CryptOn EB30 User manual

EB30/EC30/630 Upgrade Page 1

Commercial Vehicle Roller Brake Tester.

EB30/EC30/630 Upgrade

OPERATING INSTRUCTIONS TES1343/A

July 2001

EB30/EC30/630 Upgrade Page 2

IMPORTANT

Every reasonable effort has been made to ensure that information within these Operating Instructions is correct

at the time of release, but Crypton cannot accept-responsibility for any errors that may occur.

The information in these Operating Instructions is subject to change without notice, and does not represent a

commitment on the part of Crypton.

Service & Warranty

The reliability of this equipment is fully supported by our service agent.

Please refer to the page at the end of this manual for full details.

Note:

Your attention is drawn to our Terms & Conditions of Sale, particularly paragraph 2. If a service engineer is

called out. under service warranty where, upon inspection and test the equipment is found to be in full working

order and no fault found, the user is liable to be charged the cost incurred for this call out. Before calling out

an engineer, ensure your equipment is faulty by checking its operation, particularly mains supply and fault

codes/self test if applicable.

WARNING:

Do not attempt to operate this equipment unless you have read and understood these

instructions.

EB30/EC30/630 Upgrade Page 3

Index:

Safety procedures for brake testing procedures 2

Description 3

Functions and Facilities 6

PC Brake Diagnostic Program 9

The Theory of Brake Testing 12

Preparing for a Brake Test 14

Automatic Test Procedure (NOT MOT) 15

Manual Brake Test Procedure for Commercial Vehicles (MOT) 17

Manual Brake Test Procedure for Class IV and Class VII (MOT) 23

Maintenance 28

Trouble shooting 31

Terms and conditions of sale 32

After sales service 35

Notes 35

EB30/EC30/630 Upgrade Page 4

Safety procedures for brake testing

! Notice the location of the emergency stop. The switch is located in the

immediate vicinity of the brake tester.

! Read this user’s manual thoroughly before attempting to operate the brake

tester.

! Keep this user’s manual in an easily accessible place.

! Never touch the rollers when the tester is in operation.

! Do not press the third roller down with your hand, foot or any kind of tool.

! Unless authorised, do not remove or make any alteration to any part of the

tester. Contact the supplier.

! Do not use the brake tester for any other purpose than for which it is intended.

! The brake tester must not be used in environments susceptible to explosions.

! Keep unauthorised persons away from the rollers and the wheels of the vehicle

during operation of the tester.

! During service and repair of the tester: Switch the tester off and lock the switch.

! The brake tester will always stop when pressing STOP.

After having pressed STOP, the brake tester can only be restarted by pressing

START or by driving a wheel set onto the roller unit.

! Pressing the emergency stop will stop the brake tester immediately. To restart:

pull the emergency stop back and press the reset key.

! For brake testers fitted with emergency light beam circuit breaker in the pit:

Braking the light beam will stop the brake tester. Reset by pressing the reset key.

