Tektino RCC-9A User manual

TEKTINO RCC-9A maintenance manual V2.0

i

INDEX

1.Equipment description.....................................................................................................................................................1

Part description...........................................................................................................................................................1

Component layout on manifold..................................................................................................................................2

Pipeline diagram.........................................................................................................................................................3

PCA............................................................................................................................................................................ 4

2.Routine maintenance....................................................................................................................................................... 5

Maintenance of vacuum pump................................................................................................................................... 5

Change drier filter, evacuate drier filter and reset service interval time....................................................................7

Leak test......................................................................................................................................................................8

3.Troubleshooting...............................................................................................................................................................9

TEKTINO RCC-9A maintenance manual V2.0

1

1. Equipment description

Part description

1)Refrigerant gas cylinder 2)Gas cylinder support plate 3) Gas cylinder load cell

4)Oil bottle load cell 5)Oil bottle support 6)Oil bottles

7)Assembly of solenoid valve and

check valve

8)Manifold assembly 1 9)front cover (plastic)

10) Front wheel 11)Compressor 12)Vacuum pump

13

)

Condenser and cooling fan

(optional)

14)Rear wheel 15)Side cover

16)Accessory holder 17)Back cover 18)Upper cover

19)Pressure gauges 20)Manifold 2 21) Drier-filter

1

2

3

4

5

6

7

8

18

9

10

17

16

15

14

11

13

12

20

21

19

TEKTINO RCC-9A maintenance manual

2

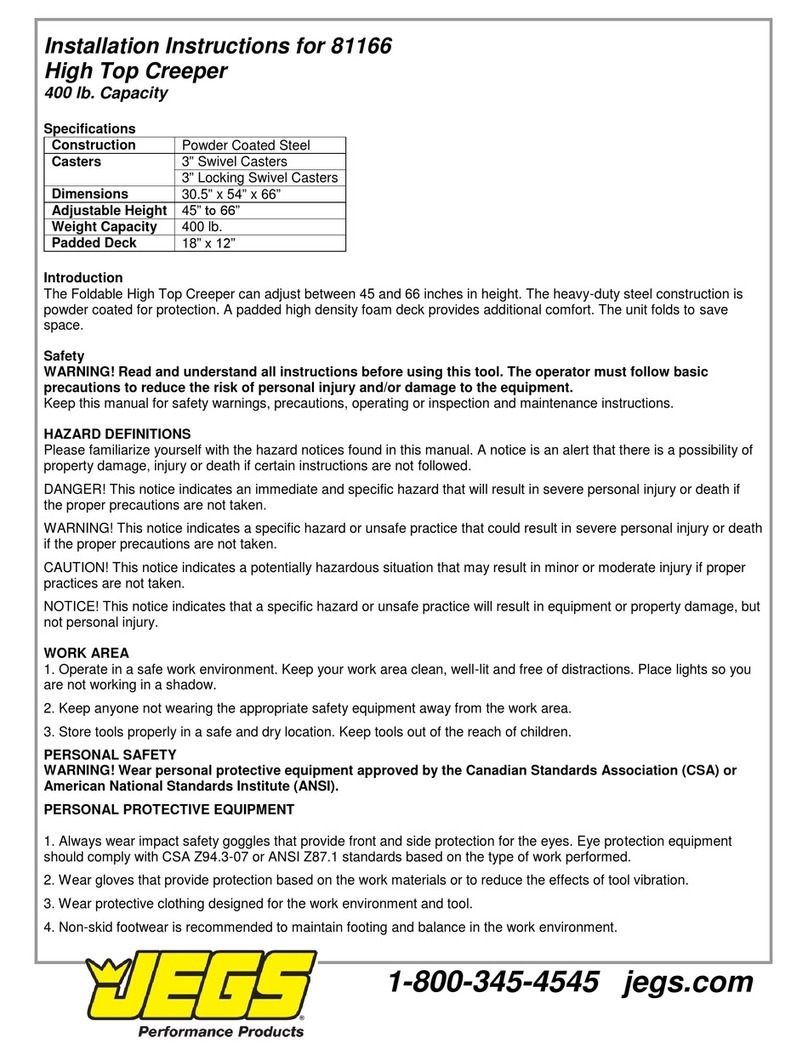

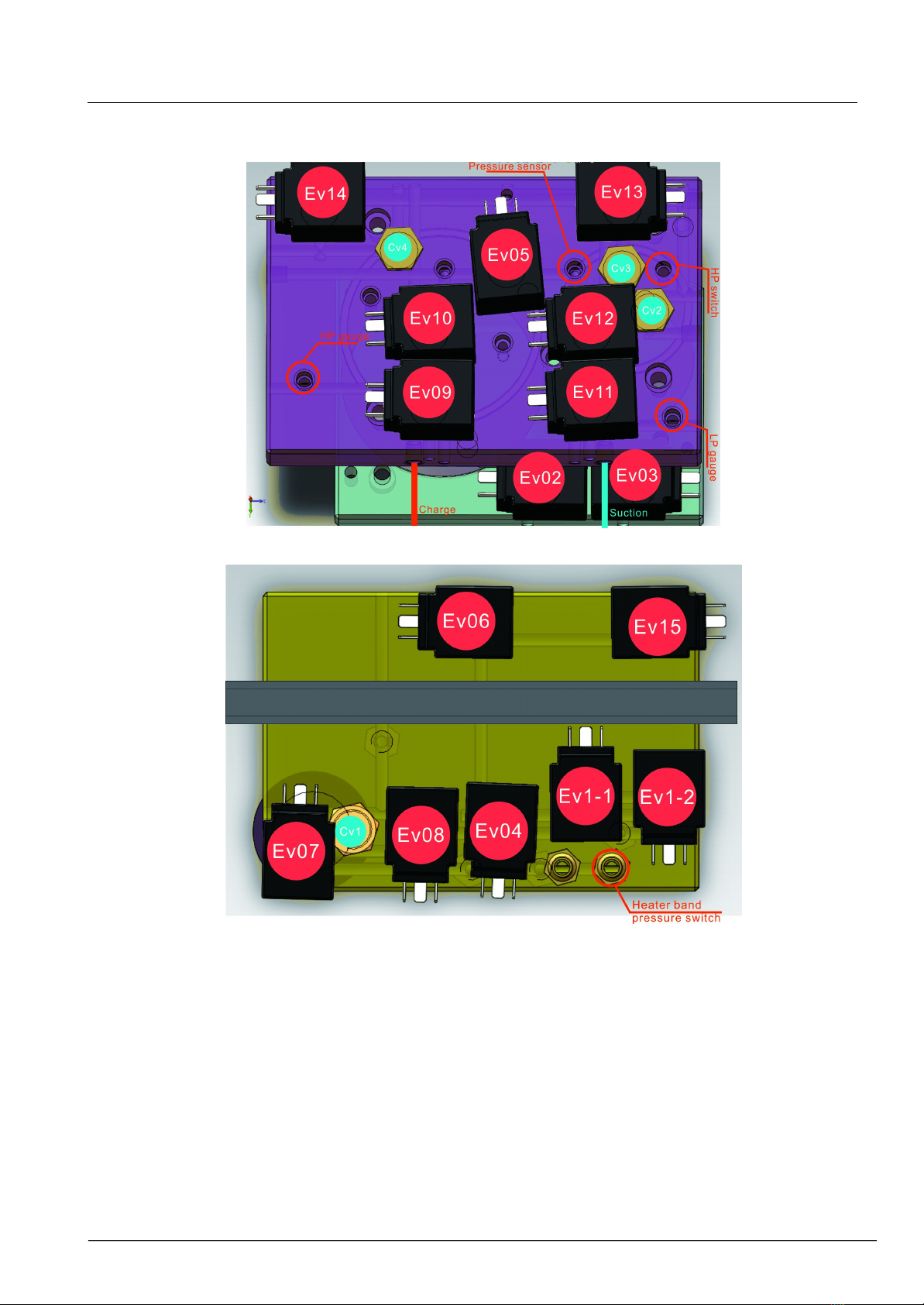

Component layout on manifold

MANIFOLD ASSEMBLY 1

MANIFOLD ASSEMBLY2

TEKTINO RCC-9A maintenance manual V2.0

3

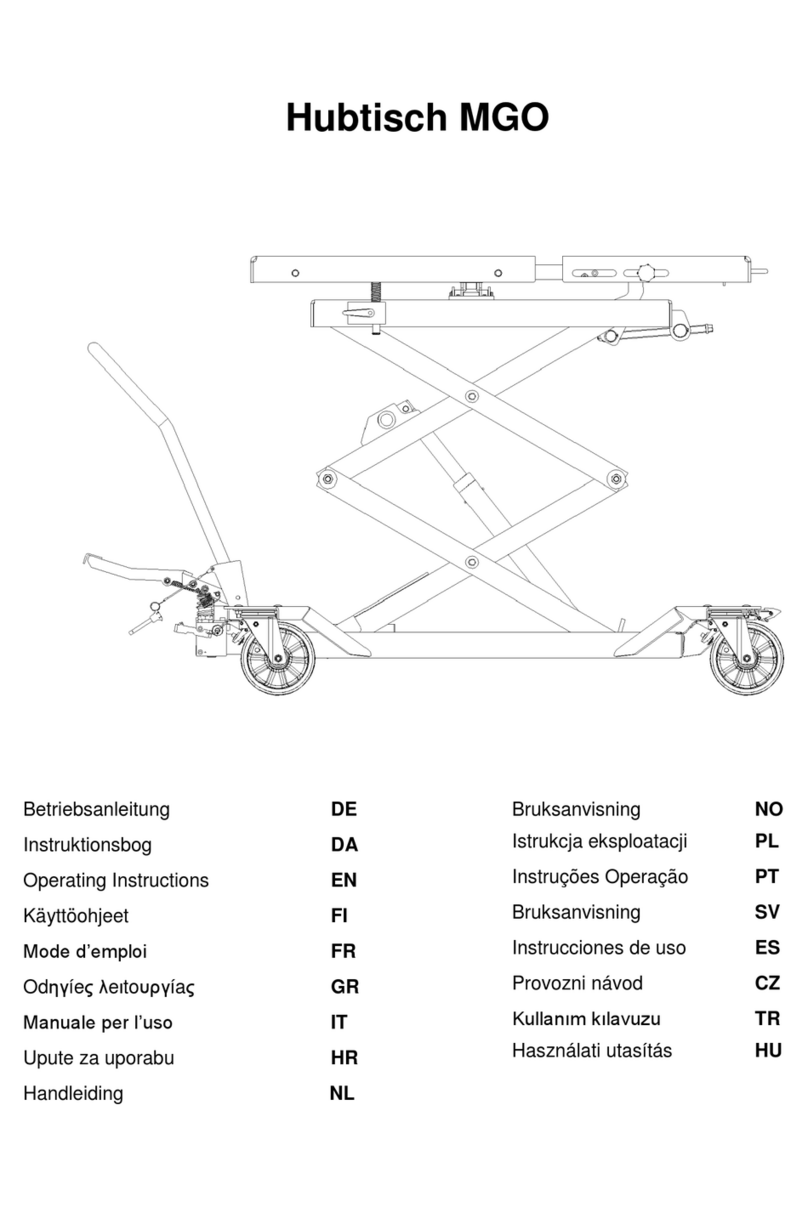

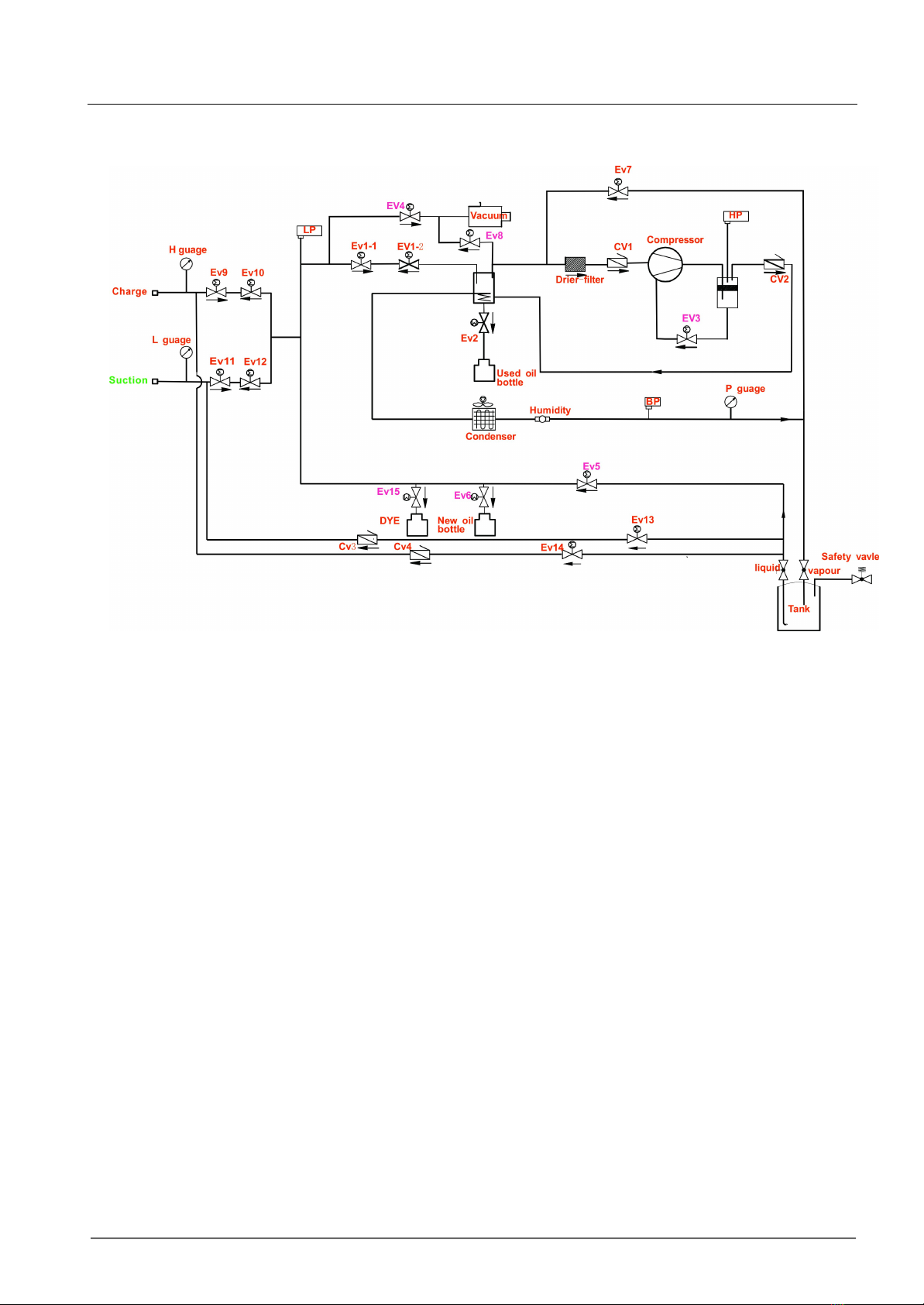

Pipeline diagram

EV: Solenoid

LP: Low pressure switch (or pressure sensor, if machine has vacuum leak test function)

