CRRC MS-ZD20 User manual

Instruction Manual

Electric

Installation

Tool

MS-ZD20

long service life

light weight

fast installation

low noise

electric driven

Meishan CRRC Fastening System Co., Ltd.

Work with You to Connect the World

Contents

1. Safe.................................................................................................................................................. 1

1.1 Work Site................................................................................................................................... 1

1.2 Electrical safety..........................................................................................................................1

1.3 Personal Safety.......................................................................................................................... 1

1.4 Maintenance Safety...................................................................................................................2

1.5 Specific Safety Rules.................................................................................................................. 2

2. Product data.................................................................................................................................... 3

2.1 Specification.............................................................................................................................. 3

2.2 Overall Dimensions....................................................................................................................4

3. Operation.........................................................................................................................................5

3.1 Before Startup........................................................................................................................... 5

3.2 Assembly of Electric Tool...........................................................................................................5

3.3 Standard of Riveting.................................................................................................................. 6

3.4 Sequence of Installation............................................................................................................6

3.5 Typical incorrect operation....................................................................................................... 7

4.1 Caution...................................................................................................................................... 8

4.2 Product Service Kit and Performance....................................................................................... 8

4.3 Replacement of Nose Assembly................................................................................................8

4.4 Replacement of Battery............................................................................................................ 8

4.5 Replacement of Other Components......................................................................................... 9

4.6 Recycle of Battery and Tool.......................................................................................................9

5. Troubleshooting Guidance............................................................................................................ 10

1

1. Safe

Please read all this manual carefully. Meishan CRRC Fastening System Co.,

Ltd.(hereinafter referred as Meishan) assumes no liability for any fire or severe injury

caused by failing to follow the instructions provided hereinafter or any damage or

personal injury resulted from lack of maintenance or improper operation.

Do not rip off the warning signs, labels or decals. In case of any problem or

concern, please contact Meishan for further instructions.

1.1 Work Site

a. Keep the tool away from inflammables such as flammable liquid, gas or dust.

b. Use the tool after children and observers leave the site.

c. Keep the tool away from fire or heat source.

1.2 Electrical safety

a. Use original or genuine lithium battery or charger.

b. Do not expose the electric tool to rain or wet environment.

c. When the tool is in fault, please remove the battery firstly.

d. The electric tool can only be repaired by qualified electric technicians. Please

contact Meishan or its authorized service center for support.

e. Properly store battery and charger while not using.

1.3 Personal Safety

a. Keep focusing on operation while using tool. Do not use tool when affected by

fatigue, drug, alcohol or medical treatment.

b. Always wear safety goggles, dust mask, anti-skid shoes, safety helmet and ear

protections while using tool.

c. Dress properly. Do not wear loose clothes or jewelries. Keep your hair and

clothes away from tool’s moving parts.

d. Inspect the pintail collector which equipped at the rear end of tool.

e. Do not abuse the tool. Reasonable care of tools by operators is an important

factor in maintaining tool efficiency, eliminating downtime, and in preventing an

2

accident which may cause severe personal injury.

f. Remove the battery immediately when trigger cannot turn on/off the tool.

g. Remove the battery before any adjustment, accessory replacement or storage of

the electric tool.

h. Keep tools away from child. People who do not understand tool is not allowed to

use the tool.

i. Tool maintenance. Inspect the moving parts for damage and other conditions

that may affect the moving of the tool. Repair any fail before use.

j. Use proper tool, nose assembly and accessories as needed.

1.4 Maintenance Safety

a. Send tool to professional repairman for repair.

b. Follow this manual for replacement of components.

c. Keep tool dry, clean and grease-free.

d. Replace worn or damaged parts by genuine products from Meishan.

1.5 Specific Safety Rules

Repairman and Operator must read manual prior to using equipment and

understand any Warning and Caution stickers/labels supplied with equipment before

connecting equipment to any primary power supply. As applicable, each of the

sections in this manual have specific safety and other information.

a. Ear protection required.

b. Inspect the collect assembly for wear, crack or damage before use.

c. Please hold the tool firmly.

d. Please always hold a good balance on feet. When operate at height, make sure

no one stays beneath.

e. Use proper nose assembly for different type of rivets.

f. Do not keep the tool continuously running for 10min, otherwise, have a break

for 3 min after using for 10 min.

3

2. Product data

Independently developed by Meishan, The electric tool MS-ZD20 is able to

install 2.4-6.4mm rivets. It provides ideal, convenient and effective installation. The

battery is able to stall at least 500 pieces of rivets.

