Crossfer LS8T-230V User manual

FOR YOUR SAFETY

READ AND UNDERSTAND THE ENTIRE MANUAL

BEFORE OPERATING MACHINE

MODEL NUMBER : LS8T-230V

SERIAL NUMBER :

Both model number and serial number may be found on the main label .

You should record both of them in a safe place for future use.

Save This Manual for Future Reference

8TON VERTICAL LOG SPLITTER

Owner’s Manual

SAFETY WARNINGS & CAUTIONS

Do not operate the log splitter while under the influence of

drugs, alcohol, or any medication that could affect your ability

to use it properly.

Always operate your log splitter on dry, solid, level ground.

Never operate your log splitter on slippery, wet, muddy, or

icy surfaces. The location you choose should be free from

any tall grass, brush, or other interferences. There should be

plenty of room for handling, and help the operator stay alert.

Keep your work area clean and well lighted. Cluttered areas

invites injuries. To avoid tripping, do not leave tools, logs, or

other components laying around the work area. Do not use

the log splitter in wet or damp areas or expose it to rain.Do

not use it in areas where fumes from paint, solvents or

flammable liquids pose a potential hazard.

Check your log splitter before turning it on. Keep guards in

place and in working order. Form a habit of checking to see

that keys and adjusting wrenches are removed from tool area

before turning it on. Replace damaged, missing or failed parts

before using it. Make sure all nuts, bolts, screws, hydraulic

fittings, hose clamps, etc. are securely tightened. Always

check the oil level in the hydraulic oil tank. Never operate your

log splitter when it is in need of repair or is in poor mechanical

condition.

Do not wear loose clothing, gloves, neckties or jewelry (rings,

wrist watches). They can be caught in moving parts. Protective

electrically non-conductive gloves and non-skid footwear are

recommended when working. Wear protective hair covering

to contain long hair, preventing it from get caught in machinery.

SYMBOL AFFIXED TO THE

MACHINE

UNDERSTAND YOUR LOG SPLITTER

DRUGS, ALCOHOL AND MEDICATION

AVOID DANGEROUS CONDITIONS

INSPECT YOUR LOG SPLITTER

l

l

l

l

l

SAFETY WARNINGS & INSTRUCTIONS

Read and understand the owner’s manual and labels affixed

to the log splitter. Learn its application and limitations as well

as the specific potential hazards peculiar to it.

DRESS PROPERLY

Any log splitter may throw foreign objects into the eyes. This

can cause permanent eye damage. Always wear safety goggles.

Everyday eyeglasses have only impact resistant lenses. They

are not safety glasses.

Improper use of extension cords may cause inefficient operation

of the log splitter which can result in overheating. Be sure the

extension cord is no longer than 10m and its section is no less

than 2.5mm2to allow sufficient current flow to the motor. Avoid

use of free and inadequately insulated connections. Connections

must be made with protected material suitable for outdoor use.

Check that the electric circuit is adequately protected and that

it corresponds with the power, voltage and frequency of the

motor. Check that there is a ground connection, and a regulation

differential switch upstream. Ground the log splitter. Prevent

body contact with grounded surfaces: pipes, radiators, ranges,

and refrigerator enclosures. Never open the switch / plug box.

Should this be necessary, contact a qualified electrician. Make

sure your fingers do not touch the plug’s metal prongs when

plugging or unplugging the log splitter.

Do not smoke or have open flames when operating or refilling

the log splitter. Never operate the log splitter near a flame or

spark. Oil is flammable and can be exploded.

Allow only one person to load and operate the log splitter.

Always keep bystanders, including visitors, children and pets

away from the work area, especially when the log splitter is

under operations. Only the operator should stand near the

machine and only within the safe operating area prescribed in

this manual. Never use another people to help you with freeing

jammed log. No one under the age of 16 should be allowed

to operate the log splitter. Any individual under the age of 18

should has the necessary training, skills to perform the functions

properly and safely and should always be under the supervision

of adult.

Never attempt to split logs containing nails, wire or debris.

Always make sure that both ends of the log you are splitting

are cut as square as possible. This will prevent the log from

sliding out of position while under pressure. Branches must be

cut of flush with the trunk.