HP: High pressure switch

CV: non-return valve

TEKTINO RCC-9A maintenance manual

4

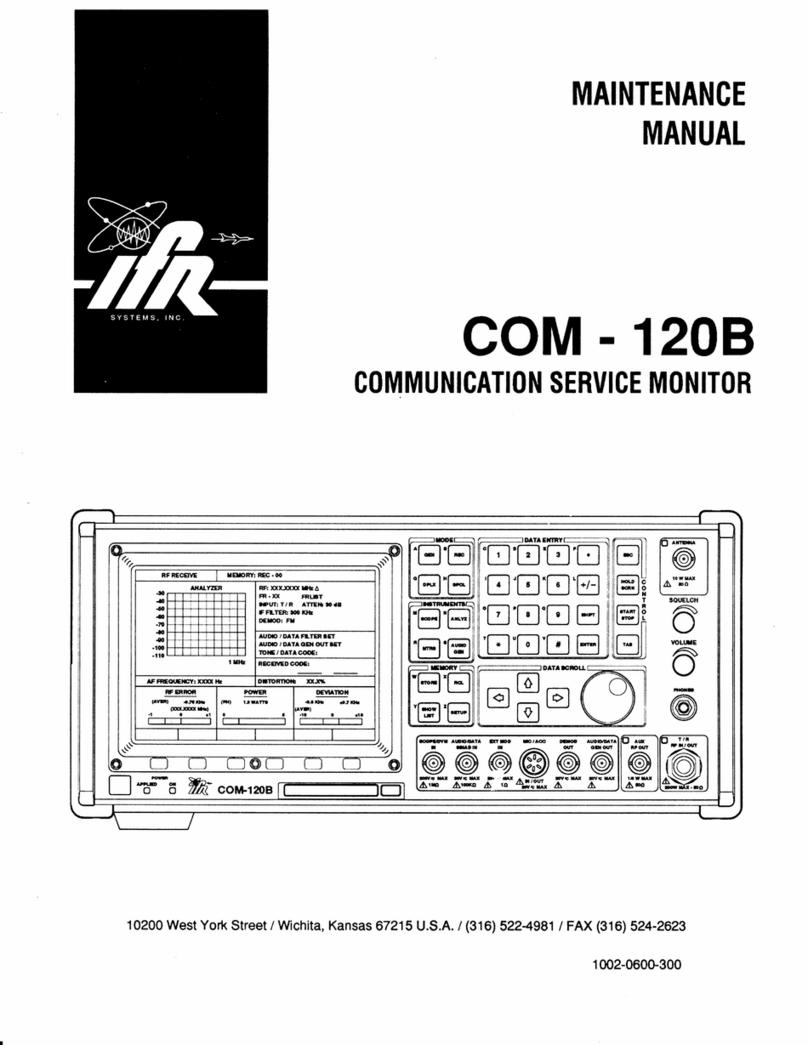

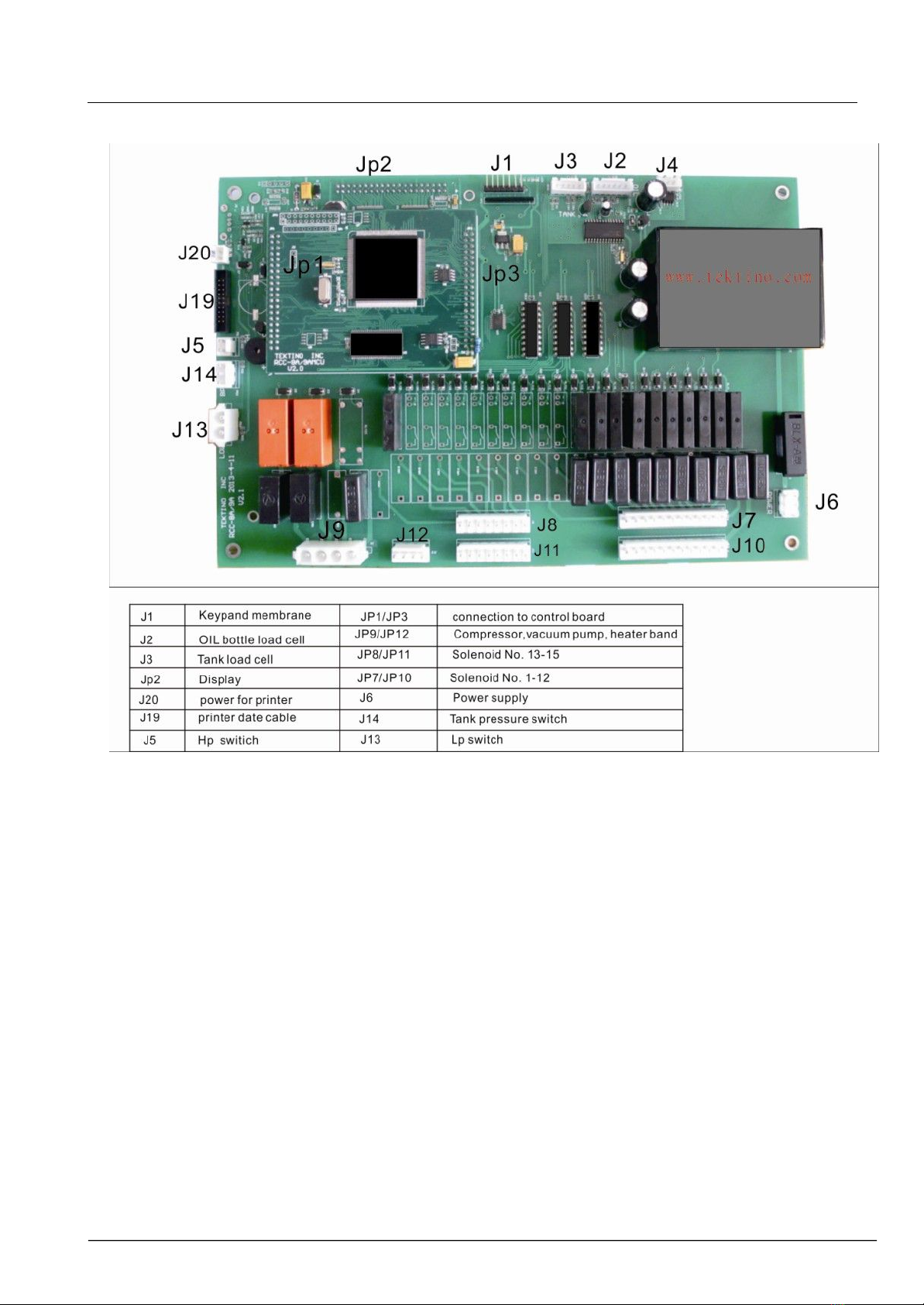

PCA

TEKTINO RCC-9A maintenance manual V2.0

5

2. Routine maintenance

Maintenance of vacuum pump

1) Vacuum pump description

1. Exhaust emission port

2. Suction port

3. Pump oil adding port

4. Oil level vision window

5 Oil discharge port

2) Change vacuum pump oil or add vacuum pump oil

The pump works over 100 hours, or turbidity or emulsion is

found, the oil should be changed. Prepare a container with

capacity bigger than 500ml to hold used oil. OIL No ISO100.

