Cross Technologies 1599-10 User manual

Instruction Manual

Model 1599-10

Noise Source

March 2010 Rev. A

Data, drawings, and other material contained herein are proprietary to Cross Technologies, Inc.,

but may be reproduced or duplicated without the prior permission of Cross Technologies, Inc.

for purposes of operating the equipment. Printed in USA.

When ordering parts from Cross Technologies, Inc., be sure to include the equipment

model number, equipment serial number, and a description of the part.

CROSS TECHNOLOGIES, INC.

6170 Shiloh Road

Alpharetta, Georgia 30005

(770) 886-8005

FAX (770) 886-7964

Toll Free 888-900-5588

WEB: www.crosstechnologies.com

E-MAIL: [email protected]

1599-10 Manual, Rev. A Page 1 01/07/10

INSTRUCTION MANUAL

MODEL 1599-10 NOISE SOURCE

TABLE OF CONTENTS PAGE

Warranty 2

1.0 General 3

1.1 Equipment Description 3

1.2 Technical Characteristics 4

2.0 Installation 5

2.1 Mechanical 5

2.2 Controls and Indicators 5

2.3 Input/Output Signals 5

2.4 Jumper Settings 5

2.5 Installation/Operation 6

2.5.1 Local Operation 6

2.5.2 Noise Level Settings, Continuous Mode 6

2.5.3 Noise Level Settings, Preset Level Mode 8

2.5.4 Selecting Fileter Bandwidths 9

2.5.5 Remote Operation 10

2.5.6 Remote Control DOS Program 10

3.0 Circuit Description 13

3.1 Block Diagram Description 13

3.2 Control Operation for 1599-10 13

3.2.1 General 13

3.2.2 Noise Level Settings, Continuous Mode 14

3.2.3 Noise Level Settings, Preset Level Mode 14

3.2.4 Selecting Filter Bandwidths 14

4.0 Environmental Use Information 16

WARRANTY - The following warranty applies to all Cross Technologies, Inc. products.

All Cross Technologies, Inc. products are warranted against defective materials and

workmanship for a period of one year after shipment to customer. Cross Technologies, Inc.’s

obligation under this warranty is limited to repairing or, at Cross Technologies, Inc.’s option,

replacing parts, subassemblies, or entire assemblies. Cross Technologies, Inc. shall not be

liable for any special, indirect, or consequential damages. This warranty does not cover parts

or equipment which have been subject to misuse, negligence, or accident by the customer

during use. All shipping costs for warranty repairs will be prepaid by the customer. There

are not other warranties, express or implied, except as stated herein.