EB30/EC30/630 Upgrade Page 5

Description

Main components

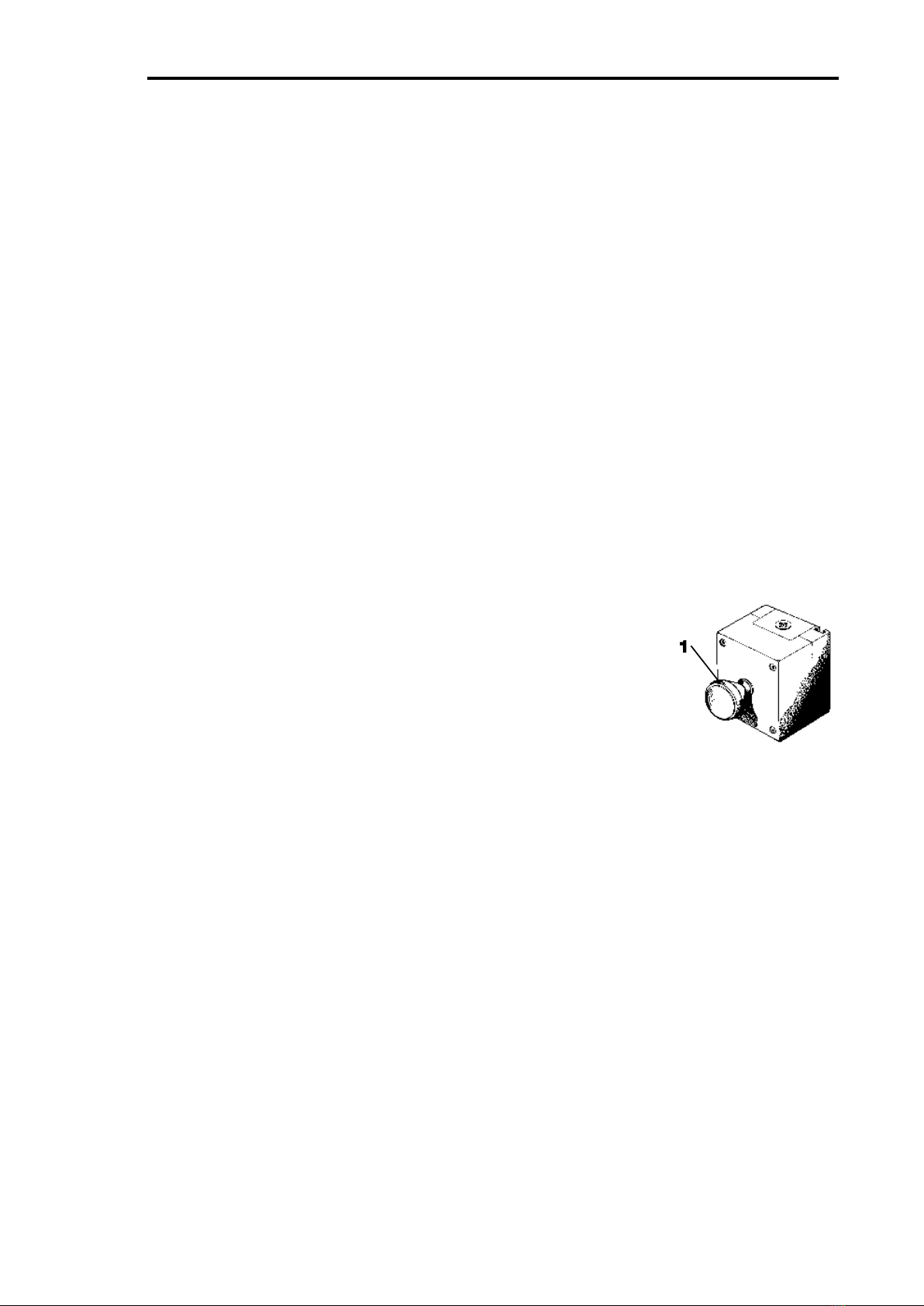

1. Emergency stop

2. Display console.

3. High voltage control unit.

4. Roller unit.

5. PC with brake diagnose program

6. Printer

7. Remote control

Accessories:

Base station for wireless air pressure transducers

Air pressure transducers - wireless

Air pressure transducers - cable connected

1. Emergency stop

Press for emergency stop.

Note: Notice the location of the emergency stop before

starting the brake tester. The emergency stop is not

necessarily positioned in the same place at every installation,

however it will always be installed in the immediate vicinity of

the brake tester.

EB30/EC30/630 Upgrade Page 6

2. Display console

1. Top digital display - air pressure, ovality and weight

2. Indicator showing type of information on top display

3. Indicator light - 4WD (accessory)

4. Indicator light - automatic operation

5. Indicator light - manual operation

6. Indicator light - scale range or 0-800 Kgf)

7. Indicator light - scale range 0-4000 Kgf)

8. Scale showing brake force

9. Pointers; red = left, black = right

10. Amber light - zeroing and fault indicator

11. Red lights - wheel locking

12. Green lights - ready for testing

13. Bottom digital display - imbalance, ovality, pressure and weight

EB30/EC30/630 Upgrade Page 7

3. High voltage control.

1. Keyboard.

2. RESET button (resetting of safety relay).

3. Main switch (power supply circuit breaker).

4. Roller unit.

1. Rollers

2. 3rd roller

Fitted with:

Strain gauge transducer.

