Creo Lotem 400 Series Operating instructions

www.creo.com

Site Preparation Guide

English

Lotem 400 /

Lotem 400 Quantum

Family

707-00144D-EN

Copyright

Copyright © 2006 Creo Inc. All rights reserved. The Creo wordmark, Creo logo, and the names of the Creo

products and services referred to in this document are trademarks of Creo Inc.

Adobe, Acrobat, Adobe Illustrator, Distiller, Photoshop, PostScript, and PageMaker are trademarks of Adobe

Systems Incorporated.

Apple, iMac, Power Macintosh, Mac OS, AppleShare, AppleTalk, TrueType, ImageWriter, and LaserWriter are

registered trademarks of Apple Computer, Inc. Macintosh is a trademark of Apple Computer, Inc., registered in

the U.S.A. and other countries.

PANTONE, Hexachrome, PANTONE Hexachrome, and PANTONE MATCHING SYSTEM are the property of

Pantone, Inc.

PEARL, PEARLsetter, PEARLhdp, PEARLdry, and PEARLgold are registered trademarks of Presstek, Inc.

XEROX® is a trademark of XEROX CORPORATION.

Other brand or product names are the trademarks or registered trademarks of their respective owners.

No copying, distribution, publication, modification, or incorporation of this document, in whole or part, is

permitted without the express written permission of Creo Inc. In the event of any permitted copying, distri-

bution, publication, modification, or incorporation of this document, no changes in or deletion of author

attribution, trademark legend, or copyright notice shall be made. No part of this document may be

reproduced, stored in a retrieval system, published, used for commercial exploitation, or transmitted, in any

form by any means, electronic, mechanical, photocopying, recording, or otherwise, without the express written

permission of Creo Inc. This document is distributed in Adobe Systems Incorporated's PDF (Portable

Document Format). You may reproduce the document from the PDF file for internal use. Copies produced

from the PDF file must be reproduced in whole.

Creo Inc.

3700 Gilmore Way

Burnaby, B.C., Canada

V5G 4M1

Tel: +1.604.451.2700

Fax:+1.604.437.9891

http://www.creo.com

Internal 707-00144D-EN

Revised January 2006

Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide 1

Introduction.................................................................................................................................................... 1

Tools Needed.................................................................................................................................................. 2

Antivirus Software .......................................................................................................................................... 2

Equipment Overview 3

Options .......................................................................................................................................................... 4

Size and Weight ............................................................................................................................................. 4

Cables, Connectors, and Receptacles .............................................................................................................. 5

Site Requirements 7

Footprint and Working Area ........................................................................................................................... 7

Debris Removal Cabinet.................................................................................................................................. 8

Environmental Conditions............................................................................................................................... 9

Floors ............................................................................................................................................................. 9

Electrical ....................................................................................................................................................... 10

Power Quality ........................................................................................................................................ 10

Heat Output .......................................................................................................................................... 11

Power Line Voltage/Frequency ............................................................................................................... 11

Power Line Disturbances ........................................................................................................................ 11

Grounding ............................................................................................................................................. 11

Air Supply..................................................................................................................................................... 13

Air Supply Qualification Procedure ......................................................................................................... 14

Cleanliness............................................................................................................................................. 14

Static Electricity...................................................................................................................................... 14

Humidity................................................................................................................................................ 15

UV Light ................................................................................................................................................ 15

Air Conditioning .................................................................................................................................... 15

Ventilation.................................................................................................................................................... 15

Telephone Link ............................................................................................................................................. 17

Network ....................................................................................................................................................... 17

Media and Processor(s) ................................................................................................................................. 17

Plates............................................................................................................................................................ 17

Plate Registration.......................................................................................................................................... 18

Shipment and Delivery 19

Customer Responsibilities ............................................................................................................................. 19

Forklift ................................................................................................................................................... 19

Doors and Hallways ............................................................................................................................... 19

Shipping Crates ............................................................................................................................................ 20

Contents

2 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Lotem 400 / Lotem 400 Quantum

Family Site Preparation Guide

Introduction

Please take a few moments to read through this document. It provides guidelines

for preparing your site for the Lotem 400 / Lotem 400 Quantum platesettter

installation.

