5

4. GROUTING

Grouting compensates for unevenness in the foundation

and prevents vibration and shifting after mounting is

complete. Build a form around the base plate to contain

the grout, and sprinkle area with water to obtain a good

bond. The base should be completely lled with a good

quality, non-shrinking grout. The usual mixture for grouting

is one part Portland cement and two parts sand with

sucient water to ow freely. It is also desirable to grout

the leveling pieces, shims or wedges in place. Foundation

bolts should be fully tightened when grout has hardened,

usually about 48 hours after pouring.

5. PIPING

The piping practices you follow will directly aect the

eciency and power consumption of your pump. Pay

particular attention to the seemingly insignicant details

involved in piping for they make the dierence between

a good and bad installation. BOTH THE SUCTION AND

DISCHARGE PIPING SHOULD BE INDEPENDENTLY

SUPPORTED NEAR THE PUMP. LIBERAL USE OF PIPE

HANGERS AND SUPPORT BLOCKS WILL PREVENT

EXCESSIVE STRAIN ON THE PUMP CASING AND ON

THE PIPE JOINTS.

PROPER PIPING ALIGNMENT IS ESSENTIAL BEFORE

CONNECTION IS MADE. PIPING ALIGNMENT SHOULD

NEVER BE ACHIEVED BY FORCE, THIS COULD

PRODUCE STRAIN ON THE PUMP CASING.

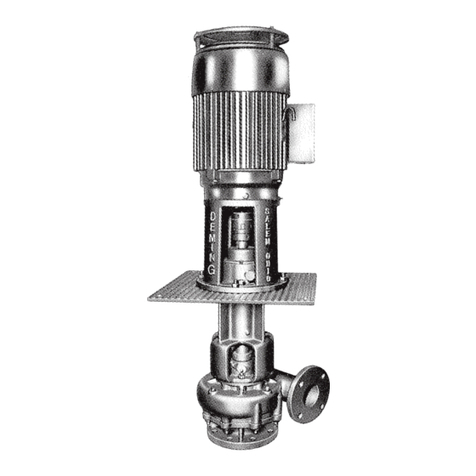

SUCTION PIPING

The illustrations on page 6 are oered as a help in

avoiding errors frequently made in suction piping, such as

abrupt changes in pipe size, the use of concentric reducer,

and the placing of an elbow in a horizontal plane next to

the suction nozzle of a single suction type of pump, etc.

The following are of equal importance and should be

carefully observed:

1. Never use pipe of a smaller size than the suction

connection of the pump. Usually, it is necessary

to use one pipe size larger, and sometimes several

sizes larger in order to avoid excessive frictional

loss with a resultant low NPSH available.

Select the size pipe necessary so that NPSHA

exceeds NPSHR by 3-5 feet.

When centrifugal pumps are operated with

insucient NPSHA, cavitation will occur, resulting in

noisy operation and damage to the pump.

2. The suction pipe, from the source of water supply,

should be laid with a gradual incline, not on a level,

toward the pump, with the highest point in the line

at the pump suction connection. If the pipe is level

and if there are any high points in the line which will

form air pockets the pump will not operate properly.

3. If conditions require the use of a foot valve and

strainer, the ow area of the foot valve should be

from 1-1/2 to 2 times the area of the suction pipe;

and the strainer should have a free-opening area

equal to 3 to 4 times the area of suction pipe.

Otherwise excessive frictional loss will result.

4. If a gate valve is used on the suction line to a

pump operating under a suction lift, the valve

stem should be placed in a horizontal plane, or a

vertical, downward position in order to avoid a

possible air leak.

5. The end of the suction pipe should always be

submerged a minimum of 18”. If only limited

submergence can be had, the end of pipe should

be belled or ared. A board oating on the surface

of water surrounding the suction pipe is be helpful

against the formation of a vortex permitting air to

enter the suction pipe.

6. On pumps operating under high suction lift, the

suction piping should be tested thoroughly for air

leaks. A small volume of air will materially reduce

the capacity of pump, and a larger volume will

frequently cause loss of prime.

7. Installations which will be subjected to considerable

temperature variation should be provided with some

means for compensating for expansion and

contraction. A 50° temperature change means

an expansion or contraction of approximately 3/8” in

a pipe line of 100ft. length. This will result in

distortion and misalignment of pump, and

sometimes actual breakage.

8. The pipe should not be pulled into position by

tightening the piping joints. The pipe should meet

the pump and the pump should not be required to

meet the pipe. All piping should be supported

indepently of the pump. Pumps are not designed for

carrying loads imposed by piping and its contents.

9. When installing, guard against the possibility of

foreign material such as nails, bolts or pieces of

waste being left in the line, likely to lodge in the

impeller and cause loss of capacity and mechanical

damage.

10. When the suction supply is taken from a tank or

sump, incoming water should never be allowed to

fall into the water near the end of suction pipe. This

will carry air down into the suction pipe.

SUCTION DIFFUSER FEATURES:

• Reduces both space and installation costs by replacing

an extended entry pipe, a long radius elbow and a

strainer.

• Disposable ne mesh start-up strainer provided on all

models, guarantees a clean system.

• Steel stabilizing vanes ensure smooth ow into the