6 308368

Installation

General Information

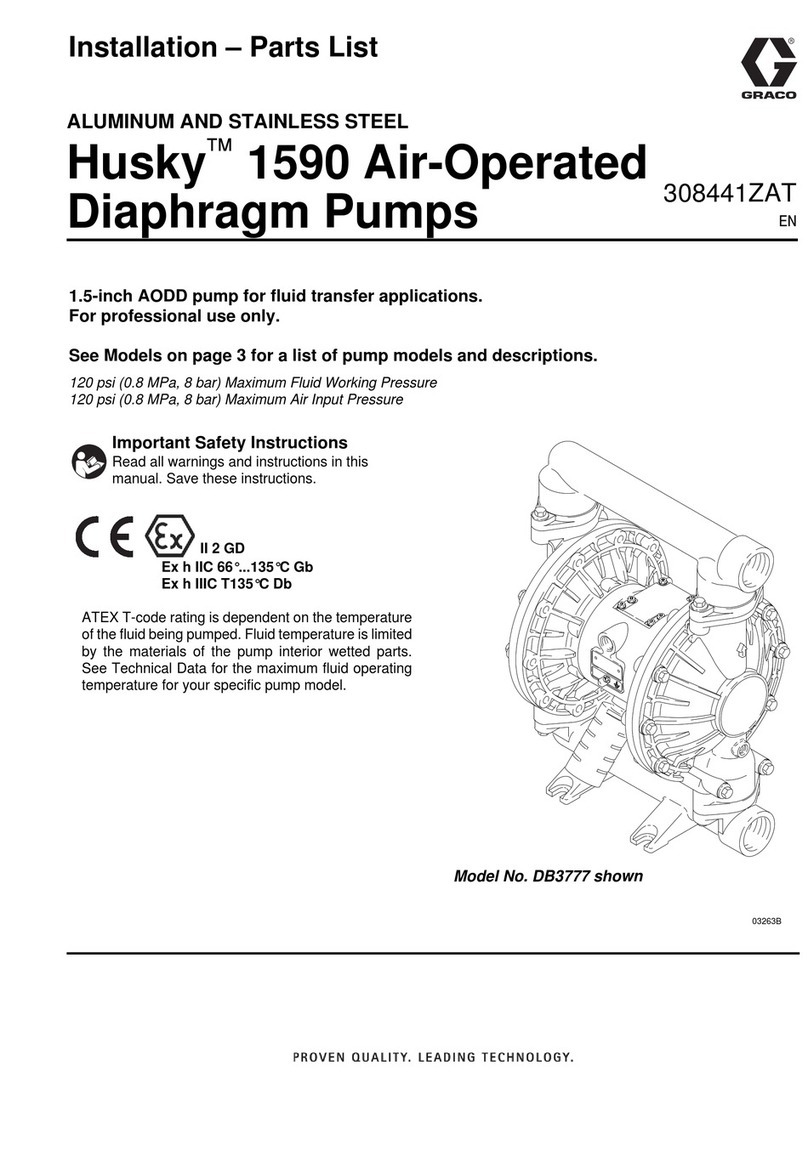

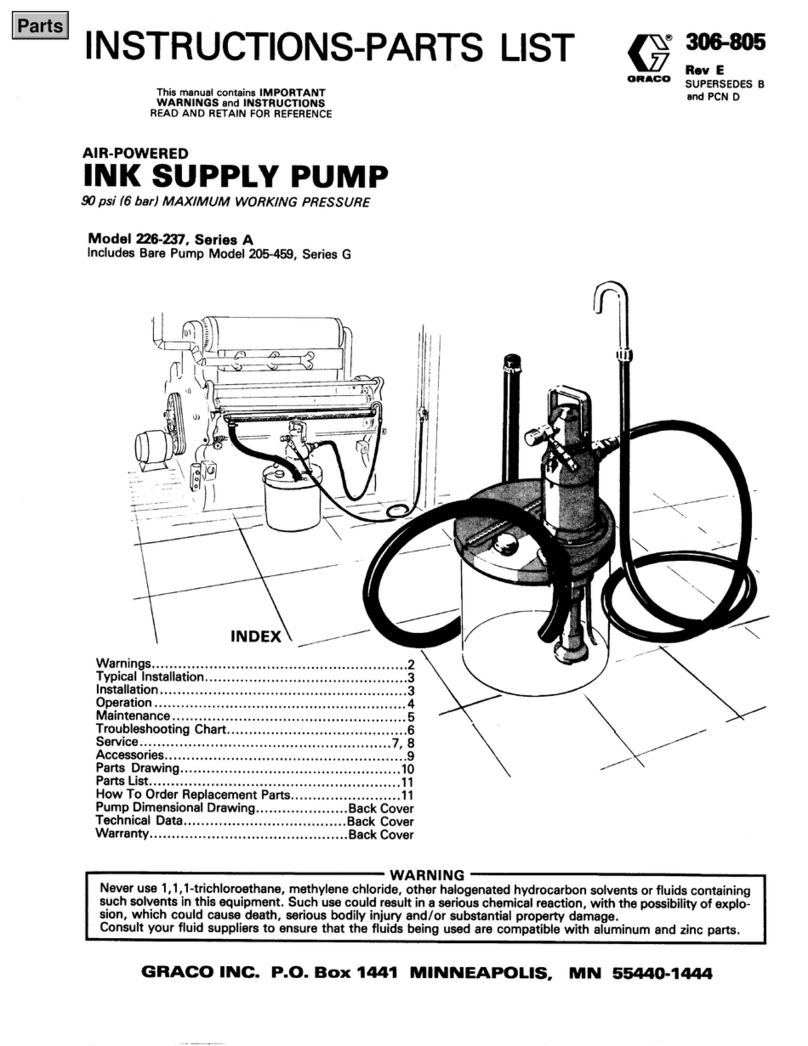

The Typical Installation shown in is only a guide for

selecting and installing system components. Contact

your Graco distributor or Graco Technical Assistance

(see back page) for assistance in planning a system

to suit your needs.

Always use Genuine Graco Parts and Accessories.

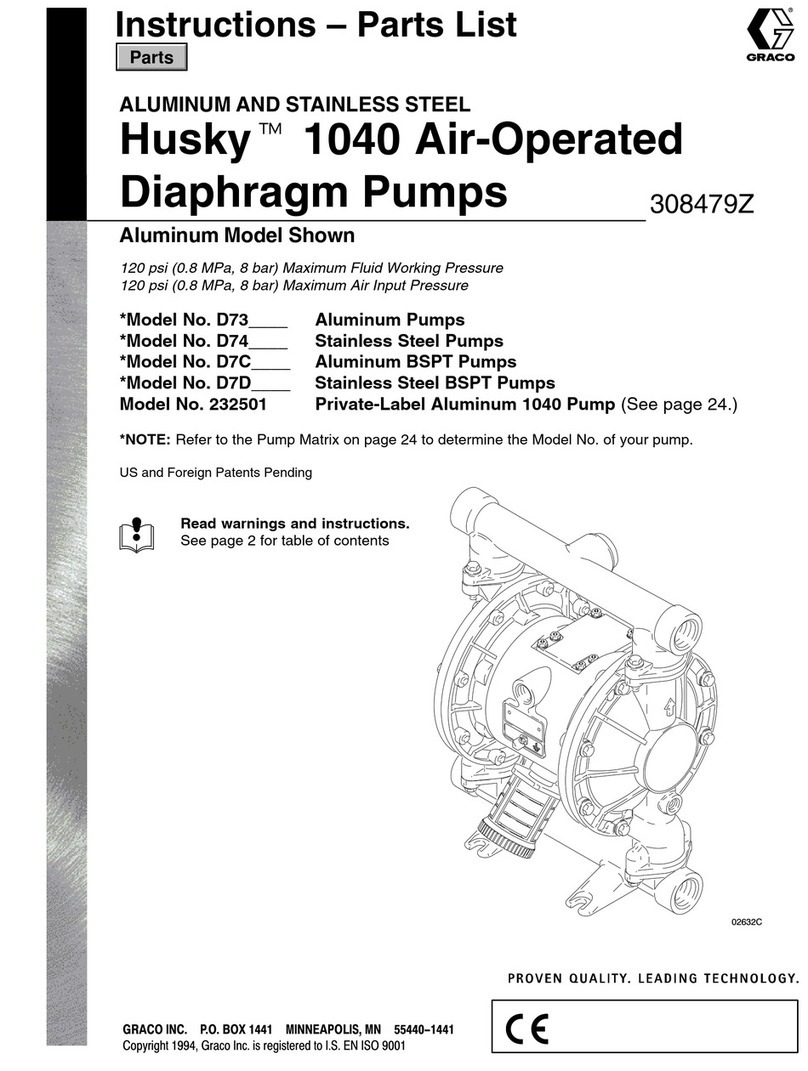

Reference numbers and letters in parentheses refer to

the callouts in the figures and the parts lists on pages

27 to 28.

The pump is very heavy. If it must be moved, have

two people lift the pump by grasping the outlet

manifold (103) securely. See FIG. 3 on page 10.

Tightening Screws Before First Use

Before using the pump for the first time, check and

retorque all external fasteners. See Torque

Instructions, page 32. After the first day of operation,

retorque the fasteners. Although pump use varies, a

general guideline is to retorque fasteners every two

months.

Tips to Reduce Cavitation

Cavitation in a diaphragm pump is the formation and col-

lapse of bubbles in the pumped liquid. Frequent or exces-

sive cavitation can cause serious damage, including

pitting and early wear of fluid chambers, balls, and seats.

