CS Instruments Vortex VX 570 User manual

VX 570 English V1.10 Page 1 of 44

Instruction manual

Vortex Flow-Sensor

VX 570

info@cs-instruments.com

http://www.cs-instruments.com/en

EN - English

SALES OFFICE SOUTH

Zindelsteiner Straße 15

D-78052 VS-Tannheim

DEUTSCHLAND

Tel.: +49 (0) 7705 978 99-0

Fax: +49 (0) 7705 978 99-20

SALES OFFICE NORTH

Gewerbehof 14

D-24955 Harrislee

Deutschland

Tel.: +49 (0) 461 807 150 0

Fax: +49 (0) 461 807 150 15

Vorwort

VX 570 English V1.10 Page 2 of 44

I. Forword

Read these operating instructions carefully and completely before

installation, start-up and maintenance work. Follow the instructions to

ensure safe operation and proper functioning.

The operating instructions must always be available at the place of use. It

is not permitted to make only individual pages available.

Important notes for installation and maintenance personnel

Installation of the flow sensor is only permitted by trained skilled staff

with knowledge and experience in compressed air and electrical

engineering.

Electrical connection, commissioning and maintenance may only be

carried out by qualified electricians in accordance with the

electrotechnical regulations (DIN EN 50110-1, DIN EN 60204-1 etc.).

Prerequisite: Professional training and knowledge of the technical

standards, EU directives and EU regulations.

Observe applicable national accident prevention regulations and

ordinances. Observe general occupational health and safety

measures,

E.g. wear suitable and prescribed personal protective equipment

(PPE). Repairs and adjustments may only be carried out by the

manufacturer.

Duties of the installer and plant operator

The flow sensor must be checked and maintained regularly by an

instructed and qualified person.

Cleaning and maintenance intervals are to be determined by the plant

operator according to DIN-ISO certification - frequency depending on

ambient conditions and expected impairments.

Calibration: As part of DIN ISO certification, have the flow sensor

calibrated at regular intervals, after 2 years at the latest.

Remove the flow sensor for calibration and send it to CS Instruments

GmbH & Co.KG.