1599-10 Manual, Rev. A Page 2 01/07/10

1599-10 NOISE SOURCE

SECTION 1 GENERAL

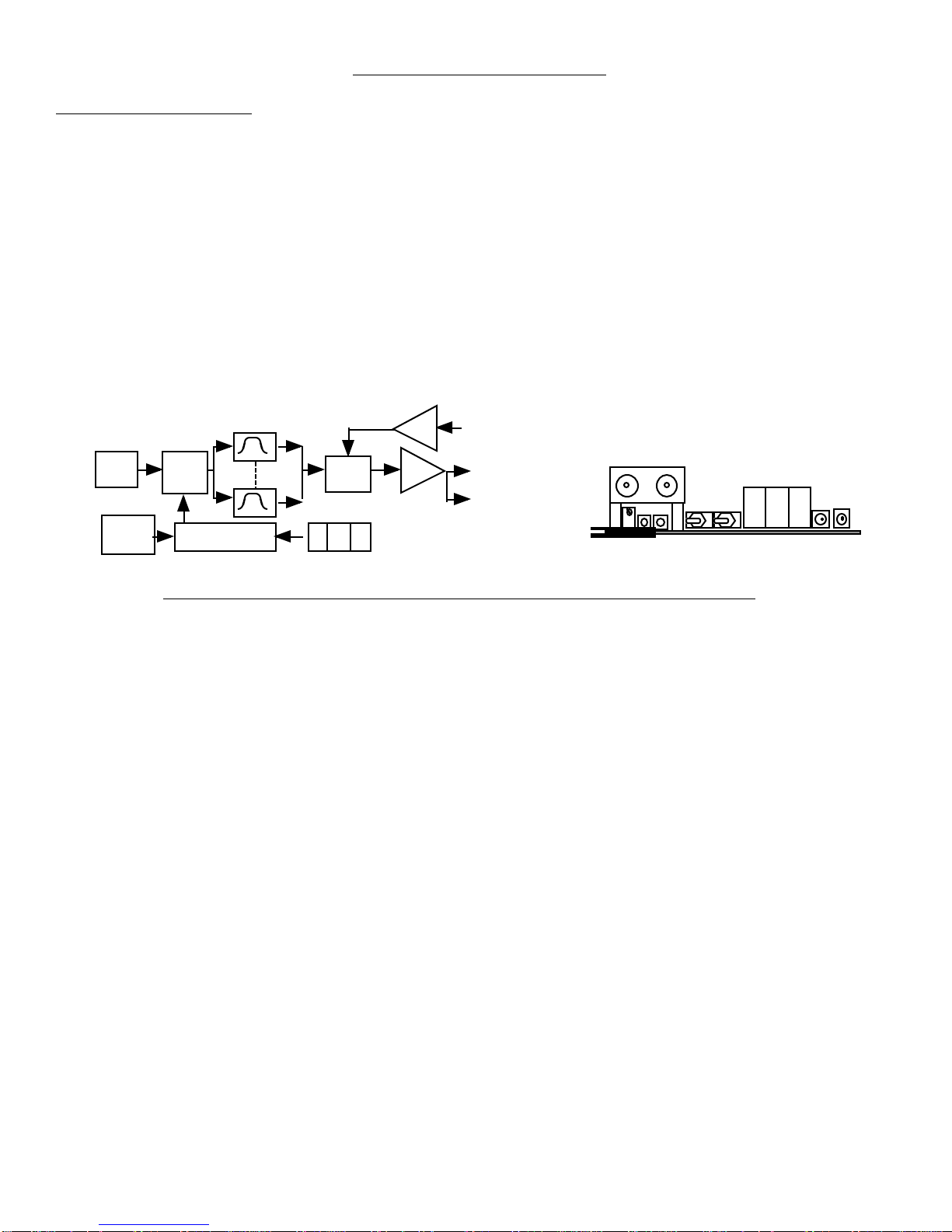

1.1 Equipment Description- The Model 1599-10 Noise Source provides 70 MHz band limited noise in 0.1dB

increments and summing of an external signal. Broad band noise goes to precision attenuators controlled by front

panel “up” and “down” pushbutton switches via the microprocessor controller. The front panel display shows

C/No or attenuation of the noise from a 50 dB- Hz C/No level calibrated for a -20 dBm carrier level. Bandpass

filters are selected with on board jumpers to band limit the noise at 70 MHz. The 1599-10 has a front panel red

LED that lights if the ambient temperature is outside the +20 to +40 C calibrated temperature range. A yellow LED

on the front panel indicates if in remote operation.

FIGURE 1.1 1599-10 Noise Source Block Diagram and Front Panel

NOISE

GEN

Atten. or

C/No

CONTROLLER

Noise Filters

1 3. 8

Voltage

variable

Atten Power

Comb.

Temp.

Detect.

Ext. IF

In

Output

-10 DB

Output

Monitor

13. 8

1599-10 Manual, Rev. A Page 3 01/07/10

1.2 Technical Characteristics

TABLE 1.0 1599-10 NOISE SOURCE SPECIFICATIONS

Characteristics Specifications*

Input Characteristics- carrier input

Input Impedance/RL 75 unbalanced/15 db

Frequency 70 MHz center

Input Level -20 dBm

Gain 0 dB ± 0.1 dB

Output Characteristics

Impedance/RL 75 unbalanced/15 db

Frequency Band 50 - 90 MHz

Level Noise power range allows C/No range of 50 to 90 dB-Hz with a -20 dBm

carrier for 10 MHz BW and 60 to 90 dB-Hz for 40 MHz bandwidth.

Monitor level -10 dB down from main output

Channel Characteristics - Noise Source

BW(MHz) 10 MHz or 40 MHz, Selectable @ 70 MHz IF

Frequency Response -3.0±1 dB, at stated bandwidths

±0.5 dB @ 0.7 X BW

Noise Power Accuracy ±0.25 dB, 60 - 80 dB-Hz C/No, 20 to 40 deg C

±0.5 dB, 50 - 60 and 80 - 90 dB-Hz C/No, 20 to 40 deg C

±0.5 dB, 60 - 80 dB-Hz C/No, 10 to 20, 40 to 50 deg C

Noise Power stability ±0.5 dB, 60 - 80 dB-Hz C/No, 20 to 40 deg C, 30 days

Controls

Test Carrier Toggle switch turns reference 70.0 MHz, -20.0 dBm carrier on and off.

Term Noise or Carrier Toggle switch terminates noise or external signal.

Output Level Potentiometer for Noise calibration.

Attenuation Push button switches with readout of attenuator or C/No setting.

Indicators

Alarm Red LED for temperature range (with FET open drain).

Remote Yellow LED lights when remote control is selected.

Level Three digit displays show C/No for a -20.0 dBm carrier or attenuation

from max noise level.

