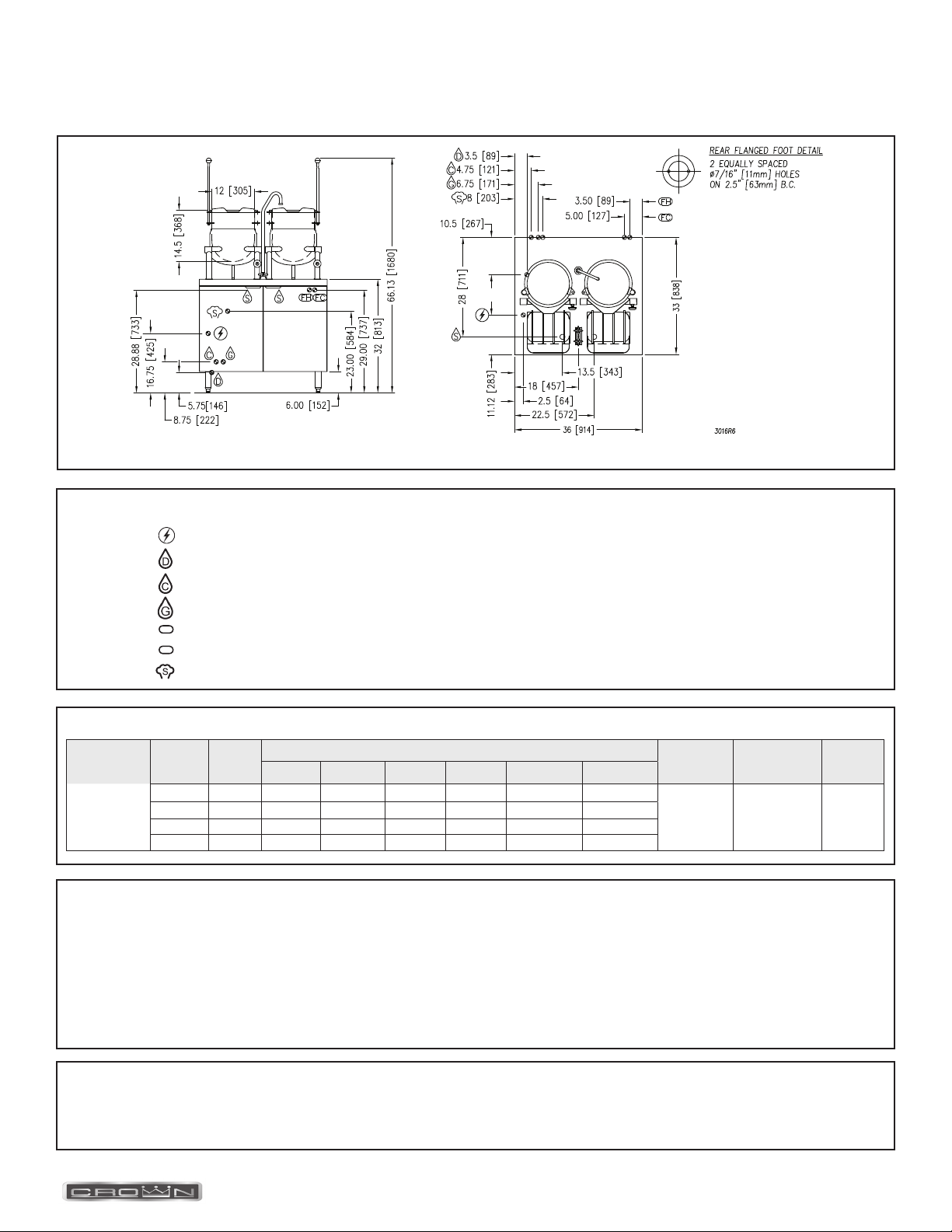

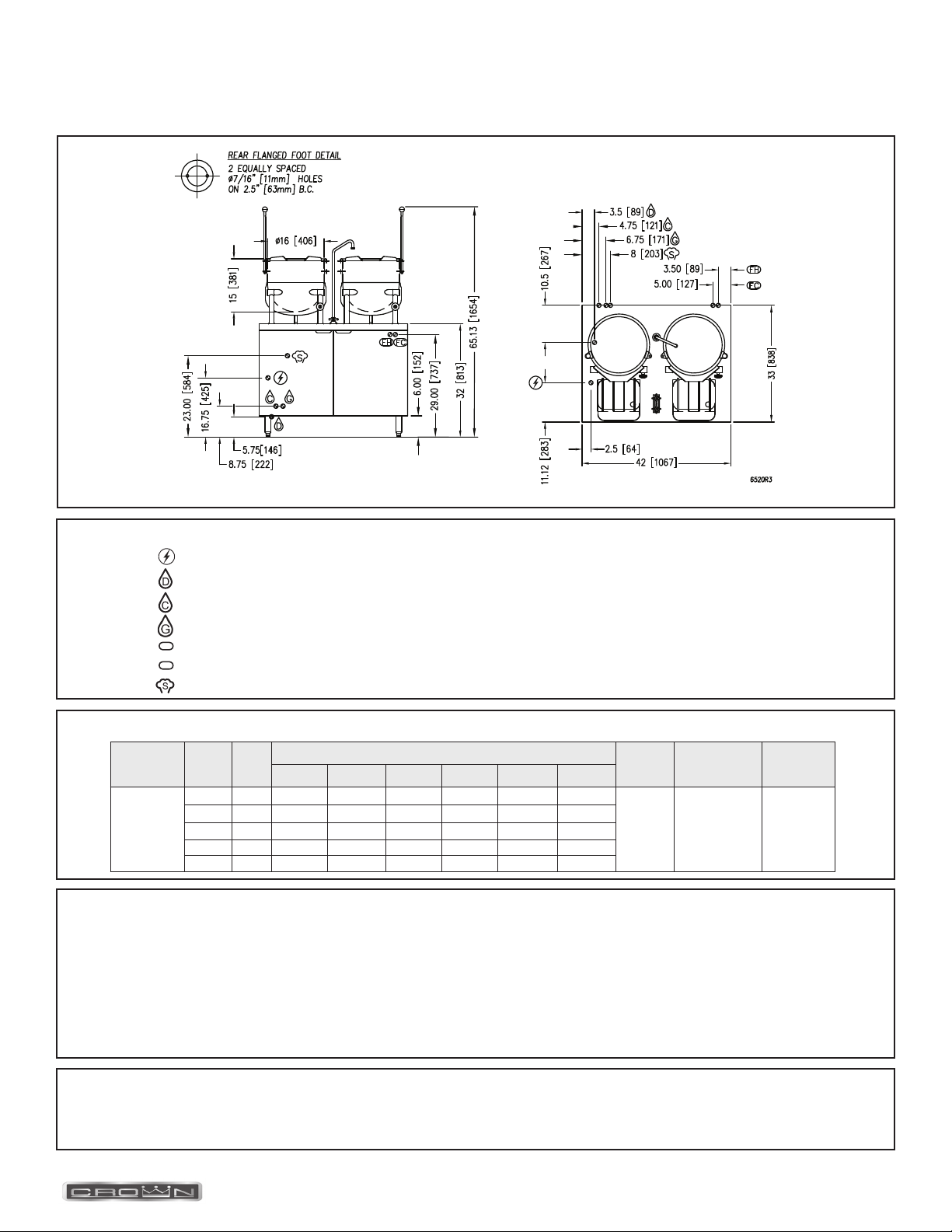

PAGE 4 OF 20 INSTALLATION & OPERATION MANUAL 10071 REV 4 (07/22)

SERVICE CONNECTIONS

DISCLAIMER

WATER QUALITY STATEMENT

............................

Total alkalinity ........................................ .........................6.8 - 7.3

.......................................................

concerning your water meeting these parameters.

*Failure or malfunction of this appliance due to poor water quality is not covered under warranty.

Reference www.crownsteamgroup.com for complete warranty details and instructions.

ELECTRICAL CHARACTERISTICS

DIMENSIONS AND SPECIFICATIONS

EMT-6 12 (305) 14.5 (368) 66.13 (1680)

3.5

(89)

10.5

(267)

8.75

(222)

5.5

(140)

7

(178)

2.5

(64)

11.12

(283)

9

(229)

12

(305)

450 lbs. [204 kg.]

EMT-10 16 (406) 15 (381) 65.13 (1654) 470 lbs. [213 kg.]

EMT-12 16 (406) 17 (432) 67.13 (1705) 479 lbs. [217 kg.]

208V 220V 240V 380V 415V 480V

EMT-6

EMT-10

EMT-12

3 24 66.6 63 57.7 36.5 33.4 28.9

3 36 99.9 94.5 86.6 54.7 50.1 43.3

3 42 116.6 110.2 101 63.8 58.4 50.5

3 48 115.5 72.9 66.8 57.7

Terry System Cartridge Changes / Installation

water supply being fed to the steamer. Failure to do so can result in component damage within the steamer which is not covered under warranty.