*Before soldering, mechanically connect the work pieces to each other

to pro_de additional stren_ to the joint. Hold the pi,eces statlona.ry

during soldering, and.apply a clamp or other device wnere outt or lap

connections are useo.

iHeat the metal parts with the iron and continue to heat until the parts

are hot enou_]h to melt the solder. Apply the rosin core solder to the

heated metal joint (not the tip) and allow the solder to flow into the joint.

Do not continue to heat the parts after solder has flowed into the joint.

Allow the parts to cool before moving to permit the bond to "set'.

After soldering, unplug the iron.

5. BRANDING

It is important to properly prepare for your project before you actually

begin the final work:

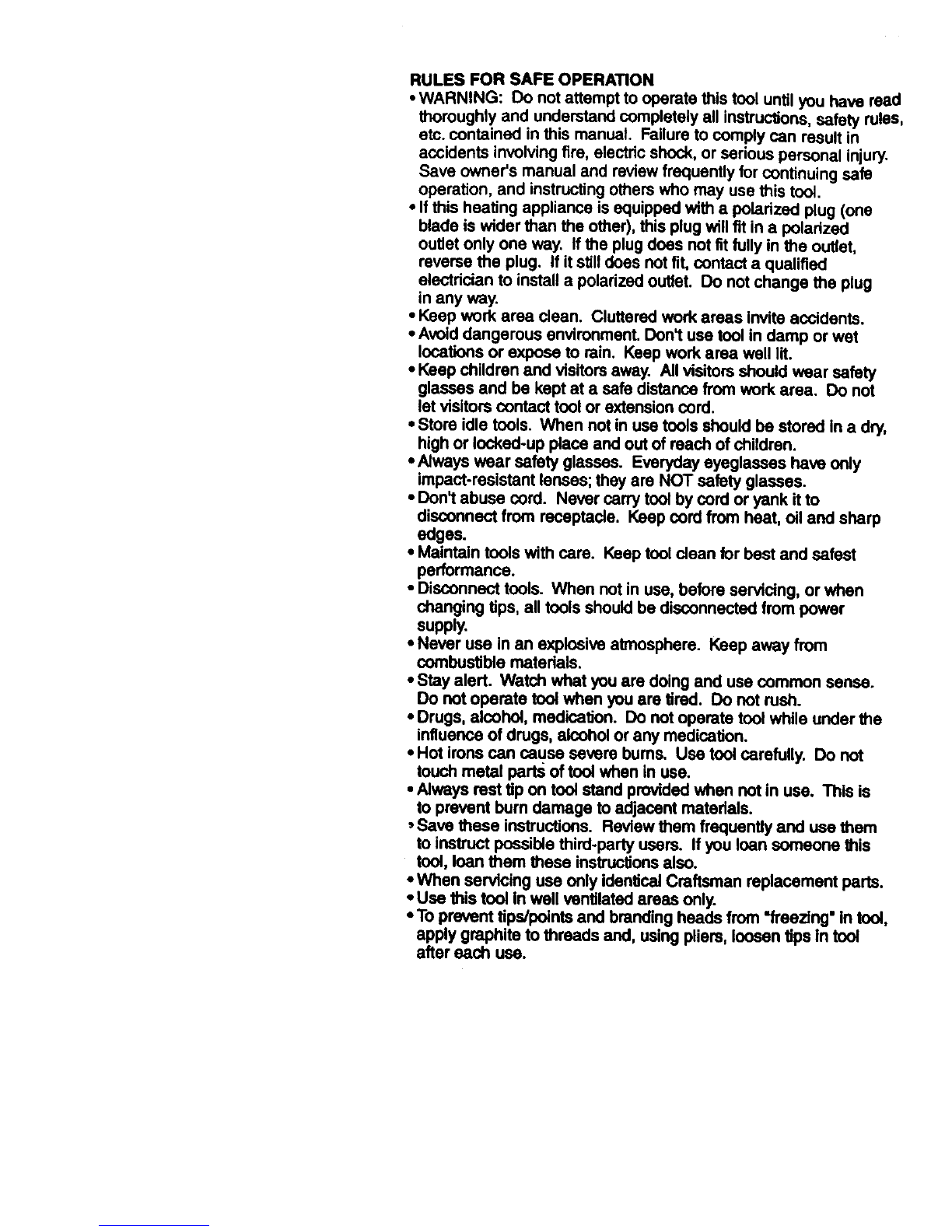

•Plan your overallpattsrn on paper using one or more of the branding

tips and add any freehand embellishments as may be appropriate. As

a check, temP0radly apply the p.roofto the surface of.the item being

branded to make sure you are I_easea with the result.

•Practice brandingthe pattem on material similar to the material on wh..ic:h.

the pattam is tobe branded. In this way you will be comfortable with

the placement of the individual designs m the overall pattern, and you

will become familiar with the branding technique neeoed for the

specific matedal being branded.

•Remove any flammable matedals from the work area. Place the brand°

ing end of the tool on the metal tool stand (supplied with the too!) to

prevent the hot br:anding encJ.from tou.ching the sun'.ounding surrace

mus protec_ng it trom burn oamage, insert the toofs plug taro .a lZU.

VAC outlet. The tool will now heat. Allow about 6-8 minutes mr me too_

to heat the branding head to branding temperature.

•In general, it is necessary to exert only a modest amount of pressure

on the branding tool/heed to achieve good results as it is the heat that

does the branding. The longer the DWELL TIME (length of time the hot

branding head remains on a surface being branded), the stronger arm

deeper the burn. When practicing on scrap material, gauge the inten-

sity Of a burn by.counting the seconds of DWELL TIME needed ,to

obtain the resu_ you want. Using this count wnen oranoing on me

finished work will allow you to achieve the result you want.

•Two factors determine 'dwell time' - type of material baln_ branded and

the temperature of the branding head. Each wood species will brand

at different temperature, while a smaller branding head size willget

hotter (requiring a shorter dwell time) than a larger one. Consid-edng

the above two factors, it takes a dwell time of from I to 6 seconds to

brand wood or rubber, 1 to 4 seconds for leather, and form 1 to 3

seconds for plastics. NOTE: unlike wood and leather, plastics and

rubber 'meR and are 'displaced' rather than being burned away.

FULL ONE YEAR WARRANTY ON CRAFTSMAN CREATIVE TOOL KIT

If_s Crafisman Tool fallsdue to a defect in matsdal or workma_ wi_in

oneyearfnxnthedataof_, Beam_II _ it,freeofcharge,

Wanantyssrviceisavei_0labyretumir)g|herodtothenearestBears

storeorservicecenter_ theUnitedStatss.

TI=wananVg_s yousped__g=_hts,andyoumay_sohaveoe_r

dghts_'tch vary_m sta;tafostats.

Sears, Roehud(& Co., DepL817WA,HoffmanEstates,IL 60179