Cressi MC9 1st STAGE Setup guide

MC9 1st STAGE

Jannuary 2009 - Rev. MC9 /B

Ed. C/13

1st STAGE MC9

Service and Repair Operative Manual

MC9 1st Stage

137

MC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

138

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

WARNING!

• This manual is intended for use by expert technicians who should attend or have already received training

in equipment repairs and maintenance from Cressi-sub.

• Avoid performing maintenance and/or repair operations on the equipment without the proper training required

to conduct these operations.

• Users must never perform maintenance themselves; all maintenance must be performed EXCLUSIVELY

by an authorized Cressi-Sub center.

• If the information provided in this document is unclear or not fully intelligible, please contact Cressi-sub before

proceeding with any disassembly or maintenance procedures.

• Before proceeding, Cressi-sub recommends that you read the following document carefully to familiarize yourself

with all the tools and techniques needed to perform proper equipment maintenance and/or repair.

• Use this document as a guide during the various steps of maintaining and/or repairing the equipment.

• All operations must be done strictly in the order provided in this document.

Failure to do so could cause the equipment to function poorly, or worse, result in an accident.

MC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

139

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

WARNING!

• To prevent any assembly errors when performing maintenance and/or repairs, we recommend using all

the replacement parts provided by Cressi-Sub in every operation.

• Pay special attention to the recommendations provided in the margin of the figures that show the various

sequences of equipment maintenance and/or repair in order to avoid any problems that could result in an accident.

• The document below in no way replaces the equipment’s instruction manual.

• According to the European Standard, the procedures described in this document are pertinent to and intended

only for the disassembly, maintenance, and assembly of equipment meant for use with air (21% oxygen, 79%

nitrogen - EEC Countries Only).

• Further information about of lubrication and cleaning of components are shown within the professional area on

www.cressi.com site.

• The instructions provided in this document are based on information referring to the most update equipment

available before printing. This document was created on the knowledge of the state of the art of the equipment

during creation of this documentation. Cressi Sub reserves the right to make changes at any time.

Pos Cod Pos Cod

1 HZ730027 17 HZ800041

MC9

MC9 SC

MC5

1st Stages

(HZ 800047)

Annual

Replacement

Kit

2 HZ770080 18 HZ800062*

3k HZ800090 19 HZ800082*

4 HZ800054 20 HZ800081

5 HZ800055*21 HZ800080

6 HZ800056*22 HZ800063

7k HZ800057*23 HZ800064

8 HZ800086 24 HZ800065

9 HZ800085*25k HZ800066*

10k HZ800058 26k HZ800067

11 HZ800059*27k HZ800047*

12 HZ730106 28 HZ800042

13 HZ730108*29 HZ800043*

14 HZ730127 30 HZ800049

15 HZ730132*31 HZ800046

16k HZ800040

HZXXXXXX* Contenuto nel kit revisione e non disponibile

singolarmente. / Only available in maintenance kit; not available

individually./ HZXXXXXX non disponibile not available.

