Cressi T10 S.C. Manual

Via Gelasio Adamoli, 501 - 16165 - Genova - Italia

Tel. +39 010 830.79.1 - Fax +39 010 830.79.220

[email protected] • www.cressi.com

erogatori

regulators

detendeur

atemregler

regulador

пользователя

呼吸调节器

Manuale d’uso

Direction for use

Manuel d’instructions

Bedienungsanleitung

Manual de istrucciones

Pуководство

潜水呼吸调节器使用手册

rev_08_2019 made in Italy

44

Introduction . . . . . . . . . . . . . . . . . . . . . . . . .page 45

Main Components . . . . . . . . . . . . . . . . . .page 45

1) FIRST STAGES . . . . . . . . . . . . . . . . . . . . . .page 47

1.1 T10 - T10 S.C.-T10 SC Cromo . . . . . . . . . . .page 48

1.2 MC9 - MC9 S.C. . . . . . . . . . . . . . . . . . . . . . . .page 52

1.3 MC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 54

1.4 AC2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 56

1.5 Performance . . . . . . . . . . . . . . . . . . . . . . . . . .page 57

2) SECO D STAGES . . . . . . . . . . . . . . . . . . .page 61

2.1 Galaxy Adjustable/Master / Master Cromo / Galaxy /

Octopus MG Balanced . . . . . . . . . . . . . . . . .page 62

2.2 Master / Master Cromo / Galaxy,

Octopus MG Balanced

disassembly and maintenance . . . . . . . . . .page 65

2.3 XS Compact Pro / XS Compact / Octopus . .page 66

2.4 XS Compact Pro / XS Compact

Disassembly and maintenance . . . . . . . . . . .page 69

2.5 XS2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 70

2.6 Performance . . . . . . . . . . . . . . . . . . . . . . . . . .page 73

3) USE A D MAI TE A CE . . . . . . . . . . .page 77

3.1 Use of the regulator and risk assessment .page 78

3.2 Checks before use . . . . . . . . . . . . . . . . . . . . .page 78

3.3 Mounting the regulator to the tank . . . . . . .page 79

3.4 Use of the regulator in cold water . . . . . . . . page 80

3.5 Care and maintenance

of the equipment . . . . . . . . . . . . . . . . . . . . . .page 80

3.5.1 Caring for the equipment . . . . . . . . . . . . . . . .page 80

3.5.2 Equipment maintenance . . . . . . . . . . . . . . . .page 81

3.6 Use with Nitrox mixtures . . . . . . . . . . . . . . . .page 81

3.7 Maintenance/recording of procedures

(Service Record) . . . . . . . . . . . . . . . . . . . . . .page 83

3.8 Cressi-sub Certified Combinations . . . . . . .page 84

4) TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 303

TABLE OF CO TE TS

ENGLISH

Introduction

Congratulations! Continual research and evolution carried out at

our technical centres, together with Cressi-sub’ s usual reliability,

have led to the product you just purchased, which will allow you

to dive comfortably and safely for a long time.

All Cressi-sub re ulator are certified to 146 ft (50 m), and some

for use in cold water with temperatures below 10° C, havin

passed the strin ent operations testin at 4° (+0-2) set forth

under the standard EN 250:2014 (and all previous editions) in

compliance with new EU re ulation 2016/425 (ex 89/686/CEE).

This re ulation establishes the conditions for brin in to market

and the essential minimum safety requirements for Personal Pro-

tective Equipment (PPE). It will officially take effect April 21, 2018,

abro atin the previous Directive 89/686/EEC, upon the conclu-

sion of a transitional period ranted to manufacturers of PPE.

Main Components

Regulators’ main task is reducing the pressure of the compres-

sed air contained in the tank to the same level as the environ-

ment’ s, supplying breathable air when required by the diver.

They are composed of a “first stage”, working as main pressure

reducer and a “second stage” (kept in the diver’ s mouth), which

adjusts the pressure precisely to the same value as the environ-

ment’ s. The regulator is part – together with tank, valves and

sling – of a complete underwater breathing system, known as

“SCUBA” (Self Container Underwater Breathing Apparatus).

This handbook describes all models of Cressi-sub range, all rea-

lized in high quality materials to guarantee pleasant dives and

high performance, together with the easiest ways of use and-

maintenance. The instructions and directions found in this manual

are based on the most up-to-date information about the equip-

ment available before printing.

Cressi Sub reserves the right to make changes at any time.

OTE: The instructions and directions found in this manual are

based on the most up-to-date information about the equip-

ment available before printing. Cressi Sub reserves the right to

make changes at any time.

OTE: This handbook does not replace a diving training cour-

se! All Cressi-sub devices must be used by divers who have

attended regular courses held by certified trainers.

Using underwater devices without a licence or the necessary

technical training may be dangerous for the diver’ s safety and

life itself.

Besides, in order to guarantee the maximum safety, the devi-

ces must be serviced only by the producer or an authorized-

centre.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: [email protected]).

WAR I G: CRESSI-SUB DECLI E A Y RESPO -

SIBILITY FOR A Y SERVICI G CARRIED OUT BY

U AUTHORIZED PERSO EL.

WAR I G: SCUBA devices complying with E

250:2014 standard must not be used by more

than a diver at the same time.

WAR I G: in case the components of a SCUBA

are set and used by more than a diver at the same

time, their performance in cold water might not

satisfy the requisites prescribed by E 250:2014

standard.

