+ Capacitors (caps) should be rated at least

150% of the expected voltage and a low

ESR is preferred. Over time, a higher

temperature rated cap will be less likely to

fail.

+ Caps have eective frequency ranges

depending on the material used in their

construction.

+ Aluminum electrolytic, or “metal can,” caps

are used for lower frequency noise and

voltage dips. These caps have positive and

negative terminals and must be connected

correctly or damage will occur. Capacitance

values ranging from tens to hundreds of

thousands of microfarads (uF) are available.

For example a 5000 uF 35 V 85 ºC aluminum

capacitor would be a good starting value.

+ Ceramic capacitors are used to control high

frequency noise. It is critical to keep these

as close a possible to the device input and

keep lead lengths short. Typical values are

0.001–0.47 uF, 50 VDC.

+ Inline inductors must be capable of

handling the full load current of the

device(s) attached to it.

+ Pi lters are typically sold as “noise lters”

by automotive audio stores. These must

also be able to handle full load current.

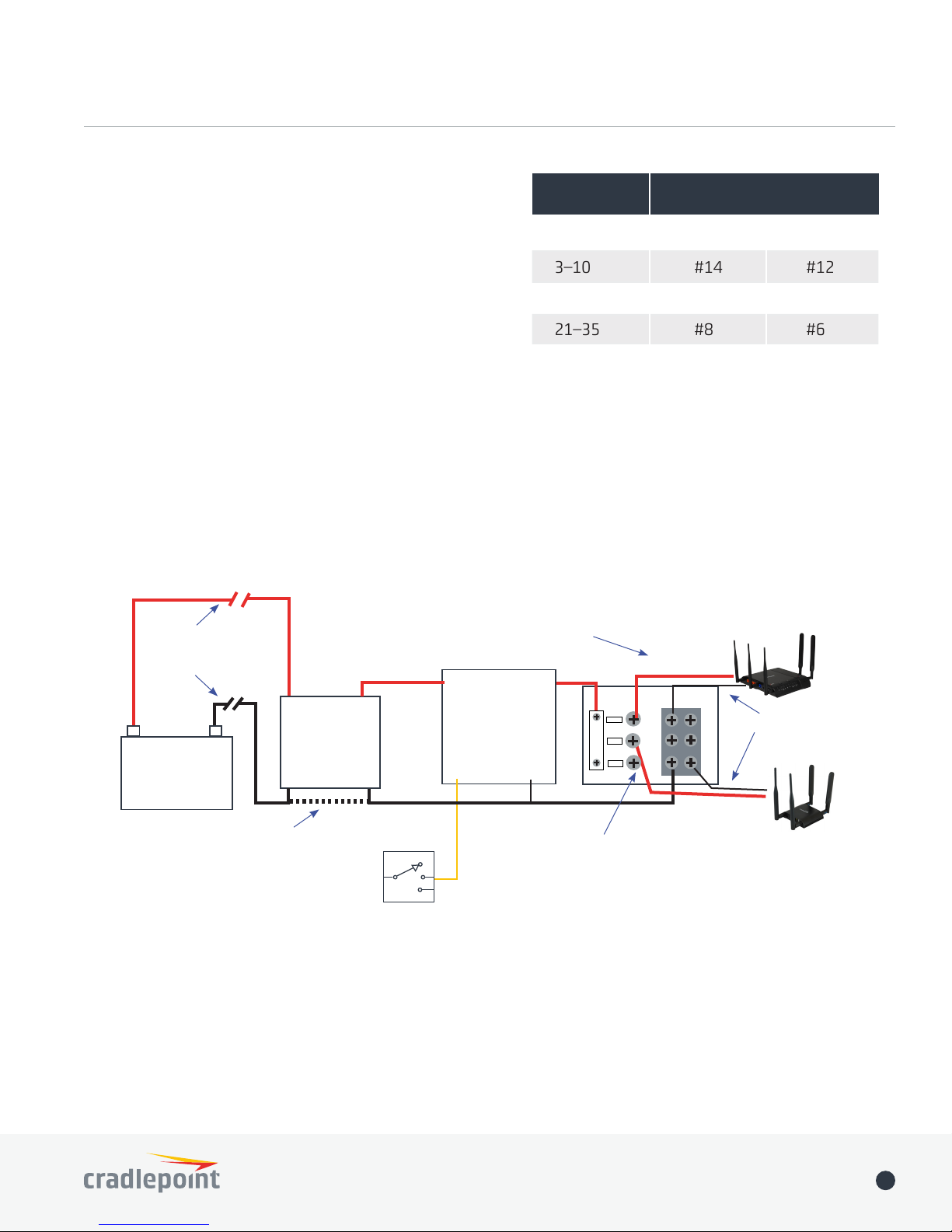

INSTALLATION, FUSING AND WIRING

Proper installation of the power conditioning

devices in relation to the mobile device you are

trying to protect is important.

