Cranford Controls IS-CP4B-PB User manual

IS-CP4B-PB

Manual Call Point –Push Button

With resistor Modules

For use in Flammable Gas and

Combustible Dust Atmospheres

1) Introduction

The IS-CP4B-PB is a push button manual call point

which is certified intrinsically safe to the European

and International Gas standards. The unit meets

the requirements of the ATEX directive 94/9/EC

and IECEx scheme.

The call point can be used in hazardous areas

where potentially flammable gas atmospheres may

be present.

The IS-CP4B-PB has up to two monitoring

resistors. The units are Group II, EPL (equipment

protection level) Ga. The equipment is certified ‘Ex

ia IIC T4 Ga’ and as such may be used in Zones 0,

1 and 2 with flammable gases and vapours with

gas groups IIA, IIB & IIC and temperature classes

T1, T2, T3 and T4.

The equipment needs to be installed with ATEX

and/or IECEx certified Zener Barriers or Galvanic

Isolators.

2) Marking

All units have a rating label, which carries the

following important information:-

Unit Type No.:

IS-CP4B-PB Manual Call Point

Code:

Ex ia IIC T4 Ga

IP66

Ui=30V Ii=500mA Pi=1.1W Ci=0 Li=0

–40ºC <= Ta <= +50ºC

Certificate No.:

SIRA 09ATEX2287X

IECEx SIR 09.0122X

Epsilon x: II 1G

CE Marking

Notified body No. 0518

Year/Serial No. i.e. 10/1CP4BPB000001

WARNING - DO NOT OPEN WHEN AN

EXPLOSIVE ATMOSPHERE MAY BE PRESENT

3) Type Approval Standards

The beacon has an EC Type examination

certificate issued by SIRA and have been approved

to the following standards:-

EN 60079-1:2006 / IEC 60079-0:2004

EN 60079-1:2009 / IEC 60079-0:2007

EN 60079-11:2007 / IEC 60079-11:2007

EN 60079-26:2007 / IEC 60079-26:2006

EN 61241-0:2006 / IEC 61241-0:2004

EN 61241-1:2004 / IEC 61241-1:2004

The equipment is certified for use in ambient

temperatures in the range -40oC to +50oC and shall

not be used outside this range.

4) Installation Requirements

Installation of this equipment shall only be carried

out by suitably trained personnel in accordance

with the applicable code of practice e.g. IEC

60079-14/EN 60079-14 and IEC 61241-14/EN

61241-14.

Repair of this equipment shall only be carried out

by the manufacturer or in accordance with the

applicable code of practice e.g. IEC 60079-19/EN

60079-19.

The certification of this equipment relies on the

following materials used in its construction:

Enclosure: Aluminium Pressure Die Cast Body

LM6

Through enclosure mechanism: Plastic Nylon Zytel

Injection Moulded

Sealing of enclosure and mechanism: O-ring

Acrylonitrile-Butadiene Rubber

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that

the type of protection is not compromised.

“Aggressive substances” - e.g. acidic liquids or

gases that may attack metals, or solvents that may

affect polymeric materials.

“Suitable precautions” - e.g. regular checks as part

of routine inspections or establishing from the

material’s data sheet that it is resistant to specific

chemicals.

Refer to certificates SIRA 09ATEX2287X and

IECEx SIR 09.0122X for special conditions of safe

use.

5) Call Point Location and Mounting

The location of the call point should enable ease of

access for operation and testing. The unit should

be mounted using the 4 off fixing holes which will

accept up to M4 sized fixings.

When installing in Zone 0 applications, ensure that

the equipment enclosure is protected from impact.

