Table of Contents

2 / 27 Doc. No.: 9.0020.0589B0

Table of Contents

0Preface.....................................................................................4

1Safety.......................................................................................5

Symbols and meanings in this document..........................................5

Markings and meanings on the device..............................................5

Safety precautions of operating the Combiner ..................................6

2General Introduction..............................................................7

Overview of Grid-tied PV system.......................................................7

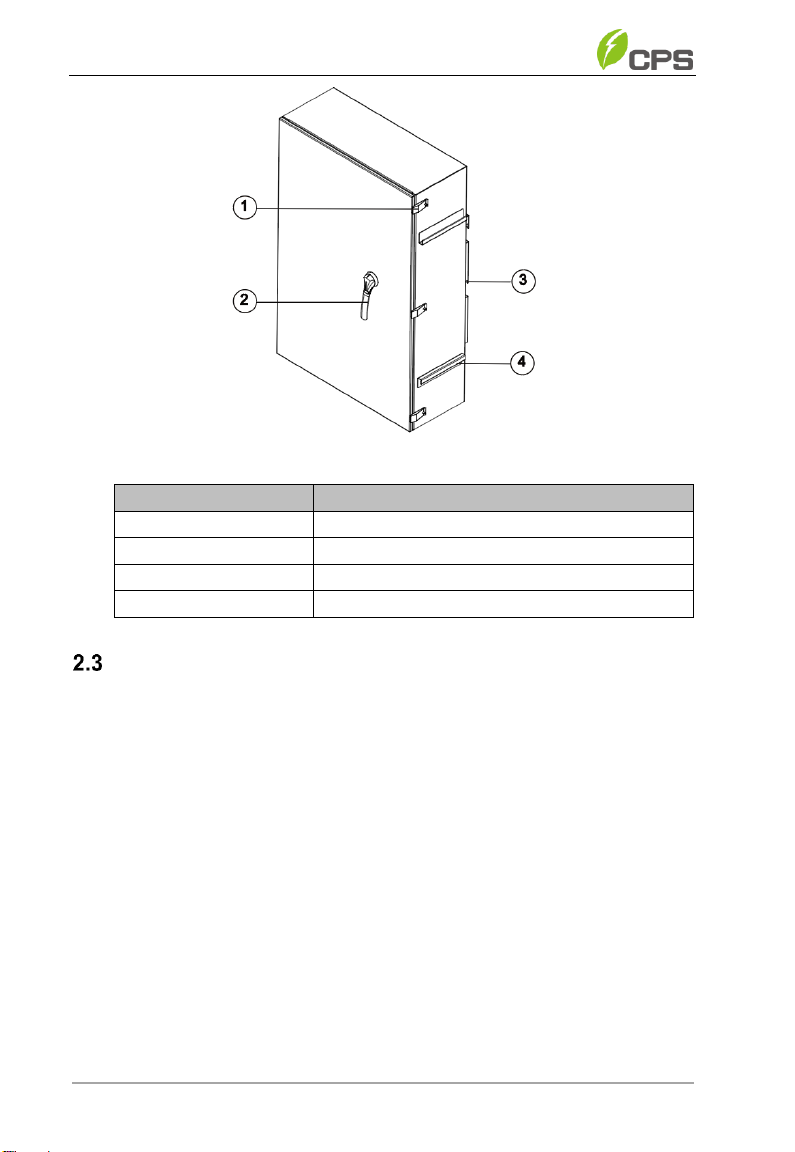

Appearance and dimension...............................................................7

Features of AC Combiner..................................................................8

Nameplate.........................................................................................9

2.4.1 Model No. .................................................................................9

2.4.2 Serial No.................................................................................10

Storage requirements......................................................................11

3Mechanical Installation........................................................12

Unpacking for Inspection.................................................................12

Installation requirements .................................................................12

3.2.1 Environment requirements......................................................12

3.2.2 Foundation requirements........................................................13

3.2.3 Installation requirements.........................................................13

Installation procedures ....................................................................13

Open and close the door.................................................................16

3.4.1 Open the door.........................................................................16

3.4.2 Close the door.........................................................................17

4Electrical Connection ..........................................................18

Electrical schematic diagram...........................................................18

Internal wiring terminals and cable specification .............................19

Recommended tools and torque values..........................................19

Wiring..............................................................................................20

4.4.1 Cable connection....................................................................20

4.4.2 Create conduit entry holes......................................................21

5Operation and Maintenance................................................22

Start up and shut down ...................................................................22

5.1.1 Start up ...................................................................................22

5.1.2 Shut down...............................................................................22

Maintenance....................................................................................23