Table of Content

VX 570 English V1.10 Seite 3 von 44

II. Table of Content

1Scope of delivery 5

2Name plate 5

3Intended Use 5

4Safety instructions 6

4.1 In this manual warning and information symbols used 6

4.2 Warnings 6

4.3 General safety instructions 7

4.4 Environmental protection 7

5Product information 8

5.1 Product features 8

5.2 Measuring ranges (under operating conditions) 8

6Technical data 13

6.1 Technical data and environmental conditions 13

7Installation 14

7.1 General notes for the Installation 14

7.2 Storage 14

7.3 Transport 14

7.4 Pipe/tube requirements 14

7.5 Inlet / Outlet runs 15

8Commissioning 15

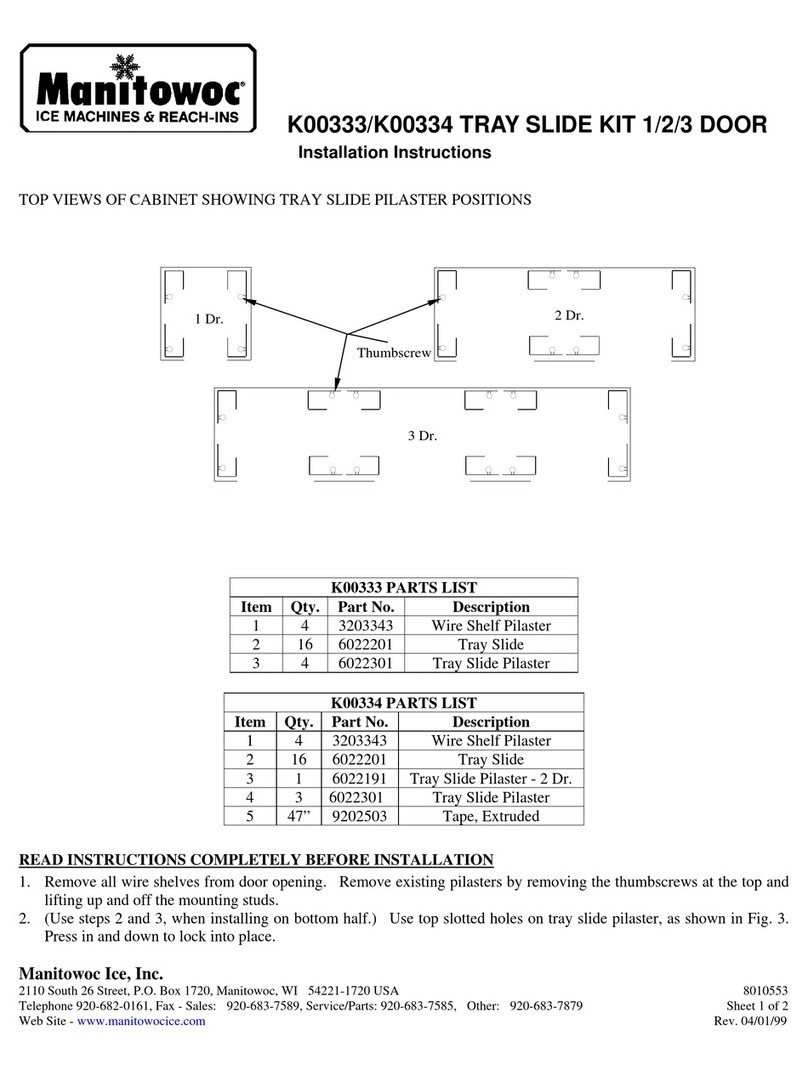

9Dimension 16

9.1 Zwischenflansch-Ausführung 16

9.2 Flange version (without temperature- / pressure-sensor) 17

9.2.1 PN 16 17

9.2.2 PN 25 18

9.2.3 PN 40 18

9.2.4 ANSI Class150 19

9.2.5 ANSI Class300 19

9.3 Flange Version with temperature- pressure-sensor 20

9.3.1 PN 16 20

9.3.2 PN 25 21

9.3.3 PN 40 21

9.3.4 ANSI Class150 22

9.3.5 ANSI Class300 22

10 Electrical wiring 23

10.1 Cable glands –clamping range 23

10.2 Connector pin assignment 23

10.3 Wiring 24

10.3.1 General 24

10.3.2 Power supply 24

10.3.3 Modbus RTU: 24

10.3.4 Service Software Interface 24

Table of Content

VX 570 English V1.10 Seite 4 von 44

11 Bedienung 25

11.1 Main menu (Home) 26

11.1.1 Initialization 26

11.2 Value screens (after switching on) 26

11.3 Settings 27

11.3.1 Sensor Setup 28

11.3.1.1 Input / change tube diameter 28

11.3.1.2 Input / change consumption counter 29

11.3.1.3 Definition of the units for flow, velocity, temperature and pressure 29

11.3.1.4 Extended Sensor Settings 30

11.3.1.4.1 Definition of the reference settings.......................................................................................30

11.3.1.4.2 Setting Filter- / AV-Time......................................................................................................32

11.3.1.4.3 Definition of used Measuring-Medium..................................................................................32

11.3.1.5 Pressur Setup 33

11.3.2 Modbus RTU 34

11.3.2.1 Setup 34

11.3.2.2 Modbus Settings (2001…2005) 35

11.3.2.3 Values Register (1001 …1500) 35

11.3.3 User Setup. 37

11.3.3.1 Password 37

11.3.3.2 Language 37

11.3.3.3 Display / Touch 38

11.3.4 Advanced 38

11.3.4.1 Factory Reset / Calibration date 38

11.3.5 Settings Outputs 4..20mA 39

11.3.6 VX 570 Info 41

12 Status / Error messages 42

12.1 Status messages 42

12.2 Error messages 43

13 Re-Calibration 44

14 Spare parts and repair 44

15 Calibration 44

16 Warranty 44

Scope of delivery / Intended use

VX 570 English V1.10 Seite 5 von 44

1 Scope of delivery

•Flow-Sensor VX 570

•Calibration certificate

•This instruction manual

2 Name plate

3 Intended Use

The VX 570 flow sensor is used for continuous flow measurement, based on the measurement of the

vortex shedding frequency, derived from the phenomenon of Karman's vortex street.

The VX 570 flow sensor is designed and constructed exclusively for the intended use described here

and may only be used accordingly.

A check as to whether the device is suitable for the selected application must be carried out by the

user. It must be ensured that the medium is compatible with the wetted parts. The technical data listed

in the data sheet are binding.

Improper handling or operation outside the technical specifications is not permitted. Claims of any

kind due to improper use are excluded

VX 570

Safety instructions

VX 570 English V1.10 Seite 6 von 44

4Safety instructions

4.1 In this manual warning and information symbols used

This symbol is found at all work safety instructions in this operating manual

where there is danger to life and limb of persons. Observance of these instructions

and cautious behavior are particularly important in these cases. All work safety

instructions must also be passed on to other users. In addition to the information in

these operating instructions, the general safety and accident prevention regulations

must also be observed.

This symbol is located at the points in the operating instructions that

require special attention in order to comply with the guidelines, regulations,

instructions and the correct sequence of operations, as well as to prevent damage

and destruction.

This symbol indicates important information or measures for environmental

protection.

This symbol indicates particularly important information for operators.

4.2 Warnings

Warnings are subdivided according to the hazard levels DANGER, WARNING and

CAUTION. Meaning of the warnings:

Danger

Immediate danger!

▶ Failure to observe this warning may result in serious injury or

death.

WARNING

Possibly dangerous situation!

▶ Failure to observe this warning may result in serious injury or

death.

Caution

Possibly dangerous situation!

▶ Failure to observe this warning may result in moderate to

minor injuries.

Note

Possibly dangerous situation!

▶ Failure to observe this warning may result in property damage.

Safety instructions

VX 570 English V1.10 Page 7 of 44

4.3 General safety instructions

Note

▶ Work on power-operated equipment may only be carried out

by trained, instructed or by authorized personnel.