Other

DC Power, max. +15 VDC, 250 ma; -15 VDC, 120 ma

RF, IF Connectors BNC, female

*Specifications subject to change without notice

2.0 Intallation

1599-10 Manual, Rev. A Page 4 01/07/10

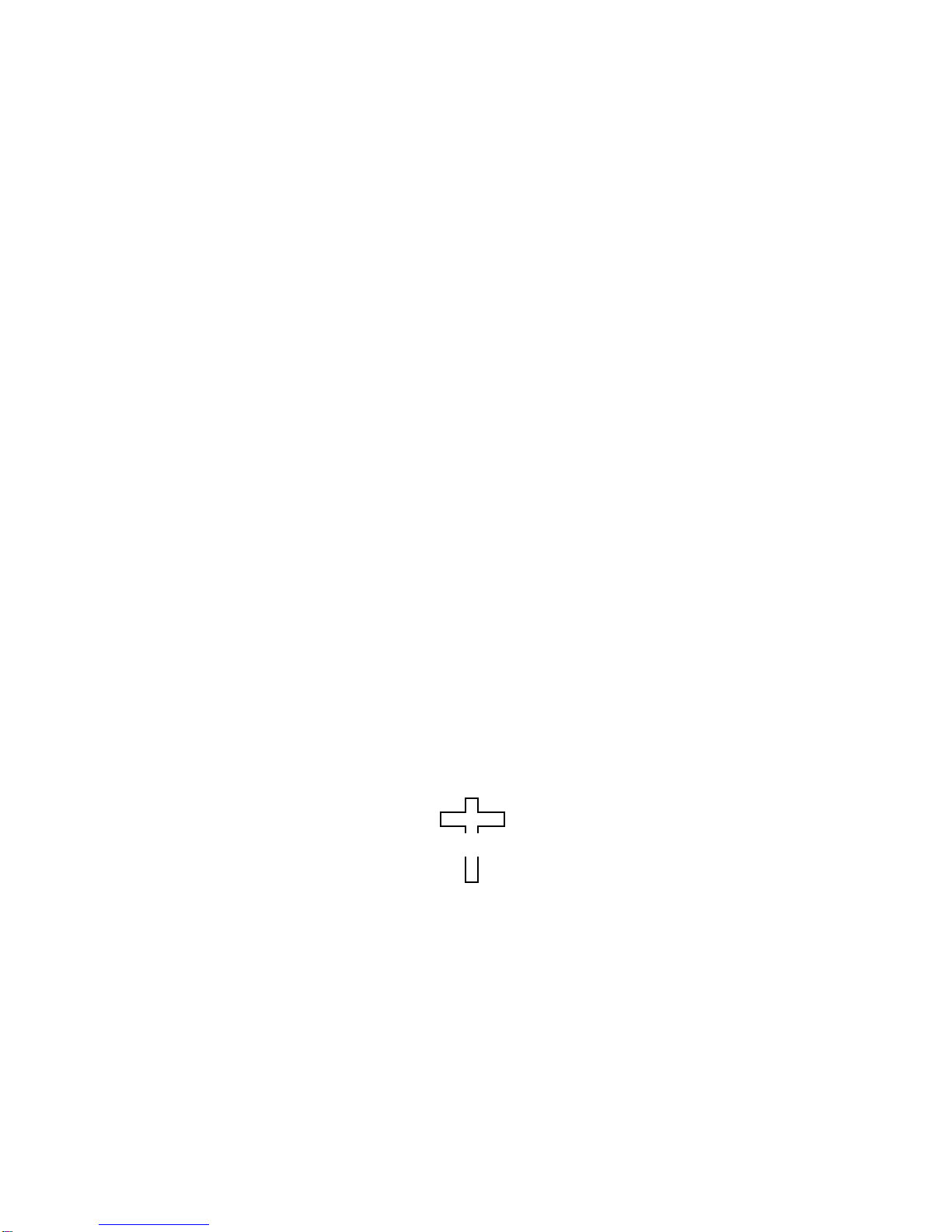

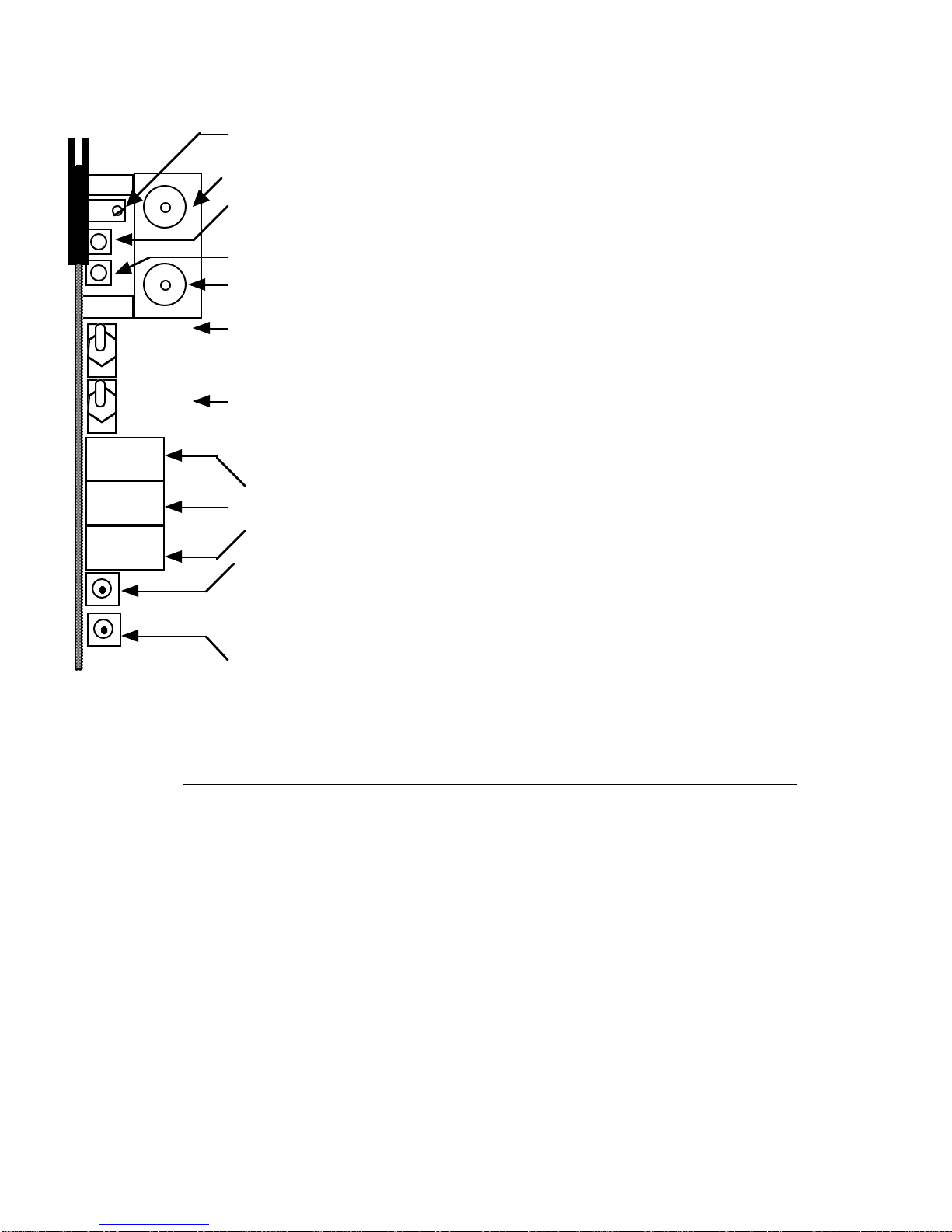

2.1 Mechanical - The 1599-10 goes in any slot of a 1601, 1651 or 1602 mainframe. It derives ±15 V from the

mainframe. Figure 2.1 shows the 1599-10 in slot 1.

1599-10 Noise Source ( fits in any slot in a 1601 or 1651 mainframe; slot 1 shown.

1599-10 Noise Source ( fits in any slot of a 1602 mainframe; slot 1 shown)

FIGURE 2.1 1599-10 MAINFRAME INTERFACE

POWER SUPPLY

1 2 P. S. J10 J9 J7 J6 J4 J5 J1J3

POWER SUPPLY

1 2 3 4 5 6 7 8 9 P. S.

70 MHz SIGNAL IN

1602 FRONT

1601 REAR

1601 FRONT

J10

2

J30

J40

J45

J42 J41

J43 12

24 13

12 1

SIGNAL + NOISE OUT

J20

-10dB MONITOR

SIGNAL + NOISE OUT

1602 REAR

70 MHz SIGNAL IN

-10dB MONITOR

2.2 Controls and Indicators - Figure 2.2 shows front panel controls and indicators.

2.3 Input / Output Signals - Figure 2.3 shows the input and output signals to the 1599-10.

Figure 2.5 is a sketch of the 1601 position 1 and 2 interconnections for reference.

2.4 Jumper Settings - Figure 2.4 shows jumpers and other on-card controls.

1599-10 Manual, Rev. A Page 5 01/07/10

2.5 Installation / Operation -

2.5.1 Local Operation -

1.) Check that on-card jumpers are set to the desired positions (Figure 2.4)

2.) Install the 1599-10 in any slot of a 1602 or 1601 mainframe (Figure 2.1 shows installation in slot 1)