EXTENSION CORDS

AVOID ELECTRICAL SHOCK

PREVENT FIRES

KEEP BYSTANDERS AWAY

INSPECT YOUR LOG

l

l

l

l

l

l

PROTECT YOUR EYES AND FACE

Do not straddle or reach across the splitting area when operating

the log splitter. Never pile logs to be split in a manner that will

cause you to reach across the log splitter. Only use your hands

to operate the control levers. Never use your foot, knee, a rope,

or any other extension device. Always pay full attention to the

movement of the wedge ram. Never attempt to load your log

splitter while the ram is in motion. Keep hands out of the way

of all moving parts. Never try to split two logs on top of each

other. One of them may fly up and hit you.

When the ram of the log splitter is in the return mode, keep

your hands off the machine – the log splitter is designed to

automatically stop when the cylinder is full retracted. Keep you

hands away from splits and cracks which open in the log. They

may close suddenly and crush or amputate your hands. Do

not remove jammed logs with you hands.

It will do a better and safer job at its design rate. Don’t use log

splitter for a purpose for which it was not intended. Do not,

under any circumstances, alter your log splitter. This equipment

was designed and engineered to be used in accordance with

the operating instructions. Altering the equipment, or using the

equipment in such a way as to circumvent its design capabilities

and capacities, could result in serious or fatal injury and will

void the warranty. Never try to split logs larger than those

indicated in the specifications table. This could be dangerous

and may damage the machine.

Don’t leave tool until it has come to a complete stop.

AVOID INJURY FROM UNEXPECTED ACCIDENT

PROTECT YOUR HANDS

DON’T FORCE TOOL

NEVER LEAVE TOOL RUNNING UNATTENDED

Keep proper footing and balance at all times. Never stand on

log splitter. Serious injury could occur if the tool is tipped or if

the cutting tools is unintentionally contacted. Do not store

anything above or near the log splitter where anyone might

stand on the tool to reach them.

DON’T OVERREACH

l

l

l

l

l

Always clean the unit after each use. Keep the log splitter clean

for best and safest performance. Follow instructions for

lubricating. Inspect all hydraulic seals, hoses and couplers for

leaks prior to use. Control levers and power switch must be

kept clean, dry and free from oil and grease at all times.

TABLE OF CONTENTS

Safety Warnings & Cautions …………………………………………………………………..........2

Application Conditions ... ……………………………………………………………………….…….....6

Specifications……………………………………………………………………………..........6

Electrical Requirements ... …………………………………………………………………………........6

Unpacking…………………………………………………………………………………………........7

Contents of Shipping Container …………………………………………………………………. .....7

Set up and Preparation for Operation…….………………………………………………………….......8

Delivering Log Splitter to Work Site ..….……………………………………......................................9

Log Splitter Operation ...........…………………………………………………………. ...................9

Replacing Hydraulic Oil ………………………......…………………………………………………....11

Sharpening Wedge ............…………………….............……………………………………….....12

Trouble Shooting ………………………………………………………………….............………....13

Wiring Diagram ………………………………………………….……………………………..........13

Plumbing Diagram …………………………………………………………………………......…….13

Parts Schematic .....………………………………………...........................................................14

PROTECT THE ENVIRONMENT

Take used oil to an authorized collection point or follow the

stipulations in the country where the log splitter is used.

Do not discharge into drains, soil or water.

Unplug when not in use, before making adjustments, changing

parts, cleaning, or working on the log splitter. Consult technical

manual before servicing.

DISCONNECT POWER

MAKE THE WORKSHOP CHILDPROOF

Lock the shop. Store the log splitter away from children and

others not qualified to use it.

MAINTAIN YOUR LOG SPLITTER WITH CARE

l

l

l

l

APPLICATION CONDITIONS

This log splitter is designed for operating under ambient temperatures between +5oC and

40oC and for installation at altitudes no more than 1000m above M.S.L. The surrounding

humidity should less than 50% at 40oC. It can be stored or transported under ambient

temperatures between -25oC and 55oC.

SPECIFICATIONS

Modell Nummer LS8T-230V

Motor

Log Size Capacity Dia.

Length

Maximum Force

Hydraulic Pressure

Hydraulic Oil Capacity

Ram Travel

Forward Speed

Retract Speed

Noise Level

Overall Sizes

Length

Width

Height

Weight

230V~ 50Hz 3000W IP54

12cm ~ 32cm

104 cm / 78 cm / 52 cm

8t

5 L

480mm

3.9cm / sec.