Note

▶ Without consultation and approval of CS Instruments GmbH

& Co. KG the warranty claim is void in case of modification works

which are not listed in this operating manual. This symbol is used

at points in the operating instructions where special attention

must be paid to ensure that the guidelines, regulations,

instructions and the correct sequence of operations are observed

and damage and destruction are prevented.

Risk of injury and accidents during operation outside the permissible

ambient/operating conditions or operating temperatures due to excess

pressure or faulty installation. Depending on the application, the pipeline

pressure can be up to 40 bar / 580 psiG depending on the application.

Ensure that the flow sensor is only operated within the permissible limit values (→

type plate, specified max. PS pressure) and that the measuring range end values

are taken into account.

Risk of injury due to unauthorized device modifications, incorrect

installation or damaged components. The operating permit becomes

invalid in these cases. Operation is only permitted with original

components.

Only operate the flow sensor when it is completely assembled. Do not operate a

damaged sensor and prevent further use until it has been repaired. The sensor

must be checked and maintained regularly by instructed and qualified persons.

Device modifications are not permitted and release the manufacturer from any

warranty and liability.

Explosion risk in Ex-protected areas due to ignition of explosive

substances when sparks are generated. The flow sensor does not have

Ex approval! Do not use the flow sensor in Ex-protected areas.

4.4 Environmental protection

The flow sensor and also the packaging contain recyclable materials

which must not be disposed of in the residual waste. Dispose of the

packaging materials and the flow sensor in an environmentally friendly

manner at the end of its service life in accordance with the regulations

applicable in your country.

The used operating and auxiliary materials as well as replacement parts

produced during operation of the flow sensor must be disposed of in

accordance with the environmental protection regulations.

DE: Disposal code according to Waste Catalogue Ordinance (AVV) 16

02 14, electrical and electronic devices and their components.

Product information

VX 570 English V1.10 Page 8 of 44

5Product information

The VX 570 is a flow sensor with integrated pressure and temperature compensation for

measurements of gas (air, mixed gases), steam (saturated or superheated steam) and

liquids.

5.1 Product features

•Measurement of standard volume flow, operating volume flow and mass flow

•Integrated pressure- and temperature compensation

•Display with indication of flow, consumption, speed, pressure and temperature

•Units freely selectable m³/h, m³/min, l/min, l/s, kg/h, kg/min, kg/s, cfm

•Modbus RTU (RS485) interface

•3x Analog output 4..20mA free assignable

5.2 Measuring ranges (under operating conditions)

Measuring ranges for Gas and liquids VX 570 under operating conditions

Pipe Inner diameter

Gas

Liquids

Inch

mm

DN

Min flow

Max flow

Min flow

Max flow

Min flow

Max flow

Min flow

Max flow

m³/h

m³/h

cfm

cfm

m³/h

m³/h

GPM

GPM

1/2″

15

DN 15

3.8

44.5

2.2

26.2

0.2

4.4

0.8

19.6

3/4″

20

DN 20

6.8

79.1

4

46.6

0.3

7.9

1.5

34.8

1″

25

DN 25

7.1

123.6

4.2

72.7

0.5

12.4

2.3

54.4

1 1/4″

32

DN 32

11.6

202.5

6.8

119.2

0.9

20.2

3.8

89.2

1 1/2″

40

DN 40

9

316.4

5.3

186.2

1.4

31.6

6.0

139.3

2″

50

DN 50

14.1

494.4

8.3

291

2.1

49.4

9.3

217.7

2 1/2″

65

DN 65

23.9

835.5

14

491.7

3.6

83.5

15.8

367.8

3″

80

DN 80

36.2

1265.5

21.3

744.9

5.4

126.6

23.9

557.2

4″

100

DN 100

56.5

1977.4

33.3

1163.9

8.5

197.7

37.3

870.6

5″

125

DN 125

88.3

3089.7

52

1818.5

13.2

309.0

58.3

1360.4

6″

150

DN 150

127.1

4449.2

74.8

2618.7

19.1

444.9

84.0

1958.9

8″

200

DN 200

226

7909.6

133

4655.4

33.9

791.0

149.3

3482.5

10″

250

DN 250

353.1

12358.8

207.8

7274.1

53.0

1235.9

233.2

5441.4

12″

300

DN 300

508.5

17796.6

299.3

10474.7

76.3

1779.7

335.8

7835.6

Measuring ranges

VX 570 English V1.10 Seite 9 von 44

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=112 °C

T=121 °C

T=134 °C

T=144 °C

P=0.5 bar(g)

P=1 bar(g)

P=2 bar(g)

P=3 bar(g)