Ed/Issue 01/09

N°Tav./Rev. MC9/B

MC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

140

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

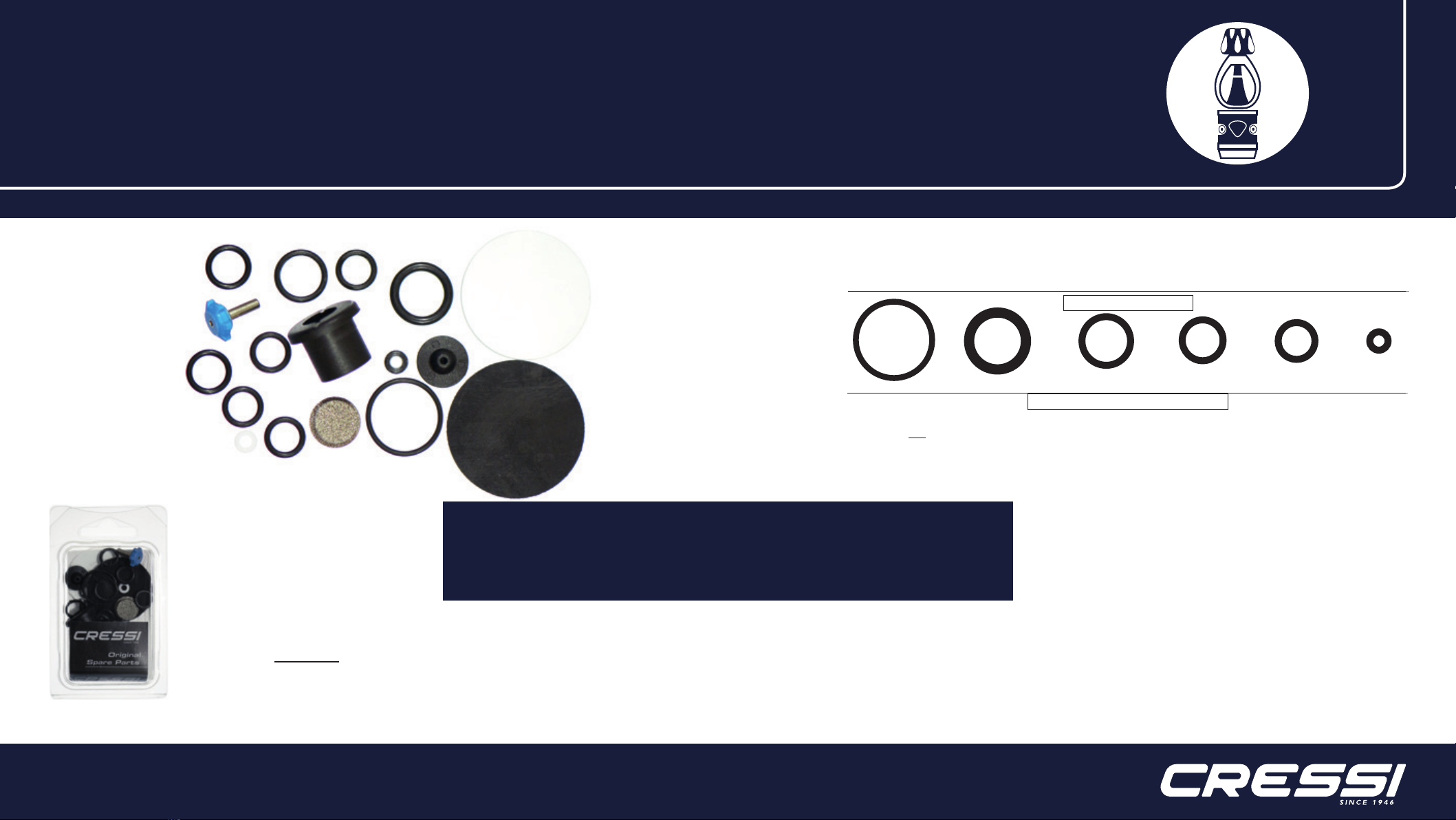

Spare parts

MC9 - MC9 S.C. - MC5

1st

STAGES (HZ 800047) ANNUAL REPLACEMENT KIT CHART

1 Diaphragm

HZ 800082

1 Back-Up Ring

HZ 800057

1 Sintered Filter

HZ 800056

1 HP Valve

HZ 800085

1 HP Valve Jacket

HZ 800059

1 Pin Support

HZ 800062

HZ 730132

HZ 800055

HZ 800066 HZ 800066 HZ 800057

HZ 800043

HZ 730108

O-RING Reference Table

SPARE PARTS - Reference Table

1 External Hydrostatic Diaphragm

(MC9 S.C. Only) HZ 800011

T10 / T10 S.C./ CROMO 1 st STAGE (HZ 800045) ANNUAL REPLACEMENT KIT CHART

O-RING Reference Table

1 Diaphragm

HZ800082

1 Back-up Ring

HZ800081

1 Sintered Filter

HZ830091

1 HP poppet valve

HZ800085

1 External Hydrostatic

Diaphragm (T10 S.C. Only)