14.5cm / sec

80.1dbA under no load ; 92.5dbA under full load

83cm

93cm

147cm

115 kg

ELECTRICAL REQUIREMENTS

With 230 Volt / 50Hz motor, the log splitter should be connected to standard 230V+10%

/ 50Hz+1Hz. Electrical supply which has protection devices of under-voltage, over-voltage,

over-current as well as a residual current device (RCD) which maximum residual current

rated at 0.03A. Electrical connection rubber cables must comply with EN60245 which are

always marked with symbol H 07 RN. Cables should be identified, as it is a legal requirement.

22Mpa

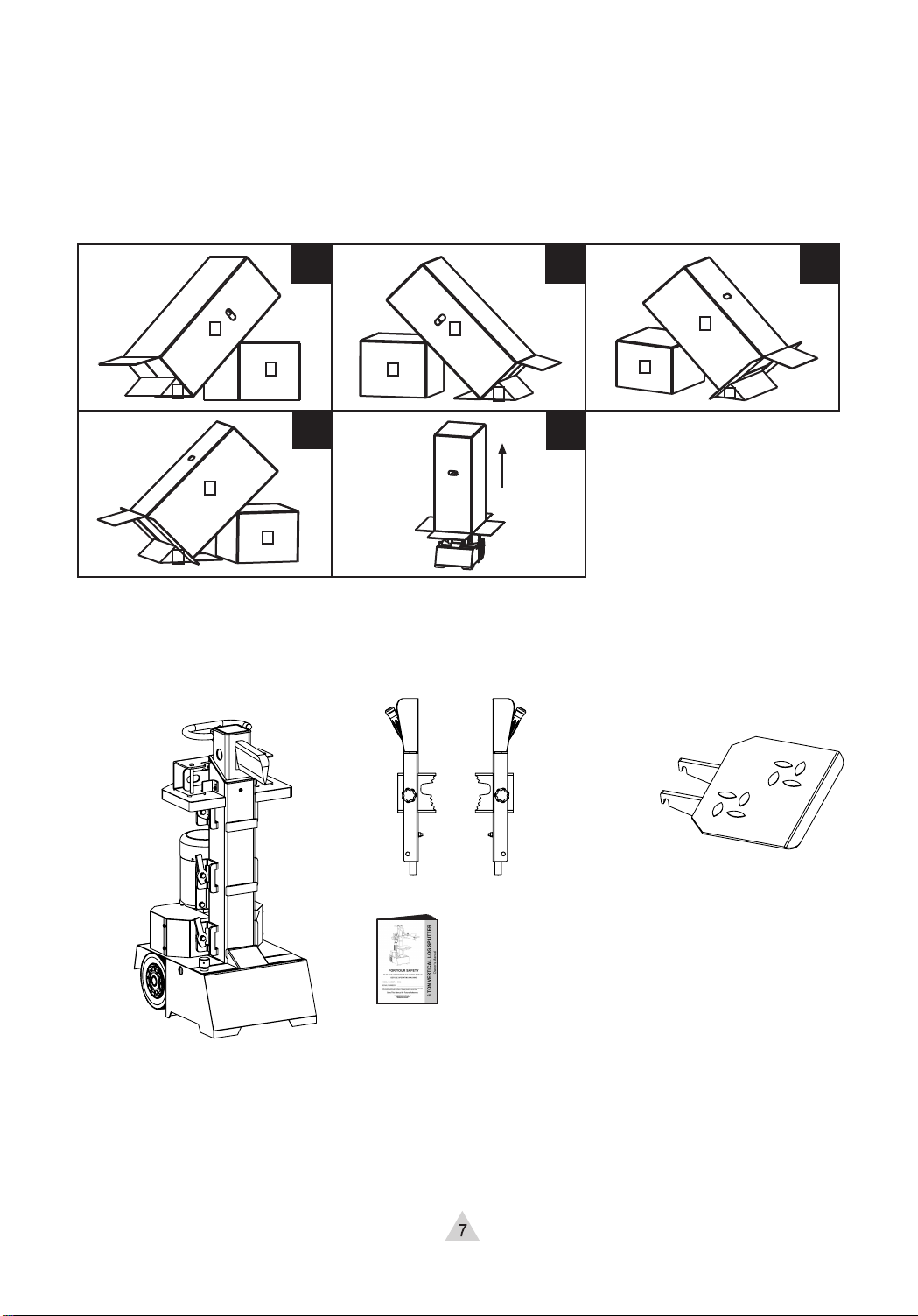

CONTENTS OF THE SHIPPING CONTAINER

A. Log Splitter Frame …………................................1 set

B. Control Lever and Guard Assy.................................2sets

C. Removable Support Table....…..............................1 pc

D. Owner’s Manual ……….....…….…........................1 pc

UNPACKING

At least 2 people required to unpack the log splitter package. Take the following steps to

