CRRC MS-ZD20S Manual

眉山中车紧固件科技有限公司

1

`

眉山中车紧固件科技有限公司

MEISHAN CRRC FASTENING SYSTEM CO.,LTD.

Battery Installation Tool (MS-ZD20S)

Operation&Maintenance Manual

眉山中车紧固件科技有限公司

2

Safety Operation Rules

Important! In order to ensure the operation safety and avoid any hidden danger, please obey the following

safety operation rules:

Please read this entire manual carefully. Meishan CRRC Fastening System Co., Ltd.(hereinafter referred as

Meishan) assumes no liability for any fire or severe injury caused by failing to follow the instructions provided

hereinafter or any damage or personal injury resulted from lack of maintenance or improper operation.

1. Work Site

a. Keep the tool away from flammable liquid, gas and dust.

b. Do not operate the tool around children or unauthorized personnel.

c. Keep the tool away from fire and heat sources.

2. Electrical Safety

a. Use original or approved lithium battery and charger.

b. Do not expose the electric tool to rain and wet environment.

c. When the tool is not functioning correctly, please remove the battery first.

d. The electric tool can only be repaired by qualified electric technicians. Please contact Meishan or its

authorized service center for support.

e. Properly store battery and charger while not using.

3. Personal Safety

a. Maintain focus and attention on the operation while using this tool. Do not operate the tool when you are

affected by fatigue, drug, alcohol or medical treatment.

b. Always wear safety goggles, dust mask, anti-skid shoes, safety helmet and ear protections while using the

tool.

c. Dress properly when operating the tool. Do not wear loose clothes or jewelries. Keep your hair and clothes away from the

tool’s moving parts.

d. Inspect the pin-tail collector which equipped at the rear end of tool.

e. Do not drop or abuse the tool. Reasonable care of the tools by operators is an important factor in maintaining

tool efficiency, eliminating downtime, and preventing an accident which may cause severe personal injury.

f. Remove the battery immediately when trigger cannot turn on/off the tool.

g. Remove the battery before any adjustment, accessory replacement or storage of the electric tool.

h. Keep tools away from children. People who do not understand how to operate the tool are not permitted to

use the tool.

i. Tool maintenance. Inspect the moving parts for damage and other conditions that may affect the moving of

the tool. Repair any part failure before continued use.

j. Use the proper tool, nose assembly and accessories from Meishan as needed.

4. Operation Safety of Battery Installation Tool

a. To compare with other installation tools, the battery tool is safer, and operator shall hold the battery tool stably

when it works.

b. If the battery tool is stuck, power source shall be shut down. The situation of battery tool with over-load which

causes tool stuck is forbidden.

c. To ensure the power switch in closing position before inserts the battery. The operator shall pay attention to

眉山中车紧固件科技有限公司

3

holding the battery tool or inserting the battery, if the fingers close to power switch and let it to open position, it

may cause accident.

d. Don’t open battery, otherwise it will cause danger of short circuit. Keep the battery away from heat sources

(such as long-term solar radiation) and fire sources, if the battery closes to heat sources or fire sources, it will

explode.

e. If the battery is broken or used improperly, there will be toxic smoke, if it occurs, the injured shall take fresh

air and be hospitalized immediately.

f. If the battery is defective, it will emit fluid which contaminates nearby objects. Please check the affected part,

and clean or replace the battery if necessary.

Operation Rules of Battery Tool

5. Operation Notices of Battery Tool

a)The situation of battery tool with over-load which causes tool stuck is forbidden. Please select the proper

model of battery tool before operation.

b)The operator shall comply with the safety operation rules, if find damage on insulation wire, plug or others,

the operator shall stop using the battery tool.

c)Don’t use battery tool which has defective power switch. The defective tool shall be repaired before operation

d)Before adjusting, the operator shall remove the plug and battery from socket and take out the battery pack

from the tool, and then replaces accessories.

e)When operator does not use battery tool, the battery tool shall be placed far away from children. For people

who are not familiar with the battery tool or don’t read operation manual are not allow to operate. The

operator shall pay attention to regular maintenance of battery tool and carefully check whether the operation

pars are in good working condition, and simultaneously detect whether there are damaged parts or parts that

may affect the operation of the battery tool.

f)After riveting about 100 rivets, the exterior sleeve of battery tool shall be disassembled to clean metal debris,

it can improve improve the service life of the battery tool.

g)It is normal that the surface temperature of the battery tool will be higher while it’s continuously working, and

the sound of internal gear will be slightly louder. We hereby suggest that the operator should stop the battery

tool for 10~15 minutes after it’s continuously working for 30 minutes, and then operates it again, so that the

service life of the battery tool will be greatly improved.

