5

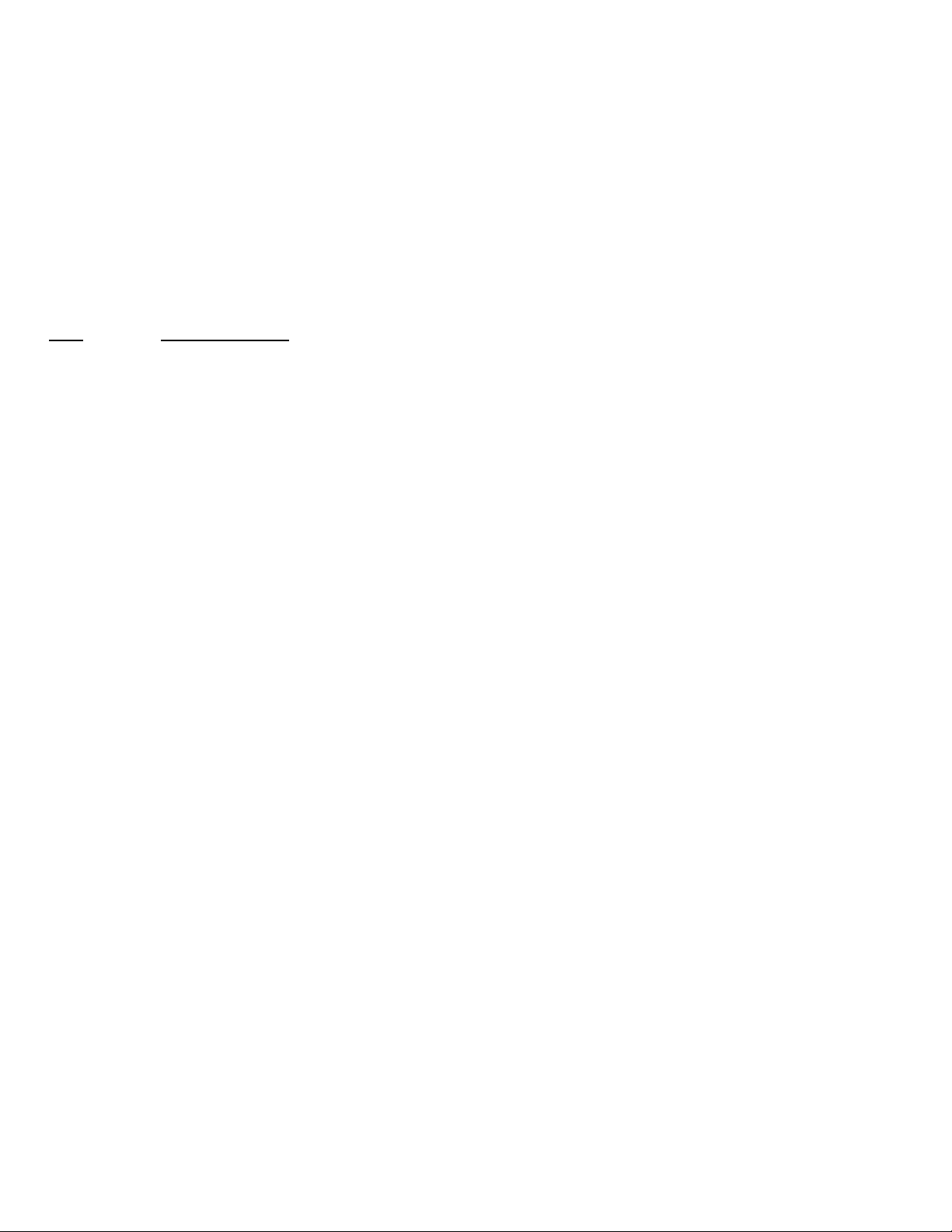

Set Up Instructions

To ensure quick, successful integration of the equipment

into your shop, please follow these set-up procedures

before the first use of the unit.

1. Check the oil drain bottle to ensure it is empty.

2. Check and open the valves on the storage tank. If

the valve will not turn counter-clockwise and seems

to be completely open, verify it is actually open by

turning the valve clockwise one quarter turn.

3. Turn on the “Main Power Switch” at the upper left

hand corner of the control panel.

4. Turn scale on.

5. Press the “Tare “ key on the touch pad.

6. Connect tank of virgin refrigerant to the (blue) low side

hose using the provided tank refill adapter. Remember

to open the tank valve on the virgin tank. Turn the virgin

tank upside down for the refill procedure.

7. Place selector switch in the “Recovery/Recycle”

position.

8. Fill the storage tank on the unit with at least 10 lb. of

refrigerant. This will insure a fast and proper charge.

9. Disconnect the tank of virgin refrigerant and press the

“Tare “ key on the touch pad.

10. Fill vacuum pump with oil to the proper level (Models

39810/39820/39822/39823 only).

The RECOVER / RECYCLE function should be used to

fully recover all refrigerant from an air conditioning

system. For instance, if the system needs to be opened

to atmosphere to replace a part, all refrigerant must be

removed before opening the system.

Recover / Recycle Operational Steps

1. Connect the high and low side auto service hoses to

the respective high and low side service ports on the

automobile A/C system. Open the service hose valves.

NOTE: If desired, the gauges can now be used to aid

investigation of an A/C system problem. Ensure the

automobile A/C system is turned off prior to running

the unit.

2. Verify the automobile air conditioning system is off.

3. Turn on “Main Power Switch.”

4. Turn scale on—press the “TARE” key on the touch pad.

5. Place selector switch to the RECOVER / RECYCLE

position.

During the recovery operation, refrigerant is removed from

both the high and low side of the automobile air condition-

ing system. The LCD will display the amount of refrigerant

being recovered.

6. When the unit achieves the proper vacuum level the

RECOVERY COMPLETE LED will illuminate.

7. Monitor the unit for five minutes after the RECOVERY

COMPLETE LED illuminates to insure that all of the

refrigerant has been removed.

8. If the pressure rises above 0 psi, repeat steps 5-8.

Note: The vacuum cycle will not run if the system pressure

is above 0 psi.

9. Press the OIL DRAIN switch for 10 seconds to drain oil

recovered during the RECOVER / RECYCLE process.

10. Observe the amount of oil removed from the auto A/C

system.

11. After service has been performed make sure to inject

the proper amount and type of oil back into the system

(see oil injection procedure).

Recover / Recycle

Vacuum

The vacuum function is designed to remove moisture from

the automobile A/C system by pulling a deep vacuum.

This mode is most often used after completing a repair

which required opening the A/C system to the atmosphere.

Moisture in an A/C system can cause erratic operation and

must be removed before recharging the system with

refrigerant.

Vacuum Operation:

Connect the high and low side auto service hoses to

the respective high and low side service ports on the

automobile A/C system. Open the service hose valves.

NOTE: If desired, the gauges can now be used to aid

investigation of an A/C system problem. Ensure the

automobile A/C system is turned off prior to running

the unit.

3. Verify the automobile air conditioning system is off.

4. Turn on “Main Power Switch.”

5. Place the selector switch in the VACUUM position.

6. Rotate the VACUUM TIMER to desired vacuum time.

7. When the VACUUM cycle is complete the timer knob

will rotate to the off position.

8. Inject oil at this time (see oil injection procedure).

NOTE: Always evacuate the A/C system for at least 15

minutes to insure that you remove as much moisture and

contamination as possible.