+ It is best to locate all conditioning

devices such as DC-DC converters, power

management devices, distribution blocks,

and lters as close to the router equipment

as possible. That being said, some are more

critical than others.

+ Filters and distribution blocks should be

located as close to the mobile device(s) as

possible. Long power leads from the lter

to the mobile device can degrade or nullify

lter performance.

+ Use the proper wire size for the amount

of current being drawn. Long cable lengths

with undersized wire will result in voltage

losses over the length of the cable and

can possibly overheat (see table for

recommended wire size).

+ Use of a dedicated ground wire, rather

than attaching to chassis ground, may be

preferred.

+ Chassis ground can be susceptible to

corrosion eects and intermittent

connections.

©2017 Cradlepoint. All Rights Reserved. |+1.855.813.3385 |cradlepoint.com 7

White Paper /COR IBR600 Vehicle Installation Guide

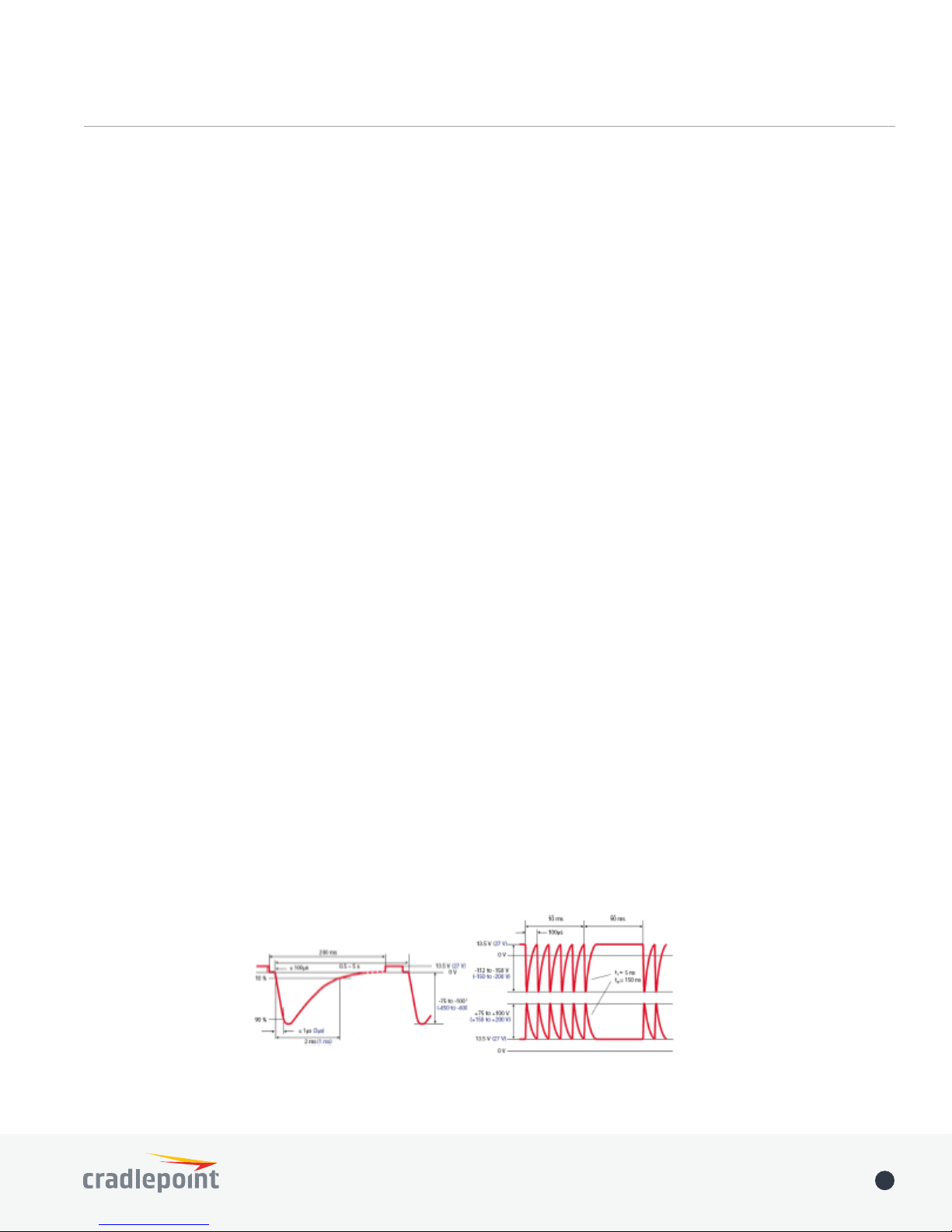

Fig 4. Standardized Examples of Automotive Transients (ISO-7637-2)