HZ800011

HZ830082 HZ830081HZ830094 HZ830094HZ800043 HZ730132 HZ730108

SPARE PARTS Reference Table

MC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

141

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

MC9 / MC9 S.C. / MC5 - Code N° HZ 800047 Annual Replacement Kit Chart

Use only original

Cressi-sub spare parts

Note: Cressi-sub recommend a full maintenance of the regulator

at least once a year or more in case of intensive use.

REAL SIZE

MC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

142

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

• Cressi-Sub recommends complete regulator maintenance at least once a year, or more frequently in the case of

particularly intense use.

• Maintenance must include replacement of all components provided in the annual equipment maintenance kit.

• The special tools for maintenance of this device are illustrated on one of next pages.

• Metal parts must be washed with hot water and neutral detergent and rinsed in fresh water. Any concretions

must be removed using ultrasound cleaning or with diluted acid solutions, always followed by long and thorough

rinsing under running water. For more information, please refer to the general procedure.

• Do not use acids or solvents on rubber components.

• The new ORs must be greased with a thin layer of lubricant: this procedure reduces to a minimum the risk of

damage during assembly.

• The metal threading can be lubricated with grease on the first two rings of threading.

Annual replacement

Annual replacement

MC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

143

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

• According to the European Standard, the procedures described in this document are pertinent to and intended

only for the disassembly, maintenance, and assembly of equipment meant for use with air (21% oxygen, 79%

nitrogen - EEC Countries Only).

• Users must never perform maintenance themselves; all maintenance must be performed EXCLUSIVELY by an

authorized Cressi-Sub center.

• You can find your authorized Cressi-Sub center by asking your dealer, or Cressi Sub S.p.A. itself by sending an

e-mail to:

info@cressi-sub.it

Annual replacement

Use only original

Cressi-sub spare parts

Annual replacement

70

Spare Parts Price List - Listino Pezzi Ricambio - Ersatzteilpreisliste - Pieces Detachees

SPECIFIC MC9 - MC9 S.C.

