Fuses

Check the continuity of the fuse. With power OFF, pull the fuse out

of the fuse block. With the ohmmeter on the R X 1 scale, measure

resistance. A reading of infinity indicates a blown fuse and must

be replaced. Replace fuse with same type, voltage and amp rat-

ing.

Indicator Lights

If defective, replace all indicator pilot lights with same type.

Magnetic Contactor

Contacts - Check the contacts for severely burnt or welded con-

tacts. The contactor arm should move freely.

Coil - Measure the coil by disconnecting one of the coil leads.

Measure the coil resistance by setting the ohmmeter on the R X 1

scale. A defective coil will read zero or infinity, indicating a short or

opened coil respectively. Replace defective contactor with same

type.

NOTE: Readings may vary depending on accuracy of the mea-

suring device.

Motor Protective Switch

Test by inserting a paper clip or other small device into the test

hole and push to the left. The relay should trip.

Alarm Horn

Moving the alarm test/normal/silence switch to the test position or

activating the alarm float should turn on the alarm horn. If the horn

does not sound replace with horn of same type.

Alarm Light

Moving the alarm test/normal/silence switch to the test position or

activating the alarm float should turn on the alarm light. If the light

does not activate, replace with bulb of same type.

Float Controls

Check the floats during their entire range of operation. Clean, ad-

just, or replace floats.

Checking the float resistance - The float resistance can be mea-

sured to determine if the float is operating correctly or is defective.

Use the following procedure to measure the float resistance:

1. Isolate the float by disconnecting one or both of the float leads

from the float terminals.

2. Place one ohmmeter lead on one of the float wires, and the

other ohmmeter lead on the other float wire.

3. Place the ohmmeter dial to read ohms and place on the R X 1

scale. With the float in the “off” position, the scale should read

infinity (high resistance). Replace the float if you do not get

this reading. With the float in the ON position, the scale should

read nearly zero (very low resistance). Replace the float if

you do not get this reading.

NOTE: Readings may vary depending on the length of wire and

accuracy of the measuring device.

Troubleshooting

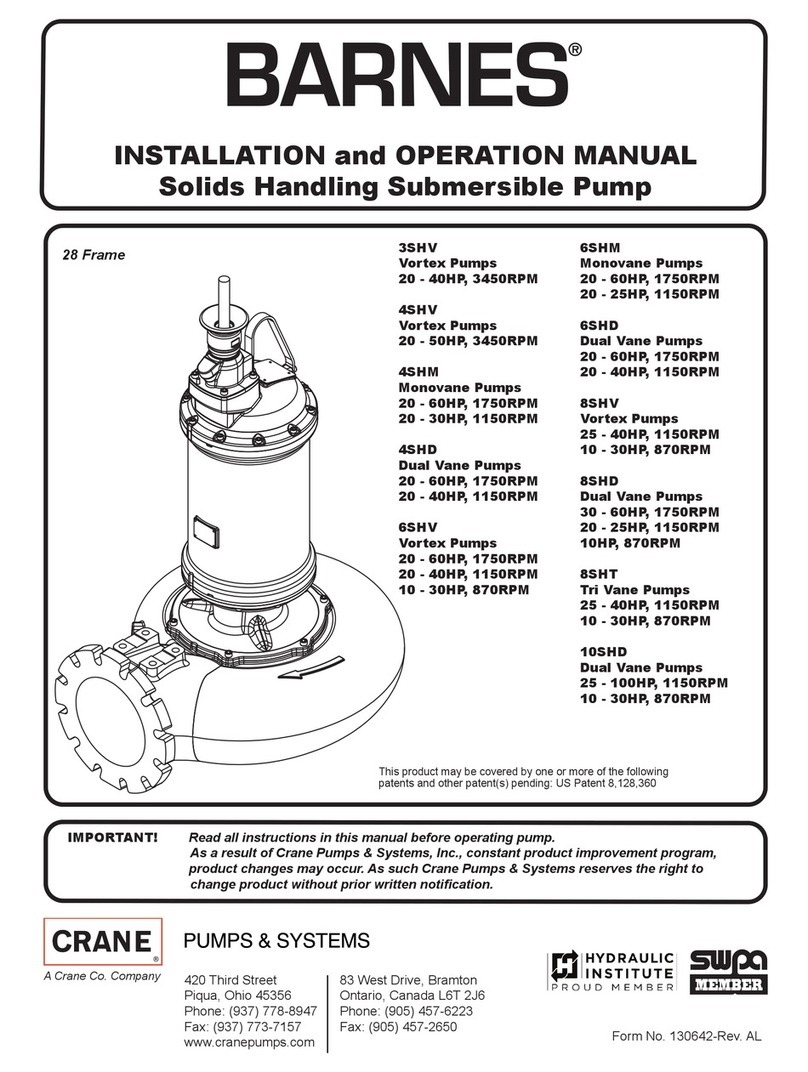

CRANE®PUMPS & SYSTEMS, INC. warrants to the original con-

sumer that this product shall be free of manufacturing defects for

three years after the date of consumer purchase. During that

time period and subject to the conditions set forth below, CRANE®

PUMPS & SYSTEMS, INC. will repair or replace, for the original

consumer, any component which proves to be defective due to

defective materials or workmanship of CRANE®PUMPS & SYS-

TEMS, INC.

ELECTRICAL WIRING AND SERVICING OF THIS PRODUCT MUST

BE PERFORMED BY A LICENSED ELECTRICIAN.

THIS WARRANTY DOES NOT APPLY: (A) to damage due to light-

ning or conditions beyond the control of CRANE®PUMPS & SYS-

TEMS, INC.; (B) to defects or malfunctions resulting from failure

to properly install, operate or maintain the unit in accordance with

printed instructions provided; (C) to failures resulting from abuse,

misuse, accident, or negligence; (D) to units which are not in-

stalled in accordance with applicable local codes, ordinances,

or accepted trade practices, and (E) to units repaired and/or modi-

fied without prior authorization from CRANE®PUMPS & SYSTEMS,

INC.

Some states do not allow limitations on how long an implied war-

ranty lasts, so the above limitation may not apply to you. Some

states do not allow the exclusion or limitation of incidental or con-

sequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

TO OBTAIN WARRANTY SERVICE: The consumer shall assume

all responsibility and expense for removal, reinstallation, and

freight. Any item to be repaired or replaced under this warranty

must be returned to CRANE®PUMPS & SYSTEMS, INC., or such

place as designated by CRANE®PUMPS & SYSTEMS, INC..

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

ARE LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY.

BARNES®SHALL NOT, IN ANY MANNER, BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES AS A RESULT OF A

BREACH OF THIS WRITTEN WARRANTY OR ANY IMPLIED WAR-

RANTY.

CRANE®Three-Year Limited Warranty