WAR I G: if the components of the SCUBA

equipment are configured and used simultaneously

by multiple divers, the equipment may not be used

at depths of greater than 30 meters, or at water

temperatures below 10 °C (if specified).

45

Direction for use regulators

FIRST STAGES

1.1 - T10 - T10 S.C. - T10 SC Cromo

1.2 - MC9 - MC9 S.C.

1.3 - MC5

1.4 - AC2

1.1. - T10 - T10 S.C.-T10 SC Cromo

The T10 balanced diaphragm first stage features a lightweight

structure of compact design, protected by the special and inno-

vative PVD (Physical Vapor Deposition) treatment, which creates

a highly resistant surface coating with extraordinary chemical-

physical characteristics and a high technical, very pleasing ap-

pearance. Unlike the T10 version, the Cromo version has a

protective surface coating of electroless chrome plating.

The ergonomics of the T10 balanced diaphragm first stage pres-

ents the functioning mechanism arranged perpendicular to the

air entry axis that thereby forms a “T” profile designed to guaran-

tee perfect arrangement of the HP and LP hoses, avoiding inter-

ference with the equipment connected to the first stage; reduced

size (particularly used in the SC version particularly suited to cold

water), as well as additional inspection capacity and access to the

HP valve mechanism to simplify maintenance and disassembling

of the regulator.

It provides outstanding respiratory performance, constant in any

use condition, thanks to the compensated diaphragm mecha-

nism that enables maximum respiratory comfort to be obtained

during any dive phase, from the surface to maximum depths.

In fact, the regulator provides the same intermediate pressure in-

dependent of the pressure contained in the tanks and maintains

performance at any depth.

Contrary to most regulators currently on the market, offering op-

timum performance when the tank is full at maximum working

pressure, the T10 first stage was designed to offer optimum per-

formance when the tank is close to empty.

This “hyper balancing”feature was possible using a system that

adapts intermediate pressure taking into account the air density

as the depth increases and the progressive increase in pressure

drop as the tank empties.

Thanks to this feature, the T10 first stage assists the diver in the

dive, guaranteeing the highest working performance which in-

creases further during the notoriously critical surfacing phase of

surfacing.

The compensated diaphragm mechanism phase, with a "T" air

entry, or rather the HP valve arranged perpendicular to the air

entry axis further guarantees considerable passage of air quantity

with a pressure drop, between the inhalation and exhalation

phase, which is reduced considerably.

These characteristics are the result of innovative technical solu-

tions in the design and make the 1st stage among the smallest

and lightest regulators on the market and one of the top perform-

ing in its category.

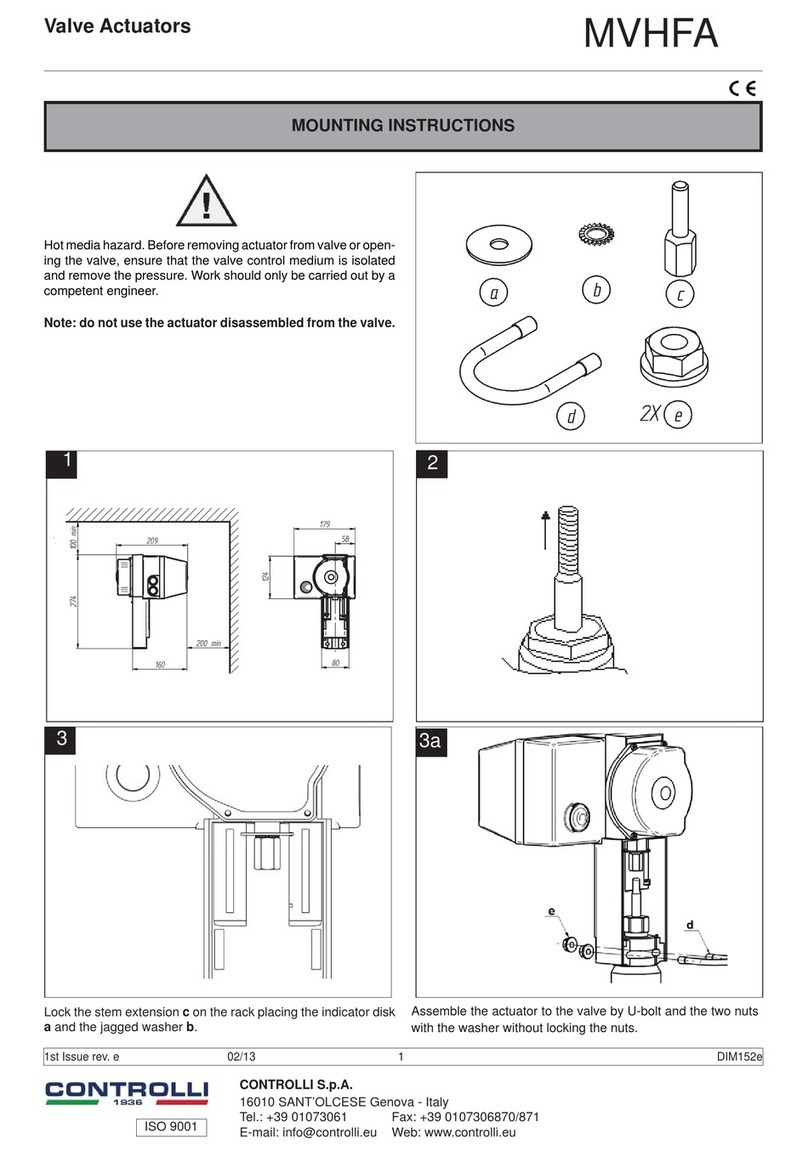

In this first stage ( ig. 1), the flexible diaphragm protects and seals

the mechanism inside the system and transmits pressure varia-

tions in the water to the high pressure valve.