1ST STAGE REGULATORS TOOLS

Price -

€

1ST STAGE SETTING PRESSURE GAUGE

MANOMETRO TARATURA 1° STADIO

MANOMETER JUSTIERUNG 1. STUFE

MANOMÈTRE DE RÉGLAGE DU 1ER ÉTAGE

49,00

49,00

49,00

49,00

HZ710010

Price -

€

THREADED BAR TO TIGHTEN THE REGULATOR IN THE VICE

BARRA FILETTATA FISSAGGIO EROGATORE IN MORSA

GEWINDESTAB ZUR BEFESTIGUNG DES ATEMREGLERS IM SCHRAUBSTOCK

ÉTAU À MAIN POUR MAINTIEN DU DÉTENDEUR DANS UN ÉTAU

9,00

9,00

9,00

9,00

HZ709008

Price -

€

YOKE NUT SOCKET AND WRENCH

CHIAVE A BUSSOLA PER RIMOZIONE BLOCCASTAFFA

SOCKET WRENCH TO REMOVE BRACKET NUT

CLÉ À DOUILLE POUR DÉVISSAGE DE L’ÉCROU

DE BLOCAGE D’ÉTRIER

56,00

56,00

56,00

56,00

HZ709012

Price -

€

REMOVING YOKE TOOL

UTENSILE UNIVERSALE SMONTAGGIO STAFFA

STECKSCHLÜSSEL ZUR ENTFERNUNG

DER BEFESTIGUNGSMUTTER DES BÜGELS

OUTIL UNIVERSEL DE DÉMONTAGE D’ÉTRIER CRESSI SUB

15,00

15,00

15,00

15,00

HZ709018

Price -

€

ALLEN KEY 6 mm

CHIAVE ESAGONALE 6 mm

SECHSKANTSCHLÜSSEL 6 mm

CLÉ SIX PANS DE 6 mm

2,00

2,00

2,00

2,00

HZ709006

Price -

€

EXTRACTION POINT TOOL

PUNTA DA ESTRAZIONE

O-RING ENTFERNER

POINTE D’EXTRACTION

4,50

4,50

4,50

4,50

HZ709004

Price -

€

TOOL TO REMOVE THE NOZZLE

UTENSILE RIMOZIONE UGELLO

WERKZEUG FÜR DIE ENTFERNUNG DER DÜSE

OUTIL POUR L’EXTRACTION DU SIÈGE

4,00

4,00

4,00

4,00

HZ709016

Price -

€

BIG COMPASS MC9 S.C. SPANNER

CHIAVE A COMPASSO GRANDE - MC9 S.C.

VERSTELLBARER STIRNLOCHSCHLÜSSEL GROß MC9 S.C.

CLÉ À COMPAS GRAND MODÈLE MC9 S.C.

19,00

19,00

19,00

19,00

HZ709003

PARTI RICAMBIO 2013-8_Layout 1 30/09/14 13.51 Pagina 70

70

Spare Parts Price List - Listino Pezzi Ricambio - Ersatzteilpreisliste - Pieces Detachees

SPECIFIC MC9 - MC9 S.C.

1ST STAGE REGULATORS TOOLS

Price -

€

1ST STAGE SETTING PRESSURE GAUGE

MANOMETRO TARATURA 1° STADIO

MANOMETER JUSTIERUNG 1. STUFE

MANOMÈTRE DE RÉGLAGE DU 1ER ÉTAGE

49,00

49,00

49,00

49,00

HZ710010

Price -

€

THREADED BAR TO TIGHTEN THE REGULATOR IN THE VICE

BARRA FILETTATA FISSAGGIO EROGATORE IN MORSA

GEWINDESTAB ZUR BEFESTIGUNG DES ATEMREGLERS IM SCHRAUBSTOCK

ÉTAU À MAIN POUR MAINTIEN DU DÉTENDEUR DANS UN ÉTAU

9,00

9,00

9,00

9,00

HZ709008

Price -

€

YOKE NUT SOCKET AND WRENCH

CHIAVE A BUSSOLA PER RIMOZIONE BLOCCASTAFFA

SOCKET WRENCH TO REMOVE BRACKET NUT

CLÉ À DOUILLE POUR DÉVISSAGE DE L’ÉCROU

DE BLOCAGE D’ÉTRIER

56,00

56,00

56,00

56,00

HZ709012

Price -

€

REMOVING YOKE TOOL

UTENSILE UNIVERSALE SMONTAGGIO STAFFA

STECKSCHLÜSSEL ZUR ENTFERNUNG

DER BEFESTIGUNGSMUTTER DES BÜGELS

OUTIL UNIVERSEL DE DÉMONTAGE D’ÉTRIER CRESSI SUB

15,00

15,00

15,00

15,00

HZ709018

Price -

€

ALLEN KEY 6 mm

CHIAVE ESAGONALE 6 mm

SECHSKANTSCHLÜSSEL 6 mm

CLÉ SIX PANS DE 6 mm

2,00

2,00

2,00

2,00

HZ709006

Price -

€

EXTRACTION POINT TOOL

PUNTA DA ESTRAZIONE

O-RING ENTFERNER

POINTE D’EXTRACTION

4,50

4,50

4,50

4,50

HZ709004

Price -

€

TOOL TO REMOVE THE NOZZLE

UTENSILE RIMOZIONE UGELLO

WERKZEUG FÜR DIE ENTFERNUNG DER DÜSE

OUTIL POUR L’EXTRACTION DU SIÈGE

4,00

4,00

4,00

4,00

HZ709016

Price -

€

BIG COMPASS MC9 S.C. SPANNER

CHIAVE A COMPASSO GRANDE - MC9 S.C.

