3.Use this pump only for backup sump pump duty in a res-

idential appfication. Ris not designed as a primary sump

pump.

4, [AWAaNING_][_azardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be sure

one hand is free when plugging in or unplugging charger.

If basement floor is wet, disconnect power to basement

before walking on floor.

5.Do not lift pump by electrical cord.

6. Pump water only with this pump.

7.Do not run pump dry. To do so will damage seals and can

cause leaking and property damage.

8. Pump is permanently lubricated at the factory. Do not try

to lubricate it!

9. Keep battery charger and battery box in a dry, cool, well

ventilated area.

10.To avoid danger of fire or explosion, keep sparks and

flame away from battery.

11. L&WARNING_ Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye protection

when working on battery.

12.Maximum vertical pumping distance is 15 feet.

13. Make sure sump is clear of debris.

BASIC TOOLS AND MATERIALS NEEDED

Pipe Wrenches Screwdriver

Hacksaw 1-1/4" Check Valve

Adjustable Wrench Teflon Tape

Knife 12-volt Battery

GENERAL INFORMATION

The Battery-Powered Back-up Sump Pump is not a substitute

for your primary sump pump. It is designed as a backup

pump to pinch-hit for your primary sump pump during a

power outage or other problem which prevents normal op-

eration. Do not use it to pump flammable liquids or chemi-

cals.

Keep battery charger dry and protected from damage.

In an emergency (such as an extended power outage)

which depletes the system battery, your automobile battery

may be temporarily substituted. Be sure to replace the sys-

tem battery as soon as possible.

CHARGER OPERATION

Backup pump vdll start automatically when sump water

level rises far enough to trip float switch. After a delay of

about 4 seconds, alarm will sound. Silence alarm by pushing

ALARM TEST/RESET button. In normal (switch actuated) op-

eration, alarm is locked-out until about 4 sec6nds after float

switch has dropped to OFF position; cycle can then begin

again.

Test alarm by pushing ALARM TEST/RESET button when

alarm is not sounding. Alarm will then sound as long as but-

ton is held down. Pushing ALARM TEST/RESET button to

test alarm overrides lockout, so alarm can be tested at any

time.

If alarm sounds, check operation of primary pump, which

may need service. If battery backup operation is due to a

power outage, alarm will sound, but no service is likely to

be required to primary pump.

Battery charger has capacity to run pump and charge battery

at the same time as long as power to the charger is not in-

terrupted. If power to charger circuit is interrupted, the

length of time that the backup pump will run depends on

the Ampere-hour capacity of the battery used.

Extended periods of operation (for example, during an ex-

tended power outage) may exhaust the battery. However,

once the load is removed, usually it will self-regenerate far

enough to allow the charger to start. The battery charger will

begin charging the battery as long as the battery has a charge

of at least 1/2 volt, and power is available to the charger.

After power is restored, charger will automatically re<barge

battery fully in about six hours.

NOTICE: Some trouble conditions will cause the alarm to

sound. See chart below for causes and action:

PROBLEM _- ACTION

Back-up pump has run Push 'Reset'. Check main pump.

Power out more than Disconnect charger from battery.

24 hours Call power company.

Continuous charging Disconnect charger from battery.

more than 24 hours Check for defective battery.

Loose connection or Disconnect charger from battery.

no power to charger Check plug, receptacle, and

power at main breaker.

After restoring power or replacing battery, alarm can be

reset.

•Purchase locally.