Your Creo service engineer will help you to ensure that your site meets all the

requirements. Proper preparation will help to prevent unnecessary problems and

delays when installing the device.

The following topics are discussed:

•Device configuration

•Floor space requirements

•Device dimensions

•Weight requirements

•Electrical requirements

•Debris removal system requirements

•Environmental conditions

•Ventilation requirements

•Network/modem requirements

•Processor specifications

With your Creo service engineer, complete the Site Inspection Checklist in

Appendix B.

2 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Tools Needed

•Air Supply Gauge (92-0373A)—to check the pressure and flow of the site’s

compressed air supply. See Air Supply Qualification Procedure on page 14.

•Floor Level Gauge ( 92-0373A)—to check the pressure and flow of the sites’

compressed air supply. See Air Supply Qualification Procedure on page 14.

•Tape measure—15 m (50 ft.)

Antivirus Software

Note: Creo supports and recommends that the customer purchase a copy of the latest

version of Symantec Antivirus Corporate Edition software. They should install it on each of

their Creo CTP Systems. Creo does not sell Symantec Antivirus software, nor do we install

or directly support it. We recommend that the customer purchase the software from a

retail vendor convenient to them. We will supply installation instructions to customers

who have signed and returned the Antivirus Waiver to Creo. To find a copy of the

Antivirus Waiver, the customer should log onto eCentral and select Self Support >

Product Documentation and type word Antivirus in the search criteria.

See the Installing Norton Antivirus document on eCentral for installation details.

Equipment Overview 3

Equipment Overview

The device consists of the following standard components:

•Platesetter

•Universal debris removal system1

1.The debris removal system consists of a vacuum pump and filtration system for

removing debris from exposed media. See the UDRC Site Preparation and

Requirements document ( 725-00089A).

4 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Options

The Lotem 400 Family includes:

•Lotem 400 platesetter

•Lotem 400 platesetter with (multi-cassette unit) MCU

•Lotem 400 platesetter with processless plates (chemistry free)

•Lotem 400 Xpose platesetter

The Lotem 400 Quantum Family includes:

•Lotem 400 Quantum platesetter

•Lotem 400 Quantum platesetter with MCU

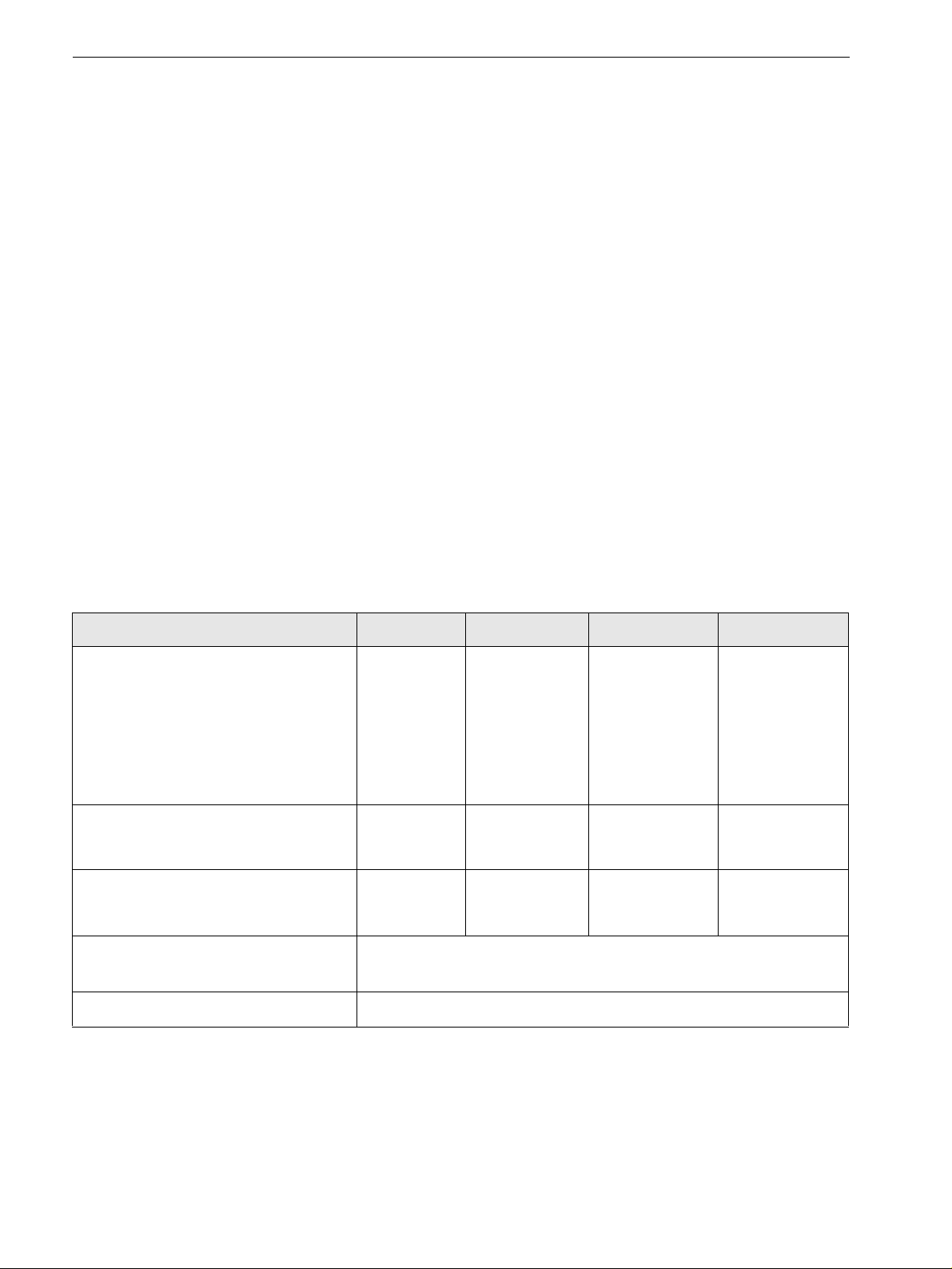

Size and Weight

Table 1 shows the maximum dimensions and weight of the Lotem 400 / Lotem 400

Quantum Family output devices and their components. The measurements are

taken facing the Lotem 400 / Lotem 400 Quantum Family output devices, with the

panels installed.

For measurements of the crates as shipped, see Table 6 on page 20.

Table 1: Size and weight of Lotem 400 / Lotem 400 Quantum Family platesetter and devices

Device Width Length Height Weight

Lotem 400

Lotem 400 Quantum platesetter

1750 mm

(69 in.)

1450 mm

(57 in.)

[includes

508 mm

(20 in.)

loading tray]

1350 mm

(53.15 in.)

750 kg

(1650 lb.)

MCU for Lotem 400 1220 mm

(48 in.)

1600 mm

(63 in.)

1350 mm

(53.15 in.)

650 kg

(1430 lb.)

Loading tray 450 mm

(17.72 in.)

Debris removal cabinet See the UDRC Site Preparation and Requirements document

(725-00089A).

Workstation Varies with configuration

Equipment Overview 5

Cables, Connectors, and Receptacles

Tables 2–4 list the supplied and required cables and connectors for the output

devices. Table 5 on page 6 lists the power/air connections.

Table 2: Cables and Interconnects—North America

Table 3: Cables and Interconnects—Europe, Australia and S.E. Asia

Note: Creo does not supply the connectors.

Cables Supplied by Creo Supplied by customera

a. The tolerances for input voltages are +6%, –10%. The specification for the frequency is 50/60Hz ±1.5%.

Branch circuits should have time delay type circuit breakers to avoid nuisance tripping caused by inrush

currents. For details, see Electrical on page 10.

Output device main power Yes

Workstation power Yes

Debris removal cabinet

power

See the UDRC Site Preparation and Requirements document

(725-00089A).

Telephone line Modem and serial cable.

Modem power supply can be

plugged into UPS.

Dedicated telephone line and

RJ-11 cable to plug into modem

(must be long enough to reach

workstation)

Cables Supplied by Creo Supplied by customera

a. The tolerances for input voltages are +6%, –10%. The specification for the frequency is 50/60Hz ±1.5%.

