Crye Precision AIRFRAME User manual

AIRFRAME™HELMET OPERATOR’S MANUAL

This manual must be carefully read by all persons who have or will have the

responsibility for using or maintaining this product.

Any warranties made by Crye Precision LLC with respect to this product are voided if the

product is not used and maintained in accordance with the instructions in this manual. For any

questions relative to the use or repair of this product, please write Crye Precision LLC or call

1-718-246-3838 during regular business hours.

• This product contains integrated ballistic

resistant regions.

• This product is designed to protect the wearer

only against the ballistic threat level stated in

the Product manual. It is not intended to protect

against rie re or sharp edged or pointed

instruments unless specied on the armor.

• Ballistic resistant regions are not intended to

protect the wearer from projectiles that hit

less than 1 inch from any edge of the ballistic

resistant regions.

• Exposure of the internal ballistic materials to

water, chemicals, or sunlight will reduce the

effectiveness of the armor.

• This armor is not ame resistant unless specied

elsewhere in this manual.

• Product that shows no signs of damage must be

replaced 5 years from date of purchase.

• Perform periodic inspections of the ballistic

resistant regions of the armor. Discontinue use

of damaged product immediately.

• DO NOT machine wash or dry clean the product.

Exposure to detergents, bleach, or solvents

may result in degradation and reduce the

effectiveness of the product.

• Inspect the product for discoloration, cuts, tears,

abrasions or cracks before and after each use.

• DO NOT alter the product in any way.

• DO NOT expose the product to open ame or

excessive heat.

• All replacement parts must be acquired from

Crye Precision LLC or a licensed distributor.

• The most current version of this manual may be

found at www.cryeprecision.com.

• DO NOT use this product except in its intended

manner.

The following are general safety warnings intended to call attention to fundamental performance

limitations and areas of the product where proper usage must be followed. Failure to use and maintain

the product according to the instructions and warnings contained herein may result in the product

failing to perform as designed, and/or the persons relying on this product sustaining serious personal

injury and/or death.

EQUIPMENT INFORMATION

01 INTRODUCTION

02 COMPONENT DESCRIPTIONS

OPERATOR INSTRUCTIONS

03 NVG MOUNTING OPTIONS

04 SHELL SIZING

05 PAD PLACEMENT

06 DONNING

07 FIT ADJUSTMENT

08 CLEANING INSTRUCTIONS

08 PREVENTIVE MAINTENANCE CHECKLIST

09 REASSEMBLY

11 SERIAL NUMBERS

CONTENTS

1AIRFRAME™HELMET

INTRODUCTION

The AirFrame™ ballistic helmet sets new standards in protection, comfort, and modularity.

Complete AirFrame™ helmets weigh less than complete ACH 2002 helmets while providing

more coverage area. The AirFrame™ was developed with a mandate to dramatically reduce

headborne weight while exceeding common frag threats. A complete medium AirFrame™

helmet weighs only 2.30 lbs., and the large weighs a mere 2.55 lbs. The unique

overlapping shell design of the AirFrame™ creates an integrated vent that provides passive

cooling and can reduce the damaging effects of explosive blast waves. Each AirFrame™

helmet features an OpsCore®H-Nape Head-Loc™ retention system for unmatched stability,

comfort, and ease of adjustment. Up-armoring the AirFrame™ with ballistic ear or face

protection is simple and fast. All helmets and components are compatible with common ear

pro systems like PELTORS®and SORDINS®. Made in the US from US materials.

FEATURES

Revolutionary vented shell design for passive cooling

Covers more of wearer’s nape than traditional designs

Modular ear and face protection available

Modular ARC-Rail™ system available (O² compatible)

Contain 3/4” pads

Can be pre-drilled at factory for 3-hole or 4-hole NVG mounts (conguration compatible

with OpsCore®and Wilcox®3-hole mounts)