6. Operation Notices of Battery

a)The operator shall use the matched charger supplied by the battery manufacturer to charge the battery.

b)The battery installation tool only accepts the matched battery. If it adopts other types of batteries, it may cause

blaze or people injured.

c)For the battery which doesn’t use, the operator shall place it far away from clip, coin, nail, screw and other

small metal objects. If the battery contacts are short-circuited, it will cause blaze or people injured.

d)The operator shall avoid contacting with the liquid leaking from the battery due to improper operation,

because the leakage will burn the skin, in case the body contacts with battery fluid, washing immediately with

water.

眉山中车紧固件科技有限公司

4

Specification

Charger/Battery Pack

Operation Instructions

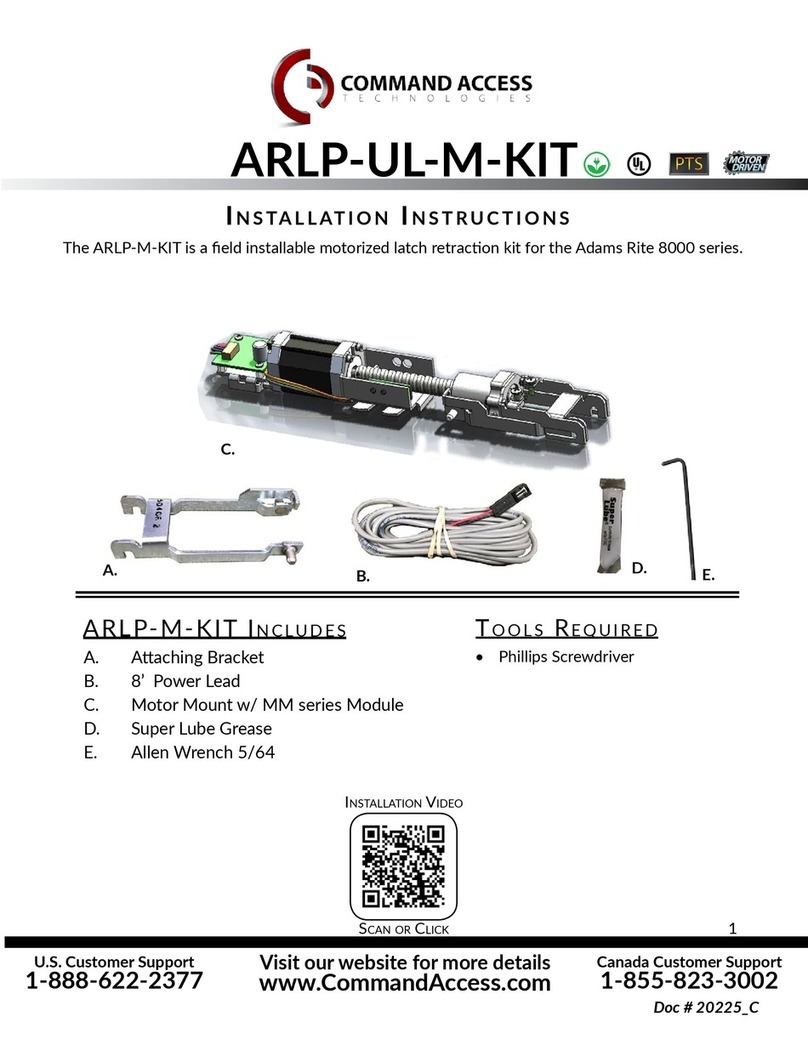

Parts Description

(A)Jaw (G)Fault indicator

(B)Anvil (H)Trigger

(C) Limit sleeve (I)Indicator

(D) Adjusting sleeve (J)Locking press-button of battery

(E) Limit fixing sleeve (K)Battery pack

(F)Peg

Rechargeable Battery

Note: When you receive the product, the battery has been partially charged.

The battery shall be fully charged before the first use. Please pay attention to the indicator on the charger (red

indicates charging and green indicates full).

Lithium-ion battery can be recharged at any time, which will not affect its service life. Interrupting the charging

will not damage the battery.

The battery is equipped with temperature monitoring system. The battery can only be recharged between 0℃ and

45℃.

Battery Pack

·Nominal voltage: 18 V

·Capacity: Lithium-ion battery 4.0 Ah (five packs)

·Weight: 0.47 kg

·With battery indicator

·With function of overload protection

Charger

·Input voltage: 100-240V AC / 50-60 Hz

·Output voltage: 21 V

·Output current: 8 A

·Charging time: 50 mins

·Weight: 0.8 kg

MS-ZD20S Battery Installation Tool

·Application: Monotail

·Body weight: 1.8 kg (not include battery)

·Circle: 1.2 S

·Working pull: 20000 N

·Rivet stroke: 23 mm

·Motor: 18V DC motor

·Battery: 18V DC 5.0 Ah

眉山中车紧固件科技有限公司

5

Battery Installation and Removal

The battery is equipped with the locking press-button.

Inserting the battery into battery tool and pressing the locking press-button until it’s firmly locked.

Pressing down the locking press-button to remove the battery from battery tool. Do not remove battery directly

and hard.

