5

PARTS BAG CONTENTS

Not all parts will be needed for t-up to any one tractor.

Discardunneededpartsafterassemblyisnished.

PARTS NOT SHOWN FULL SIZE

MM NN

RR

OO

QQ

PP

LL

REF PART NO. QTY DESCRIPTION

A 710-0367 2 Hex Bolt, 5/8" x 1-1/2"

B R74780828 2 Hex Bolt 1/2" x 1-3/4"

C 710-0865 3 Hex Bolt, 1/2" x 1"

D 43087 2 Hex Bolt, 3/8" x 1-1/4"

E 43001 6 Hex Bolt, 3/8" x 1"

F 43063 4 Hex Bolt, 5/16" x 1"

G43084 5 Hex Bolt, 5/16" x 1-3/4"

H 47025 1 Hex Bolt, 5/16" x 3-1/2"

I 1509-69 3 Hex Bolt, 1/4" x 1-3/4"

J 43350 8 Bolt, Carriage 3/8"x 1"

K 44326 2 Carriage Bolt, 5/16" x 1"

L 43346 1 Truss-Head Bolt #10-32 x 5/8"

M 712-0261 2 Nylock Nut, 5/8"

N 43262 1 Hex Lock Nut, 1/2"

O 712-3083 2 Nylock Nut, 1/2"

P 48115 2 Nylock Jam Nut, 1/2"

Q43015 2 Hex Nut, 3/8"

R HA21362 10 Nylock Nut, 3/8"

S 47810 11 Nylock Nut, 5/16"

T 43064 2 Nut, Hex 5/16"

U 47189 3 Nylock Nut, 1/4"

V43178 1 Nut, Hex 1/4"

REF PART NO. QTY DESCRIPTION

W 47171 1 Nylock Nut, #10-32

X 23658 2 Spacer, 5/8" Long

Y 24817 4 Spacer, 1/2"

Z 43343 4 Hairpin Cotter, Long

AA 43055 4 Hairpin Cotter, Short

BB 43010 6 Cotter Pin, 1/8" x 1-1/4"

CC 43093 2 Cotter Pin, 1/8" x 1-1/2"

DD 43003 6 Lock Washer, 3/8"

EE 43081 8 Washer, 5/16"

FF 43070 8 Washer, 3/8" (Small)

GG R19171616 3 Washer, 1/2" (Small)

HH 736-0247 2 Washer, 3/8" (Large)

II R19212016 6 Washer, 5/8"

JJ R19172410 8 Washer, 1/2" (Large)

KK 43601 2 Washer, 1"

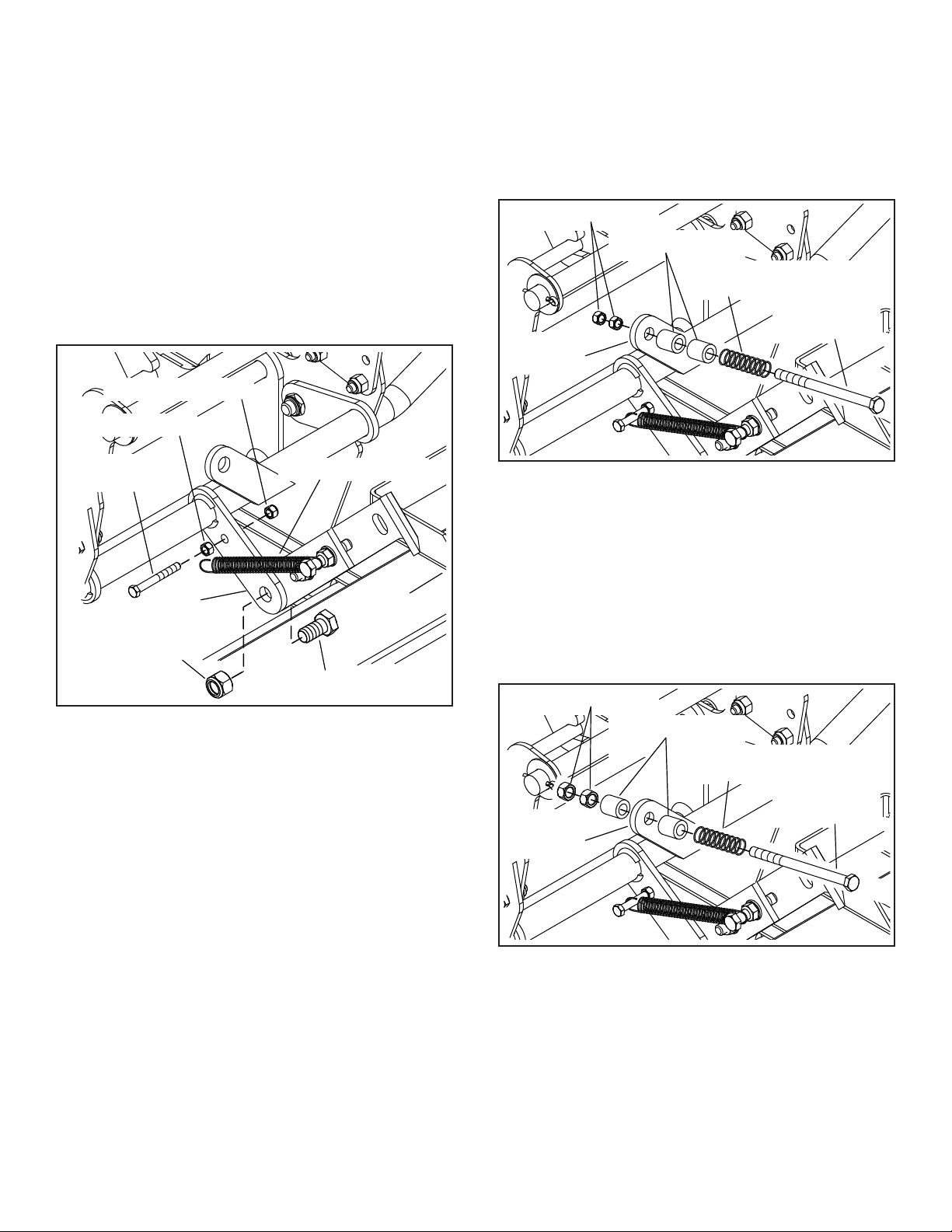

LL 44062 2 Clevis Pin, 1/2" x 1"

MM 711-0309 2 Clevis Pin, 5/8" x 1-1/4"

NN 48905 1 Compression Spring, Short

OO 732-0306 1 Compression Spring, Long

PP 726-0178 6 CableTie

QQ 26481 2 Tilt Stop Bracket

RR HA23761 1 Hose Clip