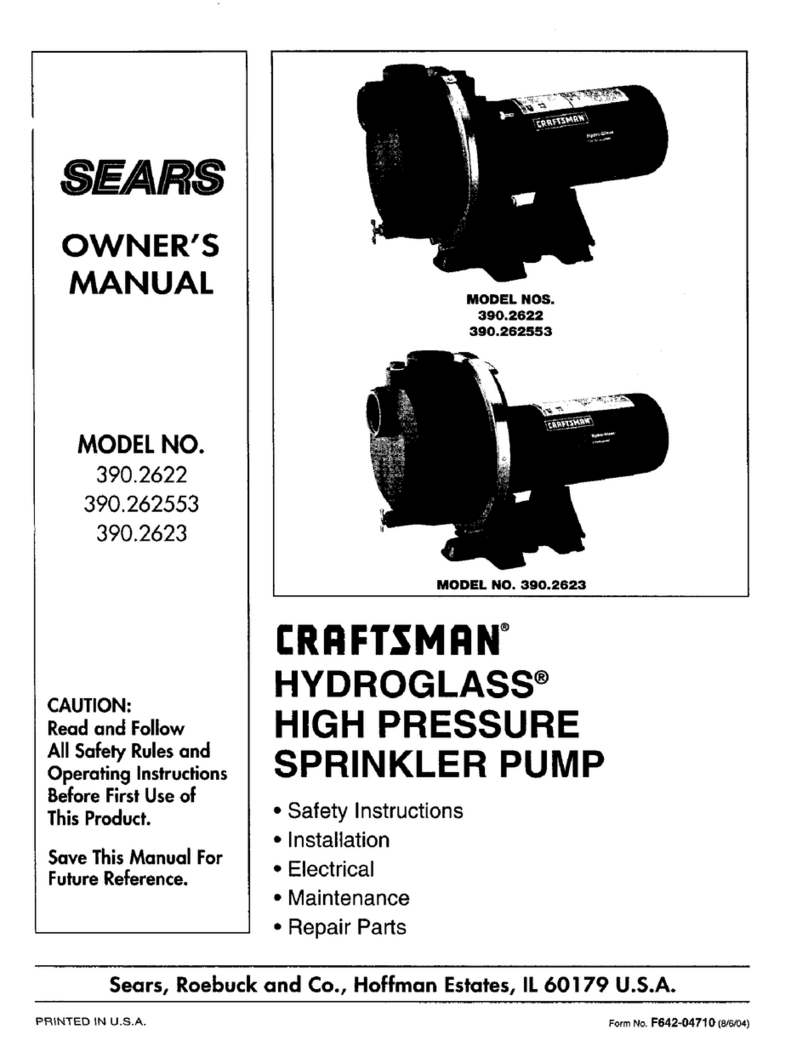

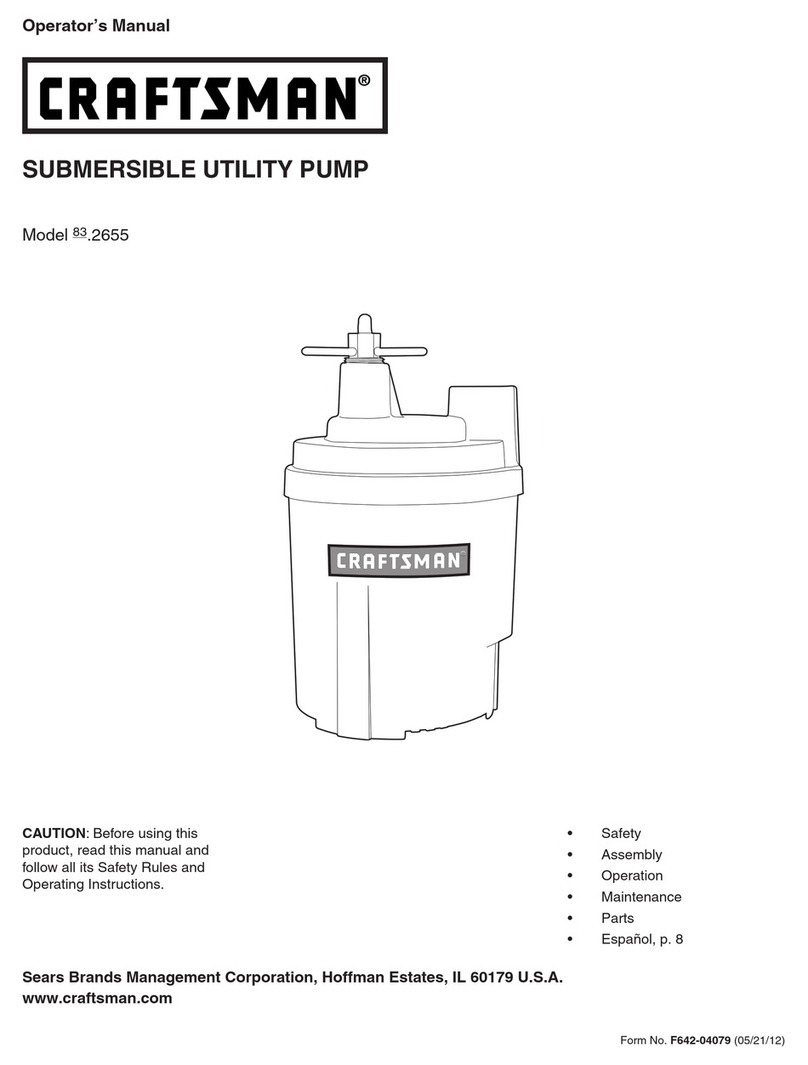

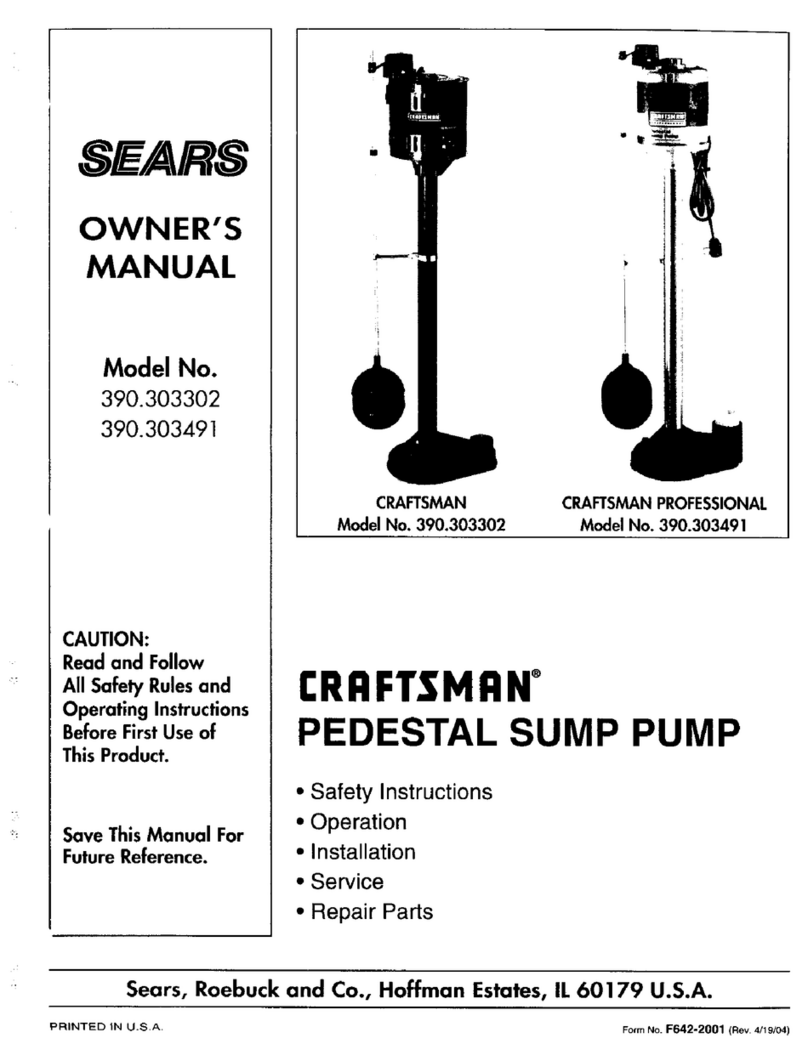

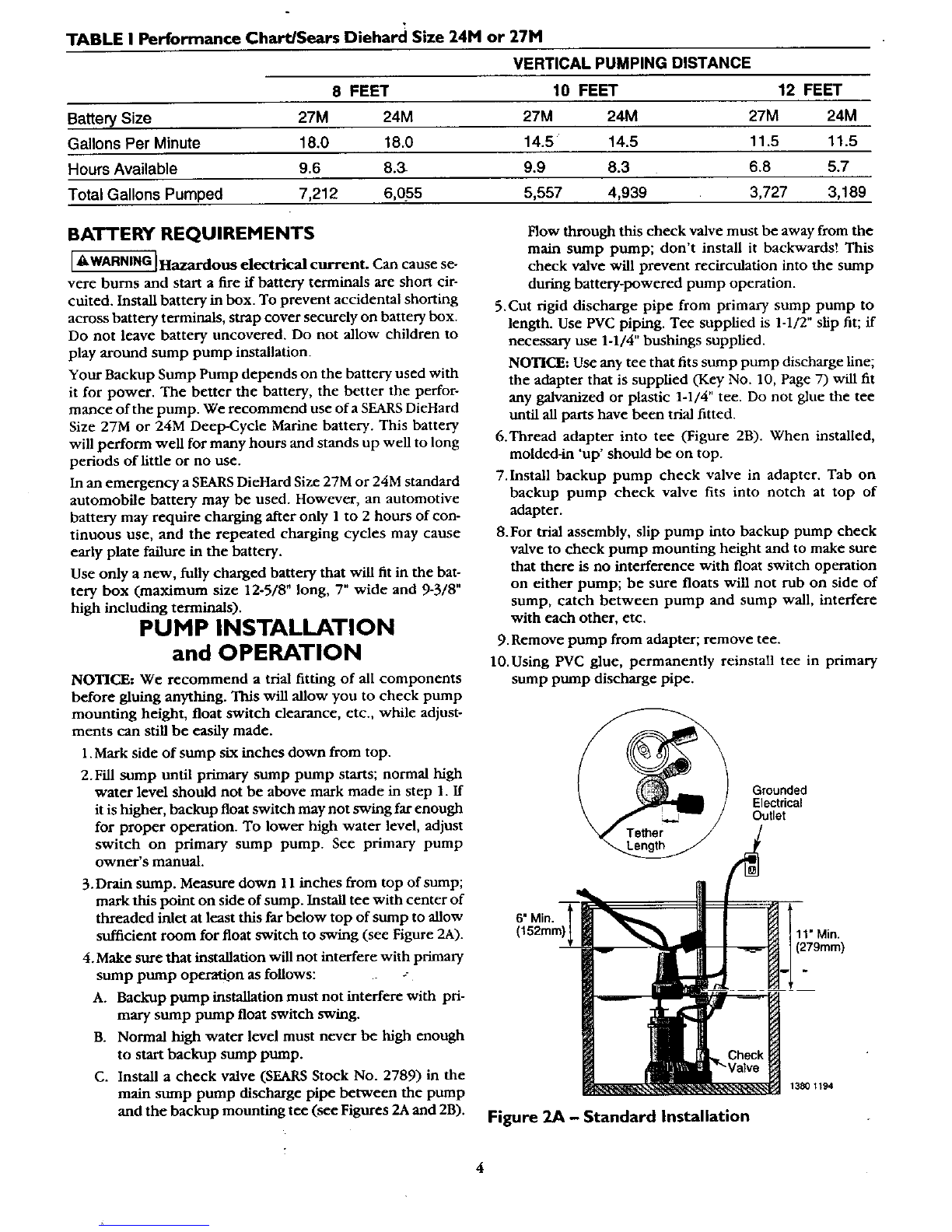

For small/shallow sump pits install as illustrated above. Installation Kit 2785

includes the necessar_ clamps and support pad needed for this installation.

Follow other instructions in the owner's manual.

Figure I - Installation in small or shallow sumps

- use Kit 2785; sump diameter is exaggerated

for clarity.