3.) Connect a -20.0 dBm 70 MHz signal to 70 MHz SIGNAL IN (Figure 2.1, Figure 2.3)

4.) Set the desired noise level by pushing SW2 or SW3. If numbers 0 to 9 appear when pushing SW2 or

SW3,

the 1599-10 is set for the preset level mode (with on-card jumper JP7, Figure 2.4).

See section 2.5.2 for noise level setting information.

5.) Be sure DS1 and DS5 are off (Figure 2.2).

8.) If needed, R48 can be adjusted (Figure 2.2) to SLIGHTLY adjust the noise level.

Note that this uncalibrates the 1599-10 from its factory calibration.

2.5.2 Noise Level Setting, Continuous Level Mode - In this mode, the noise level is selected by pushing the

up and down switches (SW2, SW3) on the front panel until the desired noise level is indicated on the front on the

display. The noise level displayed is either C/No based on a -20.0 dBm carrier input or attenuation from the

maximum 50 dB-Hz C/No noise level Note that in the 40 MHz filter setting, the maximum allowable noise level

corresponds to a 60 dB-Hz C/No and setting the the noise level higher causes the display to blink indicating an

abnormal condition. EEROM U20 stores the last noise level set so in the event of power failure the 1599-10 will

go to the noise level it was set to prior to the power outage. The front panel noise level setting switches increment

or decrement the noise level in 0.1 dB steps at approximately a 0.5 second rate. If the switch remains depressed

for approximately ten steps, the rate increases by a factor of ten.