Speed sensor on third roller.

Speed sensor on gear box

Proximity sensor on third roller assembly

5. PC with diagnostic program

1. On/off switch

2. PC keyboard

3. Monitor

6. Printer

1. On/off switch

2. Paper tray

3. Cover

7. Remote control

1. Keyboard

2. Battery cover

3. Infrared transmitter window

EB30/EC30/630 Upgrade Page 8

Functions & Facilities

The functions and facilities of the brake tester in alphabetical order.

Automatic operation (not for UK MOT use)

In automatic operational mode, the brake tester will start automatically when a

wheel set is driven onto the rollers and stop either when the wheels lock, when stop

is pressed or when driving out of the rollers.

When the brake tester is turned on it is in automatic mode.

It changes to manual mode when registering a vehicle on the PC.

It returns to automatic operational mode after having concluded a test

or after having pressed PRINT.

If STOP has been pressed so that the AUT and MAN lights are lit.

The brake tester will not start up automatically when driving a wheel

set onto the rollers. Then press STOP again before driving onto the

rollers.

Imbalance

In manual operational mode: Press DAFF after having started the rollers. The

difference of braking effect between the left and right wheel is indicated by the

positions of the pointers. The result is shown at the bottom display (as %).

In automatic operational mode: The imbalance is shown when the brake force

exceeds 40 kgf.

You toggle between imbalance and air pressure by pressing AIR and DAFF.

One-wheel operation (accessory).

In one-wheel operation one wheel is rotating whilst the other is stationary.

Press TEST and START. Choose the wheel by using UP for the left wheel and

DOWN for the right one. The display shows which one has been chosen. Press

START to start the chosen wheel.

One wheel operation is used for MOT testing and to test damaged vehicles.

Four-wheel operation. (accessory).

The brake tester can be fitted with a facility to test four-wheel drive vehicles. This

makes it possible to test one wheel whilst the other wheel on the same axle is

reversing to avoid that the torque is transmitted to other axles during the test.

Brake force is measured only on the non-reversing wheel.

Press 4WD. Drive the first set of wheels onto the rollers and press START. The

green light lights up on the side of the wheel to be tested and the relevant pointer

shows the brake force. Press OK to store the result. Press START to test the other

wheel and press OK to store the result.

EB30/EC30/630 Upgrade Page 9

Choose which wheel to be tested first before starting the test: Press 4WD once to

choose the left wheel (indicated by the left light). Press 4WD again to choose the

right wheel to be tested first. Press a third time to return to normal operation.

Parking brake.

The parking brake is tested in the same way as the foot brake. It is therefore not

necessary to make special concessions for testing the parking brake.

However in manual mode it is necessary to indicate when the parking brake is to

be tested. The reason is that special calculations are used for the parking brakes.

With a wheel set on the rollers press START and choose the transducer using the

UP and DOWN keys. Press START again to start the rollers. Press PARK to

indicate the test of the parking brake.

The bottom display shows momentarily the number of the relevant parking brake,

for example P1. Then the bottom display shows the pressure PM. The top display

shows the chosen pressure Pc.

Printed report.

A report can be printed after a test in manual operational mode. Press the PRINT

key after the last axle has been tested and accepted.

The report shows all relevant calculations both of each individual axle and of the

whole vehicle. The report can also contain relevant graphs.

The content and layout of the report is set up in the program on the PC.

Holding the result on the display.

In both manual and automatic mode the pointers and the LED displays will remain

showing the results after locking the wheels until either restarting the tester,

pressing OK or after 5 minutes have elapsed.

