RAISE BLAD

3 INCHES

E

rr-

t:7"

LD

V

<

r-.

T

~.

~

to

'---

DISTANa SHOU

BE EQUAL,

TURN BLADE-

MEASURE FROM

SAME

TOOTH

A

TABLE LEVEL

FENCE MUST LOCI<

PARAUEl WITH

MITER SLOTS

FIGURE 5

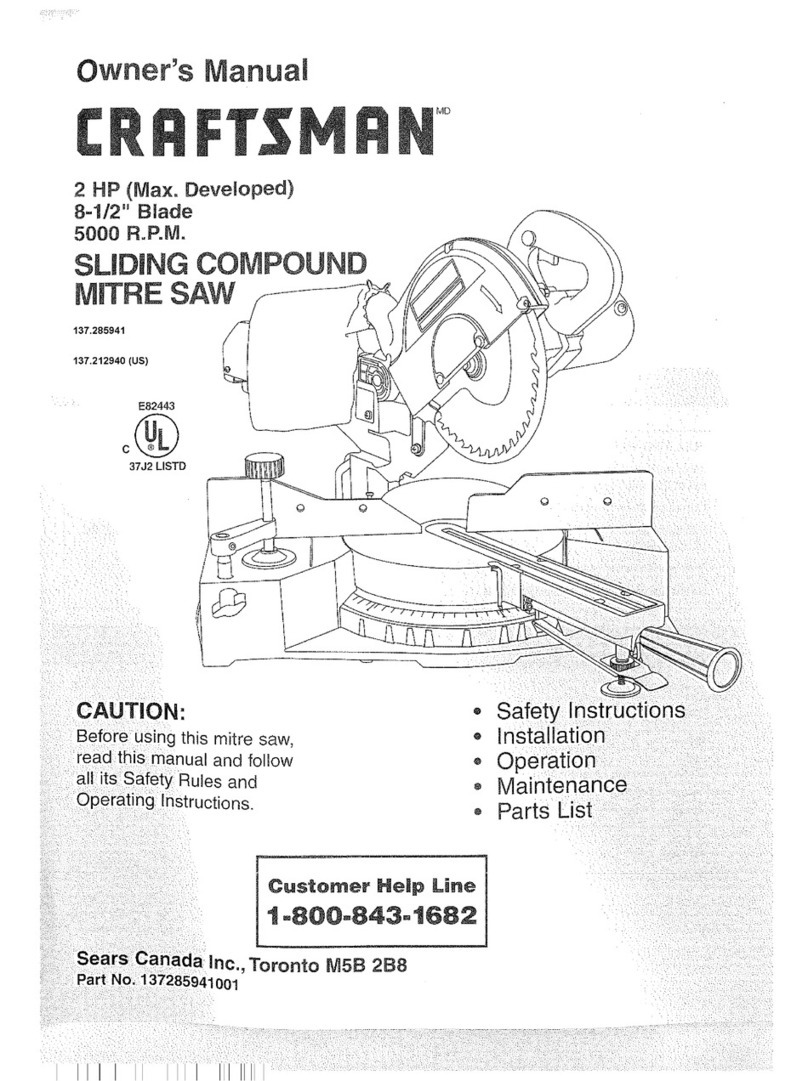

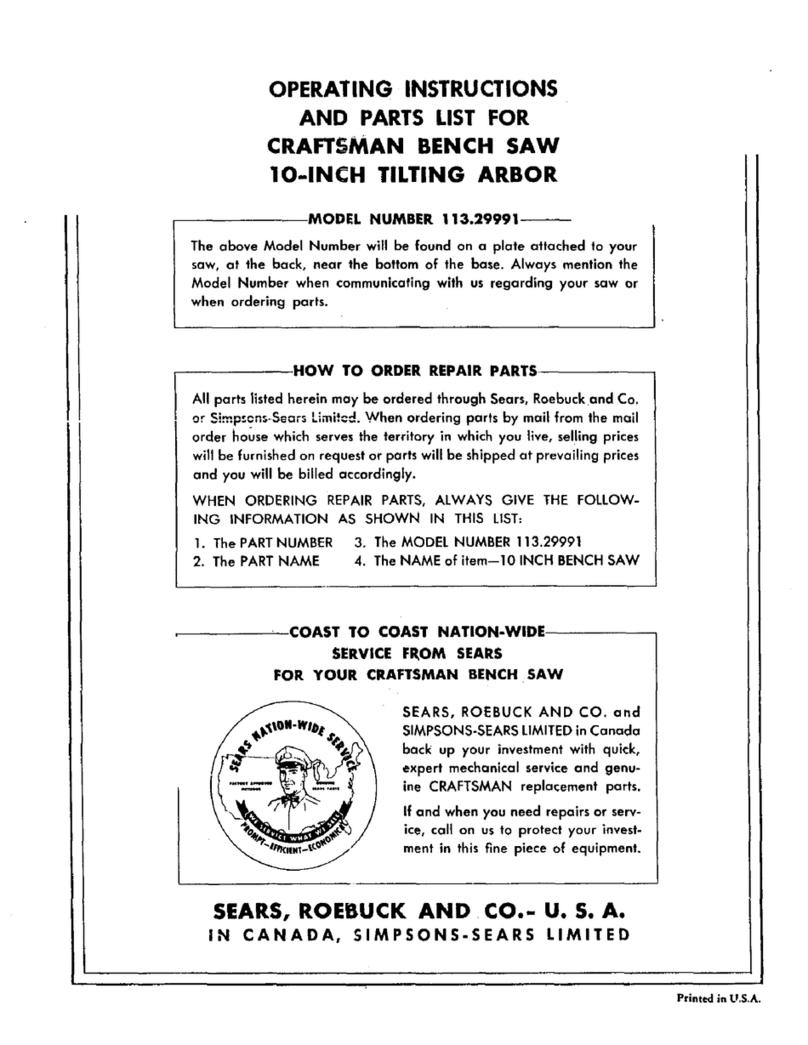

2. Measure accurately from a raker tooth on the

blade to an edge of either miter slot, as ex-

plained and shown in Fig. 5.

3. loosen the bolts, Nos. 81 and 33, holding each

trunnion, Nos. 82 and 32, to the lower table

surface. (-4 bolts total.)

4. Shift the complete under-table mechanism un-

til the blade is parallel with the miter slot.

5. Re-tighten the four trunnion screws, front pair

first.

6. Check this adjustment as previously explained

to be certain it is correct after re-assembly is

complete.

The Fence Must Lock Parallel with the Miter Slots.

Using one hand on the front end of the fence, slide

the fence to the edge of the miter slot. Push the lock

handle down slowly. If fence does not lock parallel

to miter slot adjust as follows:

1. loosen the two screws, No. 10-4, on top of the

fence end.

2. Release the fence lock handle, No. 99.

3. Adjust the two set screws on the front of the

fence end until the fence is parallel with miter

slot. Turn the two screws, on the top, up snug.

Then tighten each one securely.

-4. Check the adjustment by sliding the fence

away from the slot and returning several times

to see if it locks parallel each time. The fence

lock arm may require occasional adjustment

to maintain proper tension.

With the fence lock handle, No. 99, in the unlocked

position turn the fence lock rod, No. 108, slightly in

a clockwise direction until proper tension is attained

when fence lock handle is placed in the lock position.

The Arbor Tilt Tension Spring, No. 36, provides

tension to keep the mechanism tilted at any angle,

thus eliminating the need for a manual control lock.

After the tool is "broken in," you may find it neces-

sary to increase this tension. Loosen the lock nut,

No. 87, and turn the bolt, No. 37, until enough ten-

sion has been applied. Re-tighten the lock nut.

Note: After a few hours of operation, tighten all

pulley set screws.

FIGURE 6

The Mitre Gauge has been designed to assure a

maximum amount of accuracy. It has been adjusted

at the factory to give accurate -45° and 90° settings

and carefully packed to protect this fine setting in

shipment.

It