put the Log Splitter on the ground by tipping every side of the carton by 45 degree. Make

sure put Block (B) to support the Log Splitter package (A) at the point a little higher than

the middle. The other side of Block (B) shall be against steady object, such as a wall.

Wedge (C) shall be arranged under the tipped Log Splitter Package (A) every step to avoid

slipping. Then remove the carton off the Log Splitter.

A

BC

D

A

B

C

A

B

C

A

B

C

A

B

C

45

3

2

1

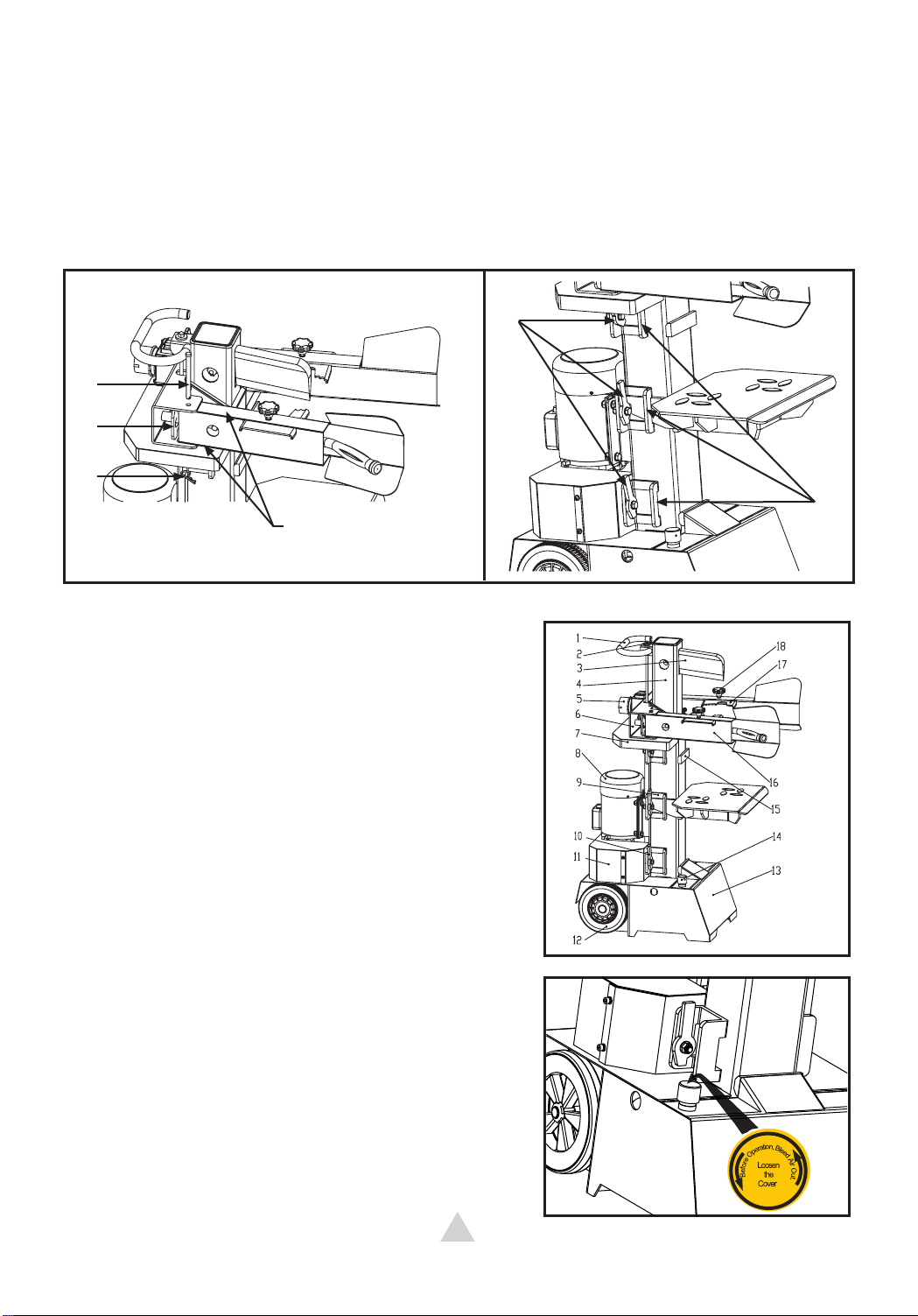

Bleed the air out of the hydraulic system before

starting the log splitter. The cover of the hydraulic

oil tank should be loosened by some rotations until

air can go in and out of the oil tank smoothly.

Air flow thru the oil tank filler should be detectable

during the operations.

Before moving the log splitter, make sure the cover

of the oil tank is tightened to avoid oil leaking from

this point.