EB30/EC30/630 Upgrade Page 10

Symbols.

The following symbols will appear on the LED display:

Parking brake and number.

Accept of signal from remote control

Emergency stop activated

The brake tester is locked and does not communicate with PC

The brake tester transmits signal to printer

Imbalance in %

Ovality in %

Testing left secondary brake.

Testing right secondary brake

Testing left parking brake.

Testing right parking brake

EB30/EC30/630 Upgrade Page 11

PC Brake Diagnostic Program

With diagnostic program, the performance of the brakes of a vehicle can be

analysed in details. The results can be analysed graphically in many ways and

stored for later comparison. The program is very user friendly and supported by a

comprehensive help system. Pressing F1 will provide the answers to most

questions. The text in the help program is dependent upon the content on the

screen and provides clear and relevant answers.

The program is easy to use. Choose menu items and buttons on the screen with

the arrow keys and press ENTER. Fill in the cell on the screen with the

specifications you are asked for by the program (You will find the instructions on

the bottom line of the screen). This insures correct and easy use.

Registration of a vehicle.

For manual testing of a vehicle it must be registered on the PC. If the vehicle has

not been tested on the brake tester before, it is necessary to key in some

specifications. If it has been tested before a lot of the specifications are stored in

the program and can easily be transferred to the new test.

Choose BRAKE TEST on the menu. If the vehicle has been registered before on

the tester, choose OPEN VEHICLE DATA and find the registration number on the

list.

If the vehicle has not been registered before:

Choose “ENTER VEHICLE DATA” and fill in the form on the window:

Name: (name of owner of vehicle) optional

Address: (address of owner) optional

Address: (address of owner) optional

Zip Code: (postal code) optional

City: (town) optional

Telephone no.: (Customers phone no.) optional

Job no.: (Internal job no.) optional

Tested by: (Initial/name of operator) optional

When the key-in data are satisfactory, choose OK.

Choose the relevant type of vehicle.

Choose “Other brake type”

Choose whether or not a trailer is hitched.

A new window appears:

EB30/EC30/630 Upgrade Page 12

Make: (Make of vehicle) Obligatory

Reg. No. (Registration no) Obligatory

Man. year (Year of manufacture) Obligatory

Gross vehicle weight (maximum allowed weight) Obligatory

Actual vehicle weight (Weight at time of test) Optional

No. of axles: (Number of axles to be tested) Obligatory

Mileage: (Mileage at day of testing) Optional

Remarks (Any relevant remark) Optional

When the data of the vehicle has been opened or keyed in they must be

transferred to the brake tester. Choose START BRAKE TESTING from the main

menu. Perform the brake test as described in the chapter "Brake testing, manual

mode"

After the completion of the test, the results can be printed out on a colour printer

and/or processed graphically on the PC - see below.

Printouts

A series of printouts can be performed on the colour printer.

You can choose between a:

Graphical processing of the results.

The results can be studied in details by using the graphical facilities in the PC

program. The results can be analysed immediately after the test, or data from an

earlier test can be called from the memory of the PC.

After the completion of the test you can choose between the before mentioned

user designed standard printout set-up or a specially designed printout. The user

designed printout is described in menu point CONFIGURATION - STANDARD

PRINTOUT. The special designed printout is described in a similar menu. Choose

the desired specifications by marking them with " " using the space key for setting

or removing the tick.

You can choose from different types of graphs, tables and calculations in the PC

program:

Brake force - PC graph -when air pressure has been measured

For each axle the brake force is shown as PC . The graph shows the relation

between the brake force and the pressure in the cylinder on each axle. This will for

example detect defective valves.

Time graph -when air pressure has been measured.

For each axle the graph shows the brake force and air pressure as they are

developing with time elapsed. If the brake pedal was released whilst the display

showed "U" the thick line shows increasing brake force whereas the thin line shows

the brake force when releasing the brake pedal.

PC - PM graph -when air pressure has been measured.

