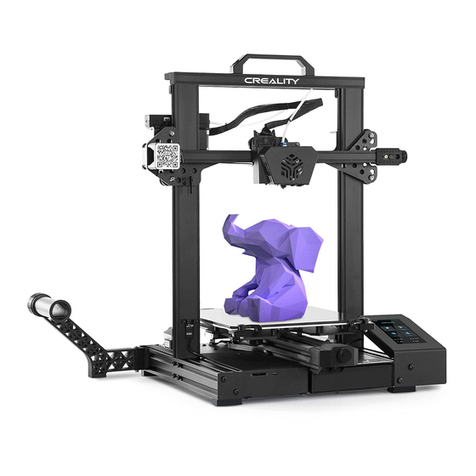

Creality Ender-3 User manual

Other Creality 3D Printer manuals

Creality

Creality CR-6 Max User manual

Creality

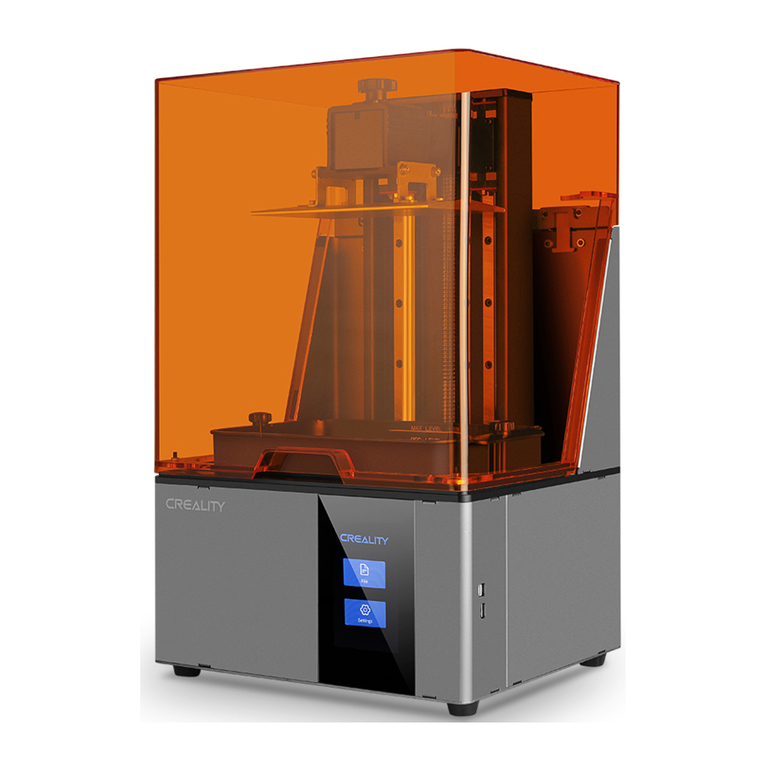

Creality HALOT-LITE User manual

Creality

Creality CR-Laser Falcon User manual

Creality

Creality Halot-Sky User manual

Creality

Creality Laser Module User manual

Creality

Creality Halot-Sky User manual

Creality

Creality CR-10S Pro User manual

Creality

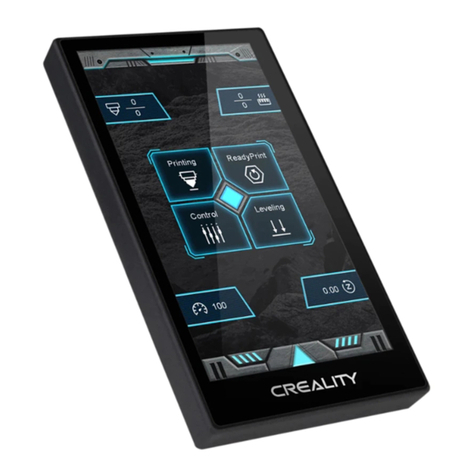

Creality 3D Pad User manual