It may result in reduced efficiency of the pump. Cavitation

damage and reduced efficiency both result in increased

operating costs.

Cavitation depends on the vapor pressure of the pumped

liquid, the system suction pressure, and the velocity pres-

sure. It can be reduced by changing any of these factors.

1. Reduce vapor pressure: Decrease the temperature

of the pumped liquid.

2. Increase suction pressure:

a. Lower the installed position of the pump relative

to the liquid level in the supply.

b. Reduce the friction length of the suction piping.

Remember that fittings add friction length to the

piping. Reduce the number of fittings to reduce

the friction length.

c. Increase the size of the suction piping.

NOTE: Be sure the inlet fluid pressure does not

exceed 25% of the outlet working pressure.

3. Reduce liquid velocity: Slow the cyclic rate of the

pump.

Pumped liquid viscosity is also very important but nor-

mally is controlled by factors that are process dependent

and cannot be changed to reduce cavitation. Viscous liq-

uids are more difficult to pump and more prone to cavita-

tion.

Graco recommends taking all the above factors into

account in system design. To maintain pump efficiency,

supply only enough air pressure to the pump to achieve

the required flow.

Graco distributors can supply site specific suggestions to

improve pump performance and reduce operating costs.

Grounding

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of

equipment. Ground all of this equipment:

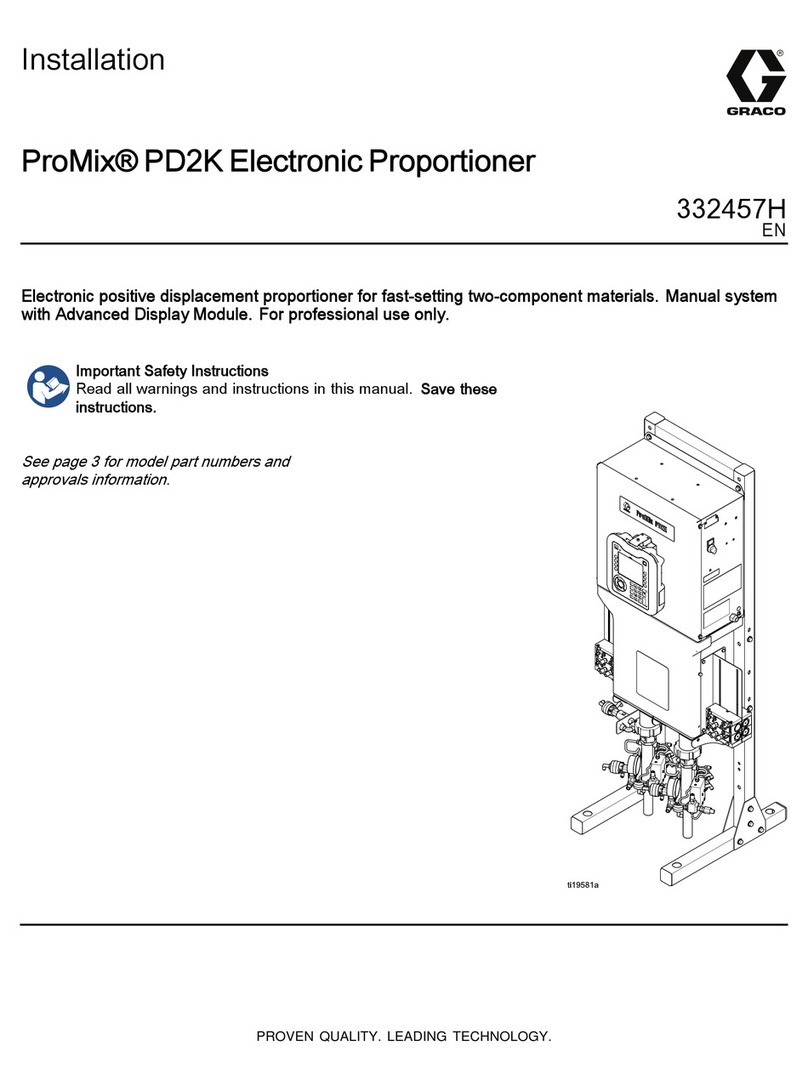

Pump: Connect a ground wire and clamp as shown in

FIG. 1. Loosen the grounding screw (W). Insert one

end of a 12 ga (1.5 mm2) minimum ground wire (Y)

behind the grounding screw and tighten the screw

securely. Connect the clamp end of the ground wire to

WARNING

HAZARDOUS FLUIDS

To reduce the risk of serious injury,

splashing in the eyes or on the skin, and

toxic fluid spills, never move or lift a pump

under pressure. If dropped, the fluid

section may rupture. Always follow the

Pressure Relief Procedure Warning on

page 12 before moving or lifting the pump.

WARNING

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before

operating the pump, ground the system as

explained below. Also, read the section

FIRE AND EXPLOSION HAZARD, on

page 4.