1599-10 Manual, Rev. A Page 6 01/07/10

DS1 - Remote LED - Lights yellow when jumper JP9 is set to REMOTE. When this LED is on,

SW1, SW3, and SW4 on the front panel are disabled and these functions are controlled remotely

J4 - 70 MHz IF Input - 75, BNC 70 MHz input . Input must be at -20.0 dBm for a calibrated

C/No reading.

J4 - -10dB Monitor - 75, BNC -10dB monitor of the 70 MHz output .

SW1 - Terminate Noise or Carrier - Terminates noise or carrier for calibration purposes.

This switch is disabled when in the REMOTE control mode.

FIGURE 2.2 1599-10 Front Panel Controls and Indicators

R48 - Noise Level Adjustment - 10 turn potentiometer that adjusts the noise level by ± 1.0 dB

for very small noise level adjustments to calibrate the 1599-10 to a specific level

DS5 - Alarm LED - Lights red when ambient temperature exceeds approximately 45 degrees C

SW4 - Test Carrier On/Off - Turns -20.0 dBm, 70.0 MHz Test carrier on and off. This carrier is

used as a reference to calibrate the desired carrier on a spectrum analyzer This switch is disabled

when in the REMOTE control mode.

-ON TEST

-OFF CARRIER

13. 8

-TERM NOISE

-OPERATE

-TERM CARRIER

DS2 - 10 dB

DS3 -

1 dB DS2, DS3, DS4 - Noise Level Displays - Display the desired output noise level in

C/No or dB below the maximum -50 dB-Hz level.

SW2 - UP Noise Level Control Pushbutton Switch - When in Continuous Noise Level mode

(as set by jumper JP7), when pushed will increment noise level in 0.1 dB steps at about a 0.5 second rate.

If held in for about 10 steps, will increment noise level in 0.1 dB steps at about a 0.05 second rate.

When in Preset Noise Level mode (as set by jumper JP7), when pushed momentarily will display the

preset level number its on. If held in will increment preset level number and when released will display

the noise level of the selected preset level.

SW3 - DOWN Noise Level Control Pushbutton Switch - Same as SW2 except decreases

noise level or preset level. PUSHING SW2 and SW3 simultaneously displays the on-card temperature in

degrees C (typically 5-7 degrees above ambient room temperature. An alarm condition occurs

about 50 degrees)

DS4 -

0.1 dB

1599-10 Manual, Rev. A Page 7 01/07/10

1599-10 Rear

FIGURE 2.3 1599-10 Inputs and Outputs

Pin 15 (J10P11) - Alarm FET open drain output -

Provides a short to ground (100 ma max) if alarm occurs.

Pin 1 (J10P12) - Ground

Pin 18 (J10P12) - Ground

Pin 9 (J10P5 - +15 VDC - 250 ma max, 220 typical

Pin 11(J10P7) - -15 VDC - 120 ma max, 100 typical

Pin 4 (J6P1) - Remote Control Data Out -RS232C,

2400 B/s ASYNC (8N1) data to external computer. Used for

handshaking during remote operation and auto-calibration.

Pin 5 (J6P3) - Remote Control Data In - RS232C,

2400 B/s ASYNC (8N1) data from external computer. Provides

commands for frequency and level during remote operation

PCB Edge Connector P1 Pin # (JxPx) = Backplane

connector and pin # in slot 1 in 1601 type

mainframe;corresponding 1602 connectors are

J1 for 1601-J1, J3 for 1601-J6, J5 for 1601-J10

J4 - 70 MHz IF Input - 75,

BNC 70 MHz input . Input must

be at -20.0 dBm for a calibrated

C/No reading.

J4 - -10dB Monitor - 75,

BNC -10dB monitor of the70

MHz output .

1599-10 FR

O

NT

Pin 2 (J1) - 75, 70MHz Signal + Noise out

2.5.3 Noise Level Setting, Preset Level Mode - Preset level selection is accomplished when the on board, but not

front panel accessible, three-pin jumper (JP7) (Figure 2.4) is set to the “preset level” (DOT) position. Ten preset

preset levels (0-9) can be selected as follows:

1. The 1599-10 is placed on an extender card to access the preset level selecting decimal switch (SW6)

and the push to program switch (SW5) (Figure 2.4). With the display mode jumper (JP7) set in the

noise level mode, the noise level set switches (SW2, SW3) are pushed to the noise level desired

(Figure 2.2).

2. The decimal switch (SW6) is set to the preset level number desired to be programmed (Figure 2.4).

3. The programming button (SW5) is pushed to program the currently displayed noise level into that

preset level number (Figure 2.4).

4. The above steps are repeated for any additional preset levels that are desired to be programmed.

At the factory, preset levels zero through nine are programmed for C/No from 60 to 70 dB-Hz in 1.0 dB steps.

When in the remote mode, noise level setting by either continuous or preset level numbers can be provided, but

programming of the preset levels can only be done locally. The noise level display (DS2, DS3, DS4) in the preset

level mode displays the current preset level number selected when SW2 or SW3 is pushed, and, if the switch is

held for more than 2 seconds, the preset level numbers are incremented or decremented depending on which button

is pushed. The display indicates zero through nine for preset level number, and, when the desired preset level is

1599-10 Manual, Rev. A Page 8 01/07/10

selected and the button is released for one to two seconds, the noise level of that preset level is shown on the noise

level display and this noise level display remains until switch SW2 or SW3 is pushed again.