Branch circuits should have time delay type circuit breakers to avoid nuisance tripping caused by inrush

currents. For details, see Electrical on page 10.

Output device main power IEC320, type C20 appliance inlet Dedicated 16A, 200–240 V branch

circuit with IEC 309 16 A

receptacle

Workstation power IEC320, type C14 inlet IEC320, type C13 connector with

8Acord

Dedicated 8 A, 200–240 V branch

circuit

Debris removal cabinet

power

See the UDRC Site Preparation and Requirements document

(725-00089A).

Telephone line Serial cable for modem Modem, dedicated telephone line,

and telephone cable long enough

to reach workstation. Also

requires separate AC power

source (UPS provided only with

IEC type 320 outlet receptacles).

6 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Table 4: Cables and interconnects—Japan

Table 5: Air and network connections

Cables Supplied by Creo Supplied by customera

Output device main power

(attached to either the Single

Cassette Unit or Multiple

Cassette Unit)

IEC320, type C20 appliance inlet

2.5 m (8.2 ft.) power cord with

IEC320 type C19 connector at

equipment end and L6-20P

connector at other end

L6-20R receptacle

Dedicated 20 A, 200 V branch

circuit with L6-20R receptacle

Workstation power 2.5 m (8.2 ft.) power cable with

5-15P connector

5-15R receptacle and dedicated

100V, 15A branch circuit

Debris removal cabinet

power

See the UDRC Site Preparation and Requirements document

(725-00089A).

Telephone line Serial cable for modem. Modem, dedicated telephone line,

and telephone cable long enough

to reach workstation. Also

requires separate AC power

source (UPS provided only with

5-15R receptacles).

a. The tolerances for input voltages are +6%, –10%. The specification for the frequency is 50/60Hz ±1.5%.

Branch circuits should have time delay type circuit breakers to avoid nuisance tripping caused by inrush

currents. For details, see Electrical on page 10.

Other connections Supplied by Creo Supplied by customera

a. For the location of the air supply, see Footprint and Working Area on page 7. For further details, see Air

Supply on page 13 and Network on page 17.

Network connection

(for connecting to the

workflow)

Ethernet:

100 Base-T (RJ-45)

Network connection and cable

long enough to reach workstation.

FDDI: Duplex SC

Shop air supply (dedicated

branch recommended—see

Air Supply on page 13)

0.5 in. national pipe thread (NPT)

female fitting on the device

A flexible air line, 0.75 in. ID

min., with 0.5 in. NPT fitting at

the end for connecting to the

Lotem 400 / Lotem 400 Quantum

Family.

The air line must be capable of

delivering 20 SCFM @ 90 psi.

Keep the air line as short as

possible and free from

restrictions. If the air line is longer

than 6.1 m (20 ft.), use a larger ID

airline.

Site Requirements 7

Site Requirements

Footprint and Working Area

Ask your service representative to see TechPlanet for the recommended work area

and dimensions for your specific Lotem 400 / Lotem 400 Quantum configuration.

Allow a recommended minimum 1200 mm (47.24 in.) at the front of device, and

1000 mm (39.37 in.) at the sides of device for operator access:

Figure 1: Footprint of Lotem 400/Lotem 400 Quantum with slider kit

8 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Figure 2: Footprint of Lotem 400/Lotem 400 Quantum platesetter

Provide an area close to the device for storing media (for immediate use), disks,

paperwork, and so on.

Debris Removal Cabinet

Certain printing media (plates or film) may release airborne emissions during the

imaging process. Creo output devices are supplied with—or may be able to be

upgraded to—a debris removal system containing a collection nozzle located on

the head and a filtration unit, such as the Universal Debris Removal Cabinet

(UDRC).

The debris removal system is designed to extract and filter the airborne emissions,

thus contributing to a healthier working environment, consistent image quality,

and general reliability and cleanliness of the imaging device. Some types of media

typically release both particulate and gaseous emissions. Other types of media,

under certain imaging conditions, may release largely particulate emissions.