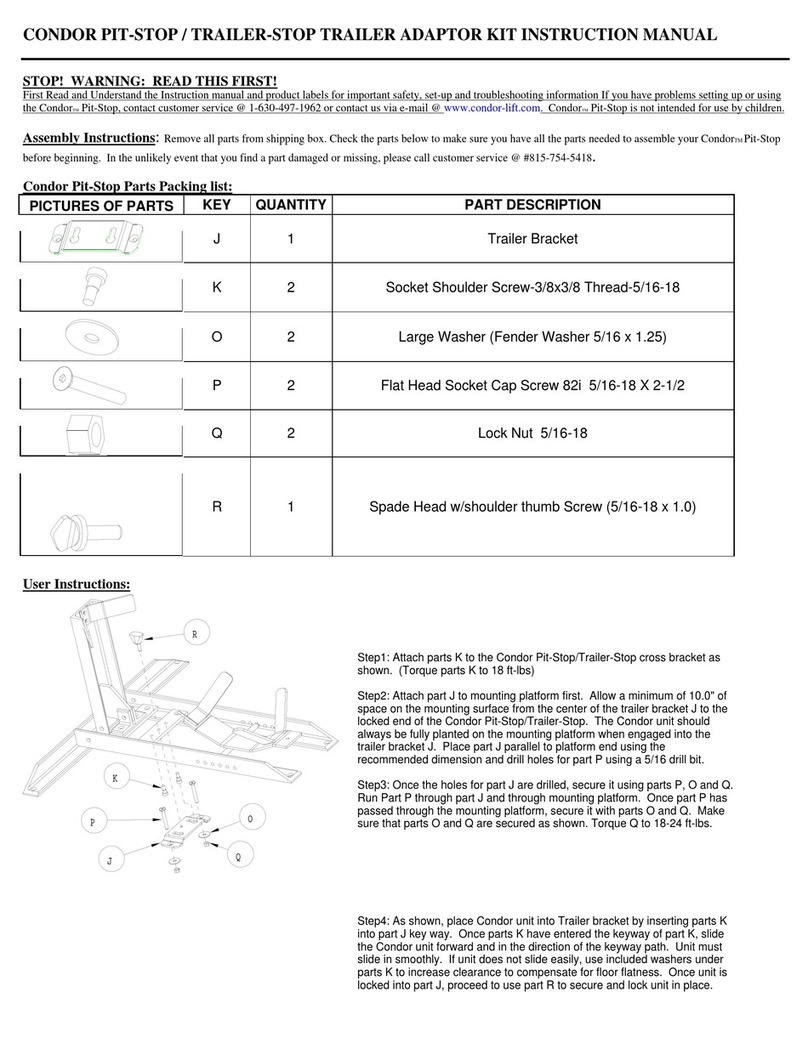

2EQUIPMENT INFORMATION

COMPONENT DESCRIPTIONS

HELMET STRAP9

SMALL T-NUT (x4)

5

FRONT SHELL

1

TRAPEZOIDAL HIT PADS (x2)11

HELMET STRAP BOLTS (x4)

7

SHELL SCREW SHORT (x2)3

MD (x6)

LG (x7)

xL (x 8)

OBLONG PADS10

NYLON INSERT (x2)

6

REAR SHELL

2

LARGE T-NUT (x4)8

SHELL SCREW LONG (x2)4

(IMAGES NOT TO SCALE)

3AIRFRAME™HELMET

NVG MOUNTING OPTIONS

AirFrame™helmets can be ordered with pre-drilled mounting holes for standard 3 or 4 hole night vision mounts. This must be specied at

the time of order.

Standard 3-hole conguration for night vision mounts

Standard 4-hole conguration for night vision mounts

3-hole night vision mount installed

4-hole night vision mount installed

A

D

B

C

4OPERATOR INSTRUCTIONS

SHELL SIZING

Follow the instructions below in order to ensure a correct shell size selection. Select helmet

size based on head circumference. If a measurement falls directly between two sizes, select

the larger size. See note at bottom of page for exceptions. When possible, try on an actual

helmet and let pads adjust for ve minutes to choose size that ts best.

*Note: Pads affect sizing—if using an alternative pad set, try helmet on to choose best size.

MEASURING HEAD CIRCUMFERENCE

Sit straight with head level. Wrap a vinyl tape measure around your head. Start just above

eyebrow ridges and wrap around widest part of the head as shown in the diagram. Pull the

tape measure tight and record the measurement. Use the table below to determine the

correct helmet size.

NOTE: HEAD SHAPES DIFFER

Users on the threshold of two sizes, but with a narrower head (6” width and below), may be

able to t into the smaller sized shell, where users with a wider head (over 6” width) should

move to the larger size.