is possible that rough handling in shipment may

have disturbed this setting. By use of a combination

square, see figure 6, its setting may be checked be-

fore use. If it should be found necessary to reset the

stops, proceed as follows:

1. Loosen the Mitre Gauge lock Knob.

2. Back off the Adusting Screws.

3:

Using a combination square, set the Mitre Pro-

tractor 90° to the Mitre Bar. Then tighten the

lock Knob. Push in the Indexing Pin and turn

the Socket Hd. Set Screw until its oval tip con-

tacts the Indexing Pin.

-4. Repeat the operation above to adjust the two

-45° positions using the 45° face of the Com-

bination Square.

5. The pointer may also have to be re-adjusted to

indicate exactly 9.0° and 45°.

OPERATION:

The Blade provided with this saw may be used for

both cross-cutting and ripping.

For proper chip clearance and best general results,

the blade should project through the work-piece ap-

proximately

%

inch.

Do not force material into the Blade too fast. Use

a straight, direct, steady feed which does not over-

tax the cutting capacity of the blade.

To eliminate creep of your work when making a

Miter cut, clamp the work ~ce to the gauge.

Support long work as it leaves the rear of the

table.

If overall thickness of Dado set exceeds

%

of an

inch in width, the Saw Clamp Washer, No. 86, should

not be used in order to insure proper thread engage-

ment of Hex Nut No. 85, on the Arbor.

For other ideas, suggestions, etc. pertaining to the

operation of Circular Saws, refer to the Circular Saw

Booklet found in the envelope.

NOTE: After a few hours of operation, tighten all

Pulley Set Screws.

SAFETY:

While the bench saw is one of the most widely used

woodshop power tools, it is by nature of its general

design, one of the most dangerous in the hands of

inexperienced or careless operators. The bench saw

is not, however, an unsafe tool when used with com-

mon sense and good judgment.

Use a push block rather than letting the hands get

closer than 3· inches to the blade on narrow cuts.

Never hold the hands over the blade when making

blind groove type cuts. Stand to one side when com-

pleting a cut. A loose piece caught by the blade can

fly back with surprising force.

Always stop the saw when removing waste stock

from near the blade, when making adjustments, or

when changing settings.

Do not wear dangling neckties, loose baggy sleeves,

etc., while operating power tools.

-4