fig. 1

48 FIRST STAGES

ENGLISH

The HP poppet valve, which is extremely resilient and easily re-

placed during periodic maintenance, is manufactured in the latest

generation thermoplastic elastomers. This valve boasts the exclu-

sive feature of sliding inside a special lined cylinder, also manufac-

tured in self-lubricating thermoplastic material. The inner surface of

this cylinder, which is completely free of oxidation phenomena,

drastically reduces friction and makes the valve stroke extremely

fluid and precise, guaranteeing optimum respiratory comfort. The

HP poppet valve can also work perfectly guided on a pneumatic

seal compartment, guaranteed to last long thanks to the special

design of the piston sleeve that hinges the valve, without even

making it rotate on its own axis. By doing so, the 1st stage perform-

ance can be kept constant and unchanged over time.

The HP valve closure nozzle, manufactured in stainless steel 316, is

interchangeable to facilitate periodic maintenance of the 1st stage.

Air entry in the first stage is protected by a sintered conical filter in

compact, sintered and nickel-plated phosphor bronze micro-

spheres, to enable better air filtering thanks to the broader filtering

surface guaranteed by the shape which also guarantees the pas-

sage of an elevated air flow, typical of this regulator and withholds

any impurities from tank and valve.

The intermediate pressure regulation system of the T10 balanced

diaphragm 1st stage follows the tradition of all Cressi-sub first

stages, allowing convenient and fast regulation of intermediate

pressure without having to disassemble parts of the regulator.

WARNING: intermediate pressure regulation should only be

carried out by authorised Cressi-sub centres and the calibration

values CANNOT and MUST NOT be changed by the user, to

avoid prejudicing the good working order of the regulator. We

cannot be held in any way liable for any intervention carried out

by staff unauthorised by Cressi-sub.

The Cressi-Sub authorised centres can be indicated

by retailers or, alternatively by Cressi Sub s.p.a.

(email: [email protected]).

The balanced diaphragm first stage features a lightweight structure

of compact design, made from seagoing brass, protected on the

surface by means of a PVD (Physical Vapor Deposition) treatment

(version T10SC) or coated with chromed copper (version T10 S.C.

Cromo); the interior components are made of stainless steel,

chromed brass and new generation thermoplastic resins.

It avails of 4 low pressure (LP) 3/8” ports, adequately angled for

optimal distribution of the hoses that avoid interference with the

attached equipment, and 2 high pressure (HP) 7/16” ports with a

micrometric perforation for air release, ensuring maximum safety

also in the event of accidental breakage of the high pressure

hose, avoiding the risk of rapid tank emptying.

WARNING: on the H ports of the first stage, an underwater

gauge and/or an underwater computer must be connected to

also incorporate the gauge function. Since the tanks are not

equipped with a reserve device, it is absolutely indispensable to

use a gauge that indicates progressive air consumption when

diving and which clearly highlights the reserve pressure has been

reached, which should be considered as unusable air for the

purpose of the dive itself, but only as an emergency air reserve.

Diving without a gauge is dangerous because there is no way of

controlling consumption and you can suddenly find yourself with-

out air during a dive, putting your life in serious danger.

Connection of the first stage to the tank valve can take place

using an international connection, using a new yoke with an ex-

tremely modern design or a threaded coupling DIN 300 bar, both

according to EN ISO 12209 as referenced in the standard EN

250:2014.

As with all regulators in the Cressi-sub range, the T10 first stage

offers the possibility of making certain manufacturing compo-

nents of the regulator compatible, allowing interchanging parts

with other diaphragm first stages in the current range.

49

FIRST STAGES

Use of the T10 balanced diaphragm first stage is advised, com-

pared to the piston models, for diving in waters full of suspended

particles or dissolved mineral salts, or for use in cold water (with

temperatures under 10°C), because all parts of the regulator

mechanism are insulated for contact with water.

or diving in extreme conditions we recommend using combina-

tions with the T10SC or the T10 Cromo SC versions equipped with

the Seal Chamber (S.C.)

WARNING: to deal with diving in cold water (temperature

<10°C or < 50°F) Cressi-sub recommends use of a tank

equipped with a pillar valve with two independent ports outlet,

where two complete regulators can be connected.

WARNING: adequate technical preparation is necessary to

deal with diving in cold water (temperature <10°C or < 50°F ).

Cressi-sub recommends you carry out this type of diving after

taking a specific course given by qualified instructors. It is im-

portant not to wet the regulator before use and then expose it

to air (which can be well under zero degrees). Do not use the

purge button, particularly with the regulator level with Venturi

effect in the “dive” position. If possible, keep the regulator in

warm surroundings when not in use.

The Seal Chamber is used to make the T10 balanced diaphragm

first stage completely waterproof, avoiding water entry not only

inside, but also in contact with the diaphragm and the calibration

spring on the 1st stage, thereby creating an air chamber up-

stream of the regulator and its components, working like a proper

thermal barrier. All problems are therefore avoided relating to

contact with water full of suspended particles, sand, dissolved

mineral salts and with cold water which, especially at tempera-

tures below 10°C could form the foundation for possible freezing

of the regulator.