2.5.4 Selecting Filter Bandwidths - Filter noise bandwidths of 10 MHz or 40 MHz can be selected by

positioning jumpers JP2, JP3, and JP8 to DOT (10 MHZ) or NON-DOT (40 MHz). The noise power level range

for the 10 MHz position provides for a C/No of 50 dB-Hz to 90 dB-Hz with a -20.0 dBm input carrier and the 40

MHz position provides for a C/No of 60 dB-Hz to 90 dB-Hz with a -20.0 dBm input carrier. The 40 MHz

bandwidth allows noise levels greater than 60 dB-Hz but this will cause the C/No display to blink indicating an

abnormal condition and the likelihood of nonlinearity due to possible gain compression.

FIGURE 2.4 1599-10 On-Card Jumpers and Controls

U23

SW5

SW6

R48

JP5 JP6 JP8JP7

SW2

SW3

SW4

SW1

JP1

JP2 JP3

JP9

JP10 JP4

JUMP

E

ER

JUMPER DESCRIPTION

JP # Description Dot Non-dot Normal COMMENTS

JP1 TEST-SWEEP IN TEST OPERATE NON FOR TEST ONLY

JP2 FILTER SELECT 10 MHz 40MHz DOT SELECTS BAND LIMITING 70MHz FILTER

JP3 FILTER SELECT 10 MHz 40MHz DOT SELECTS BAND LIMITING 70MHz FILTER

JP4 TEST-WDOG TEST ENABLE NON FOR TEST ONLY

JP5 ATTN/C/No SELECT ATTN C/No NON DISPLAY READS C/No OR ATTN FROM MAX NOISE LEVEL

JP6 ALARM ENABLE ENABLE DISABLE DOT ALLOWS ALARM TO BE DISABLED

JP7 PRESET/CONT. LEVEL PRESET CONT. NON NOISE ADJUSTMENT CONTINUOUS/1 OF 10 PRESET LEVELS

JP8 FILTER SELECT 10 MHz 40MHz DOT SELECTS BAND LIMITING 70MHz FILTER

JP9 REMOTE/LOCAL LOCAL REMOTE DOT SELECTS REMOTE OR LOCAL OPERATION

SW5- PRESET LEVEL PUSH TO PROGRAM SWITCH PUSH TO

PROGRAM DISPLAYED NOISE LEVEL IN PRESET # SHOWN ON SW6

SW6 - PRESET # SELECT SWITCH

SELECTS PRESET NUMBER TO

PROGRAM DISPLAYED NOISE LEVEL

TO WHEN SW5 IS PUSHED

1599-10 Manual, Rev. A Page 9 01/07/10

2.5.5 Remote Operation - Noise level (either continuous or preset noise levels), test carrier on/off, and

termination of carrier or noise can be remotely commanded from an external (not supplied) PC using a simple

DOS program. To place the 1599-10 in the Remote mode, place on-card jumper JP9 in the NON-DOT position

(Figure 2.4) and observe yellow LED DS1 (Figure 2.2) is on. Serial ASYNC (8N1) data is received via RS232C

receiver U21 and sent via RS232C transmitter U38 at a 2.4 kB/s data rate. When in the remote mode, either

continuous or preset noise levels can be adjusted, but programming of the preset levels can only be done locally.

The 1599-10 noise power settings can be automatically calibrated with an HP3708A Noise Test Set.

Contact Cross Technologies, Inc. (888-900-5588) for details.

2.5.6 Remote Control DOS Program - The 1599-10 remote control program (REMOTE.EXE) runs on an IBM

compatible computer under DOS. (If you plan to operate in the remote mode using this program please contact

Cross Technologies, Inc. (770-662-5858) and request a disk containing this program.) The user is prompted to

select one of three possible functions, which are:

1. Set Noise Level

2. Set Preset Level Number

3. Test Carrier On/Off

4. Terminate Carrier or Noise

When Set Noise Level is selected, the up arrow and down arrow keys are used to increase or decrease the 1599-

10’s output noise level in 0.1 dB increments.

When Set Preset Level Number is selected, the up arrow and down arrow keys are used to select one of ten

possible preset noise levels. The noise level of each preset level must be programmed locally, as described in the

1599-10 instruction manual.

When Test Carrier On/Off is selected, the up arrow and down arrow keys are used to select On or Off.

When Terminate Carrier or Noise is selected, the up arrow and down arrow keys are used to select Terminate

Noise, Operate or Terminate Carrier.

The remote control program sends commands to the 1599-10 through pin 5 of the card edge connector. Pin 5 is

an RS232C serial port set to accept 8N1 formatted data. Each command sent to the 1599-10 is two or three bytes

long. The first byte is an instruction byte and the second and third bytes are data bytes.

