English (original instructions) 1

Français (traduction de la notice d’instructions originale) 16

Español (traducido de las instrucciones originales) 23

WARNING: Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in damage or seriousinjury.

WARNING: Never modify the product or any part of

it. Damage or personal injury couldresult.

WARNING: To reduce the risk of injury, read the

instructionmanual.

If you have any questions or comments about this or

any product, call toll free at:

1-888-331-4569.

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk

of personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderateinjury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in propertydamage.

SAFETY WARNINGS

WARNING: Read all safety warnings,

instructions, illustrations and specifications

provided with this tool. Failure to follow all

instructions listed below may result in fire and/or

seriousinjury.

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE

Safety Warnings

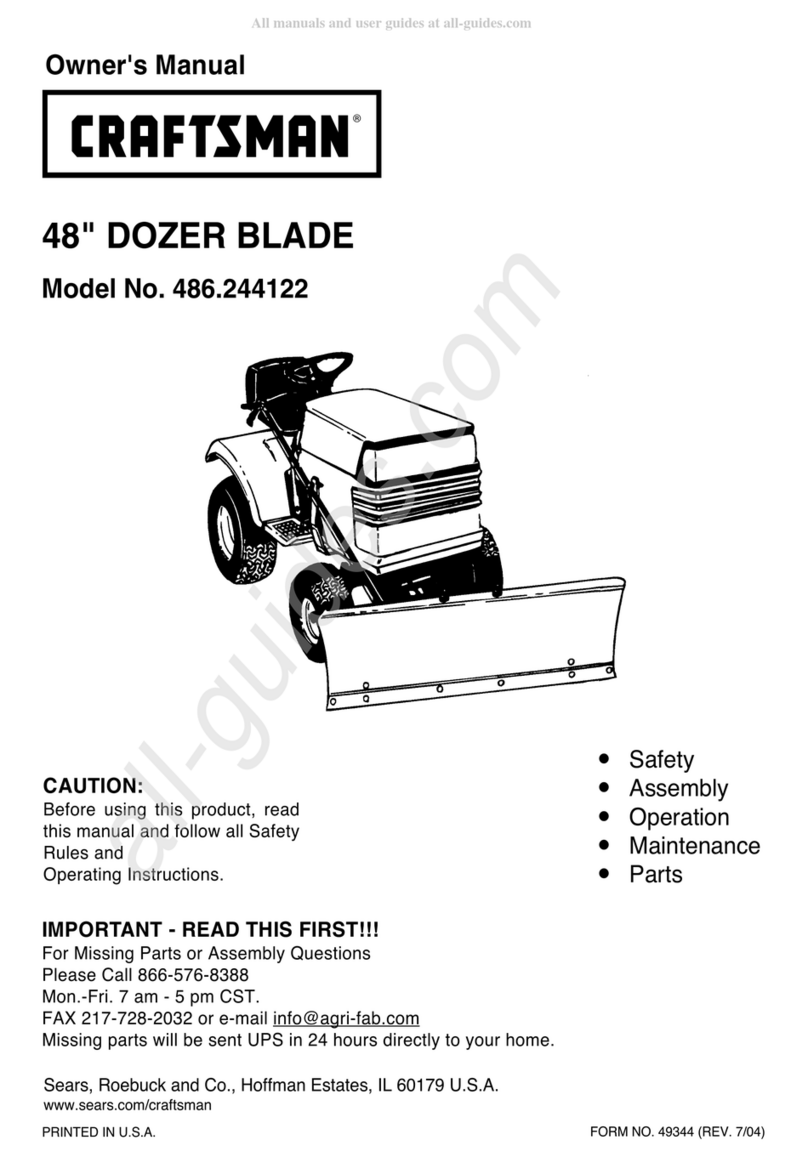

a ) Read the tractor and snow blade owner's manuals

and know how to operate your tractor before using

tractor with snow blade attachment.

b ) Never operate tractor and snow blade without

wearing proper clothing suited to weather conditions

and operation of controls.

c ) Never allow children to operate tractor and snow

blade, and do not allow adults to operate without

proper instructions.

d ) Always begin with transmission in first (low) gear and

gradually increase speed as conditions permit.

Look for this symbol to point out

important safety precautions. It

means — Attention!! Become

alert!!Your safety is involved.