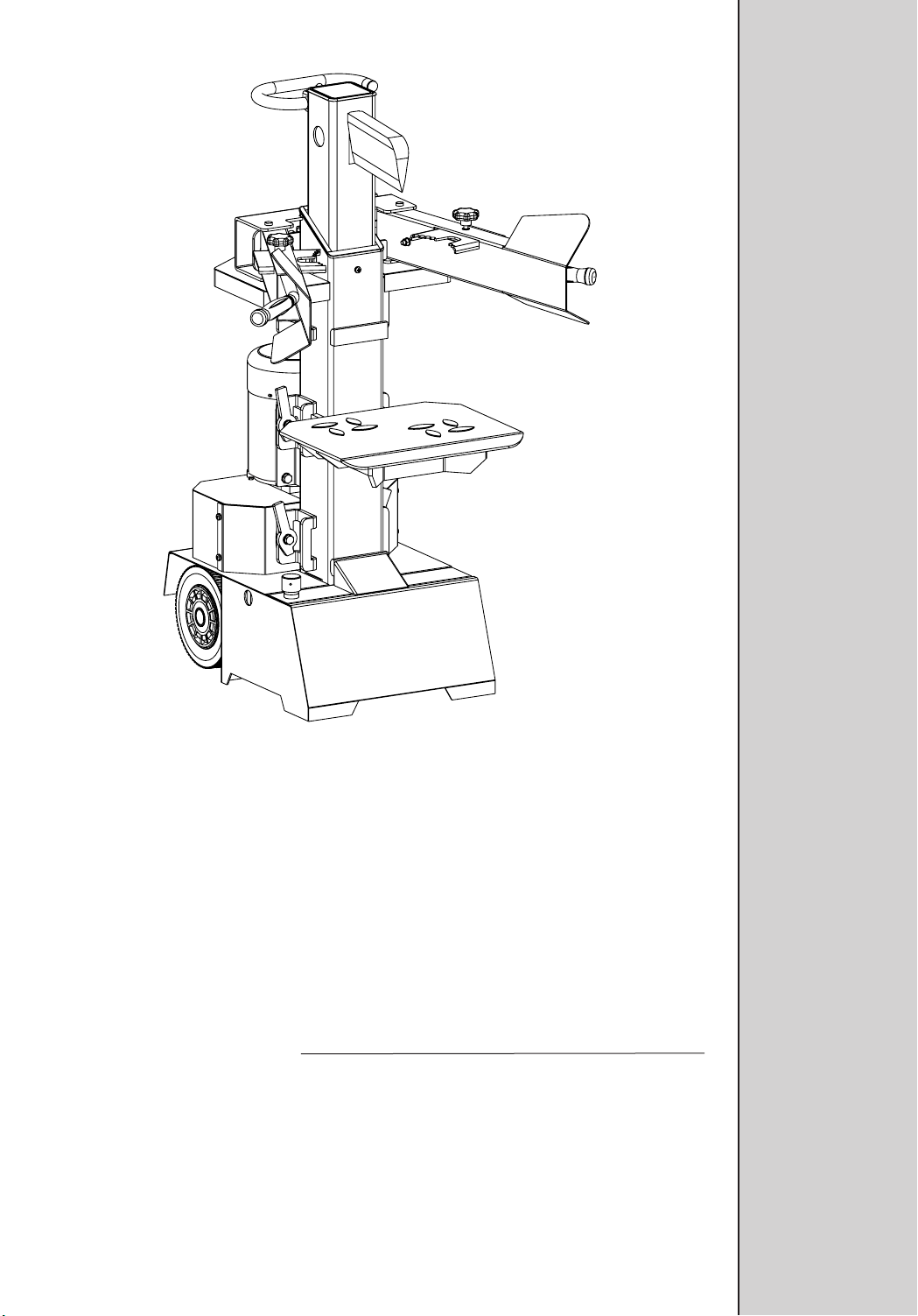

1. Transport Handle

2. Ram Travel Adjusting Rod

3. Split Wedge

4. Ram

5. Plug & switch

6. Control Levers Connection Bracket

7. Top Motor Shield

8. Motor

9. Side Bracket for Support Table

10. Table Lock Down Hook

11. Base Cover

12. Wheels

13. Base

14. Oil Tank Cover / Air Bleeder

15. Front Bracket for Support Table

16. Control Lever Guard

17. Adjustable Log Holder

18. Log Holder Adjusting Knob

8

SET UP AND PREPARATION FOR OPERATION

1. Pull Spring Pin (A) to remove the Lock Pin (B). Apply a thin coat of grease to both surfaces of the Control

Lever Guard as illustrated. Insert the Control Lever and Guard Assy and make sure the Control Lever End

goes into the slot of Connection Bracket (C). Lock the Control Lever and Guard Assy. down with the Lock

Pin (B) and Spring Pin (A). Follow the same steps to install the other Control Lever and Guard Assy on the

other side.

2. 3 installation positions available for the Support Table for different splitting length. At every installation

positions, Lock Down Hooks (D) are available. Insert the Support Table in the selected Brackets (E). Turn

the Lock Down Hooks (D) on both side by 90 degrees to lock the Support Table down.

3. Familiarize yourself with the controls and features of this log splitter in the illustrations.

A

B

C

Grease

D

E

FAILED TO LOOSEN THE OIL TANK COVER WILL KEEP THE SEALED AIR

IN HYDRAULIC SYSTEM BEING COMPRESSED AFTER BEING

DECOMPRESSED. SUCH CONTINUOUS AIR COMPRESSION AND

DECOMPRESSION WILL BLOW OUT THE SEALS OF THE HYDRAULIC

SYSTEM AND CAUSE PERMANT DAMAGE TO THE LOG SPLITTER.

DELIVERYING LOG SPLITTER TO WORK SITE

The log splitter is equipped with 2 wheels for minor moving.

To move the log splitter to the work site. Grip the handle (A)

to tilt the log splitter slightly after making sure the oil tank cover

is tightened.

LOG SPLITTER OPERATION