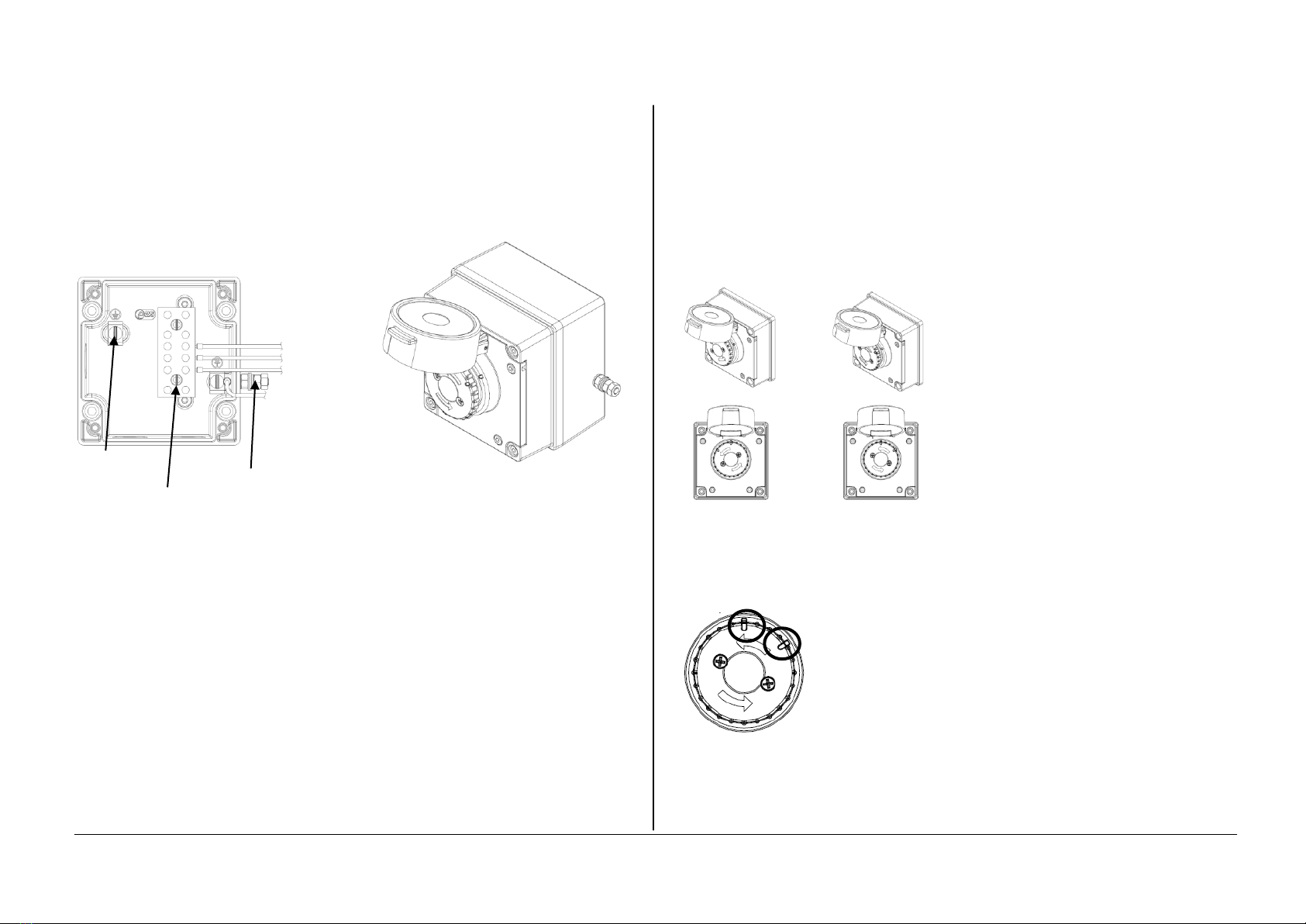

View of base unit showing fixing centres.

To gain access to the mounting holes in the base

the front cover must be removed.

This is achieved by removing the 4 off M4 cap

head bolts holding on the cover.

Once the screws are removed the cover will hang

down out of the way to gain access to the Ex e

terminal block, the internal earth terminal and

mounting hole recesses.