2.1 Specification

P.N. of Tool

MS-BT20

Motor

18 V, DC motor

Operating temp. range

°C

0-60

Noise

dBA

78.8±3

Max. Vibration

m/s²

2.5

Weight of Tool

kg

2.25

Effective Displacement

mm

20

Riveting Pressure

kN

20

Standards

EN 2006/42/EG

Specifications of battery and charger:

Product

Battery

Charger

Rated Vol.

V

18

Input Vol.

V

100-240

Output Vol.

V

18.0

Operating temp. range

℃

0-60

0-60

Max. Current

A

15

Weight

kg

0.38

0.37

Brand

Milwaukee

Milwaukee

Standard of Socket

CE/ECM/UL/ETL/CB/SAA

4

2.2 Overall Dimensions

Overall dimensions of MS-ZD series products:

Com

pone

nt

Dime

nsion

mm

A

290

B

300

C

56

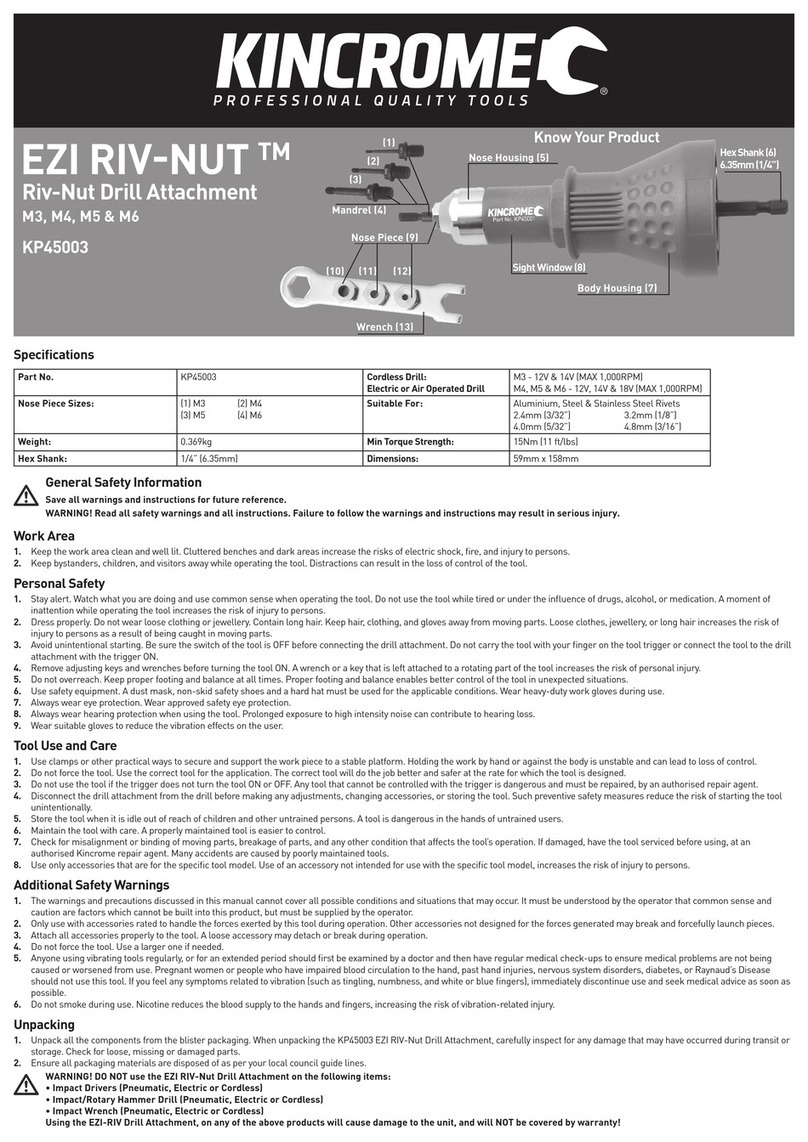

2.3 Product Structure and Nomenclature

MS-ZD20 electric riveting tool

1. Anvil (nose assembly)

2. Jaw (nose assembly)

3. Anvil socket (nose

assembly)

4. Collect Assembly (nose

assembly)

5. Sensor (nose assembly)

6. Nut sleeve (nose assembly)

7. Cylinder

8. Pintail collector

9: Lamp

10: Trigger

11: Power indicator

12: Lithium battery

13: LCD display

5

3. Operation

3.1 Before Startup

a. Inspect the connection of moving parts.

b. Inspect the connection of pintail collector.

c. Inspect the battery.

3.2 Assembly of Electric Tool

STEP1: Thread the nut sleeve into front of cylinder until the end.