MEDIUM

20½”–22½”

LARGE

22½”–24½”

X-LARGE

>24½”

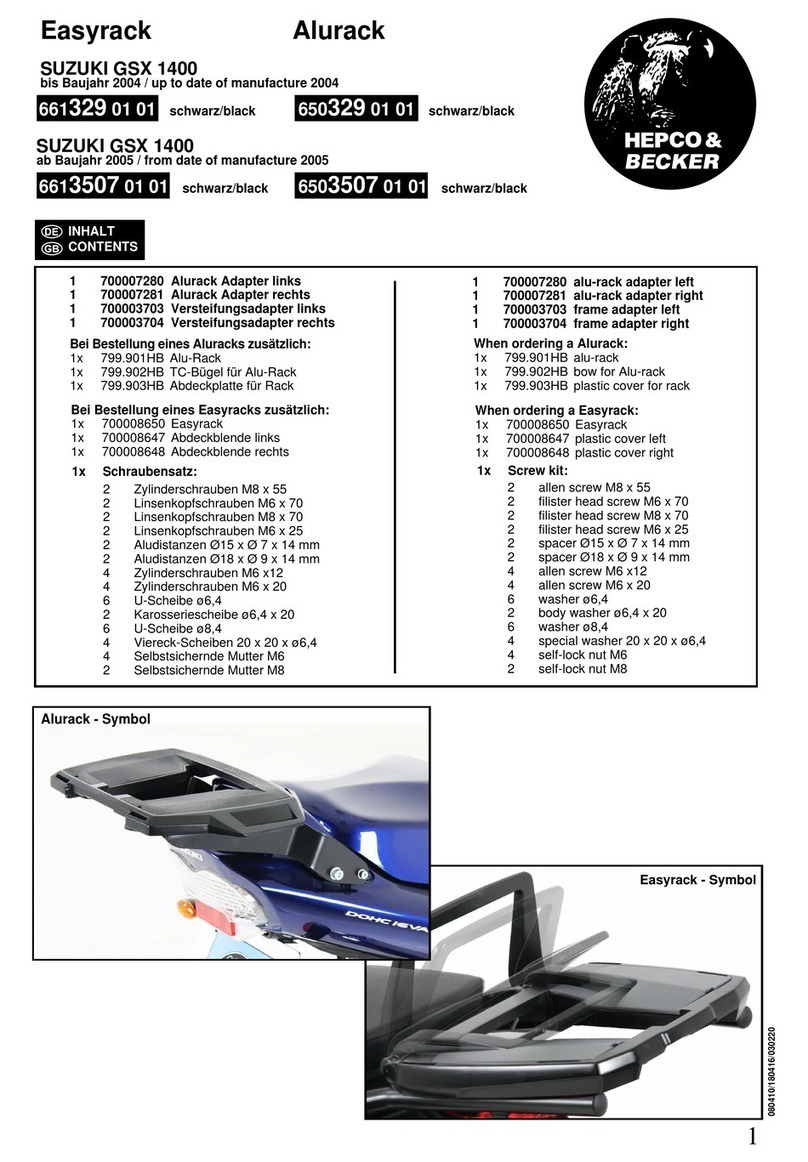

5AIRFRAME™HELMET

PAD PLACEMENT

Standard AirFrame™pad placement is shown below. The number of oblong pads varies with helmet size. MEDIUM helmets require 6 oblong

pads, LARGE helmets require 7 oblong pads, and EXTRA LARGE helmets require 8 oblong pads. All helmets require two trapezoidal pads.

EXTRA LARGELARGE

FRONT OF HELMET

BACK OF HELMET

MEDIUM

Pad placement is designed to offer optimal protection and comfort. It is critical that pads are placed as shown in the below diagrams and that

the pads nearest chinstrap hardware mounting points are situated to overlap said hardware—failure to do so may result in injury or death.

A B

6OPERATOR INSTRUCTIONS

*Straps may need to be retightened after a few minutes of wear as helmet pads can soften.

Don helmet and ensure that nape pad is

positioned correctly.

Buckle chin strap.

Pull the front and rear strap adjusters

until snug.

Ensure chinstrap is unbuckled and all

straps are loosened.

The nape pad can be tightened by pulling

on nape adjuster. The nape pad adds

additional stability to the helmet, which

can be useful when wearing NVGs.