The Seal Chamber (fig.2) consists of a special metal insert with a

particular “radiator” shape designed to increase thermal ex-

change between the ambient temperature and the temperature

inside the regulator, preventing its possible freezing effect, and a

metal cap containing a silicone membrane inside. This, on warn-

ing of the ambient pressure variations, inverts and thereby trans-

mits oscillations to the ambient pressure transducer beneath

which, coming in contact with the main diaphragm, acts as a

transmission element which transfers all information on the ex-

treme pressure variations to the diaphragm. The main diaphragm

which, in turn, protects and seals the mechanism inside the sys-

tem, then transmits the pressure variations of the water to the

high pressure valve.

NOTE: before assembling the S al Chamb r S.C. the

balanced diaphragm first stage must be calibrated. To ensure

the regulator works properly, strictly comply with the calibration

values outlined in the regulator performance table. Regulator

calibration is not restricted by the ambient pressure variations

transmission disk.

fig. 2

50 FIRST STAGES

ENGLISH

WARNING: intermediate pressure adjustment should only

be carried out by authorised Cressi-sub centres and the cali-

bration values CANNOT and MUST NOT be changed by the

user, to avoid prejudicing the good working order of the regu-

lator. We cannot be held in any way liable for any intervention

carried out by staff unauthorised by Cressi-sub.

The Cressi-Sub authorised centres can be indicated

by retailers or, alternatively by Cressi Sub s.p.a.

(email: [email protected]).

The T10 first stage can therefore be used in cold water (with

water temperature below 10 °C/50 ° ), since it complies with Di-

rective 89/686/EEC dated 21/12/1989, checked and certified by

Test Authority No. 0474 RINA located in Genoa, tested in compli-

ance with standard EN 250:2014 that establishes the require-

ments for Personal Protective Equipment (PPE) category III. It

therefore bears the CE marking followed by identification of the

certification authority (0474) that checks its manufacture pur-

suant to module B+C2 of EU Regulation 2016/425. The standard

also dictates the essential health and safety requirements for Cat-

egory III PPE and governs the conditions for bringing it to market.

The considerable technical solutions, combined with the high

quality of the materials used, ensure that this first stage regulator

is fully reliable and capable of providing the highest performance

extended over time.

Additional important information relating to our equipment can be

found on the website www.cressi.com

51

FIRST STAGES

1.2 - MC9 - MC9 S.C.

The MC9 - MC9 S.C. balanced diaphragm first stage features a

lightweight structure of compact design, enclosed in an “aes-

thetic-protective” shell made from a special elastomer, specially

conceived to protect the regulator from impact.

It guarantees high breathing performance in every condition,

thanks to its balanced diaphragm mechanism, allowing the

maximum breathing comfort in every diving phase, starting from

the surface up to the maximum depth. The regulator, in fact,

supplies the same intermediate pressure independently from

the tank pressure, and keeps its performance independently

from the depth.

Unlike the most regulators on the market, offering their best

performance when the tank is loaded at its maximum working

pressure, MC9 first stage was designed to give its best perfor-

mance when the tank is about to empty. This ”hyper-balanc-

ing” feature is possible thanks to a system of regulation of the

intermediate pressure, which takes into account both the

air density as the depth increases and the progressive pressure

decrease due to the tank running down.

Thanks to this feature, MC9 first stage assists the diver during

the whole dive, guaranteeing the highest performance, which

improves during the most critical phase of surfacing.

Moreover, the balanced diaphragm mechanism, delivering air

“online”, allows remarkable amounts of air to pass, by a very small

pressure decrease between inhalation and exhalation phases.

These features are the results of several innovating technical

solutions taken by designing MC9 1st stage, making it one of the

best performing small and light regulators on the market.

In this first stage (fig. 3), the elastic diaphragm protects and seals

the system’ s inner mechanism, transmitting the changes of

water pressure to the high pressure valve.

The latter is made of special thermoplastic state-of-the art ela-

stomers, is highly resistant and easily replaceable. It boasts the

exclusive innovation of sliding inside a special self-lubricating

cylinder in a special thermoplastic material. The cylinder’ s inner

surface is completely free of oxidation, reduces any friction dra-

matically and makes the valve slide in an extremely easy and

precise way, guaranteeing the highest breathing comfort.

The HP seat is made of 316 stainless steel and is interchangea-

ble, in order to make the maintenance of the 1st stage easier.

The passage of air through the first stage is protected by a spe-

cial cup-shaped conical sintered filter, retaining any impurity from

tank and valves.

The regulation system of intermediate pressure in MC9 balanced

diaphragm first stage is the same as all other Cressi-sub first

stages, which allows an easy and quick adjustment of interme-

diate pressure without having to disassemble any component of

the regulator.

fig. 3

52 FIRST STAGES

ENGLISH

WARNING: intermediate pressure must be set only at au-

thorized Cressi-sub centres; the setting values must NOT and

can NOT be modified by the user, in order not to affect the

good working of the regulator. Cressi-sub decline any responsibility

for any intervention carried out by unauthorized personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: [email protected]).

Balanced diaphragm first stage features a light compact structure

in chromium-plated brass with inner components in stainless steel,

chromium-plated brass and state-of-the-art thermoplastic resins.

It is supplied with four low pressure (LP) 3/8” ports - specially

angled to allow the best hose positioning, avoiding any encum-

brance among different devices - and two high pressure (HP)

7/16” ports with a micrometric air exit hole, guaranteeing maxi-

mum safety even in the case of damage to the high pressure

hose, since it greatly reduces air loss from the thank.