The UDRC configuration may include various filter options tailored to suit specific

qualified media types. The configuration for a particular customer site is typically

specified in a Creo proposal, sales agreement, order form, product specification, or

equivalent document.

The cabinet must be located within the cable and hose limitations.

For more information on the debris removal cabinet, please see the UDRC Site

Preparation and Requirements document (725-00089A).

WARNING: Emissions, either particulate or gaseous, that are not properly filtered can

endanger your health. For a list of airborne emissions that pertain to the media you are

using, see the media MSDS or contact the media manufacturer or distributor directly.

WARNING: Filtration of airborne emissions is not 100% efficient and must be

complemented by adequate outdoor air room ventilation. Failure to ensure adequate

ventilation may result in exposure to airborne emissions in excess of applicable regulatory

limits and in possible discomfort, illness, injury, and/or disability.

Site Requirements 9

Environmental Conditions

Install the device in a clean prepress area wherever possible. It is not advisable to

install the device in a pressroom environment.

The operating environment for the Lotem 400 / Lotem 400 Quantum Family

devices must be:

Te m p e r a t u r e 2 0 o—30oC (68o–86oF)

Humidity 55%—±5% RH, non-condensing

For the UDRC operating environment, please see the UDRC Site Preparation and

Requirements document (725-00089A).

Floors

The floor must be level and not subject to high levels of vibration. If the customer

site is close to heavy car or rail traffic routes, or is near an industrial site, the device

may be exposed to high levels of vibration through the floor.

Note: Some media types may restrict the operating environment of the Lotem 400 /

Lotem 400 Quantum Family devices. Consult the media manufacturer for their

recommended temperature and humidity ranges for plate operation and storage.