2

TEKTINO RCC-9A maintenance manual

6

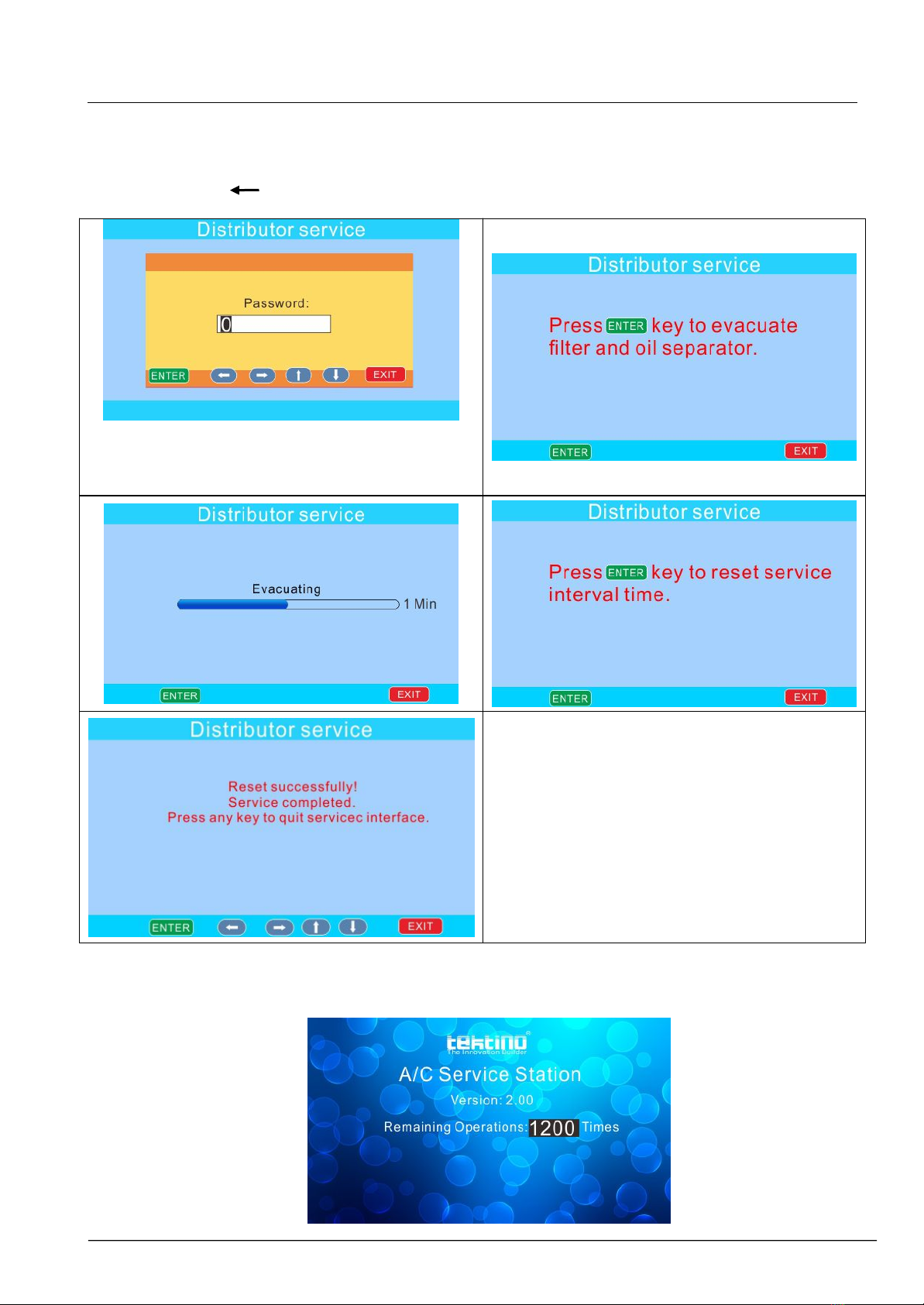

Change drier filter, evacuate drier filter and reset service interval time

When a drier filter is replaced, the moisture may enter into equipment pipeline and affects quality of refrigerant

in the equipment tank. Thus it is mandatory to evacuate the drier filter each time a drier filter is replaced.

a) Remove the used drier filter, and mount the new one.

b) By pressing and ENTER key, turn on the machine, the machine requests password to enter distributor

service page:

Up/down arrow: increase/decrease number

Left/right arrow: move digit

Password: 441329

c) Turn off the machine and turn it on again, to check if service interval time has been set successfully. The

machine should be permitted to operate 1200 time again.

TEKTINO RCC-9A maintenance manual V2.0

7

LEAK TEST

Under the following situations, it is possible that the machine has leakage in pipeline connections, thus need to

make leakage test:

1. The refrigerant volume in equipment tank reduces, without operations;

2. Compressor and Solenoids work well, while recovery works too slow or can not work normally;

3. Any operations or equipment maintenance that needs to disconnect and connect the pipelines or adaptors

that may cause leakage. For example, change drier-filter.