WARNING: an underwater pressure gauge or a computer

with such function must be connected with the H ports of

the first stage.

Since the tanks are not supplied with a reserve device, a pres-

sure gauge must always be used, reporting the progressive

air consumption by diving and the reaching of reserve pres-

sure, which has to be considered as not to be used by diving

but only as emergency air supply.

Diving without any gauge is dangerous, since the diver can

not control his own air reserve, which might suddenly run out,

at his own high risk.

The first stage can be connected to the tank valve with an inter-

national, by means of an extremely modern designed bracket, or

with a threaded connection DIN 300 (EN ISO 12209) bar, both-

complying with EN 250:2014 standard.

Like all Cressi-sub regulators, whose components are often in-

terchangeable one with the other, MC9 is compatible with other

diaphragm first stages of the present range.

MC9 balanced diaphragm first stage, like other Cressi-sub diaph-

ragm first stages as well, is to be recommended rather than other

piston models, by diving in suspension or mineral salts rich water,

or in cold water at temperature lower than 10 °C/50 ° . All inner-

components of the regulators are in fact perfectly watertight.

or diving in extreme conditions we recommend using combina-

tions with the MC9SC version, equipped as standard with the Seal

Chamber (S.C.).

WARNING: In case of dives in cold water (temperature less

than 10°C/50° F), Cressi-sub recommend to use a tank sup-

plied with a valve featuring two separate outlet ports, with

which two complete regulators are to be connected.

WARNING: diving in cold water at temperature lower than

10°C/50 °F requires a special technical training. Cressi-sub

recommend such diving only after attending a special training

course by certified trainers. The regulator must absolutely not

get wet and exposed to freezing air before use. Do not press

the discharge button, particularly when the Venturi effect

adjustment lever is on “dive”. If possible, keep the regulator in

a warm place before use.

The Seal Chamber’ s task is to make MC9 balanced diaphragm

first stage perfectly watertight, preventing water from seeping

inside or on the diaphragm and the main spring: it works as an air

chamber above the regulator and its components, like a real

thermal barrier. It avoids any problem caused by contact with

suspension, sand, mineral salts rich water and with cold water,

which might eventually cause the regulator to freeze, especially

at temperature lower than 10° C/50° .

fig. 4

53

FIRST STAGES

The Seal Chamber is composed of a metal cap containing a sili-

con seal. The seal responds to any environmental pressure

change bending towards the inside and transmitting it to the

underlying plate; the latter transmits such information to the main

diaphragm. The main diaphragm protects and seals the device’

s inner mechanism, transmitting pressure changes to the high

pressure valve.

OTE: before assembling the Seal Chamber S.C. the

balanced diaphragm first stage must be set. In order to get

the regulator to work perfectly, the setting values must be

strictly those reported in the regulator’s performance table.

The setting is independent from the plate transmitting envi-

ronmental pressure changes.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres, while the setting values can

NOT and must NOT be modified by the user, in order not to

affect the regulator’ s performance. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself (email:

The MC9 S.C. first stage can therefore be used in cold water (with

water temperature below 10 °C/50 ° ), since it complies with Di-

rective 89/686/EEC dated 21/12/1989, checked and certified by

Test Authority No. 0474 RINA located in Genoa, tested in compli-

ance with standard EN 250:2014 that establishes the requirements

for Personal Protective Equipment (PPE) category III. It therefore

bears the CE marking followed by identification of the certification

authority (0474) that checks its manufacture pursuant to module

B+C2 of EU Regulation 2016/425. The standard also dictates the

essential health and safety requirements for Category III PPE and

governs the conditions for bringing it to market.

Its remarkable technical features, together with its high quality

materials, make this first stage a highly reliable regulator, guaran-

teeing best performances for a long time.

Visit our web-site www.cressi.com, where you can find further in-

formation relating to your safety.

1.3 – MC5

MC5 balanced diaphragm 1st stage features an extremely light

and compact structure enclosed in an “esthetical-protective”

shell of a special elastomer, designed to protect the regulator

from collision.

It guarantees high breathing performance in every condition,

thanks to its balanced diaphragm mechanism, allowing the

maximum breathing comfort in every diving phase, starting from

the surface up to the maximum depth. The regulator, in fact,

supplies the same intermediate pressure independently from

the tank pressure, and keeps its performance independently

from the depth.

The balanced diaphragm mechanism, delivering air “on line”,

allows remarkable amounts of air to pass, by a very small pres-

sure decrease between inhalation and expiration phases.

These features are the results of innovating technical solutions

taken by designing MC5 1st stage, making it one of the best

performing small and light regulators on the market.

fig. 5

54 FIRST STAGES

55

ENGLISH

In this first stage (fig. 5), the elastic diaphragm protects and seals

the system’ s inner mechanism, transmitting the changes of

water pressure to the high pressure valve.

The latter is made of special thermoplastic state-of-the art ela-

stomers, is highly resistant and easily replaceable. It boasts theex-

clusive innovation of sliding inside a special self-lubricating cylinder in

a special thermoplastic material. The cylinder’ s inner surface is com-

pletely free of oxidation, reduces any friction dramatically and makes

the valve slide in an extremely easy and precise way, guaranteeing

the highest breathing comfort.

The passage of air through the first stage is protected by a special

cup-shaped conical sintered filter, retaining any impurity from tank

and valves.