D=0.8798 kg/m3

D=1.155 kg/m3

D=1.672 kg/m3

D=2.185 kg/m3

Inch

mm

DN

Min

Max

Min

Max

Min

Max

Min

Max

1/2″

15

DN 15

3.4

39.1

4.4

51.4

6.4

74.4

8.3

97.2

3/4″

20

DN 20

6.0

69.6

7.8

91.4

11.3

132.2

14.8

172.8

1″

25

DN 25

6.2

108.7

8.2

142.7

11.8

206.6

15.4

270.0

1 1/4″

32

DN 32

10.2

178.1

13.4

233.9

19.3

338.6

25.3

442.4

1 1/2″

40

DN 40

8.0

278.4

10.4

365.4

15.1

529.0

19.8

691.3

2″

50

DN 50

12.4

434.9

16.3

571.0

23.6

826.6

30.9

1080.2

2 1/2″

65

DN 65

21.0

735.0

27.6

964.9

39.9

1396.9

52.2

1825.5

3″

80

DN 80

31.8

1113.4

41.8

1461.7

60.5

2116.0

79.0

2765.2

4″

100

DN 100

49.7

1739.7

65.3

2283.9

94.5

3306.2

123.4

4320.6

5″

125

DN 125

77.7

2718.3

102.0

3568.6

147.6

5166.0

192.9

6751.0

6″

150

DN 150

111.8

3914.4

146.8

5138.8

212.5

7439.0

277.8

9721.4

8″

200

DN 200

198.8

6958.9

261.0

9135.6

377.9

13224.9

493.8

17282.5

10″

250

DN 250

310.7

10873.2

407.8

14274.4

590.4

20663.8

771.5

27003.9

12″

300

DN 300

447.4

15657.5

587.3

20555.1

850.2

29755.9

1111.0

38885.6

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=159 °C

T=165 °C

T=171 °C

T=176 °C

P=5 bar(g)

P=6 bar(g)

P=7 bar(g)

P=8 bar(g)

D=3.182 kg/m3

D=3.671 kg/m3

D=4.218 kg/m3

D=4.723 kg/m3

Inch

mm

DN

Min

Max

Min

Max

Min

Max

Min

Max

1/2″

15

DN 15

12.1

141.6

14.0

163.3

16.1

187.7

18.0

210.1

3/4″

20

DN 20

21.6

251.7

24.9

290.4

28.6

333.6

32.0

373.6

1″

25

DN 25

22.5

393.3

25.9

453.7

29.8

521.3

33.4

583.7

1 1/4″

32

DN 32

36.8

644.3

42.5

743.3

48.8

854.1

54.6

956.3

1 1/2″

40

DN 40

28.8

1006.7

33.2

1161.4

38.1

1334.5

42.7

1494.3

2″

50

DN 50

44.9

1573.0

51.9

1814.8

59.6

2085.2

66.7

2334.8

2 1/2″

65

DN 65

76.0

2658.4

87.6

3066.9

100.7

3523.9

112.7

3945.8

3″

80

DN 80

115.1

4026.9

132.7

4645.8

152.5

5338.0

170.8

5977.1

4″

100

DN 100

179.8

6292.1

207.4

7259.0

238.3

8340.7

266.8

9339.3

5″

125

DN 125

280.9

9831.4

324.1

11342.2

372.4

13032.3

416.9

14592.6

6″

150

DN 150

404.5

14157.2

466.7

16332.8

536.2

18766.5

600.4

21013.3

8″

200

DN 200

719.1

25168.4

829.6

29036.2

953.2

33362.7

1067.3

37357.1

10″

250

DN 250

1123.6

39325.6

1296.3

45369.0

1489.4

52129.2

1667.7

58370.4

12″

300

DN 300

1618.0

56628.8

1866.6

65331.4

2144.7

75066.1

2401.5

84053.4

Measuring ranges

VX 570 English V1.10 Seite 10 von 44

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=185 °C

T=192 °C

T=199 °C

T=210 °C

P=10 bar(g)

P=12 bar(g)

P=14 bar(g)

P=18 bar(g)

D=5.752 kg/m3

D=6.671 kg/m3

D=7.706 kg/m3

D=9.593 kg/m3

Inch

mm

DN

Min

Max

Min

Max

Min

Max

Min

Max

1/2″

15

DN 15

21.9

255.9

25.4

296.8

29.4

342.9

36.6

426.8

3/4″

20

DN 20

39.0

455.0

45.2

527.6

52.2

609.5

65.0

758.8

1″

25

DN 25

40.6

710.9

47.1

824.5

54.4

952.4

67.7

1185.6

1 1/4″

32

DN 32

66.6

1164.7

77.2

1350.8

89.2

1560.4

111.0

1942.4

1 1/2″

40

DN 40

52.0

1819.8

60.3

2110.6

69.7

2438.1

86.7

3035.1

2″

50

DN 50

81.2

2843.5

94.2

3297.8

108.8

3809.5

135.5

4742.3

2 1/2″

65

DN 65

137.3

4805.5

159.2

5573.3

183.9

6438.0

229.0

8014.5

3″

80

DN 80

208.0

7279.4

241.2

8442.4

278.6

9752.2

346.9

12140.3

4″

100

DN 100

325.0

11374.0

376.9

13191.2

435.4

15237.9

542.0

18969.2

5″

125

DN 125

507.8

17771.9

588.9

20611.3

680.3

23809.1

846.8

29639.4

6″

150

DN 150

731.2

25591.5

848.0

29680.3

979.6

34285.2

1219.4

42680.7

8″

200

DN 200

1299.9

45496.0

1507.6

52765.0

1741.5

60951.4

2167.9

75876.8

10″

250

DN 250

2031.1

71087.6

2355.6

82445.3

2721.0

95236.6

3387.4

118557.6

12″

300

DN 300

2924.7

102366.1

3392.0

118721.2

3918.3

137140.7

4877.8

170722.9

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=215 °C

T=233.6 °F

T=249.8 °F

T=273.2 °F

P=20 bar(g)