INSTRUCTION MANUAL

IS-CP4B-PB Push Button Manual Call Point

For use in Flammable Gas and Dust Atmospheres

Zone 1

Explosive gas air mixture likely to occur in

normal operation.

Zone 2

Explosive gas air mixture not likely to occur,

and if it does, it will only exist for a short time.

www.acornfiresecurity.com

www.acornfiresecurity.com

6) Earthing

The unit has both internal and external earth

terminals.

It is recommended that a cable crimp lug is used

on the earth wires.

The internal earth wire is placed under a earth

clamp which will stop the cable twisting. This

secured by an M4 screw and spring washer.

The external earth lug should be located between

the two M5 washers provided and securely locked

down with the M5 spring washer and two locknuts.

Internal Earth

terminals External

Earth Stud

Terminal block

7) Cable connections

There are 3 off cable entries for M20x1.5 cable

glands or stopping plugs.

Cable glands or stopping plugs must be rated IP66.

The unit can be wired in a number of different ways

depending on the resistor combination selected.

Option 1 –EOL (End of line) Resistor

Option 2 –Series (In line) resistor

Option 3 –Series and EOL resistors

The equipment needs to be installed with ATEX

and/or IECEx certified Zener Barriers or Galvanic

Isolators.

8) Testing unit operation

The push button unit can be tested without the

need to replace any element.

To test, lift the cover lift flap to reveal the push

button. The button should be pressed into the body

to activate the unit and place it into the operated

condition.

The call point switch will now change over it’s

contacts to operate the alarm.

Once testing is complete the unit needs to be reset

from the operated condition.

Rotate the push button anticlockwise by an angle

of 55º, see guide alignment marks on button and

cover, shown below (1). The push button should

pop back up to its original position.

Ensure that the push button has also twisted back

clockwise by 55º to its original position see guide

marks on button and cover, shown below (2).

The unit is now reset.

1. On operated unit 2. Button should pop

Twist push button up and twist back to

Anticlockwise 55º original position

to reset

Note: use alignment

marks circled to

indicate the push

button’s status

/position.

Unit currently shown

as ‘standby

condition’

Resetting an operated unit is the same as resetting

a tested unit.

www.acornfiresecurity.com

www.acornfiresecurity.com

1A - Circuit shown in Unoperated condition

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

EOL (End Of Line ) Resistor

1B - Circuit shown in Operated condition (Button Pressed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Series Resistor

2A - Circuit shown in Unoperated condition

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

2B - Circuit shown in Operated condition (Button Pressed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

EOL & Series Resistors

3A - Circuit shown in Unoperated condition

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

3B - Circuit shown in Operated condition (Button Pressed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