The instruction byte to set output noise level in the continuous mode is AAH (hex). This byte must be followed by

a data byte that selects one of 401 possible output noise levels. The following list describes the relationship

between data bytes and output noise levels.

1599-10 Manual, Rev. A Page 10 01/07/10

Data Byte Output Noise Level (dB-Hz)

500 50.0

501 50.1

502 50.2

. .

. .

900 90.0

The instruction byte to set preset levels is ABH. This byte must be followed by a data byte that selects one of 10

possible preset levels. The following list describes the relationship between data bytes and output frequencies.

Data Byte Preset Level

00 0

01 1

. .

. .

09 9

The instruction byte to turn the test carrier on and off is ACH. This byte must be followed by a data byte as

follows:

Data Byte Test Carrier Condition

01 Carrier On

02 Carrier Off

The instruction byte to terminate carrier or noise the is ADH. This byte must be followed by a data byte as

follows:

Data Byte Test Carrier Condition

01 Terminate Noise

02 Operate

03 Terminate Carrier

1599-10 Manual, Rev. A Page 11 01/07/10

1599-10 CARD,

TOP

J2

J3

J8

J1

J9

J6J7

J10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

A2 A1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1 2 3 1 2 3

1 2 3 1 2 3

J1=J11=J21=J31

J2=J12=J22=J32

J3=J13=J23=J33

J6=J16=J26=J36

J7=J17=J27=J37

J8=J18=J28=J38

J9=J19=J29=J39

A1=A3=A5=A7

A2=A4=A6=A8

CONNECTOR EQUIVALENTS

= GROUND

GROUND...................

.

70 MHz Carrier + Noise out..

Not Used........................

Remote Data In..............

Remote Data Out...........

Not Used........................

Not Used......................

Not Used......................

+15 VOLTS................

Not Used........................

-15 VOLTS.................

Not Used........................

Not Used......................

Not Used........................

FET closure to GND ........

Not Used........................

Not Used........................

GROUND...................

.

FIGURE 2.5 CONNECTIONS FOR 1599-10

CARD IN A 1601 MAINFRAME IN SLOTS

1, 3, 5, OR 7

HWW

5/12/95

1601 MAINFRAME - LOOKING AT THE BACKPLANE

FROM THE CONNECTOR SIDE

+15

VOLTS

-15 VOLTS

AB

CONNECT1601

CC = CONTACT CLOSURE OR OPEN - COLLECTOR

1599-10 Manual, Rev. A Page 12 01/07/10

Circuit Description

3.1 Block Diagram Description - 1599-10 (Figure 3.1) - Broadband noise is generated by noise diode CR1

followed by various amplifiers (U1, U3, U6, U8 with 21 dB gain; U15 with 13 dB Gain), a 200 MHz lowpass filter

(L16, C58, C62), 70 MHz bandpass filters (10 MHz consists of L3 - L6 and associated parts; 40 MHz consists of

L18 - L 21 and associated parts), voltage controlled attenuators (U3, U7, U14), and a noise termination switch (U5)

before being summed with the external signal by a resistive summing network (R43, R44, R38). The input signal

goes through a variable attenuator (R42) for precise unity gain to the output, signal termination switch (U11), and

buffer amplifier U13 before being summed with the noise by resistive summing network, R43, R44, R38. The

combined signal plus noise goes to output amplifier U9 and output monitor amplifier U10. Controller U23 and

associated circuitry provide attenuation commands to the attenuator D/A U17 and the noise diode bias D/A U16

which provides 0.1 dB steps and slight temperature compensation as needed to maintain the noise power accuracy

over temperature as specified.

Commands for the D/A’s, noise termination switch, signal termination switch, and test oscillator switches are

provided from microprocessor U23 which receives serial RS232C commands from an external (not supplied) PC

via RS232C receiver IC, U21. Microprocessor U23 can send serial RS232C commands to an external PC via

RS232C transmitter IC, U38. Noise level (either continuous or preset noise levels), test carrier on/off, and

termination of carrier or noise can be remotely commanded from an external (not supplied) PC using a simple

DOS program.

Microprocessor U23 uses its internal oscillator controlled by the 3.6864 MHz crystal Y2. U19 is a watch dog

timer for microprocessor U23. IC’s U30, U31, U32, U27, U28, U29 provide multiplexing and strobing of displays

DS2, DS3, DS4.

3.2 Controller Operation for 1599-10 Noise Source

3.2.1 General - The controller consists of a microprocessor and associated circuitry which receives inputs from:

a) the front panel noise level set switches (SW2, SW3),

b) the front panel terminate noise/carrier switch (SW1),

c) the front panel test carrier switch (SW4),

d) the on card display mode jumper (JP7),

e) the on card preset level programming decimal switch (SW6),

f) the on card preset level programming “push to program” switch (SW5),

g) the on card local / remote control mode jumper (JP9), and

h) the on temperature detector IC (U35)

The controller provides command signals to the:

a) noise level D/A’s (U16, U17),

b) carrier, noise terminating switches (U5, U11),

c) test carrier enable switch (Q2), and

d) the front panel noise level display (DS2, DS3, DS4).