VERSTELLBARER STIRNLOCHSCHLÜSSEL GROß MC9 S.C.

CLÉ À COMPAS GRAND MODÈLE MC9 S.C.

19,00

19,00

19,00

19,00

HZ709003

PARTI RICAMBIO 2013-8_Layout 1 30/09/14 13.51 Pagina 70

70

Spare Parts Price List - Listino Pezzi Ricambio - Ersatzteilpreisliste - Pieces Detachees

SPECIFIC MC9 - MC9 S.C.

1ST STAGE REGULATORS TOOLS

Price -

€

1ST STAGE SETTING PRESSURE GAUGE

MANOMETRO TARATURA 1° STADIO

MANOMETER JUSTIERUNG 1. STUFE

MANOMÈTRE DE RÉGLAGE DU 1ER ÉTAGE

49,00

49,00

49,00

49,00

HZ710010

Price -

€

THREADED BAR TO TIGHTEN THE REGULATOR IN THE VICE

BARRA FILETTATA FISSAGGIO EROGATORE IN MORSA

GEWINDESTAB ZUR BEFESTIGUNG DES ATEMREGLERS IM SCHRAUBSTOCK

ÉTAU À MAIN POUR MAINTIEN DU DÉTENDEUR DANS UN ÉTAU

9,00

9,00

9,00

9,00

HZ709008

Price -

€

YOKE NUT SOCKET AND WRENCH

CHIAVE A BUSSOLA PER RIMOZIONE BLOCCASTAFFA

SOCKET WRENCH TO REMOVE BRACKET NUT

CLÉ À DOUILLE POUR DÉVISSAGE DE L’ÉCROU

DE BLOCAGE D’ÉTRIER

56,00

56,00

56,00

56,00

HZ709012

Price -

€

REMOVING YOKE TOOL

UTENSILE UNIVERSALE SMONTAGGIO STAFFA

STECKSCHLÜSSEL ZUR ENTFERNUNG

DER BEFESTIGUNGSMUTTER DES BÜGELS

OUTIL UNIVERSEL DE DÉMONTAGE D’ÉTRIER CRESSI SUB

15,00

15,00

15,00

15,00

HZ709018

Price -

€

ALLEN KEY 6 mm

CHIAVE ESAGONALE 6 mm

SECHSKANTSCHLÜSSEL 6 mm

CLÉ SIX PANS DE 6 mm

2,00

2,00

2,00

2,00

HZ709006

Price -

€

EXTRACTION POINT TOOL

PUNTA DA ESTRAZIONE

O-RING ENTFERNER

POINTE D’EXTRACTION

4,50

4,50

4,50

4,50

HZ709004

Price -

€

TOOL TO REMOVE THE NOZZLE

UTENSILE RIMOZIONE UGELLO

WERKZEUG FÜR DIE ENTFERNUNG DER DÜSE

OUTIL POUR L’EXTRACTION DU SIÈGE

4,00

4,00

4,00

4,00

HZ709016

Price -

€

BIG COMPASS MC9 S.C. SPANNER

CHIAVE A COMPASSO GRANDE - MC9 S.C.

VERSTELLBARER STIRNLOCHSCHLÜSSEL GROß MC9 S.C.

CLÉ À COMPAS GRAND MODÈLE MC9 S.C.