10 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

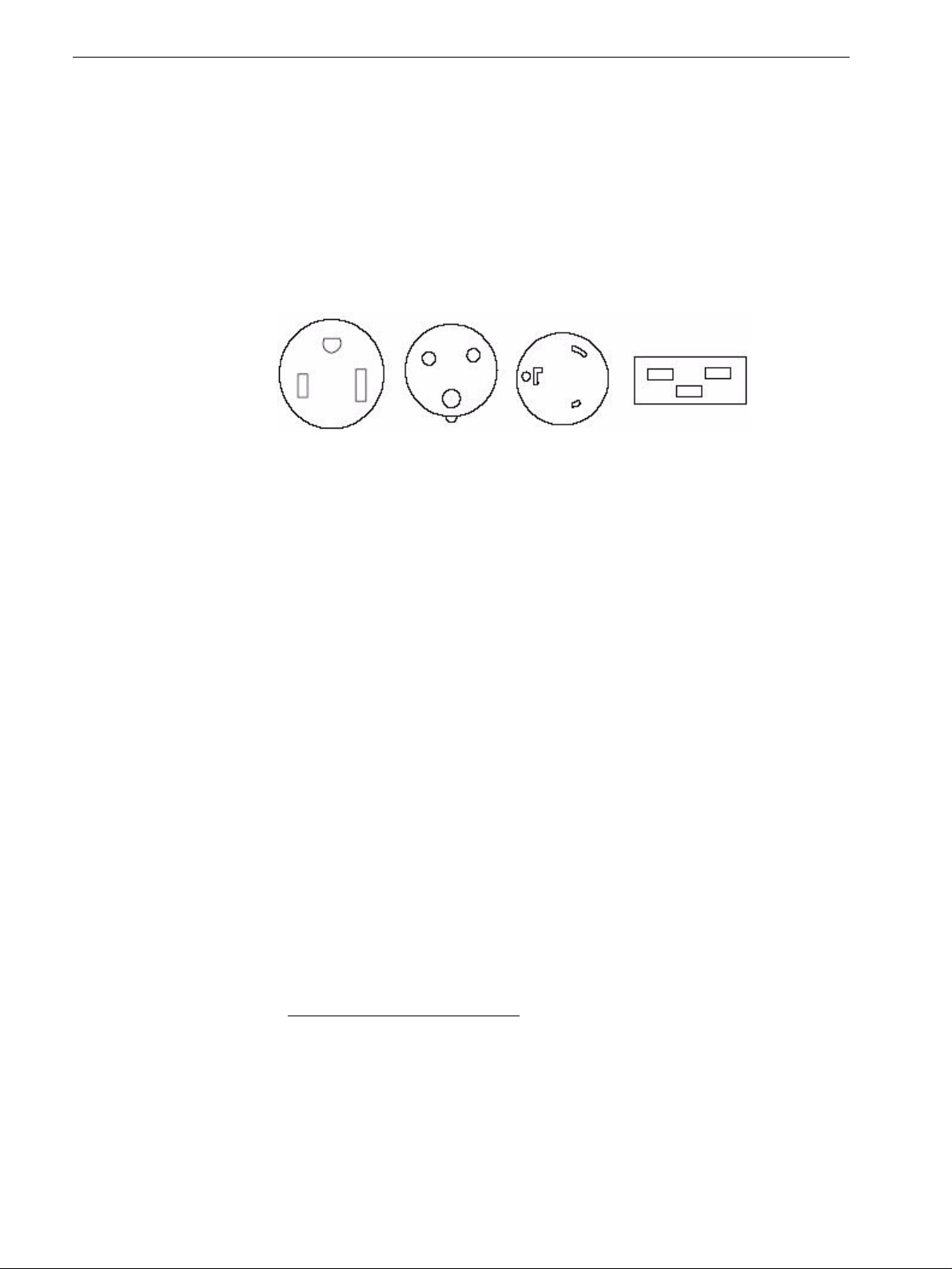

Electrical

The dedicated branch circuit for the following components must be supplied from

the same AC supply panel to ensure that both branch circuits are at the same

ground potential:

•Output device main power

•Wor ks tation ma in p ower

Figure 3 shows the configuration of the receptacles used by the output devices and

peripheral equipment.

Figure 3: Receptacles used on output devices

Power Quality

Before installing the device, a power monitor should be placed at the site to

measure power quality for one week1. If the power quality at the customer site is

outside Creo specifications (+6%/–10%), the customer should purchase a line

conditioner, 3000 VA, for the Lotem 400 / Lotem 400 Quantum Family circuit

from a local supplier.

If there are concerns about power quality (blackouts or brownouts) at the

customer site, an online uninterruptible power supply (UPS) device can be ordered

directly from a local supplier. A UPS is designed to allow the correct and complete

shutdown of the device, as opposed to a line conditioner that is designed to allow

the device to function for extended periods of time where the power conditions

may be outside of the Lotem 400 / Lotem 400 Quantum specifications.

UPS specifications are available from the supplier.

Special Precautions

The plug(s) on the power cord(s) of the workstation are intended for each separate

device. Therefore, the branch circuit receptacle(s) must be installed near the

workstation and be easily accessible.

5-15R IEC320IEC309 L6-20R

1. Creo America has a contract with Re Monitoring Services in Manchester, NH to

provide power and environmental site surveys for the NAFTA region. The monitoring

service includes voltage, current, temperature, humidity, dust and air pressure. Rx

Monitoring Services will provide the equipment to be installed at the customer site for

a maximum of 10 days. They will then monitor it and send a report via e-mail. Outside

North America, contact your local product support specialist.

Site Requirements 11

Heat Output

The nominal heat output of the output device itself is 22,250-26,250 BTU/hr.

For heat output of the UDRC, please see the UDRC Site Preparation and

Requirements document (725-00089A).

Power Line Voltage/Frequency

Line voltage at the customer site must remain within +6%/–10% of the

Lotem 400 / Lotem 400 Quantum Family output devices rated voltage of 200 V–

240 V for

110 V countries, or between 180V and 254 V for 220 V countries.

The frequency is 50/60 Hz ±1.5%.

The electrician at the customer site should install the correct outlet to provide

power to the device. The device must be powered from a different line than the

workstation. Tolerances for the specified input voltages require balanced power

inputs (L1–G=L2–G, or L1G=L1–N).

Power connectors must be of the locking type in North America and Industrial

type B in Europe, due to the high leakage current of the equipment. Frequency is

50/60Hz ±1.5%. See “Erratic performance of platesetter - Uninterupptable power

supply (UPS)/power conditioner requirement” document on eCentral.