P=7.3 psi(g)

P=14.5 psi(g)

P=29 psi(g)

D=10.57 kg/m3

D=0.0034 lb/ft3

D=0.0721 lb/ft3

D=0.1044 lb/ft3

Inch

mm

Min

Max

Min

Min

Max

Min

Max

Min

Max

1/2″

15

DN 15

40.3

470.3

7.4

86.3

9.7

113.3

14.1

164.0

3/4″

20

DN 20

71.7

836.0

13.2

153.4

17.3

201.4

25.0

291.6

1″

25

DN 25

74.6

1306.3

13.7

239.7

18.0

314.7

26.0

455.6

1 1/4″

32

DN 32

122.3

2140.3

22.4

392.7

29.5

515.6

42.7

746.4

1 1/2″

40

DN 40

95.5

3344.2

17.5

613.7

23.0

805.6

33.3

1166.2

2″

50

DN 50

149.3

5225.3

27.4

958.9

36.0

1258.8

52.1

1822.2

2 1/2″

65

DN 65

252.3

8830.7

46.3

1620.5

60.8

2127.3

88.0

3079.6

3″

80

DN 80

382.2

13376.7

70.1

2454.7

92.1

3222.5

133.3

4664.9

4″

100

DN 100

597.2

20901.1

109.6

3835.4

143.9

5035.1

208.3

7289.0

5″

125

DN 125

933.1

32658.0

171.2

5992.8

224.8

7867.4

325.4

11389.0

6″

150

DN 150

1343.6

47027.5

246.6

8629.7

323.7

11329.1

468.6

16400.2

8″

200

DN 200

2388.7

83604.5

438.3

15341.7

575.4

20140.5

833.0

29155.8

10″

250

DN 250

3732.3

130632.1

684.9

23971.4

899.1

31469.6

1301.6

45556.0

12″

300

DN 300

5374.6

188110.2

986.3

34518.8

1294.7

45316.2

1874.3

65600.6

Measuring ranges

VX 570 English V1.10 Seite 11 von 44

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=291.2 °F

T=318.2 °F

T=329 °F

T=339.8 °F

P=43.5 psi(g)

P=72.5 psi(g)

P=87 psi(g)

P=101.5 psi(g)

D=0.1364 lb/ft3

D=0.1986 lb/ft3

D=0.2292 lb/ft3

D=0.2633 lb/ft3

Inch

mm

Min

Max

Min

Min

Max

Min

Max

Min

Max

1/2″

15

DN 15

18.4

214.3

26.8

312.1

30.9

360.1

35.5

413.7

3/4″

20

DN 20

32.7

381.0

47.6

554.9

54.9

640.1

63.0

735.5

1″

25

DN 25

34.0

595.3

49.5

867.0

57.2

1000.2

65.7

1149.3

1 1/4″

32

DN 32

55.7

975.4

81.2

1420.5

93.6

1638.8

107.6

1882.9

1 1/2″

40

DN 40

43.5

1524.1

63.4

2219.5

73.2

2560.6

84.1

2942.1

2″

50

DN 50

68.0

2381.3

99.1

3467.9

114.3

4000.9

131.3

4597.0

2 1/2″

65

DN 65

115.0

4024.5

167.5

5860.8

193.2

6761.5

222.0

7768.9

3″

80

DN 80

174.2

6096.2

253.7

8877.9

292.6

10242.2

336.2

11768.4

4″

100

DN 100

272.2

9525.3

396.3

13871.7

457.2

16003.4

525.4

18388.0

5″

125

DN 125

425.2

14883.3

619.3

21674.5

714.4

25005.4

820.9

28731.3

6″

150

DN 150

612.3

21432.0

891.8

31211.3

1028.8

36007.7

1182.1

41373.1

8″

200

DN 200

1088.6

38101.4

1585.3

55486.7

1829.0

64013.8

2101.5

73552.2

10″

250

DN 250

1701.0

59533.4

2477.1

86698.0

2857.8

100021.5

3283.6

114925.3

12″

300

DN 300

2449.4

85728.1

3567.0

124845.2

4115.2

144031.0

4728.4

165492.4

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=348.8 °F

T=365 °F

T=377.6 °F

T=390.2 °F

P=116 psi(g)

P=145 psi(g)

P=174 psi(g)

P=203 psi(g)