19,00

19,00

19,00

19,00

HZ709003

PARTI RICAMBIO 2013-8_Layout 1 30/09/14 13.51 Pagina 70

MC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

144

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

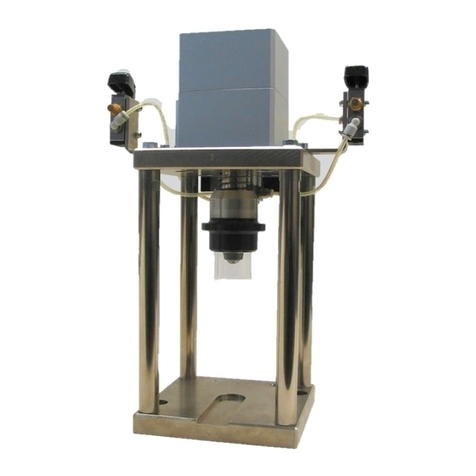

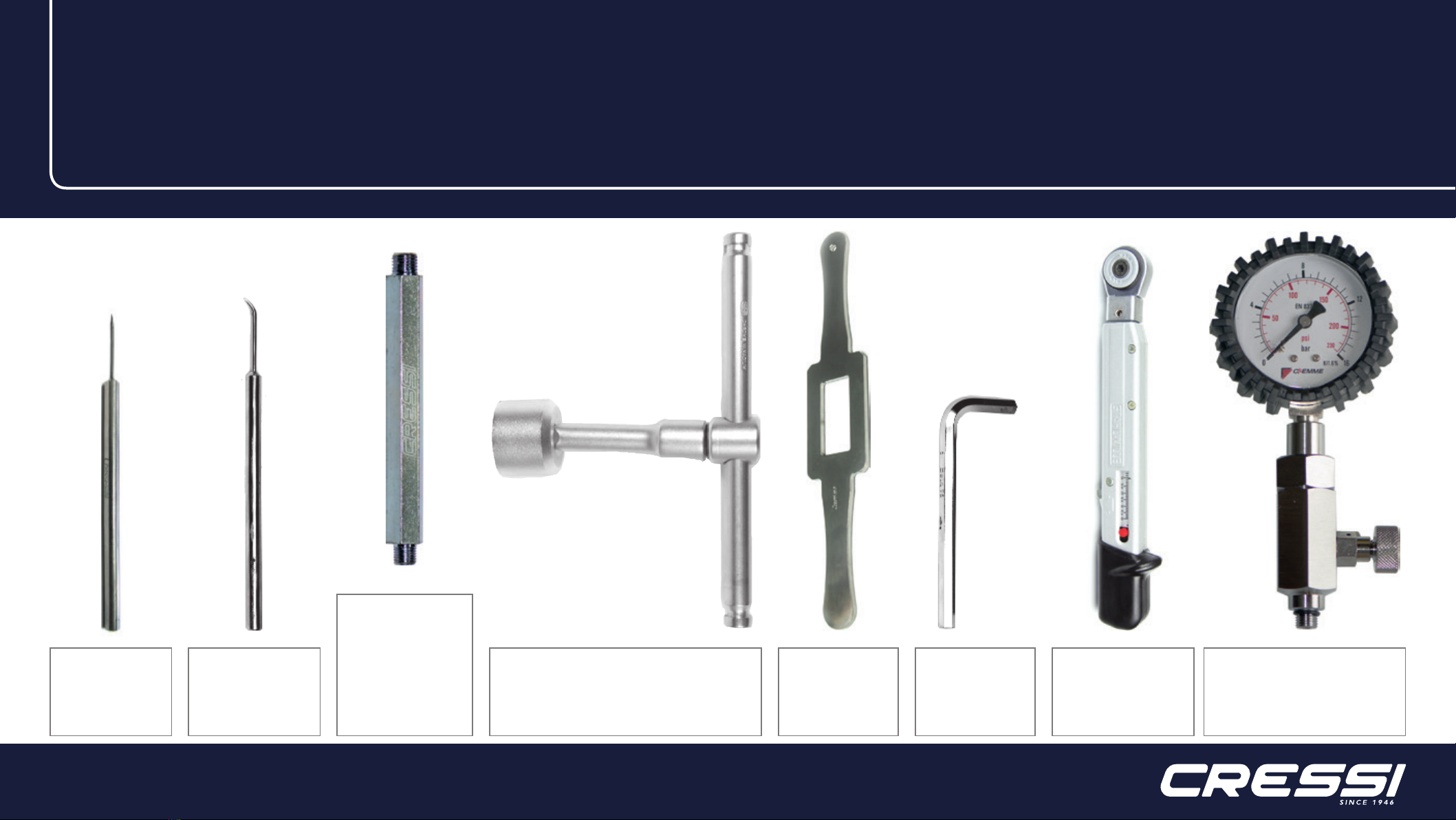

Special tools

HZ 709004

extration

point tool

HZ 709016

tool to remove

the orifice

HZ 709006

allen key

6 mm

dynamometric

wrench

(unavailable)