The graph shows the development of the air pressure in the cylinder in comparison

with the pressure in the main line. The pressure in the cylinder is shown on the Y-

EB30/EC30/630 Upgrade Page 13

axis and the main line pressure on the X-axis. -The graph is used for analysing the

function of the reduction valve.

Retardation graph -when air pressure has been measured.

The retardation graph shows the main line pressure on the X-axis and the

retardation on the Y-axis

Result as table.

The table shows all recorded values of brake force and air pressure. The results

are projected on line with the values recorded simultaneously on the same line.

Results summary.

The result summary shows the vehicle’s braking performance and forces at the

point of locking together with the calculated ovality, imbalance and retardation.

EB30/EC30/630 Upgrade Page 14

The Theory of Brake Testing.

Brake testing on roller brake tester.

Measuring the brake force is done as described in the following: An asynchronous

motor turns the wheels of the vehicle. The brake force of a wheel affects the rollers

with a torque, which is measured electronically. The torque is in proportion with the

brake force, which therefore can be shown on the dial display with a high degree of

accuracy.

Brake test on rollers offers several advantages:

Imbalance.

Imbalance is the difference in brake force between the right and the left wheel on

the same axle. The imbalance is measured progressively during the test and is

converted into % before it is shown on the display.

The imbalance in % is calculated as the difference in % of the highest actual brake

force. For example:

Class IV and Class VII:

If, in a given time the brake force on the right side is 200 kgf and on the left

side is 220 kgf. The difference is 220 -200 = 20 kgf. Must not exceed 25%

The highest brake force is 220 kgf. The imbalance is then:

220 -200 x 100 = 9%

220

HGVs and PSV:

On commercial vehicles the imbalance is the difference between the brake

force measured at the time of locking of the wheels on the same axle. It is

only obligatory to measure imbalance on the steering axles (MOT

regulations).

The imbalance on the steering axle on commercial vehicles must not exceed

30%.

If the imbalance is too great, the vehicle will have a tendency to be drawn to the

side with the highest brake force when applying the brakes. In critical situations a

sideslip is eminent.

Ovality.

Ovality is a description of varying brake force measured during one revolution of a

wheel at a constant brake pressure. Often this is caused by oval drums or uneven

brake discs. Ovality can also indicate broken or rusty drums or discs. The values is,

like brake force, measured as kgf. However it can also be shown as a percentage

of the actual brake force.

MOT does not accept an ovality of more than 70%.

Brake Pedal Pressure. (Available as accessory).

EB30/EC30/630 Upgrade Page 15

The pressure asserted by the foot on the brake pedal is called the brake pedal

pressure. Especially interesting is the highest brake pedal pressure measured at

the moment the wheels lock. The highest brake pedal pressure must be less then

50 - 70 kilos depending on the type of vehicle. Greater brake pedal pressure can

be caused by worn brake pads or for example defective brake booster or reduction

valves.

Rolling Resistance.

The rolling resistance is the brake force measured during a test without activating

the brake pedal. Dragging brakes, maladjusted brakes or defective valves can

cause this. A high rolling resistance can cause considerably wear of the tyres, and

on the brake pads and can result in higher fuel consumption.

Calculated brake force.

It may not always be possible to measure the maximum brake force on a roller

brake tester. The reason for this is that the point of locking of the wheels will be

reached sooner if the vehicle is not fully laden. It is therefore necessary to calculate

the brake force at a higher pressure. The calculation is done using the measured

maximum brake force, the measured maximum pressure and the allowed total

weight of the vehicle. This calculation will reveal how the vehicle’s brakes will

perform during an emergency stop.

Gross vehicle weight.

This is the allowed maximum weight of the vehicle and payload according to the

law.

The maximum weight is noted in the vehicle’s registration papers. This weight is

being used for the calculation of the braking ability of the vehicle.

Guaranteed pressure.

The guaranteed pressure is the lowest legal level of the highest attained pressure

at maximum braking action. This pressure is also used for calculating the braking

ability of the fully laden vehicle.

PC-pressure. When air transducers are fitted.