Creality

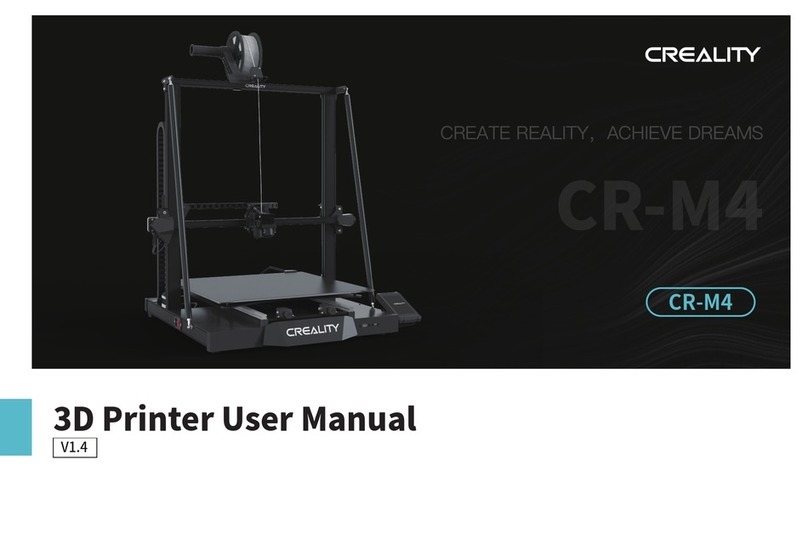

Creality CR-M4 User manual

Creality

Creality CR-6 Max User manual

Creality

Creality Sermoon V1 User manual

Creality

Creality 3D Pad User manual

Creality

Creality BLTouch User manual

Creality

Creality CR-10S Pro Manual

Creality

Creality Ender-5 Manual

Creality

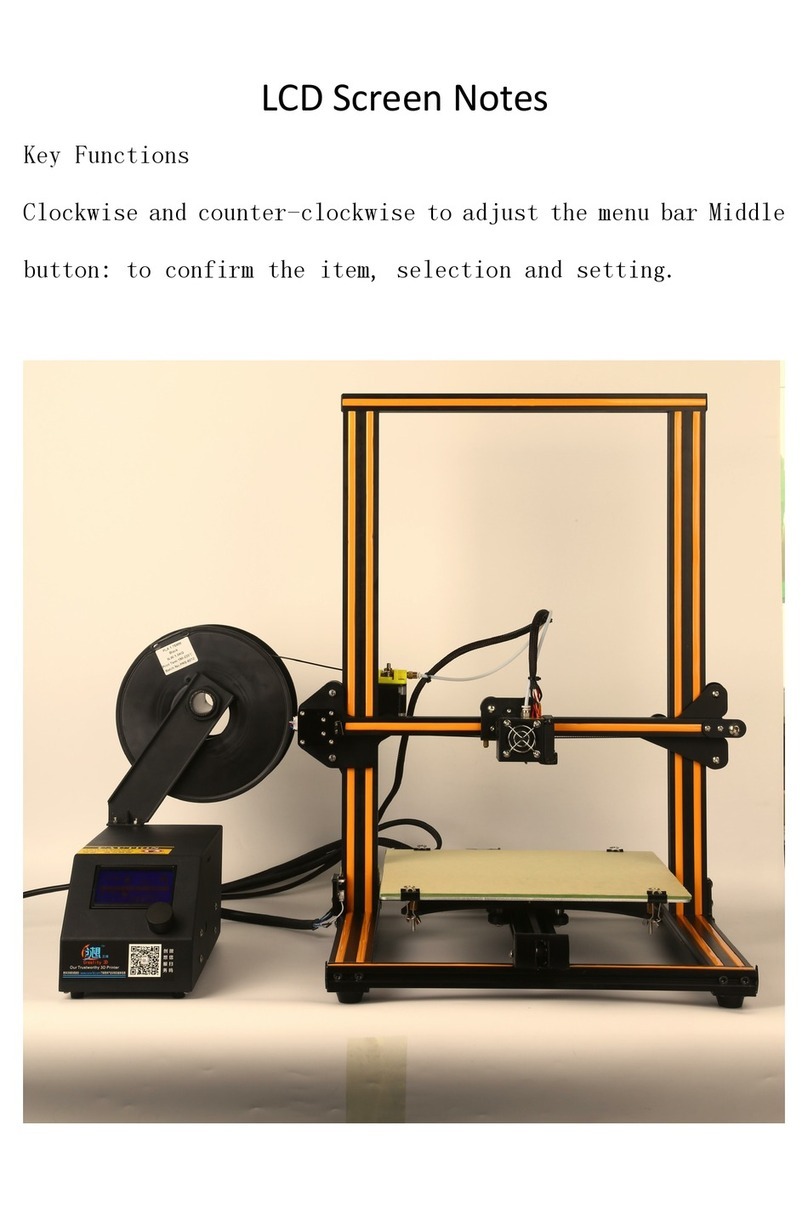

Creality CR-10 Series User manual

Creality

Creality CR-10 Series User manual

Creality

Creality HALOT-LITE User manual

Creality

Creality CR-5 User manual