If using a crane, lay hoist sling around the

housing. Never try to lift the log splitter at the

Handle (A).

1. Plan your work site. Work safely and save effort by planning your work before hand. Have

your logs positioned where they can be easily reached. Have a site located to stack the

split wood or load it onto a nearby truck or other carrier.

2. Prepare the logs for splitting. This splitter accommodates logs

up to 104cm in length. When cutting up limbs and large sections,

do not cut sections any longer than 100cm. With 3 support

table positions for splitting for 52cm, 78cm 104cm in length.

Insert the support table in position nearest the log length, and

secure the support table with the locking hook.

3. To Apply a thin coat of grease to the surfaces of the ram before

operation will lengthen the durability of the ram.

Do not attempt to split green logs. Dry, seasoned

logs split much more easily, and will not jam as

frequently as green wood.

9

52cm

78cm

104cm

Grease

A

10. Adjust the Log Holders (A) according to

the diameter of the log to obtain most

comfortable Control Levers angle.

4. Route the power cord. Route the cord from the power source to the splitter in a way that

safeguards against tripping on the cord, or the cord becoming damaged during the work

session. Protect the power cord from impacts, pulling or corrosive materials.

5. Open the Air Bleed. Loosen the oil tank cover a few turns whenever the splitter being used.

Retighten this cover when you finished.

6. While operating under extremely low temperature, keep the log splitter running under no

load for 15 minutes to preheat the hydraulic oil.

7. Before initial operation, check to be sure the two-handed operation is properly functioning

by following steps:

8To set wedge ram stroke, take the following steps:

(1) Lower both control levers, splitting wedge lowers to approx 5cm above the take above

the highest table position.