The regulation system of intermediate pressure in MC5 balan-

ced diaphragm first stage is the same as all other Cressi-sub first

stages, allowing an easy and quick adjustment of intermediate pres-

sure without having to disassemble any component of the regulator.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres, while the setting values can

NOT and must NOT be modified by the user, in order not to

affect the regulator’ s performance. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: [email protected]).

Balanced diaphragm first stage features a light compact structu-

re in chromium-plated brass with inner components in stainless steel,

chromium-plated brass and state-of-the-art thermoplastic resins.

It is supplied with three low pressure (LP) 3/8” ports - specially

angled to allow the best hose positioning, avoiding any encum-

brance among different devices - and a high pressure (HP)7/16”

port with a micrometric air exit hole, guaranteeing maxi-

mum safety even in the case of damage to the high pressure-

hose, since it prevents the tanks from emptying.

WARNING: an underwater pressure gauge or a compu-

ter with such function must be connected with the H port of

the first stage.

Since the tanks are not supplied with a reserve device, a pres-

sure gauge must always be used, reporting the progressiveair

consumption by diving and the reaching of reserve pressure,

which has to be considered as not to be used by diving but only

as emergency air supply.

Diving without any gauge is dangerous, since the diver can

not control his own air reserve, which might suddenly run out,

at his own high risk.

The first stage can be connected to the tank valve with an inter-

national, by means of an extremely modern designed bracket,

orwith a threaded connection DIN 300 bar (4350 psi) (EN ISO

12209), both complying with EN 250:2014 standard.

Like all Cressi-sub regulators, whose several components are

interchangeable one with the other, MC5 is compatible with

other diaphragm first stages of the present range.

MC5 balanced diaphragm first stage, like other Cressi-sub

diaphragm first stages, having all inner components watertight,

is to be recommended, rather than other piston models, by

diving in suspension or mineral salts rich water.

MC5 conforms to EU Regulation 2016/425, having been tested

and certified by Notified Body number 0474, RINA, with registered

office in Genoa, with testing conducted pursuant to standard EN

250:2014 which specifies the requirements for class III Personal

Protective Equipment (PPE), and therefore it bears the CE mark

followed by the ID data of the notified body (0474) pursuant to

form B+C2 of EU regulation 2016/425.

Its remarkable technical features, together with its high quality

materials, make this first stage a highly reliable regulator, guaran-

teeing best performances for a long time.

Visit our web-site www.cressi.com, where you can find further in-

formation relating to your equipment.

FIRST STAGES

1.4 - AC2

AC2 regulator has the task to reduce the tanks’ pressure. It isconnected

to the second stage by means of a hose supplying the diver with

breathable air at environmental pressure. The first stage’ s main task is

therefore to reduce the tanks’ air to an intermediate pressure, about

10 bar (145 psi) higher than the environmental.

Small dimensions, light weight, extremely simple structure, special stur-

diness and easy maintenance: here are the main features of this in-line

first stage, offering as high performances as a balanced piston model’s.

Its compact and attractive design features four low pressure

3/8” ports in pairs, with preset angles to allow easy connection with

any accessory equipment. The setting is easily performed thanks to

the special revolving ring system, allowing a quick, precise and con-

tinuous adjustment, without having to disassemble the regulator.

WARNING: intermediate pressure must be set only at

authorized Cressi-sub centres; the setting values must NOT

and can NOT be modified by the user, in order not to affect

the good working of the regulator. Cressi-sub decline any

responsibility for any intervention carried out by unauthorized

personnel.

You can find your authorized Cressi-Sub center by

asking your dealer, or Cressi Sub S.p.A. itself

(email: [email protected]).

Inside, a conical filter provides a filtering action 200% higher than

a standard flat filter.

Airflow capacity is remarkable, due to new larger air ports, offe-

ring unequalled performance in this class of regulators.

Both international yoke and DIN (at 200 or 300 bar) (2900÷4350

psi) connection are fully interchangeable and are replaced with

each other very quickly (only at authorized Cressi-sub centres).

Its satin finish guarantees the regulator’ s best surface perfor-

mance, while contributing to its outstanding strength and relia-

bility. The first stage is manufactured with the finest materials and

Cressi-sub experience.

The first stage can be connected with the tank’ s valve either

with an international through an extremely modern designed

bracket, or with a threaded connection DIN (EN ISO 12209), both

complying with EN 250:2014 standard. Should the tank sused

have a working pressure higher than 200 bar (2900 psi), a DIN

connection is recommended.

Besides its technical innovations, this first stage differs from pre-

vious models as to its new esthetical look, enriched with careful

particulars in its finishing as well. It is a top quality high technology

regulator, showing a pleasant as well as aggressive look, united

with outstanding sturdiness and easy mechanics, which allows

an easy and simple maintenance.

The AC2 first stage conforms to EU Regulation 2016/425, having

been tested and certified by Notified Body number 0474, RINA, with

registered offices in Genoa, with testing conducted pursuant to stan-

dard EN 250:2014 which specifies the requirements for class III Per-

sonal Protective Equipment (PPE), and therefore it bears the CE

mark followed by the ID data of the notified body (0474) pursuant to

form B+C2 of EU regulation 2016/425.

Its remarkable technical solutions, together with high quality

materials, make this first stage a highly reliable regulator, offering

top quality performance for a long time.