Creality

Creality CR20Pro Manual

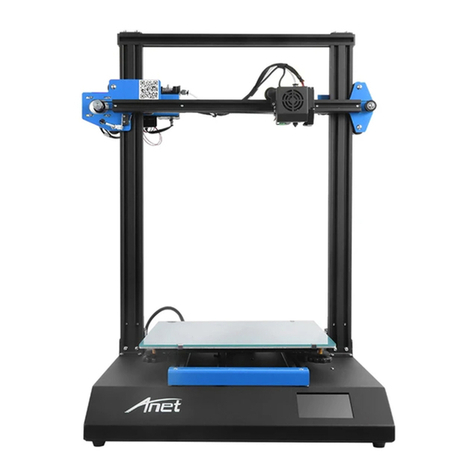

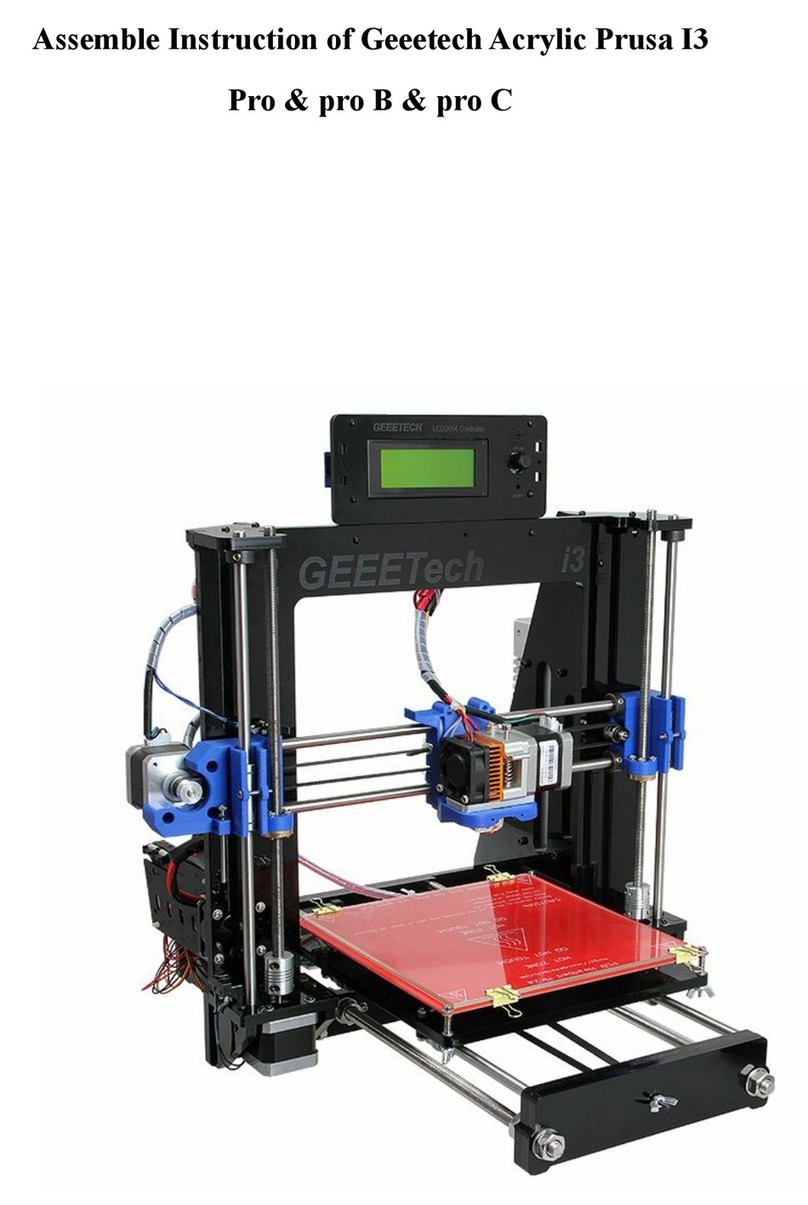

Popular 3D Printer manuals by other brands

FELIXprinters

FELIXprinters FELIX One Assembly manual

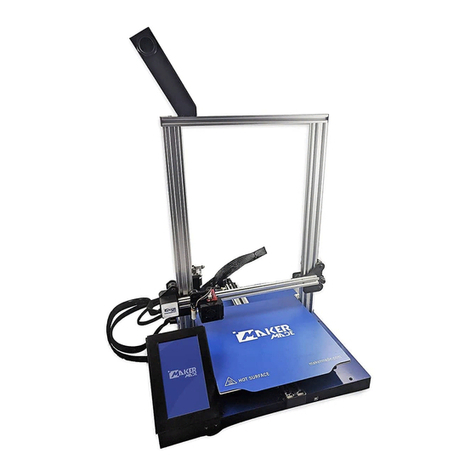

Makermade

Makermade 300X Setting up

3D Upfitters

3D Upfitters Ender 5 Plus R1 Enclosure Kit installation manual

Zcorporation

Zcorporation Z 406 user manual

Zcorporation

Zcorporation ZPrinter 310 troubleshooting guide

FELIXprinters

FELIXprinters Tec 4 user manual