DONNING

1

4

2

5

3

7AIRFRAME™HELMET

FIT ADJUSTMENT

HELMET IS TOO LOOSE OR TOO LOW

If helmet is too low on brow, helmet is not compatible with eyewear,

or has other similar compatibility issues, it may be too loose.

Increase the number of pads in shell (additional pads can be

purchased separately)

If additional pads do not correct fit, a smaller helmet shell may

be required

HELMET IS TOO TIGHT OR TOO HIGH

It is extremely important that the helmet not be sized and tted

to sit too high on the head. If crown pads do not hit head (wearer

cannot feel pads), then helmet may be too high. When tting, look

upward by moving eyes, but without moving head. If rim of helmet

cannot be seen, helmet may be too tight.

Try rearranging pads

If rearranging the pads does not alleviate the tightness, a larger

helmet shell may be required

A

B

8OPERATOR INSTRUCTIONS

CLEANING INSTRUCTIONS

HELMET SHELL

Remove helmet pads from helmet shell and clean separately. Helmet shell can be washed

with a mild soap and water using a soft brush or cloth. Towel dry the helmet shell and

allow to air dry completely indoors or in a shaded area.

HELMET PADS

Helmet pads should be washed by hand using a mild soap and cold water. A soft bristled

brush or wash cloth can be used to remove dirt. Allow pads to air dry indoors or in a

shaded area. DO NOT WRING.

PREVENTIVE MAINTENANCE CHECKLIST

In order to ensure optimal performance, the user should routinely inspect the helmet for

damage, wear marks, or missing components. Any damaged components should be replaced

immediately. Any of the following issues should be immediately reported and remedied:

Shell cracks

Bubbles

Signs of ply separation

Fraying webbing

Damaged plastic hardware

Peeling helmet edging

Loose fasteners

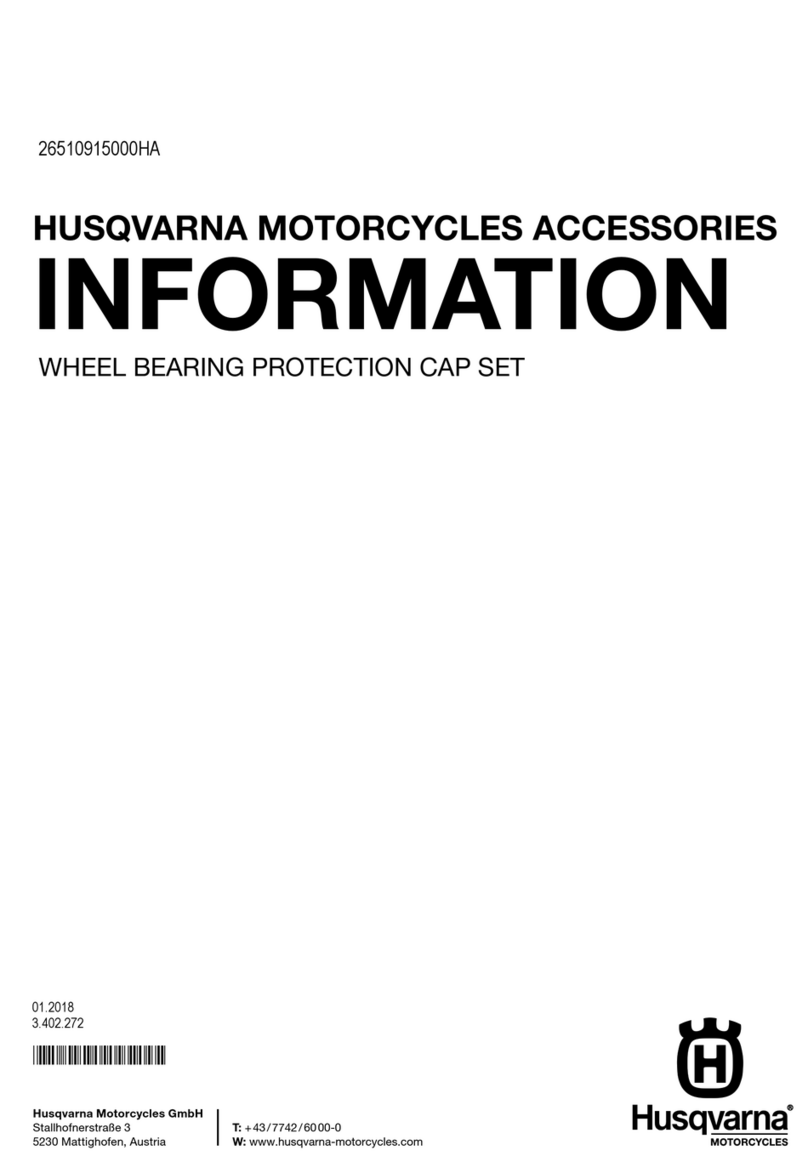

9AIRFRAME™HELMET

Place the REAR SHELL onto the LONG SHELL SCREWS and loosely

thread on SMALL T-NUTS.

Insert two SHORT SHELL SCREWS into the side holes and loosely

thread on SMALL T-NUTS.

With FRONT SHELL held upside down, install the two LONG SHELL

SCREWS and two NYLON SPACERS.

REASSEMBLY

Instructions for reassembly of helmet shell halves.

*If assembling AirFrame™ accessories such as Chops, Ears, or Rails, refer to their instructions for greater detail.

1 2

3 3

10OPERATOR INSTRUCTIONS

Table 1: Torque Values

Helmet Shell Screws 6 in. Lb. (.7 Nm)

Strap Bolts 20 in. Lb. (2.3 Nm)

4Once all helmet SHELL SCREWS are

installed, tighten by hand to torque

values specied in Table 1.

5Insert LARGE T-NUTS through plastic

strap anchors and loosely thread STRAP

BOLTS through shell.

6Once all STRAP BOLTS are installed,

tighten one at a time to the torque

value specied in Table 1. Ensure strap

anchors are positioned as shown in the

images to the left.

7Reinstall helmet PADS, referring to pad

placement instructions (PG 5).

5

5

11 AIRFRAME™HELMET

SERIAL NUMBERS

Front and rear helmet shells each have a unique serial number located on the inner shell surface. Write your helmet serial numbers below for

future reference. Serial numbers should be included when contacting Crye Precision about issues with your helmet or for replacement parts.

FRONT SHELL REAR SHELL

12NOTES

NOTES

ABOUT US

Crye Precision designs and manufactures

truly innovative equipment for America’s

ghting forces. We are proud and

honored to serve our customers' needs.

We spend as much time as we can with

users, continuously incorporating their

experience and feedback into the gear.

We give them our full support and are

indebted to them for their service and

their sacrice. We make uncompromising

gear for uncompromising individuals.

We work hard to provide smart, high-

performance, long-wearing gear for people

who demand the best. We make all of our

gear in America from American materials.

Every item is designed to help you

perform better.

WARRANTY

If a defect in materials or workmanship

is found in any of our products, we will

repair or replace it, free of charge, for

the lifetime of the product. This excludes

normal wear and tear. Be aware that

the customer is responsible for any

and all return shipping charges. This

applies to the original purchaser and is

nontransferable.

BODY ARMOR

It is against Federal Law for a person

convicted of a violent felony to purchase

or possess body armor. In addition,

various states also have laws restricting

the purchase or possession of body

armor by persons convicted of certain

felonies, other crimes of violence, or drug

crimes. By purchasing body armor, you

acknowledge and certify that (i) you have

no felony convictions, (ii) you have not

been convicted of any other crime that

would restrict your ability to purchase or

possess body armor under any Federal or

State law, (iii) you do not intend to use

the body armor for any criminal purpose

and (iv) you are over 18 years old. Crye

Precision reserves the right, in its sole

discretion, to refuse to sell body armor

to any person. Additionally, the sale of

body armor to residents of Connecticut is

restricted to in-person sales, unless the

sale is made to certain law enforcement

or military personnel. We require that all

orders of body armor be accompanied by

a government issued photo identication.

CONTACT INFO

Crye Precision LLC

Brooklyn Navy Yard

63 Flushing Ave Unit 252

Brooklyn, NY 11205

Phone: 1.718.246.3838

Fax: 1.718.246.3833

www.cryeprecision.com

COPYRIGHT

© 2019 Crye Precision LLC. AirFrame™

and the ‘CP’ logo are trademarks of Crye

Precision LLC.

REV 032019

15 AIRFRAME™HELMET

Other manuals for AIRFRAME

1

Table of contents

Other Crye Precision Motorcycle Accessories manuals