(2) Release either of the levers, splitting wedge should remains in the original position.

(3) Release both levers, the ram should rise to the highest position automatically.

(1) Move splitting wedge to desired position.

The upper position of the ram wedge

travel should be about 3~5cm over the

logs to be split.

(2) Release a control lever or switch off

motor

(3) Release the Setscrew (A) with L key.

Raise Adjusting Rod (B) until Adjusting

Rod (B) is started to be stopped by the

spring inside. Tighten the Setscrew (A).

(4) Release both control levers or switch

on motor

(5) Check upper position of splitting wedge.

10

9. Place log onto splitter. Place the log onto the support table vertically and sitting flat on

the support table. Be sure the wedge and support table will contact the log squarely on

the ends. Never attempt to split a log at an angle.

Break log in the direction of its growing grain. Do not place log

across the log splitter for splitting. It may be dangerous and may

seriously damage the machine.

11. Hold the log with clamping brackets closely in the control lever guards. lower levers to

start the splitting. Releasing either lever stops the motion of the splitting wedge. Releasing

both handles to return the splitting wedge to the upper position.

12. Stack as you work. This will provide a safer work area, by keeping it uncluttered, and avoid

the danger of tripping, or damaging the power cord.

Accumulated split wood and wood chips can create a hazardous

work environment. Never continue to work in a cluttered work area

which may cause you to slip, trip or fall.

11

REPLACING HYDRAULIC OIL

The hydraulic system is a closed system with oil tank, oil pump and control valve. Check oil

level regularly with dipstick. Low oil levels can damage the oil pump. Oil Level should measure

approx. 1 ~ 2 cm lower than the upper surface of the oil tank.

The oil should be completely changed once a year.

Make sure moving parts stops and the log splitter is unplugged.

Make sure that no dirt or debris finds its way into the oil tank

Collect used oil and responsibly recycle.

Following an oil change, activate the log splitter a few times without actually splitting

Following hydraulic oils or equivalent are recommend for the log splitter’s hydraulic

transmission system:

SHELL Tellus 22

MOBIL DTE 11

ARAL Vitam GF 22

BP Energol HLP-HM 22

l

l

l

l

12

SHARPENING WEDGE

This log splitter is equipped with reinforced splitting wedge which blade is specially treated,

After long periods of operation, and when required; sharpen the wedge using a fine-toothed

file removing any burrs or flat spots on the edge.

After oil has been completely drained from the

machine, reinstall drain plug.

Add the hydraulic transmission system with

recommended oil through filler plug opening.

Use a drain pan to aid in the removal of all

used oil and particles.

Remove oil drain plug to drain oil from the

hydraulic transmission system. Examine oil

for metal chips as a precaution to future

problems.

Max.

Min. Oil level

Read dipstick to determine the maximum and minimum of the oil level.

Low oil can damage the oil pump. Overfilling can result in excessive

temperature in the hydraulic transmission system.

Oil filler plug

Oil drain plug

TROUBLE SHOOTING

WIRING DIAGRAM

13

PLUMBING DIAGRAM

PROBLEM PROBABLE CAUSE REMEDY SUGGESTED

Motor does not start

No current in the socket Check mains fuse

Electrical extension line defective Unplug, Check and replace.

Have checked by Electrician

Incorrect motor rotation

direction Incorrect connection Change pole switching device

in the plug with a screw driver

Reverse polarity by electrician.

Log Splitter does not work

while motor running

Valve is not opened owing to

the connection parts loosening Check and tighten the parts.

Switch or capacitor defective.

Log Splitter works with

abnormal vibration and

noise

Control Levers or Connection

parts bent. Repair the bent parts

Lower hydraulic oil level Check and refill hydraulic oil.

Lower hydraulic oil level Check and refill hydraulic oil.