Visit our web-site www.cressi.com, where you can find further

information relating to your equipment.

fig. 6

56 FIRST STAGES

Direction for use regulators

1.5 - Performance First Stages

1.5 - Performance

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (200 bar feeding)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

Weight without hose MC9

Weight without hose MC9 SC

0÷232 bar - (0÷3365 psi)

0÷300 bar - (0÷4350 psi)

10 bar - (145 psi)

4500 l/min (*)

2

4

590 gr (INT) - 450 gr (DIN)

650 gr (INT) - 510 gr (DIN)

MC9 / MC9 S.C.

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (200 bar feeding)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

Weight without hose MC5

0÷232 bar - (0÷3365 psi)

0÷300 bar - (0÷4350 psi)

10 bar - (145 psi)

3000 l/min (*)

1

3

450 gr (INT) - 350 gr (DIN)

MC5

(*) Values measured at LP port with second stage connected and tank pressure at 200 150 bar (2900 2175 psi)

(*) Values measured at LP port with second stage connected and tank pressure at 200 150 bar (2900 2175 psi)

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (with 200 bar supply)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

Weight without hose T10 SC

0÷232 bar

0÷300 bar

10 bar

4500 l/min (*)

2

4

720 gr (INT) - 602 gr (DIN)

T10 / T10 S.C. / T10 S.C. Cromo

(*) Values measured on LP port with second stage connected and 200 150 bar pressure in the tanks.

58

ENGLISH

1.5 - Performance

Working pressure (INT connection)

Working pressure (DIN connection)

Calibration pressure (200 bar feeding)

Air supply

High pressure (HP) ports

Low pressure (LP) ports

0÷232 bar - (0÷3365 psi)

0÷300 bar - (0÷4350 psi)

10 bar - (145 psi)

2100 l/min (*)

1

4

AC2

(*) Values measured at LP port with second stage connected and tank pressure at 200 150 bar (2900 2175 psi)

59

Direction for use regulators

SECO D STAGES

2.1 - Galaxy Adjustable /Master / Master Cromo / Galaxy /

Octopus MG Balanced

2.2 - Master / Master Cromo / Galaxy / Octopus MG Balanced

disassembly and maintenance

2.3 - XS Compact Pro / XS Compact

2.4 - XS Compact Pro / XS Compact, disassembly and servicing

2.5 - XS2

2.1. - Master / Master Cromo / Galaxy /

Octopus MG Balanced

Cressi sub's line of balanced second stages is represented by

revolutionary pneumatic balanced regulators. They are elliptical in

shape and are more lightweight (in fact, the adjustable Master

version weighs just 207 gr - the lightest in its category!). Their fu-

turistic designs boast many innovative patented features and are

available in three different versions: Galaxy Adjustable ( ig. 7),

Master ( ig. 8) (adjustable) and Galaxy ( ig. 9) (non-adjustable).

Both versions provide air on-demand, i.e. only when the diver in-

hales through the mouthpiece, generating slight negative pressure

inside the regulator - it needs to be as light as possible so as not to

cause undue respiratory exertion. The special adjustable elliptical

diaphragm reacts to the negative pressure; it is designed to in-

crease its usable surface accordingly, in order to keep the breath-

ing effort to the absolute minimum. This regulator’s level of

performance is guaranteed to be similar - if not superior - to any

other regulator of a bigger in size.

The diaphragm gets sucked back inside the casing and brings the

central disc - made of state-of-the-art friction-proof thermoplastic

- into contact with the new lever designed with revolutionary geo-

metrics in order to enhance performance and drastically reduce

friction.

The lever is subsequently lowered and in doing so, opens the valve.

Cressi-Sub’s range of second-stage balanced regulators are

equipped with a pneumatically balanced piston with a hole of min-

imal diameter going through it lengthwise.

The air from the first-stage comes through this hole and enters a

small chamber (called the “balance chamber”) positioned at the

edge of the piston.

The air contained in this chamber exercises a level of pressure

which varies according to the depth of the water and pushes the

closing piston towards the valve nozzle. This way, a certain balance

62 SECO D STAGES

fig. 11

fig. 8

fig. 7

fig. 9 fig. 10

ENGLISH

is reached between the pressure that arises when the valve opens

and closes so that a low-load carrying spring can be used so that

no effort whatsoever is involved in opening the valve.

The pressure of the air flowing through the nozzle generates a re-

action on the part of the pad, which subsequently opens. The pad

is perforated as well and placed at the edge of the shaft, where

the pressure is contrasted by the combined force of the spring and

the air penetrating the balance chamber.

The end result of this in practical terms is a breathing effort reduced

to near inexistent levels, and an outstanding level of performance

even in very deep waters.

The adjustable Galaxy/Master second-stage regulator makes it

possible to modify the inhalation effort thanks to the external metal

knob, thus directly affecting inhalation resistance. In practice,

screwing the external knob clockwise increases inhalation resist-

ance whereas screwing it anticlockwise decreases inhalation re-

sistance. This regulation system includes two seals designed to

protect the water infiltration mechanism. When adequately lubri-

cated during manufacturing/maintenance phase, these seals pro-

tect the mechanism thread from the formation of oxide which

could stiffen or even block the rotation of the regulation knob.

This way, the knob remains consistently effortless and the subse-

quent adjustment of the inhalation effort can be achieved with pre-

cision and ease as the regulating mechanism thread remains

waterproof.

The Galaxy second-stage regulator (fig.9) doesn’t allow you to ad-

just the inhalation effort since it isn’t equipped with the regulation

mechanism. It does however include all the other features of the

adjustable Master version.