Working Mode

·The battery tool has function of overload protection, for example, if there’s overload situation the rivet process

will stop immediately and fault indicator will demonstrate red light. In above case, please remove and re-insert the

battery and press switch to let jaw back to original position.

·The control device can indicate block when it returns (for example, any debris, dirt, etc., existed in steel metal).

Meantime, the battery tool will stop working and back to end place. The fault indicator will demonstrate red light.

The operator can detect fault before removes the battery, then re-inserts the battery to actuate battery tool.

·The indicator will be actuated when the riveting starts. The indicator will be stopped, if there’s no operation in

30s.

Disassembly of Jaw and Anvil

A.(a)Fixing sleeve (b)Limit fixing sleeve (c)Adjusting sleeve (d)Limit sleeve (e)Anvil(f)Snap

ring (g)Jaw

B. Loosening and disassembling the anvil (e) from limit sleeve (d) by wrench with counterclockwise rotation.

C. Loosening and disassembling the limit fixing sleeve (b) and fixing sleeve (a) in sequence from machine by

wrench with counterclockwise rotation.

D. One hand presses snap ring (f) along the direction of arrow and the other rotates the jaw (g) along

counterclockwise direction to loosen and disassemble.

Note: All parts are disassembled by rotating along counterclockwise direction.

眉山中车紧固件科技有限公司

6

Jaw Assembly

A.(h)Connecting shaft (f)Snap ring (g)Jaw

B. To rotate the jaw (g) which needs to be replaced into thread of connecting shaft (h) along clockwise direction,

and let the end face of jaw (g) fully fit with front step surface of connecting shaft (h).

C. To check whether the concave of jaw (g) is stuck with tap of snap ring (f), if it occurs, rotating the jaw (g) to

adjust.

Note: In the premise of the stuck situation, the clearance between the end face of jaw and front step surface

of connecting shaft shall be the minimum value (to the best of tightening).

Anvil Assembly

A.(d)Limit sleeve (e)Anvil

B. To rotate the anvil (e) which needs to be replaced into thread of limit sleeve (d) along clockwise direction, and

tighten the anvil on the limit sleeve by wrench.

Note: Tightening the anvil on the limit sleeve and there shall be no clearance between two components by

visual check.

眉山中车紧固件科技有限公司

7

Tool Nose Assembly

A.(b)Limit fixing sleeve(a)Fixing sleeve(d)Limit sleeve(i)Connecting shaft(c)Adjusting sleeve

B. The nose assembly equipped with anvil shall be installed on the tool which has been equipped with jaw, the operator shall pay

attention to the connection between limit sleeve (d) and connecting shaft (i), then, put the fixing sleeve (a) into adjusting sleeve (c)

and tighten by wrench. The limit fixing sleeve (b) shall be installed on the nose assembly after the grip range is successfully

adjusted.

Adjusting Rules

A. (a)Fixing sleeve(b)Limit fixing sleeve(c)Adjusting sleeve (d) Limit sleeve

B. To refer the following picture: The scale value (0-4) on limit sleeve (d) represents the grip range (adjusting to

No.2 scale value means the grip range is 2mm). The operations are as follows: The limit fixing sleeve (b) shall be

rotated along anticlockwise direction and the adjusting sleeve (c) shall be rotated along clockwise direction and

limit sleeve (d) will move inward (the scale value will be changed gradually from 0 to 4, on the contrary, if the

adjusting sleeve is rotated along counterclockwise direction, the value will be changed gradually from high to

low). After the scale is confirmed, the limit fixing sleeve (b) shall be rotated along anticlockwise direction to

connect firmly with fixing sleeve (a), and the grip range can not be changed when tightening.

Note: The grip range is from 0 to 5mm (carrying out the riveting operation only within the adjusting range

from 0 to 5mm), if the operation exceeds the grip range, the tool will be damaged. Therefore, please do not

exceed the allowable grip range and do not press the tool switch to adjust the grip range!

眉山中车紧固件科技有限公司

8

Optimization of The Battery

·The battery shall not be affected with damp or water. The battery can only be placed in environment with

temperature from 0℃-45℃.

·Do not leave the battery in the car, especially in summer.

·Lithium ion battery: Do not dispose of waste batteries in the same way as household waste. Do not throw

batteries into water or fire. The batteries shall be collected, recycled or disposed in environmentally friendly way.

Maintenance

·Keep the battery tool and ventilation slot clean to ensure the safety operation.

·If the battery tool has fault, it should be returned to the original factory for repairing.

·In order to ensure the battery tool can be used safely, only professionals are allowed to repair battery tool and

only original spare parts can be used.

眉山中车紧固件科技有限公司

9

MEISHAN CRRC FASTENING SYSTEM CO.,LTD.

Add:#821, 2nd Rd of Sci-tech Zone, Dongpo district, Meishan City, Sichuan Province, China

Tel:0086 185 8383 5723 0086 28 38283773

Fax:0086 28 38164262

Other CRRC Tools manuals