D=0.2948 lb/ft3

D=0.3591 lb/ft3

D=0.4165 lb/ft3

D=0.4811 lb/ft3

Inch

mm

Min

Max

Min

Min

Max

Min

Max

Min

Max

1/2″

15

DN 15

39.7

463.3

48.4

564.2

56.1

654.3

64.8

755.9

3/4″

20

DN 20

70.6

823.6

86.0

1003.0

99.7

1163.3

115.2

1343.7

1″

25

DN 25

73.5

1286.8

89.6

1567.2

103.9

1817.6

120.0

2099.6

1 1/4″

32

DN 32

120.5

2108.4

146.7

2567.7

170.2

2978.0

196.6

3440.0

1 1/2″

40

DN 40

94.1

3294.3

114.6

4012.1

132.9

4653.1

153.6

5375.0

2″

50

DN 50

147.1

5147.4

179.1

6268.9

207.7

7270.4

240.0

8398.4

2 1/2″

65

DN 65

248.5

8699.1

302.7

10594.4

351.1

12287.0

405.5

14193.3

3″

80

DN 80

376.5

13177.3

458.5

16048.3

531.8

18612.3

614.3

21500.0

4″

100

DN 100

588.3

20589.6

716.4

25075.4

830.9

29081.7

959.8

33593.7

5″

125

DN 125

919.2

32171.2

1119.4

39180.3

1298.3

45440.2

1499.7

52490.2

6″

150

DN 150

1323.6

46326.5

1612.0

56419.7

1869.5

65433.9

2159.6

75585.9

8″

200

DN 200

2353.1

82358.2

2865.8

100301.6

3323.6

116326.8

3839.3

134374.9

10″

250

DN 250

3676.7

128684.7

4477.8

156721.3

5193.2

181760.7

5998.9

209960.7

12″

300

DN 300

5294.5

185306.0

6448.0

225678.6

7478.2

261735.4

8638.4

302343.4

Measuring ranges

VX 570 English V1.10 Seite 12 von 44

Measuring range for steam VX 570 under operating conditions in kg/h

Pipe Inner diameter

T=410 °F

T=419 °F

P=261 psi(g)

P=290 psi(g)

D=0.5989 lb/ft3

D=0.6599 lb/ft3

Inch

mm

Min

Max

Min

Min

Max

1/2″

15

DN 15

80.7

940.9

88.9

1036.8

3/4″

20

DN 20

143.4

1672.8

158.0

1843.2

1″

25

DN 25

149.4

2613.7

164.6

2879.9

1 1/4″

32

DN 32

244.7

4282.4

269.6

4718.5

1 1/2″

40

DN 40

191.2

6691.2

210.6

7372.7

2″

50

DN 50

298.7

10455.0

329.1

11519.8

2 1/2″

65

DN 65

504.8

17668.9

556.2

19468.4

3″

80

DN 80

764.7

26764.8

842.6

29490.6

4″

100

DN 100

1194.9

41819.9

1316.5

46079.1

5″

125

DN 125

1867.0

65343.7

2057.1

71998.6

6″

150

DN 150

2688.4

94094.9

2962.2

103678.0

8″

200

DN 200

4779.4

167279.8

5266.2

184316.4

10″

250

DN 250

7467.8

261374.7

8228.4

287994.4

12″

300

DN 300

10753.7

376379.5

11848.9

414711.9

Technical data

VX 570 English V1.10 Page 13 of 44

6Technical data

6.1 Technical data and environmental conditions

Measurement values

Flow rate, total consumption, pressure, temperature,

velocity

Measuring medium

Primarily single-phase gases, mixed gases,

saturated steam, superheated steam and liquids

Sensor technology

Vortex frequency measurement

Measuring range

See chapter 5.2 (measuring ranges)

Accuracy

Volume flow m³/h

Gas / Steam

±1 % f.m. (Re> 20000) **

±2 % f.m. (10000 <Re < 20000) **

Liquid

±0,75 % f.m. (Re> 20000) **

±2 % f.m. (10000 <Re < 20000)**

Accuracy

Mass flow (kg/h)

Standard volume flow Nm³/h)

Gas / Steam

±1,5 % f.m. (Re> 20000) **

±2,5 % f.m. (10000 <Re < 20000) **

Media temperature

-40 ... 350 °C

Ambient temperature

-20 ... 60 °C

Storage temperature

-40 ... 80 °C

Process pressure

Up to 40 bar (63bar on request)

Power supply

18 bis 36 VDC über SELV-Versorgung,5 W

Signal output

Modbus-RTU (RS-485)

3x 4…20 mA (flow, pressure, temperature or

velocity)

Option: Ethernet

Measuring span

Gas: 1:30

Steam: 1:35

Liquid: 1:23

Viscosity

DN15 ≤ 4mPas

DN25 ≤ 5 mPas

DN40..DN300 ≤7mPas

Protection class

IP 67

Process connection

Flange DIN EN1092-1

Flange ANSI

Intermediate flange(wafer)

** f.m. = of measured value | f.e. = of final value

Commissioning

VX 570 English V1.10 Page 14 of 44

7 Installation

7.1 General notes for the Installation

Information!

Check the packaging carefully for damage. In case of damage, please contact the carrier or CS

Instruments GmbH & Co.KG.

