Switch

To

Motor

Figure 4 - Wiring Schematic

• Removing the rocker switch will lock the unit and

prevent unauthorized use.

A manual reset overload protector is installed in line

with the power supply to the motor. If the planer/molder

is overloaded, the protector will break the circuit.

If the breaker is tripped, turn the planer/molder "off" and

reset the circuit

by

pressing the button.

OPERATION

Refer to Figures 5 - 16.

DESCRIPTION

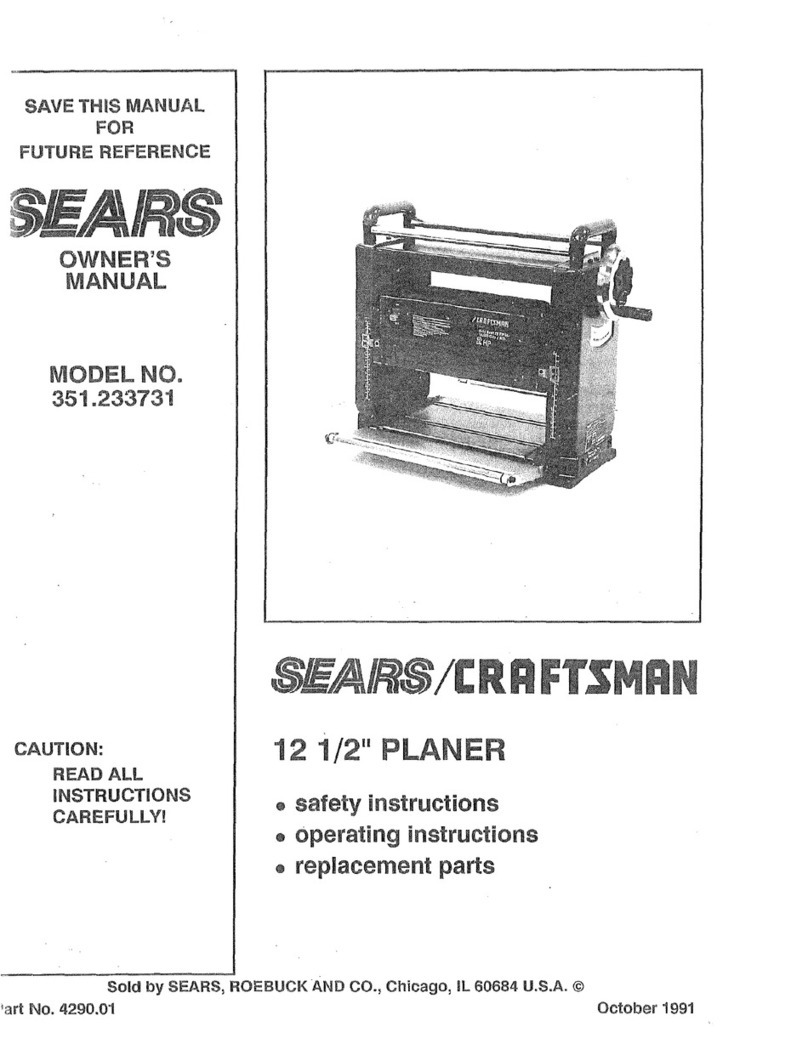

Sears 12W' planer/molder finishes rough-cut lumber to

size and planes soft and hardwoods up to 5" thick and

12W' wide. Produces decorative designs including fur-

niture moldings, baseboards, casings, picture frames,

tongue and groove, glue joints, rabetting and much

more.Wood feeds into three-blade cutterhead by

adjustable rubber in-feed/out-feed rollers. Large 12W' x

19" cast iron table has precision ground steel columns

for smooth feeding of the workpiece and reducing vibra-

tion. Motor has overload protection and is enclosed

in

the base of the machine, away from wood chips and

dust. The gearbox offers two speeds; 26 ftlmin. for fast

planing, and

13ft/min

for smooth finish molding. The

tool comes with anti-kickback mechanism for added

safety, and

bu

ilt-in carrying handles.

OPERATION SAFETY RULES

WARNING: Operation of any power tool can result

in

foreign objects being thrown into eyes which can result

in severe eye damage. Always wear safety goggles

complying with United States ANSI Z87.1 (shown on

package) before commencing power tool operation.

CAUTION: Always observe the following safety pre-

cautions:

• Know general power tool safety. Make sure all pre-

cautions are understood (see pages 2, 3 and 5).

• Whenever adjusting

or

replacing any parts on

planer/molder, turn switch off and remove plug from

power source.

• Make sure all guards are properly attached and

securely fastened.

• Make sure all moving parts are free from interference.

• Always wear eye protection or face shield.

• Make sure knives are aligned and properly attached

to cutterhead.

5

• Do not plug in planer/molder unless switch is in "off"

position. After turning switch on, allow planer/molder

to come to full speed before operating.

• Do not attempt to perform an abnormal

or

little used

operation without study and the use

of

adequate jigs,

fixtures and the like.

• Keep hands clear

of

all moving parts.

• Do not force cut. Slowing or stalling will overheat

motor. Allow automatic feed to function properly.

• Use quality lumber. Blades last longer and cuts are

smoother with good quality wood.

• Do not plane material shorter than

14Y2'',

narrower

than 3

.4"

, wider than 12W'

or

thinner than W'.

• Never make planing cut deeper than %".

• Maintain the proper relationships of infeed and out-

feed table surfaces and cutterhead knife path.

•

Do

not back the work toward the infeed table.

• Take precautions against kickback. Do not permit

anyone

to

stand or cross in line of cutterhead's rota-

tion. Kickback

or

thrown debris will travel in this

direction.

• Turn switch off and disconnect power whenever plan-

er/molder is not

in

use.

• Replace

or

sharpen knives as they become dam-

aged

or

dull.

• Keep planer/molder maintained. Follow maintenance

instructions (see page 12}.

DEPTH

OF

CUT

• Thickness planing refers to the sizing of lumber to a

desired thickness while creating a level surface par-

allel

to

the opposite side of the board.

• Quality

of

thickness planing depends on the opera-

tor's judgement about the depth of cut. Depth of cut

depends on the width, hardness, dampness, grain

direction and grain structure of the wood.

• Maximum thickness of wood which can be removed

in

one pass is

%2''

for planing operations. For opti-

mum planing performance, the depth of cut should

be

less than

~6,.

• Board should be planed with shallow cuts until the

work has a level side.Once level surface has been

created, flip the lumber and create parallel sides.

Plane alternate sides until the desired thickness is

obtained.

• When half of total depth of cut is taken from each

side, the board will have a uniform moisture content

and additional drying will not cause

it

to warp.

• Depth of cut should be shallower when work is wider.

• When planing hardwood, take light cuts or plane the

wood in thin widths.

• Make test cut when working with a new type

of

board or different kind

of

operation.

• Check accuracy of test cut prior to working

on

fin-

ished product.