HZ 709012

yoke nut socket

and wrench

HZ 710010

1st stage setting

pressure gauge

HZ 709008

threaded bar

to tighten the

regulator in

the vice

HZ 709018

removing

yoke tool

MC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

145

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

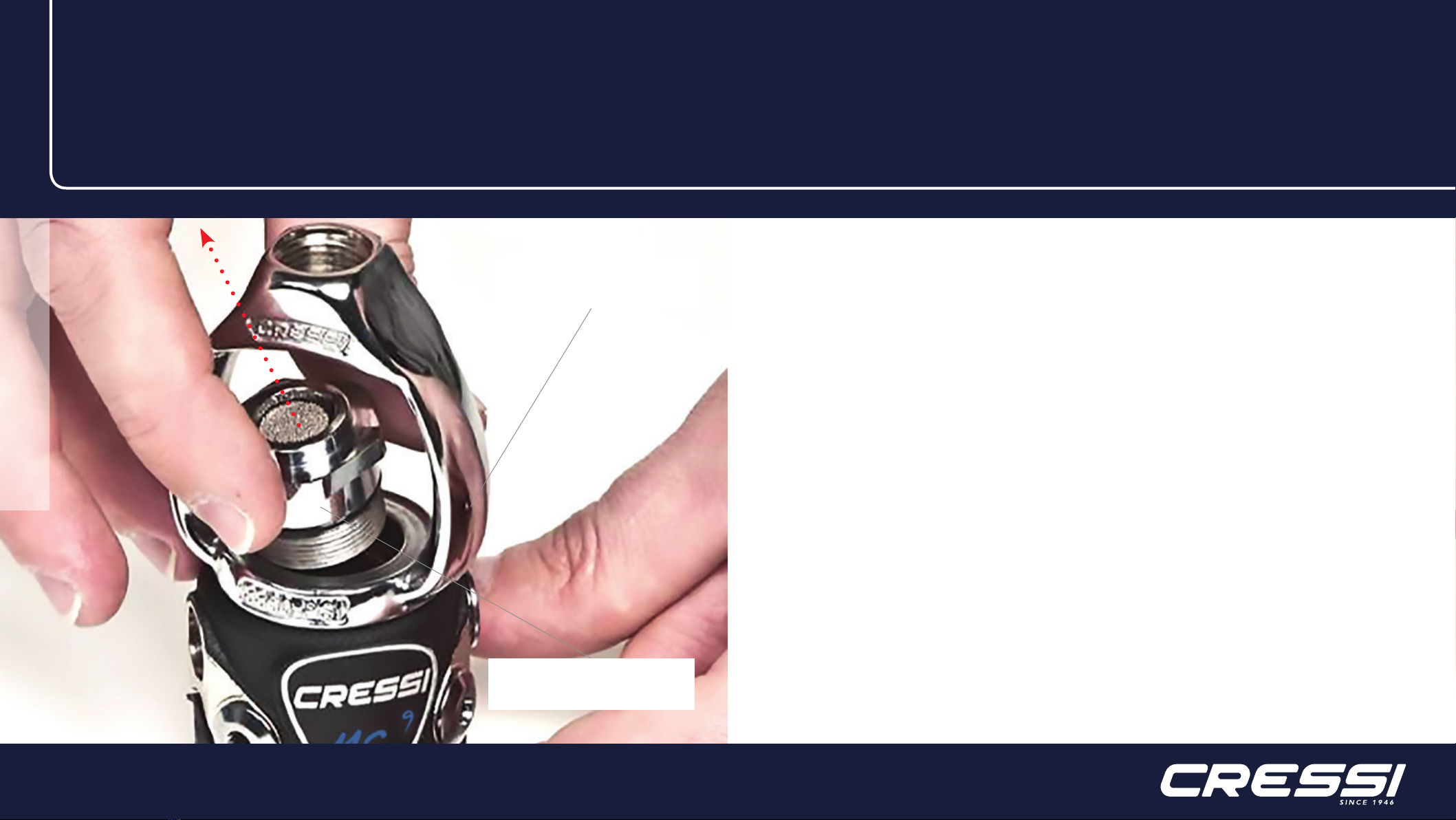

Disassembling procedures

• Remove and replace all O-rings;

• Use a plastic tool or a round pointed metal one in order not to damage the O-ring seat;

• To replace the O-ring correctly, press its sides to create a bulge inside which to insert the round pointed tool, as shown in the pictures;

• Attention: USE ONLY ORIGINAL CRESSI-SUB SPARE PARTS

MC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

146

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

In case the regulator has been

used under water for a long time

and shows oxidation traces,

it may be useful to tap gently

with a plastic hammer all along

the perimeter of the area to be

removed.

MC9 1st STAGE INTMC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

147

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

MC9 1st STAGE INTMC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

148

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

Remove the bracket nut using the

special spanner, as shown in the

picture.

After inserting the threaded tool in

one of the first stage ports, tighten

the regulator in a vice.

HZ 709018

MC9 1st STAGE INTMC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

149

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

In case the special spanner is not

available, the bracket nut can be

removed using a large adjustable

spanner as shown in the picture.

HZ 770080

HZ 800054

MC9 1st STAGE INTMC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

150

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Remove the first stage bracket nut

and bracket.

Disassembling procedures

Kit OR DIN

HZ 800066

MC9 1st STAGE DINMC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

151

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