Information!

Check the completeness of the delivery.

7.2 Storage

•Store the sensor in a dry and dust-free place

•Store the sensor in the original packaging

•The permissible storage temperatures are -40°C ... 80°C

7.3 Transport

Attention!

•There is a risk of injury from unsecured devices.

During transport, prevent the device from slipping or turning

unintentionally.

•Do not use transport chains, as these will damage the housing.

•The unit must not be lifted by the housing head for transport.

•For transport, use carrying straps which you place around both process

connections.

7.4 Pipe/tube requirements

•Correctly sized gaskets

•Correct aligned flanges and gaskets

•Diameter mismatch at the pipe junctions should be avoided but must be less

than 1mm. For further information see ISO 14511

•Ensure clean pipes after installation

Measuring ranges

VX 570 English V1.10 Seite 15 von 44

7.5 Inlet / Outlet runs

In order to maintain the accuracy stipulated in the data sheets, the sensor must be inserted in the

center of a straight pip e section with an undisturbed flow progression.

An undisturbed flow progression is achieved if the sections in front of the sensor (inlet) and behind the

sensor (outlet) are sufficiently long, straight and without any obstructions such as edges, seams, curves

etc.

Therefore, it is necessary to ensure the recommended inlet and outlet runs.

Flow obstruction before the measurement section

Min length

Inlet run (L1))

Min length

Outlet run (L2))

Slight curve

(elbow < 90°)

15 x D

5 x D

Reduction

(Pipe narrows to the measurement section)

15 x D

5 x D

Expansion

(Pipe expands to the measurement section)

15 x D

5 x D

90° elbow or T-piece

25 x D

5 x D

2x elbow á 90°in einer Ebene

50 x D

5 x D

2x elbow á 90° 3-dimensional

50 x D

5 x D

Control valve

50 x D

5 x D

15 x D 5 x D

15 x D 5 x D15 x D

25 x D 5 x D

50 x D 5 x D

50 x D 5 x D

5 x D50 x D

The values represent the min. lengths. In case the min. inlet / outlet runs could not be ensured, it must

be expected to get increased or significant deviations of the measurement values.

8 Commissioning

•Depressurize the system

•Ensure correct direction of flow during installation

•Maintain an undisturbed flow course while observing the required calming distances in

the measuring range, see section 7.5

Dimension

VX 570 English V1.10 Page 16 of 44

9Dimension

9.1 Zwischenflansch-Ausführung

Intermediate (wafer) Version

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Height H

150℃

250℃

350℃

15

15

75

65

294

335

475

20

20

75

65

294

335

475

25

25

75

65

289

330

470

32

32

80

65

293

334

474

40

40

84

65

296

337

477

50

50

94

65

301

342

482

65

65

105

65

309

350

490

80

80

120

65

316

357

497

100

100

140

90

327

368

508

125

125

165

65

341

382

522

150

150

190

65

353

534

534

200

200

240

85

378

559

559

250

250

290

100

404

585

585

300

300

340

120

429

609

609

Dimension

VX 570 English V1.10 Seite 17 von 44

9.2 Flange version (without temperature- / pressure-sensor)

Flange-Version

9.2.1 PN 16

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Flange- Dimension [mm]

height H [mm]

ØW

C

ØM

Qty [n]

150°C

250°C

350°C

15

15

95

180

65

14

14

4

294

335

475

20

20

105

180

75

16

14

4

294

335

475

25

25

115

180

85

16

14

4

293

334

474

32

32

140

180

100

18

18

4

301

342

482

40

40

150

180

110

18

18

4

303

344

484

50

50

165

180

125

20

18

4

307

348

488

65

65

185

200

145

20

18

8

314

355

495

80

80

200

200

160

20

18

8

326

367

507

100

100

220

200

180

22

18

8

336

377

517

125

125

250

220

210

22

18

8

345

386

526

150

150

285

220

240

24

22

8

360

541

541

200

200

340

220

295

26

22

12

385

586

586

250

250

405

250

355

29

26

12

413

594

594

300

300

460

300

410

32

26

12

446

627

627

Dimension

VX 570 English V1.10 Seite 18 von 44

9.2.2 PN 25

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Flange- Dimension [mm]

Height H [mm]

ØW

C

ØM

Qty [n]

150°C

250°C

ØW

15

15

95

180

65

14

14

4

294

335

475

20

20

105

180

75

16

14

4

294

335

475

25

25

115

180

85

16

14

4

293

334

474

32

32

140

180

100

18

18

4

301

342

482

40

40

150

180

110

18

18

4

303

344

484

50

50

165

180

125

20

18

4

307

348

488

65

65

185

200

145

22

18

8

314

355

495

80

80

200

200

160

24

18

8

326

367

507

100

100

235

200

190

26

22

8

336

377

517

125

125

270

220

220

28

26

8

345

386

526

150

150

300

220

250

30

26

8

360

541

541

200

200

360

220

310

32

26

12

385

586

586

250

250

425

250

370

35

30

12

413

594

594

300

300

485

300

430

38

30

16

446

627

627

9.2.3 PN 40

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Flange- Dimension [mm]