The pressure measured in a brake cylinder when being tested.

PC-start pressure. When air transducers are fitted.

The pressure measured in a brake cylinder at the moment braking effect begins.

PM-pressure. When air transducers are fitted.

The pressure measured in the main air line leading to the trailer. For vehicles with

Duomatic valve this pressure is called the duomatic pressure.

EB30/EC30/630 Upgrade Page 16

Preparing for a Brake Test.

Turn the power on at the main switch of the brake tester and press RESET.

Turn the power on by turning the switch to "I". Press the RESET button, which is lit

up. This turns on the safety system.

Do not drive the vehicle onto the rollers until the amber zero indicator is turned off.

The brake tester cannot operate as long as this light is lit.

During this procedure the brake tester checks the electronic system and zeros the

settings. When the tester is not in use the zeroing is performed at regular intervals

with only seconds apart.

.

When the amber light is turned off the brake tester is ready for use.

It is in automatic mode for a quick test.

For manual mode, register the vehicle on the PC before driving it onto the rollers.

EB30/EC30/630 Upgrade Page 17

Automatic Brake Test Procedure.

- NOT ALLOWED FOR MOT TESTING!

Automatic operation provides the following advantages:

The brake tester starts automatically when a wheel set in driven onto the rollers

and is stopped either when the wheels lock or when the wheel set is driven out of

the rollers, or manually by pressing STOP.

The brake tester will start up in the automatic mode and remain here if no vehicle is

registered on the PC. The tester is always left in automatic mode after conclusion

of a test.

Note. Automatic mode does not provide many facilities such as registering the

vehicle, measuring air pressure nor is the analytic facility available.

Automatic operation is a way of performing a quick and simple test on all types of

vehicles, and recommended when that is all, which is required.

Testing Procedure:

1 Drive the first axle onto the rollers.

2 Wait for start and green light.

3 Measure ovality at 100 - 500 kgf.

4 Slowly increase the brake force.

5 The brake tester stops automatically when the wheels lock.

6 Tests the parking brakes.

7 Repeat the test on the remaining axles.

1 Drive the first axle onto the rollers.

The bottom display shows "U" for each wheel placed on the rollers. Both

wheels must be on the rollers before the brake tester will start.

2 Wait for start and green light.

A moment after the wheels have been placed on the rollers, the brake tester

will start automatically. When the tester is ready the red lights will turn off and

the green lights will turn on. Do not assert pressure on the brake pedal until

the green lights are turned on.

Before pressing the brake pedal the pointers show the rolling resistance.

When applying the brakes the pointers show the brake force, whereas the

bottom display shows the imbalance when the brake force exceeds 50 kgf on

both wheels.

3 Measure ovality at 100 - 500 kgf.

EB30/EC30/630 Upgrade Page 18

To measure ovality takes approximately three seconds. Press gently on the

brake pedal until the pointers are at 500 kgf for commercial vehicles (100 kgf

for cars). Keep the pressure steady and press OVAL to start the test. Follow

procedure in MOT manual for relevant class of MOT testing.

The symbol "()" is showing on the bottom display together with the largest

ovality in %. The arrows show, which side has the largest ovality. The top

display shows the ovality of the individual side as kgf.

Keep a constant pressure on the pedal until the imbalance symbol "<>"

appears on the bottom display, this indicates that the ovality test has been

completed. Now the top display shows the ovality on both the right and the left

wheel and the bottom display shows the imbalance between the wheels again

as a percentage.

4 Slowly increase the brake force.

Press the brake pedal slowly down and notice the movements of the pointers,

they must follow each other without too much difference.

5 The brake tester stops automatically when the wheels lock.

The brake tester stops automatically just before the wheels skid on the rollers.

This is to avoid unnecessary wear to the tyres.

The pointers will remain at the position they had just before the wheels

locked. They will keep the position until the brake tester is restarted. The

display will show the greatest imbalance measured during the test. If ovality

was measured, the top display will show the ovality of both wheels.