MC9 1st STAGE DINMC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

152

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

Using a threaded bar, tighten the first

stage body in a vice.

Unscrew the DIN connector from the

relating thread on the DIN filter, using

a 6 mm. Allen wrench.

MC9 1st STAGE DINMC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

153

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

Warning: in case the disassembling

operations are difficult, do not carry

out them using wrench extensions,

since this might damage details of the

equipment!

In such case, we recommend to

contact Cressi-sub at once, before

carrying out any disassembling

operation.

HZ 800046

MC9 1st STAGE DINMC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

154

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Disassembling procedures

Remove the DIN connector ring

from the DIN filter.

HZ 800049

MC9 1st STAGE DINMC9 1st STAGE

MC9 1st Stage

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

155

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Unscrew the DIN filter using

a 24 mm hexagonal spanner, as

shown in the picture.

Pay particular attention: unscrewing

the thread causes the inner valve

spring to lessen its resistance, which

might make the inner valve dart out

of its seat.

Disassembling procedures

HZ 800056

HZ 800058

MC9 1st STAGE

Service and Repair Operative Manual

JANNUARY 2009 - REV. MC9 /B - ED. C/13

156

This manual is restricted to Authorized Centers Cressi sub. Repair, maintenance, overhaul, calibration and any other intervention made to the dispensers must be made exclusively by trained

personnel of the Authorized Centers Cressi sub. Cressi sub accepts no responsibility for actions on the dispensers carried out by an authorized and specifically trained by the same Cressi sub.

Remove the bracket nut O-Ring (same as the DIN filter one)

and take the HP jacket-piston bush completely out of its seat.

Remove the

sintered filter

and take out

the first stage

valve completely.

Disassembling procedures