www.acornfiresecurity.com

www.acornfiresecurity.com

Popular Fire Alarm manuals by other brands

E2S

E2S BExTBG05D instruction manual

Teknim

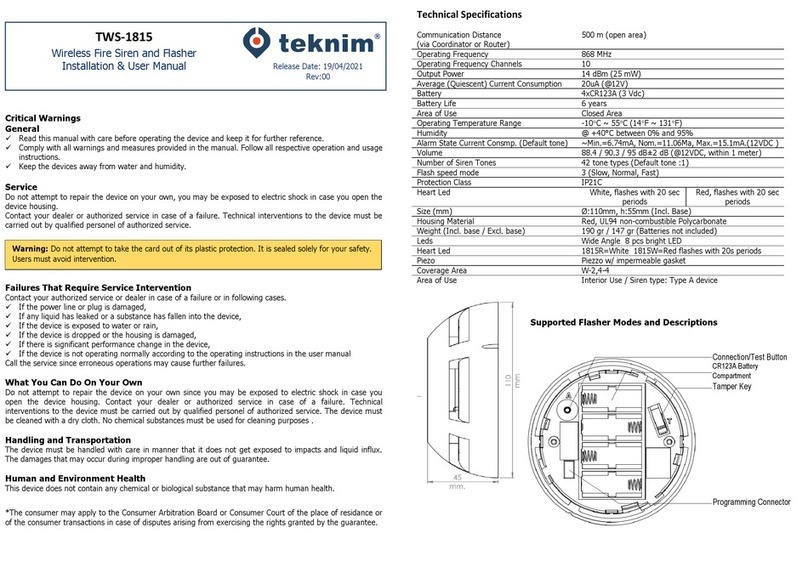

Teknim TWS-1815 Installation & user manual

Ziton

Ziton ZP1-F2 installation manual

Honeywell

Honeywell Fire-Lite Alarms LCD-80F manual

Teknim

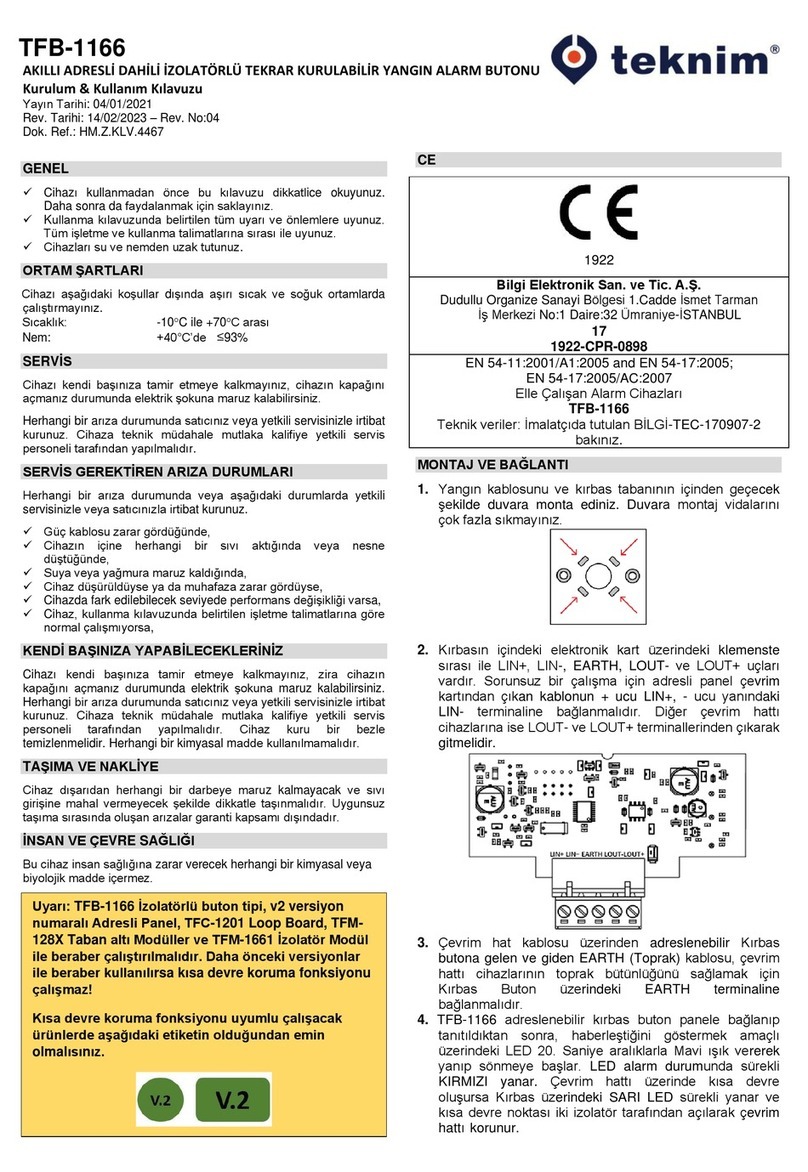

Teknim TFB-1166 Installation & user manual

Silent Call Communications

Silent Call Communications FA41-MC Installation and operating instructions