The adjustable nozzle is positioned inside the valve compartment

so that when the mechanism is opening, the air that comes out of

it is directed towards the mouthpiece thanks to the extremely pre-

cise and detailed design of the inner walls and casing of the regu-

lator.

In order to ensure the negative pressure isn’t too violent for the

body - which could potentially suck the diaphragm back in and

make the regulator to free-flow - there’s a diaphragm balance hole

inside the valve unit.

Once the airflow delivered through the injector and directed to-

wards the mouthpiece becomes consistent, it generates negative

pressure inside the regulator casing due to the increase in airflow

speed. This phenomenon of negative pressure called the “Venturi

effect”, keeps the diaphragm flat, which in turn significantly reduces

the inhalation effort of the diver.

The Venturi effect immediately ceases as soon as the diver stops

breathing; the diaphragm then reverts back to its normal position

and the lever, actioned by the spring, lifts up and makes the piston

touch the nozzle, which interrupts the passage of air.

In order to enhance the Venturi effect, both stages of Cressi-Sub

regulators are equipped with an air flow deflector which can be po-

sitioned two ways, as indicated by the etched scale on the casing:

In the first position, the flow-limitation device place in the mouth-

piece’s inlet duct, is actioned and the Venturi effect is stopped and

any free-flowing is prevented. In the “+” position however, the Ven-

turi effect is unrestrained and the air flow provided by the regulator

to the maximum level subsequently increases.

WARNING: always remember to keep the flow deflector

lever in pre-dive position (-) when the regulator is not in use; if

not, any accidental impact or pressure on the manual switch

when the regulator isn’t positioned inside the mouth, or if it is

63

SECO D STAGES

DIVE PRE-DIVE

fig. 12

suddenly removed or the self-breathing apparatus falls into the

water, can generate even violent high air-consumption free-

flowing. The dive position (+) must exclusively be used under-

water and only when the regulator is positioned inside the

mouth.

When the diver is breathing, he generates an increase in the pres-

sure inside the regulator casing which opens the oblique elliptical

release valve whose larger diameter makes it possible for the air

to exit outwards. The exhaust port delivers the air to the sides of

the head and prevents the valve being opened because of poten-

tial water turbulence, or from being flooded whenever the inner

case is not being pressurized.

Another special feature to be found in Cressi-Sub’s second-stage

regulators comes into play when the regulator is used in cold wa-

ters (water temperature of <10°C or 50° ), a feature engineered

with great precision and detailed attention and made possible

thanks to the special design of the regulator’s valve unit.

Indeed the valve unit’s internal flap takes advantage of the temper-

ature increase generated by the diver when he/she exhales,

specifically around the nozzle area of the valve, where the risk of

freezing is the highest. This patented system greatly enhances the

regulator’s freeze-resistance.

WARNING: for diving in cold waters (temperature <10°C)

Cressi-Sub recommends the use of a tank with a pillar valve

with two independent outputs, to which two complete regula-

tors can be connected.

WARNING: adequate technical preparation is required be-

fore undertaking cold water diving (temperature <10°C).

Cressi-Sub recommends undertaking this type of diving only

after having taken a specific training course with qualified in-

structors. The use of diving equipment in cold water without a

certification or adequate technical preparation is potentially

dangerous for the diver's health and wellbeing.

It is important not to wet the regulator before use (it would then be

exposed to an air temperature of potentially well under zero de-

grees).

Do not use the purge button, particularly when the adjustable Ven-

turi effect knob is in the “dive” position. If possible, keep the regu-

lator in a warm environment before use.

The Cressi-Sub balanced second-stage regulators are connected

to one of the 3/8” ports of the first-stage via a new medium-pres-

sure, high-capacity flexible hose in thermoplastic, a material which

has excellent mechanical qualities, very high elastic flexibility and

remains anti-kink in any situation due to its internal structure. This

high-performance material, combined with the regulators’ special

aesthetically pleasing look and scratch-resistant features make

them unique on the current market. Production batches per tube

and fittings are labelled according to standard EN 250:2014.

All Cressi-Sub second-stage regulators are downstream, i.e.

equipped with an automatic valve opening in the event of first-

stage calibration loss or a sudden increase in intermediate pres-

sure.

This means that any excess upstream pressure on the second-

stage will never lead to the regulator getting blocked but indeed to

spontaneous free-flowing.

The casing of Cressi-Sub second-stage balanced regulators is

made of new engineered fabrics with impressive mechanical qual-

ities and characteristics, noise-absorption being one of them.

The new cap (only in the adjustable version) is aesthetically pleas-

ing and designed with special etched Titanium, a material of unsur-

passable lightness and corrosion resistance.

The aforementioned cap is computer-designed and the various

water passages in the frontal parts of the casing have been thor-

oughly studied in order to enhance and improve the already im-

pressively high level of performance of Cressi-Sub second-stage

regulators.

Cressi-Sub second-stage regulators meet the requirements set

by standard EU 250:2014 in compliance with regulation UE

64 SECO D STAGES

Other manuals for T10 S.C.

1

This manual suits for next models

7

Table of contents

Other Cressi Controllers manuals

Popular Controllers manuals by other brands

adept technology

adept technology MV Instruction handbook

Telcoma

Telcoma CLASSIC PLUS Instruction handbook

Siemens

Siemens AEROGYR RWI65.02 manual

Extron electronics

Extron electronics Basic MediaLink Controllers MLC 52 IR user manual

Siemens

Siemens SIMATIC S5 manual

LOVATO ELECTRIC

LOVATO ELECTRIC DCRL3 instruction manual