In addition, when in the remote control mode, the microprocessor U23 accepts a serial data stream which is

generated by a simple DOS program (by an external, not provided, PC) that selects the noise level and the output

level. Serial data is received via RS232C receiver U4 and sent via RS232C transmitter U38. The following

provides additional detail.

1599-10 Manual, Rev. A Page 13 01/07/10

3.2.2 Noise Level Setting, Continuous Level Mode - In this mode, the noise level is selected by pushing the up

and down switches (SW2, SW3) on the front panel until the desired noise level is indicated on the front on the

display. The noise level displayed is either C/No based on a -20.0 dBm carrier input or attenuation from the

maximum 50 dB-Hz C/No noise level Note that in the 40 MHz filter setting, the maximum allowable noise level

corresponds to a 60 dB-Hz C/No and setting the the noise level higher causes the display to blink indicating an

abnormal condition. EEROM U20 stores the last noise level set so in the event of power failure the 1599-10 will

go to the noise level it was set to prior to the power outage. The front panel noise level setting switches increment

or decrement the noise level in 0.1 dB steps at approximately a 0.5 second rate. If the switch remains depressed

for approximately ten steps, the rate increases by a factor of ten.

3.2.3 Noise Level Setting, Preset Level Mode - Preset level selection is accomplished when the on board, but not

front panel accessible, three-pin jumper (JP7) (Figure 2.4) is set to the “preset level” (DOT) position. Ten preset

preset levels (0-9) can be selected as follows:

1. The 1599-10 is placed on an extender card to access the preset level selecting decimal switch (SW6)

and the push to program switch (SW5) (Figure 2.4). With the display mode jumper (JP7) set in the

noise level mode, the noise

level set switches (SW2, SW3) are pushed to the noise level desired (Figure 2.2).

2. The decimal switch (SW6) is set to the preset level number desired to be programmed (Figure 2.4).

3. The programming button (SW5) is pushed to program the currently displayed noise level into that

preset level number (Figure 2.4).

4. The above steps are repeated for any additional preset levels that are desired to be programmed.

At the factory, preset levels zero through nine are programmed for C/No from 60 to 70 dB-Hz in 1.0 dB steps.

When in the remote mode, noise level setting by either continuous or preset level numbers can be provided, but

programming of the preset levels can only be done locally. The noise level display (DS2, DS3, DS4) in the preset

level mode displays the current preset level number selected when SW2 or SW3 is pushed, and, if the switch is

held for more than 2 seconds, the preset level numbers are incremented or decremented depending on which button

is pushed. The display indicates zero through nine for preset level number, and, when the desired preset level is

selected and the button is released for one to two seconds, the noise level of that preset level is shown on the noise

level display and this noise level display remains until switch SW2 or SW3 is pushed again.

3.2.4 Selecting Filter Bandwidths - Filter noise bandwidths of 10 MHz or 40 MHz can be selected by

positioning jumpers JP2, JP3, and JP8 to DOT (10 MHZ) or NON-DOT (40 MHz). The noise power level range

for the 10 MHz position provides for a C/No of 50 dB-Hz to 90 dB-Hz with a -20.0 dBm input carrier and the 40

MHz position provides for a C/No of 60 dB-Hz to 90 dB-Hz with a -20.0 dBm input carrier. The 40 MHz

bandwidth allows noise levels greater than 60 dB-Hz but this will cause the C/No display to blink indicating an

abnormal condition and the likelihood of nonlinearity due to possible gain compression.

1599-10 Manual, Rev. A Page 14 01/07/10

1599-10 Manual, Rev. A Page 15 01/07/10

4.0 Environmental Use Information

A.Rack-Mounting - To mount this equipment in a rack, please refer to the installation instructions located in the

user manual furnished by the manufacturer of your equipment rack.

B. Mechanical Loading - Mounting of equipment in a rack should be such that a hazardous condition does not

exist due to uneven weight distribution.

C.Elevated Operating Ambient Temperature - If installed in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack may be greater than room ambient temperature. Therefore,

consideration should be given to Tmra.

D. Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow

required for safe operation of the equipment is not compromised. Additional space between unit may be

required.

E. Circuit Overloading - Consideration should be given to the connection of the equipment to the supply circuit

and the effect that overloading of circuits could have on over current protection and supply wiring.

Appropriate consideration of equipment name plate rating should be used when addressing this concern.

F. Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connection to the Branch (use of powerstrips).

G. Top Cover - There are no serviceable parts inside the product so, the Top Cover should not be removed. If the

Top Cover is removed the ground strap and associated screw MUST BE REINSTALLED prior to Top Cover

screw replacement. FAILURE TO DO this may cause INGRESS and/or EGRESS emission problems.

1599-10 Manual, Rev. A Page 16 01/07/10

CROSS TECHNOLOGIES, INC.

6170 Shiloh Road

Alpharetta, Georgia 30005

(770) 886-8005

FAX (770) 886-7964

Toll Free 888-900-5588

WEB www.crosstechnologies.com

E-MAIL [email protected]

2010 •Printed in USA

1599-10 Manual, Rev. A Page 17 01/07/10

Table of contents

Other Cross Technologies Music Equipment manuals