ISO 9001

Sistemi di regolazione automatica per:

condizionamento/riscaldamento/processo termico industriale.

The performances stated in this sheet can be modified without any prior notice due to design improvements

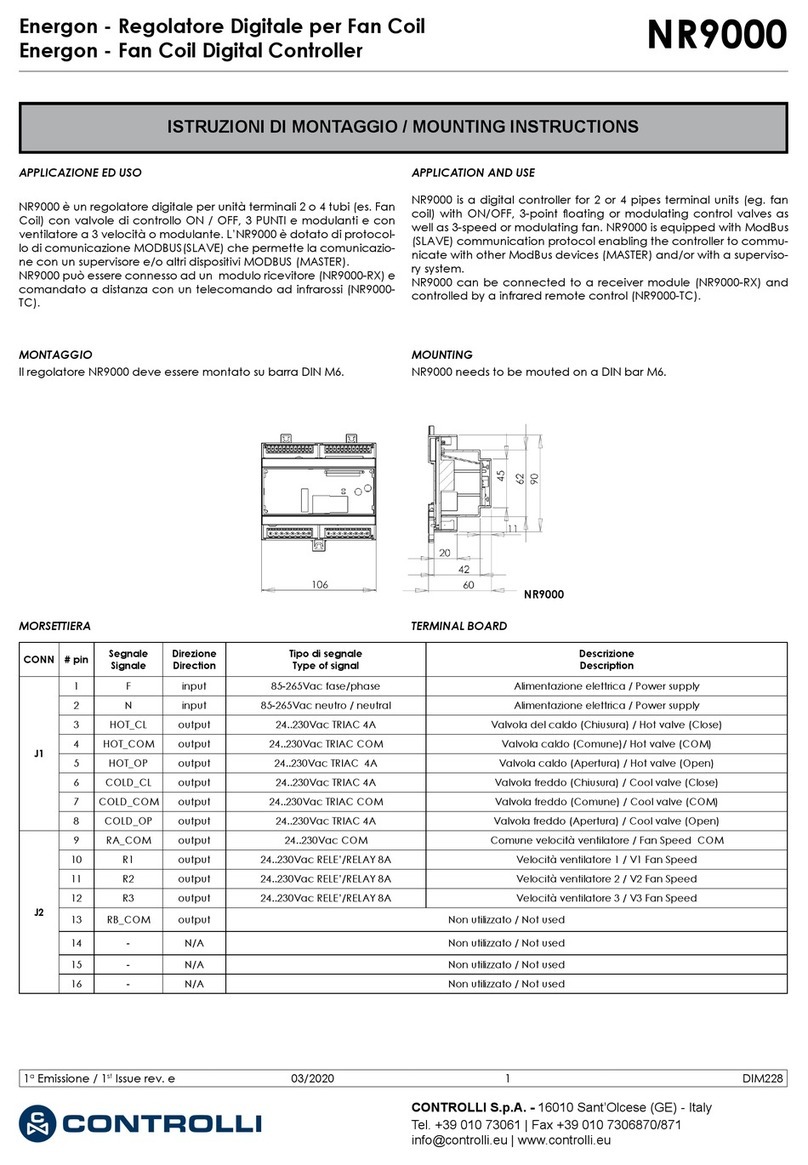

Function in the Description

“OFF” pos. “ON” position

1 2-10 Vdc 0-5 Vdc Feedback signal

2 Modulating Increase/decrease Control (not at Sequence)

3 – Sequence Sequence control

4 0-10 V 2-10 V Voltage range

5 1-5 V, 4-7 V 6-9 V, 8-11 V Part of voltage range

6 60 s 300 s Running time

7 Normal Inverted Direction of movement

8 Normal Linear/Logarithmic Valve characteristic

9 Operation End position adjust Operation/End position adjustment

There are nine switches in a row on the

circuit board. On delivery (’Factory’), all

switches are in the “OFF” position.

1 Feedback signal — 2-10 / 0-5 Vdc

MVHFA actuators are equipped with a 2

-10 and 0-5Vdc position feedback signal

selectable by Switch No 1.

2 Control signal—MOD / INC

Actuator can either be controlled by a

variable direct voltage, a so called mod-

ulating signal (MOD), or by an increase/

decrease signal (INC).

3 Sequence or parallel control—

– – – / SEQ

Withsequence(orparallel)control(SEQ),

twoactuators/valvescanbecontrolledby

only one control signal.

For each of these you can choose which

part of the voltage range to use, the up-

per one, 6-9 V (8-11 V) or the lower one,

1-5 V (4-7 V).

If the switch NORM / INV is in NORM

position, the higher voltage corresponds

to 100% flow and the lower one to 0%.

With NORM / INV in the INV position you

will get the opposite function.

4 Voltage range—0-10 / 2-10

Youcanchoosewhethertousethecontrol

signal voltage range 0-10 V or 2-10 V.

5 Part of voltage range—

0-5, 2-6 / 5-10. 6-10

You can choose which part of a volt-

age range to use, the lower one 1-5 V

(4-7 V) or the upper one 6-9 V (8-11 V).

If the switch is in the NORM position, the

highervoltage correspondsto100% flow

and the lower one to 0%. To achieve the

opposite function, the switch should be

put in its INV position.

6 Running time—60 s / 300 s

With increase/decrease control, you can

choose a running time between 60 s or

300 s.

With modulating control, the running time

is always 15 s / 20 s / 30 s.

7 Direction of movement—

NORM / INV

WhenNORMisselected,thespindleofthe

actuator moves inwards when the control

voltage decreases or if the actuator gets

a decrease signal.

WiththeswitchNORM/ INV,the direction

of movement can be changed.

8 Linearization—NORM / LIN/LG

Themotorizedvalvecharacteristicscanbe

modified.Ifyouwishforthecharacteristics

tobeaffected,thesettingLIN/LGwillmake

the characteristics of an equally modified

percentage (EQM) valve almost linear.

On the other hand, with LIN/LG a motor-

izedvalveequippedwithalinearvalvewill

operatewith”Quickopencharacteristics”.

Thismeansthatwithasmallcontrolsignal,

the valve will be almost completely open.

9 End position adjustment—OP / ADJ

This switch is only used to adjust the end

positions when the actuator is commis-

sioned.

With powered actuator, momentarily put

theswitchintheONposition.Theactuator

willautomaticallyfind theend positionsof

the valve.At the end of the adjustment all

the other dip switch settings (1 to 8) will

be read again.

Note! For the actuator to register new

settings of the switches, the supply

voltage must be cut, the settings done

and then the power on

or

the end position adjustment must be

done again (see point 9).

Refer also to illustration on page 2.

(This does not apply to the switch OP/

ADJ).

1st Issue rev. e 02/13 5 DIM152e