There are two methods to make leakage tests: Leakage detector and high pressure test:

1. Leakage test with refrigerant detector: When equipment pipeline is full of refrigerant, for example,

during running recovery, use refrigerant detector to find out the leakage points.

2. High pressure leakage test:

a) Connect Nitrogen generator (In case no nitrogen generator can be found, can use air compressor) to

equipment SUCTION or CHARGE port, and run recovery until it stops with high pressure alarm

b) Block the SUCTION and CHARGE ports with nut caps.

c) Enter “Component test” page by following procedure

P.W.: 111111

d) In “Component test” page, turn on V1, V5, V9, V10, V11 and V12. Wait until the pressure shown in 3

pressure gauges become equal, turn off the equipment.

TEKTINO RCC-9A maintenance manual

8

d) Write down the pressure of each gauge, shut down the equipment. After 4 hours, check pressure of the

three gauges. If any gauge shows more than 0.1 BAR pressure down, means the pipeline related to that

pressure gauge has leakage (refer to pipeline diagram of this manual).

e) Use soapy water to find the exact connection that causes leakage, as pic. 9.

Pic. 9

f) Tighten the connection and make leakage test again.

TEKTINO RCC-9A maintenance manual V2.0

9

3. Main troubleshooting

Ma lf un ctio n Re ason s So lut io n

Low vacuum degree

1. Insufficient vacuum pump oil.

2. Pump oil emulsion, dirty

3. Pump oil inlet plugged.

4. Leakage in pump connection.

5. Components worn out.

1. Add oil to central line

2. Put new oil

3. Clean oil inlet.

4. Check connection

5. Put new pump.

Vacuum pump inject

oil.

1. Excessive oil volume.

2. Entrance pressure too high.

1.Discharge oil to central line

2.Run Recovery function first.

No display

1. Fused (in Power cable connection

box, or PCA)

2. PCA burnt.

3. Power cable loosened.

4. LCD not work

1. Change fuses.

2. Change PCA.

3. Connect power cable reliably.

4. Change LCD.

Recovery does not

stop

1. Leakage in automotive A/C or

equipment pipeline.

2. Compressor not work

Remarks: In winter, it is normal

that recovery takes longer time.

1. Make leakage test. Machine leakage test

with referenc to service manual.

2. Change compressor.

No change in

recovery volume

1. No refrigerant in A/C.

2. Support screw of gas cylinder load

cell not loosened.

3.Gas cylinder load cell not work or

PCA failure.

4.For RCC-6A, hand valves not

opened.

1. Stop recovery.

2. Unsrew the support screw in the bottom of

the weight sensor.

3. Calibrate gas cylinder load cell, or change

the load cell, or change PCA.

4. Open RCC-6A HP/LP hand valves

While auto A/C has

refrigerant,

equipment displays

alarm 005

1. Low pressure switch plug

disconnected from PCA socket.

2. For RCC-6A, hand valves closed

1. Fasten low pressure switch plug.

2. Open RCC-6A HP/LP hand valves

High pressure alarm

004 but gas cylinder

gauge does not show

excessive pressure

value

1. High pressure switch plug

disconnected from PCA socket.

2. Pipeline connecting compressor

exit blocked.

1. Fasten high pressure switch plug.

2. Change compressor exit side hoses.

No charge or slow

charge.

1.Insufficient refrigerant in

equipment

2.System has pressure.

3.Charge solenoid not work.

1. Add refrigerant to 5kg.

2. Run recovery first.

3.Check solenoid No5.

TEKTINO RCC-9A maintenance manual

10

During recovery,

vacuum pump is

pressurized. After

period too much oil

in vacuum pump

The contact between solenoid valve

No.4 and valve base is not well

sealed.

Remove solenoid No.4 from valve base,

clean the solenoid valve and valve base.

During vacuum,

there is suction in old

oil bottle.

The contact between solenoid valve

No.2 and valve base is not well

sealed.

Remove solenoid No.2 from valve base,

clean the solenoid valve and valve base.

Table of contents