If locking of the wheels has not been reached, the tester can be stopped by

pressing STOP on the remote control or on the keyboard. The pointers will

remain in the brake force they showed at that moment and the display will

show the greatest imbalance measured during the test. The brake tester will

attempt to restart after approximately 2 seconds. If it has been stopped by

pressing STOP, it will only start again by pressing the START button

6 Tests the parking brakes.

On axles on which the parking brake is fitted, test it after having tested the

foot brakes. When the wheels have locked the brake tester will stop for 2

seconds and will then restart. Now slowly apply the parking brake until the

wheel locks.

7 Repeat the test on the remaining axles.

After having tested an axle, drive the vehicle forward to place the next wheel

set on the rollers. Remember that the two "U"s must appear on the display to

indicate that both wheels are in place before you can start the test.

EB30/EC30/630 Upgrade Page 19

Manual Brake Test Procedure

Procedure for MOT testing commercial vehicles.

The brake tester starts up in manual operational mode when you register the

vehicle on the PC. This facilitates the use of the analytic facilities which aids the

identification of faults in the brake system.

Manual operational mode is used for all vehicles with mechanical, hydraulic and air

brake systems, and when a thorough and detailed analysis is wanted and when

conducting a MOT test.

Procedure:

Follow the brake test procedure detailed in the latest version of the relevant

MOT inspection manual.

1) Ensure there is no vehicle in the rollers

2) Switch on Console

3) Press white RESET button (to the right of safety stop)

4) Switch on PC

5) WAIT for ‘jumping men’ and PC password screen

6) Enter password (default = 123456) and press RETURN

7) If PC has a blank screen, ensure BRAKETEST in top Left Hand corner is

highlighted and press RETURN

8) If the vehicle is in the database, highlight ‘LOAD VEHICLE DATA’ and press

RETURN (In not in database, use ENTER VEHICLE DATA, SAVE VEHICLE

DATA and then do step 8)

9) Highlight vehicle registration in the list and press RETURN

10)

Highlight ‘BEGIN A BRAKETEST’ in list and press RETURN top LH lights on

console should switch from AUTO to MANUAL

11) Get in vehicle and use handset from now on

12) Drive front wheels of vehicle into rollers, lower display = U 1 U

13) Press START, both rollers should start, wait for two green lights

14) Centre vehicle in rollers and apply brake to about 500kgf and hold steady

15) Press OVALITY, wait about 5 seconds for readings to stabilise

EB30/EC30/630 Upgrade Page 20

16) Press STOP

17) Press OK to store ovality result for front axle

18) Press START, left roller only should start, wait for LH green light

19) Apply foot brake smoothly until front LH wheel locks and roller stops

20) Press OK to store front near side brake result

21) Press START, right roller only should start, wait for RH green light

22) Apply foot brake smoothly until front RH wheel locks and roller stops

23) Press OK to store front off side brake result

24) Drive rear wheels of vehicle into rollers, lower display = U 2 U

25) Press START, both rollers should start, wait for two green lights

26) Centre vehicle in rollers and apply brake to about 500kgf and hold steady

27) Press OVALITY and wait about 5 seconds until readings stabilise

28) Press STOP

29) Press OK to store ovality result for rear axle

30) Press START, left roller only should start, wait for LH green light

31) Apply foot brake smoothly until rear LH wheel locks and roller stops

32) Press OK to store rear near side brake result

33) Press START, right roller only should start, wait for RH green light

34) Apply foot brake smoothly until rear RH wheel locks and roller stops

35) Press OK to store rear off side brake result, WAIT for lock and key symbols to

appear and disappear.

36) Press PARK to start test of parking brake lower display = UP1 S U

37) Press START, left roller only should start, wait for LH green light

38) Apply parking brake smoothly until wheel locks and roller stops

39) Press OK to store rear near side parking brake result, lower display = U SU

40) Press START, right roller only should start, wait for RH green light

This manual suits for next models

2

Table of contents

Other CryptOn Test Equipment manuals