14

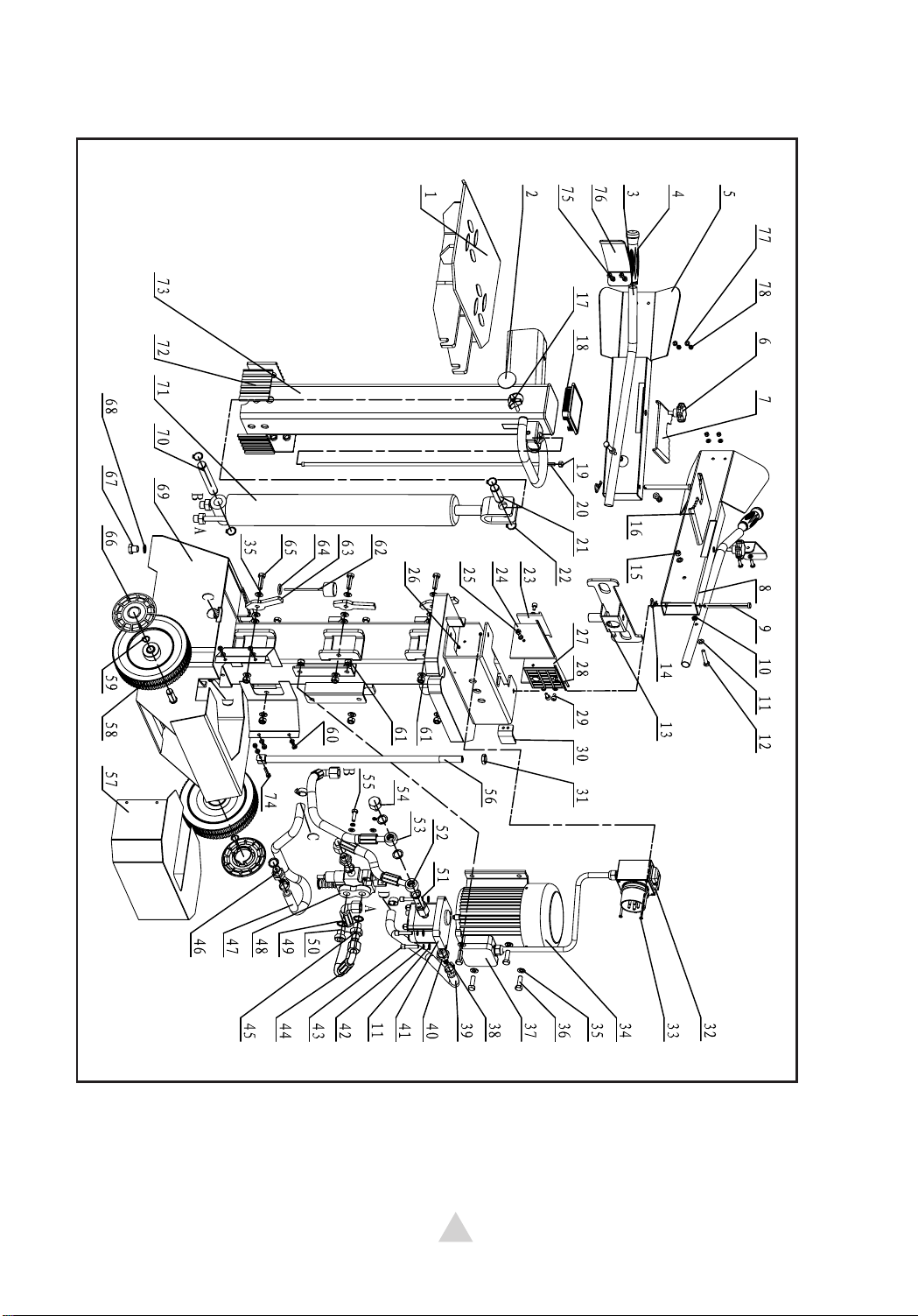

PARTS SCHEMATIC

Table of contents

Popular Log Splitter manuals by other brands

Trolla

Trolla 12232 instruction manual

Gearmore

Gearmore T34B Assembly, operating instructions and parts list

Jobsite

Jobsite CT3270 instruction manual

Palax

Palax KS 50s operating instructions

Elem Garden Technic

Elem Garden Technic FBHT65-12TCH Original instructions

Vito Agro

Vito Agro VIRLG12 instruction manual

Northern Industrial Tools

Northern Industrial Tools 1187 owner's manual

The Handy

The Handy THLS-6-PLUS Operators manual & partslist

Scheppach

Scheppach HL455 Translation of original instruction manual

Sportsman

Sportsman LS5T instruction manual

Villager

Villager PLS 10T Original instruction manual

Homelite

Homelite UT49102 Operator's manual