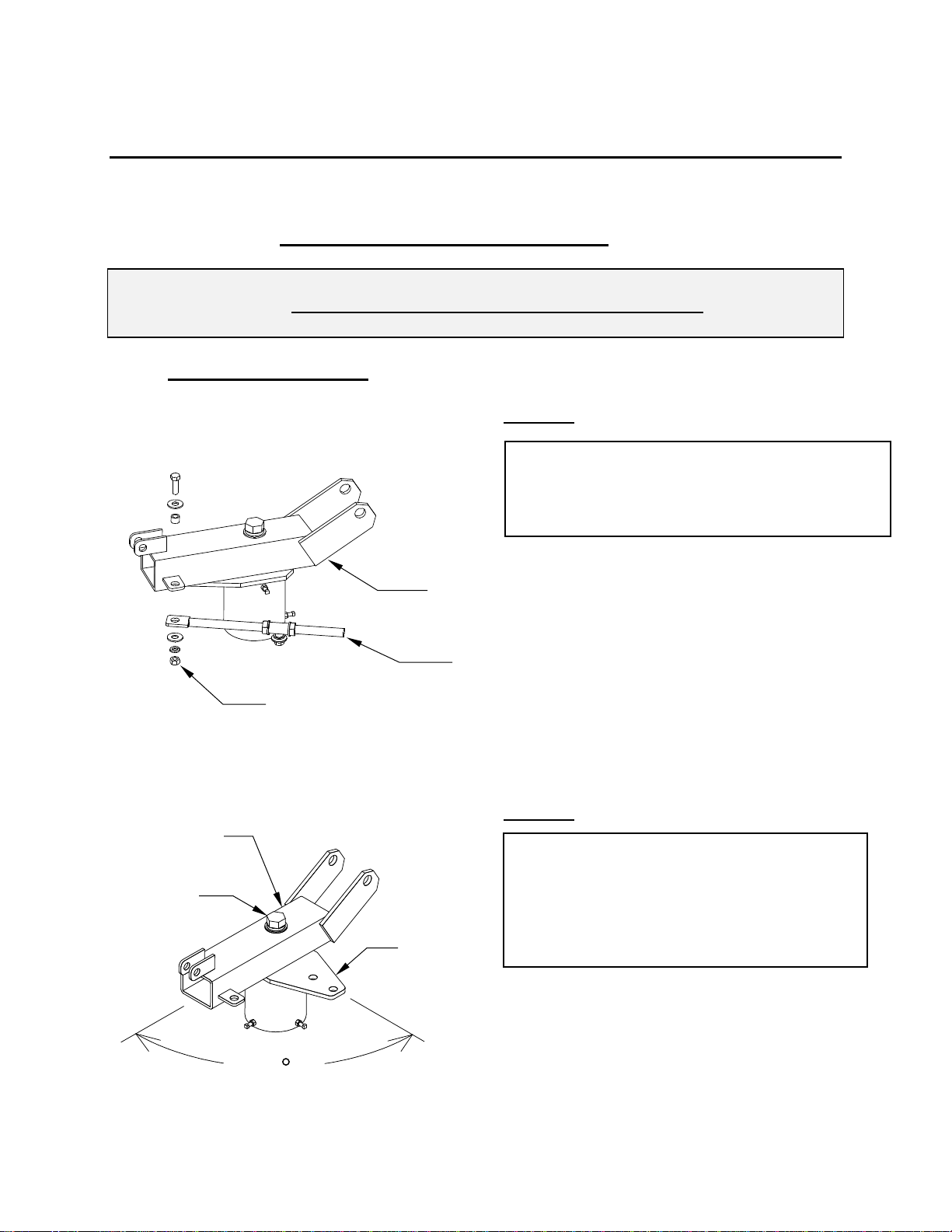

SECTION II ANTENNA SYSTEM ASSEMBLY............................................................. 9

2.0 ANTENNA ASSEMBLY ............................................................................ 9

2.1 FEED SUPPORT ASSEMBLY................................................................ 14

SECTION III ANTENNA POINTING............................................................................. 18

3.0 ANTENNA POINTING............................................................................. 18

SECTION IV MAINTENANCE ...................................................................................... 20

4.0 MAINTENANCE OVERVIEW.................................................................. 20

4.1 PERIODIC INSPECTION......................................................................... 20

4.2 REFLECTOR........................................................................................... 20

4.3 MOUNT AND REFLECTOR SUPPORT STRUCTURE........................... 21

4.4 FEED AND FEED SUPPORT.................................................................. 21