Power Line Disturbances

The reliable operation of computer systems depends on the availability of relatively

noise-free AC power. Lightning, line faults, or power switching commonly found

in machinery, office equipment, and factory environments, can generate line

transients that far exceed the peak value of the applied voltage. If not attenuated,

these microsecond pulses can disrupt system operation. The power line to the

machine should be run away from electrically noisy power cables. If power line

disturbances are affecting the operation of the machine, the use of a power

stabilizer is highly recommended.

Dips in power should not exceed 30% of nominal voltage, having maximal

duration of 10 ms. Fast transient disturbances on the power line should not exceed

1.0 kV.

Grounding

At 60 Hz sites, 208 Vac (between 2 phases of 120 Vac each).

At 50 Hz sites, 380 Vac grounds.

Grounding requirements for platesetter – and all equipment communicating with

it – should be observed to ensure trouble-free operation.

12 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Grounding requires the following:

•Grounding wires that are insulated and at least equal in size to the phase

conductors.

•Ground impedance less than 2 Ohms.

•A single point and dedicated ground.

•Each system load (such as platesetter, host) is fed through an isolated ground

outlet and has a separate ground, as well as neutral and phase line of equal size

wire.

Note: Chained neutrals and grounds are not permitted

Site Requirements 13

Air Supply

The Lotem 400 / Lotem 400 Quantum output device requires a clean, dry, oil-free,

dust-free, and moisture-free air supply at 7 bar (100 psi), of shop air according to the

table that follows:

*SLPM measured at 7 bar, SCFM measured at 100 psi

A standard 1/4’’ BSP port female outlet connector is required. It should be

mounted on the wall up to 5 m from the device.

The air supply should conform to ISO class 4.

•Maximum particle size 15 µ (0.006 in.)

•Concentration of solid contaminants: 8 mg/m3(0.000216 oz./yd.3)

•Maximum pressure dew point 3°C @ 8 bar [37.4°F @120 psi]

•Maximum oil content 5 mg/m3(0.000135 oz./yd.3)

Examples of typical compressed air systems that you may use:

For Lotem 400

For Lotem 400 with MCU

Configuration Average air consumption* Compressor air supply*

Lotem 400 10 SLPM (0.35 SCFM) 70 SLPM (2.47 SCFM)

Lotem 400 with MCU 90 SLPM (3.18 SCFM) 170 SLPM (6.0 SCFM)

Note: Do not add lubricant.

Note: The temperature of the airline going from the drying device to the machine must

be kept above 3° C.

Manufacturer Kaeser Atlas Copco

Compressor type Piston Piston

Compressor Model Premium-Silant 130/10 LFx-1.0-T20

Air receiver (liter) 10 50

Dryer (230 V-AC) TAH-4 FX1

Automatic Water Drainer according to air receiver according to air receiver

Manufacturer Kaeser Atlas Copco

Compressor type Screw Screw

Compressor Model SX-3 GX2-10 (50 Hz)

Air receiver (liter) 250 (or 280) 250

Dryer (230 V-AC) TA-5 FX1

Automatic Water Drainer ECO-21-PLUS WD80

14 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Air Supply Qualification Procedure

This procedure helps determine whether the customer’s air supply is adequate for

satisfactorily running the output device. It requires a measurement tool

(92-0373A) made specifically to test the output device’s air supply.

1. Mount the device to the end of the air hose or pipe that would normally be

connected to the output device. A few extra adapter fittings and a roll of

Teflon® tape have been included for this purpose.

2. Turn on the valve on the tool.

3. Record the results in Table on page 31.

4. Repeat this test two more times during the day at well-spaced intervals to

confirm that the air supply is not being compromised by other machines, and

so on.

The gauge must never fall below 90 psi at any time during the tests. If the air supply

fails to maintain this pressure at a minimum, it is below specifications for the

output device.

Cleanliness

Filters in the air conditioning system should be able to block 60% of all 10 micron

dust particles.

Clean air is vital as an unclean environment can cause hotspots on your plates as

well as machine malfunction.