Height H [mm]

ØW

C

ØM

Qty [n]

150°C

250°C

ØW

15

15

95

180

65

14

14

4

294

335

475

20

20

105

180

75

16

14

4

294

335

475

25

25

115

180

85

16

14

4

293

334

474

32

32

140

180

100

18

18

4

301

342

482

40

40

150

180

110

18

18

4

303

344

484

50

50

165

180

125

20

18

4

307

348

488

65

65

185

200

145

22

18

8

314

355

495

80

80

200

200

160

24

18

8

326

367

507

100

100

235

200

190

26

22

8

336

377

517

125

125

270

220

220

28

26

8

345

386

526

150

150

300

220

250

30

26

8

360

541

541

200

200

375

220

320

36

30

12

385

586

586

250

250

450

250

385

42

33

12

413

594

594

300

300

515

300

450

52

33

16

446

627

627

Dimension

VX 570 English V1.10 Seite 19 von 44

9.2.4 ANSI Class150

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Flange- Dimension [mm]

Height H [mm]

ØW

C

ØM

Qty [n]

150°C

250°C

ØW

15

15

90

180

60.3

11.6

15.9

4

294

335

475

20

20

100

180

69.9

13.2

15.9

4

294

335

475

25

25

110

180

79.4

14.7

15.9

4

293

334

474

32

32

117.3

180

88.9

16.3

15.9

4

301

342

482

40

40

127

180

98.4

17.9

15.9

4

303

344

484

50

50

152.4

180

120.7

19.5

19

4

307

348

488

65

65

180

200

139.7

22.7

19

4

314

355

495

80

80

190.5

200

152.4

24.3

19

4

326

367

507

100

100

230

200

190.5

24.3

19

8

336

377

517

125

125

255

220

215.9

24.3

22.2

8

345

386

526

150

150

280

220

241.3

25.9

22.2

8

360

541

541

200

200

345

220

298.5

29

22.2

8

385

586

586

250

250

406.4

250

362.0

30.6

25.4

12

413

594

594

300

300

485

300

431.8

32.2

25.4

12

446

627

627

9.2.5 ANSI Class300

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Flange- Dimension [mm]

Height H [mm]

ØW

C

ØM

Qty [n]

150°C

250°C

ØW

15

15

95.2

180

66.7

14.7

15.9

4

294

335

475

20

20

117.5

180

82.6

16.3

19

4

294

335

475

25

25

125

180

88.9

17.9

19

4

293

334

474

32

32

135

180

98.4

19.5

19

4

301

342

482

40

40

156

180

114.3

21.1

22.2

4

303

344

4894

50

50

165.1

180

127

22.7

19

8

307

348

488

65

65

191

200

149.2

25.9

22.2

8

314

355

495

80

80

210

200

168.3

29

22.2

8

326

367

507

100

100

255

200

200

32.2

22.2

8

336

377

517

125

125

280

220

235

35.4

22.2

8

345

386

526

150

150

320

220

269.9

37

22.2

12

360

541

541

200

200

381

220

330.2

41.7

25.4

12

385

586

586

250

250

445

250

387.4

48.1

28.6

16

413

594

594

300

300

521

300

450.8

51.3

31.7

16

446

627

627

Dimension

VX 570 English V1.10 Seite 20 von 44

9.3 Flange Version with temperature- pressure-sensor

Flange-Version

9.3.1 PN 16

Pipe

[DN]

ØD

[mm]

ØK

[mm]

L

[mm]

Flange- Dimension [mm]

Height H [mm]

ØW

C

ØM

Qty [n]

150°C

250°C

ØW

15

15

95

180

65

14

14

4

294

335

475

20

20

105

180

75

16

14

4

294

335

475

25

25

115

180

85

16

14

4

293

334

474

32

32

140

180

100

18

18

4

301

342

482

40

40

150

180

110

18

18

4

303

344

484

50

50

165

180

125

20

18

4

307

348

488

65

65

185

200

145

20

18

8

314

355

495

80

80

200

200

160

20

18

8

326

367

507

100

100

220

200

180

22

18

8

336

377

517

125

125

250

220

210

22

18

8

345

386

526

150

150

285

220

240

24

22

8

360

541

541

200

200

340

220

295

26

22

12

385

566

566

250

250

405

250

355

29

26

12

413

594

594

300

300

460

300

410

32

26

12

446

627

627

Table of contents

Other CS Instruments Accessories manuals

CS Instruments

CS Instruments VA 521 User manual

CS Instruments

CS Instruments VA 570 User manual

CS Instruments

CS Instruments VD 500 User manual

CS Instruments

CS Instruments VA 452 User manual

CS Instruments

CS Instruments VA 500 User manual

CS Instruments

CS Instruments VA 550 User manual

CS Instruments

CS Instruments VA 400 User manual

CS Instruments

CS Instruments VA 525 User manual

CS Instruments

CS Instruments VA 500 User manual

CS Instruments

CS Instruments FA 550 User manual