STEP2: Push the sensor to cylinder; thread the nut sleeve at anti-clockwise to

sensor; tighten 4 set screws from nut sleeve to sensor.

STEP3: Thread collect assembly into cylinder.

STEP4: Thread anvil socket into collect assembly.

STEP5: Insert jaw into anvil, then thread jaw into sensor and anvil socket.

STEP6: Install pintail collector to rear of cylinder.

STEP7: Install battery.

STEP8: Adjust the riveting force: Set the riveting force to 5 kN by the buttons

under the LCD display, and then lock down the force.

Notes of Reset/lamp switch:

a. the lamp can be turned on only when force is locked;

b. Depress the Reset/lamp switch for 3 to 5 seconds to reset the tool.

Lock

Up

Down

Reset/lamp switch

6

3.3 Standard of Riveting

Standard of installed rivet: completely deformed collar and complete pintail.

Qualified

Unqualified

Unqualified

3.4 Sequence of Installation

a. Thread the collar until the pintail fully exposed.

b. Insert the tool, and make sure the jaw catch on proper area of pintail.

c. Depress the trigger to swage collar.

d. Release the trigger until collar fully swaged.

7

3.5 Typical incorrect operation

Standard operation is required to avoid any accident. Please follow the figure

below, otherwise, the incorrect operation shown below may lead to fail of

installation, damage to tool’s moving parts, even personal injury.

Incorrect operation (Jaw catch on

incorrect area)

Correct operation

8

4. Maintenance

4.1 Caution

a. Remove the battery before inspection or maintenance.

b. Do not use gasoline, benzene, diluent, alcohol or similar substances to clean

tool. Otherwise, it may cause the tool to change color, deform or crack.

c. Contact Meishan or its authorized service center for tool’s repair and

maintenance.

4.2 Product Service Kit and Performance

S/N

Description

Drawing No.

Service Life

Remarks

1

Anvil

MS-7922-01

20000 times

Consumables

2

Jaw

MS-7922-02

10000 times

3

Anvil socket

MS-ZD-01

20000 times

4

Collect Assembly

MS-ZD-02

20000 times

Optional

configuration

5

Sensor

MS-ZD-03

Inspect every

1 or 2 years

6

Nut sleeve

MS-ZD-04

20000 times

4.3 Replacement of Nose Assembly

The nose assembly is moving and consumable part. See Clause 2.3 for detailed

structure.

For replacement of other parts, see Clause 3.2 and disassemble the nose

assembly in opposite order.

4.4 Replacement of Battery

Milwaukee quick charge lithium battery (M18) is adopted. If battery failed,

contact Meishan or Milwaukee to purchase the same one.

9

4.5 Replacement of Other Components

In case of any damage to other parts and components, please contact the client

service center of Meishan CRRC Fastening System Co., Ltd. We will always be at your

service 24 hours a day.

4.6 Recycle of Battery and Tool

Do not abandon the used battery, Meishan will provide discount on next purchasing

if user return the used battery or tool.

Except the battery, all other components are of specific parts to the tool. Please

contact Meishan for more support.

10

5. Troubleshooting Guidance

Problem

Cause

Solution

Tool fails to

operate when

trigger is

pressed.

Battery run out.

Charge the battery.

No battery equipped.

Or improper equipped battery.

Re-install the battery.

The battery is damaged.

Replace the battery.

Overheat of battery.

Turn off tool and use it latter

Nose fails to

return

completely

when trigger

released

Electrical failure

Re-install the battery and restart

the program.

Stuck clutch.

Clean and lubricate the clutch

and shaft.

Jaw gets stuck in anvil by

improper operation (as shown

in clause 3.5)

Break the pintail by force,

disassemble the nose assembly,

then remove the broken pintail.

Scored or excessive worn anvil

Replace the anvil.

Foreign matters in jaw and

anvil

Repair and clean the jaw, anvil

and other components.

The pintail

cannot be

caught by the

jaw properly as

indicated in 3.5

Jaw has been threaded too

much into tool; or anvil has

not been completely

threaded.

Thread and adjust the jaw

and/or anvil.

11

Pintail broken.

Excessive high force of tool;

Adjust the force

Deformed jaw;

Replace the jaw

Improper operation.

Correctly operate

Tool stops in

advance

Overheat of battery.

Turn off tool and use it latter

Improper anvil equipped

Replace the anvil

Lower force or travel than

needs

Set the correct force or travel.

Note: In case of any unsolvable problems, please disconnect the power supply of

tool immediately and consult the technicians of Meishan.

Table of contents

Other CRRC Tools manuals