According to IEC-721-3-3,7

Name: Mechanically active substances

Class: 3S2, 7S1

Severity: Sand 30 mg/m^3

•Dust (suspension) 0.2 mg/m^3

•Dust (sedimentation) 1.5 mg / (m^2 X h)

Static Electricity

•Humidity must be 55% ±5% to reduce the static electricity with the plates. See

Humidity below.

•Use of floor carpeting is not recommended in the Lotem 400 / Lotem 400

Quantum output device area. If carpets are used, only anti-static carpets

should be installed at the site. Carpet thickness should be up to 0.5 inch (12

mm).

Site Requirements 15

Humidity

The output device requires relative humidity of 55% ±5%.

An industrial steam humidifier can be used to meet specified humidity.

UV Light

Some plates, such as Kodak DITP, are sensitive to UV light. When such plates are

used or when the Lotem 400 / Lotem 400 Quantum output device is directly

connected to a plate stacker, you need an appropriate safe light.

Air Conditioning

Sufficient air conditioning should be present to provide heat dissipation for the

output device, plus all additional equipment residing in the system room, and an

additional minimum 25% safety margin. Ensure that the ventilation system can

circulate the entire volume of air in the room 16 times per hour.

The output device requires a constant temperature of 23×C ±2×C

(73.5×F ±3×F).

The calculated air conditioning requirements for the output device (in BTU/hour)

are shown in below table.

Please note the following guidelines:

•The system room should ideally contain both a thermometer and a

hygrometer, permanently mounted in a central location.

•In addition, it is highly recommended that you have a humidity and

temperature recorder.

Ventilation

No filtration can be 100% efficient (for example, carbon monoxide is not captured

by Creo filters). That is why outdoor air ventilation is required with the debris

removal system. Air exhaust vents (where air is drawn out of the room) should be

located as close to the debris removal cabinet and output device as possible.

The Lotem 400 / Lotem 400 Quantum Family output devices require a minimum

of 1.1 m3/min (40 cfm)1outdoor air ventilation. This air ventilation prevents the

accumulation of airborne emissions that may be released when certain media are

imaged.2

Platesetter 12,000-16,000 BTU/hour

Host 2,500 BTU/hour

Debris removal system 4,800 BTU/hour

Other misc. 1,500 BTU/hour

Safety margin (25% of above) 6,250 BTU/hour

Total 27,050-31,050 BTU/hour

16 Lotem 400 / Lotem 400 Quantum Family Site Preparation Guide

Outdoor air ventilation must not be confused with air circulation in the room that

results from temperature control or humidity control. Outdoor air ventilation may

be roughly estimated to be 10% to 30% of the air circulation rate in the room. To

achieve adequate air mixing, Creo recommends at least 3 ACH (air changes per

hour).

These recommendations apply to a single device with no other equipment in the

room. Other imaging equipment, processors, ovens, HVAC systems, and so on,

may contribute additional emissions to the work environment, increasing the

amount of outdoor air ventilation required.

The customer is responsible for assessing the level of airborne emissions in the

room to ensure that, upon installation of the Lotem 400 / Lotem 400 Quantum

Family, the requirements of local, state, provincial, regional, and national

regulations for occupational health and safety are satisfied. In the event of any

uncertainty about the levels of airborne emissions, the customer should arrange for

an indoor air quality assessment to be conducted by a qualified industrial hygienist.

1.This is a default value. Certain media may require higher ventilation; to check the

recommended value for specific media, please seeseesee CTP Media Imaging

Performance Database (available from your Creo representative), where it will be

specified if different from default.

2. Information on the hazardous compounds released by a particular media during

imaging should be available from the media manufacturer’s Material Safety Data

Sheet or equivalent document.

This manual suits for next models

1

Table of contents

Popular Office Equipment manuals by other brands

Vivo

Vivo DESK-V001G instruction manual

Steelcase

Steelcase Elective Elements Powerway SPB89 installation instructions

hushoffice

hushoffice hushwork HUS-BX-009 Maintenance and safety manual

LDI

LDI Safco 5228 Assembly instructions

Framery Q

Framery Q Maggie installation instructions

Steelcase

Steelcase FlipTop Twin Assembly instruction