Z Corporation Z406 System User Manual

2Z Corporation Service (781)852-5050/(887)88-ZCORP

Table of Contents:

1YOUR Z406 SYSTEM .................................................................................................. 6

1.1 INTRODUCTION ................................................................................................... 6

1.1.1 OVERVIEW...................................................................................................................6

1.1.2 HOW IT WORKS ..........................................................................................................7

1.2 THE PARTS OF THE Z406 3D PRINTER........................................................... 10

1.3 THE PARTS ON THE PRINTER ASSEMBLY AND GANTRY ............................ 11

1.4 Z406 SYSTEM COMPONENTS .......................................................................... 12

1.4.1 STEP 1: IMPORTING THE FILE.................................................................................13

1.4.2 STEP 2: PREPARING THE 3D PRINTER ..................................................................13

1.4.3 STEP 3: PRINTING THE PART..................................................................................13

2PREPARING THE Z406 SYSTEM TO PRINT........................................................... 14

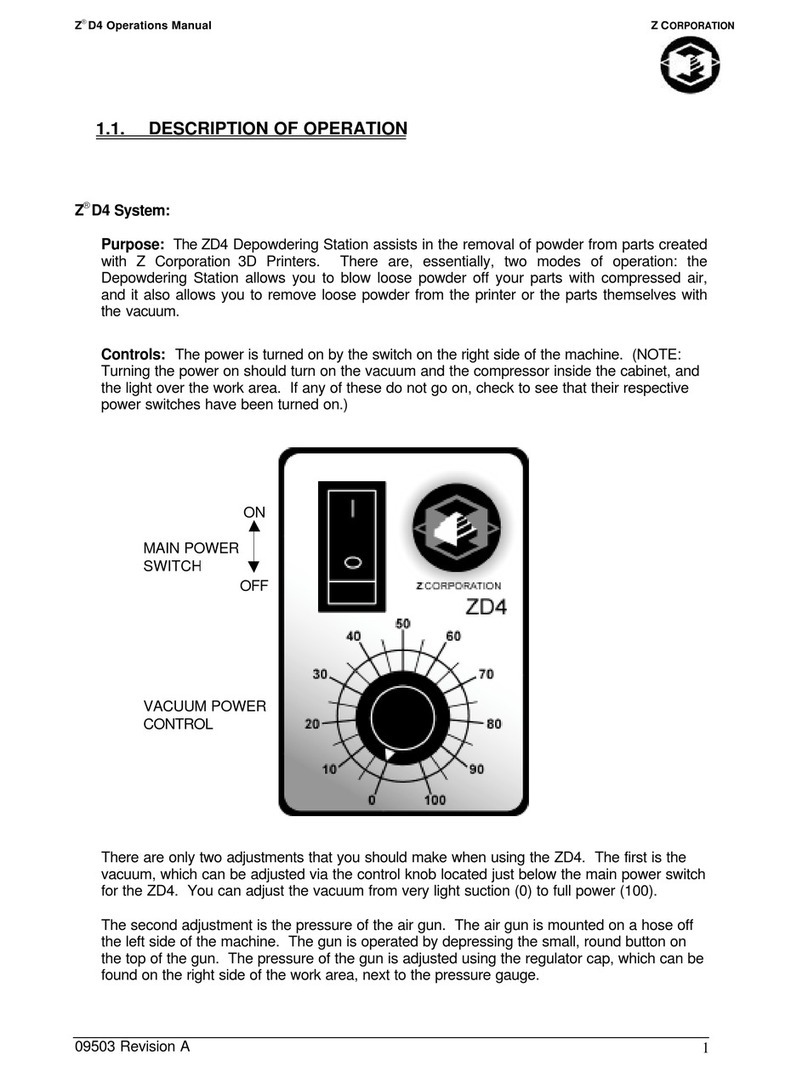

2.1 HARDWARE CONTROLS ................................................................................... 14

2.2 PREPARING THE 3D PRINTER ......................................................................... 15

2.2.1 FILLING THE FEED BOX WITH POWDER ................................................................16

2.2.2 CLEANING THE SERVICE STATION ........................................................................18

2.2.3 CHECKING FLUID LEVELS .......................................................................................20

2.2.4 CHECKING POWDER OVERFLOW BIN....................................................................21

2.2.5 PUTTING THE MACHINE ONLINE ............................................................................22

3SETTING UP THE BUILD.......................................................................................... 23

3.1 OPEN OR IMPORT THE FILE............................................................................. 23

3.2 ORIENTING THE PART ...................................................................................... 24

3.2.1 PART CONTAINING AN OPENING OR HOLLOW AREA ..........................................24

3.2.2 PART CONTAINING OVERHANGS ...........................................................................24

3.3 CHECKING BUILD SETTINGS ........................................................................... 25

3.3.1 POWDER SETTINGS.................................................................................................26

3.4 PRINTING THE BUILD ........................................................................................ 27

4POST PROCESSING THE PART.............................................................................. 28

4.1 REMOVING THE FINISHED PART..................................................................... 28

4.2 DEPOWDERING THE PART............................................................................... 29

4.3 DRYING THE PART ............................................................................................ 30

4.3.1 STARCH AND PLASTER PARTS ..............................................................................30

4.3.2 ZCAST PARTS ...........................................................................................................30

4.4 INFILTRATING THE PART.................................................................................. 31