CS Instruments VA 452 User manual

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

VA 452

thermal mass flow sensor

Operating Instruction

11A Floor, D3 Building, TCL International E City, No. 1001

Zhongshanyuan Road, Nanshan District,

Shenzhen 518057, China

Tel: +86 (0)755 - 8619 3164

Fax: +86 (0)755 - 8619 3165

Website: http://www.csinstrument.com

CS Instruments (Shenzhen) Co. Ltd.

Room 1506, Hong Qiao Silver City Building, No.933

Zhongshan Road(w), Shanghai 200051, China.

Tel: +86 (0) 21-5111 3860

Fax: +86 (0) 21-5111 3861

Website: http://www.csinstrument.com

CS Instruments (Shanghai) branch

Asia Head Quarters

Room 31, Tower B, Cambridge Plaza,188 San Wan Road,

Sheung Shui, N.T. , Hong Kong

Tel: +86 (0)755 - 8619 3164

Fax: +86 (0)755 - 8619 3165

Website: http://www.csinstrument.com

CS Instruments (Asia) Co. Ltd.

Shanghai office

Hong Kong office

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

2

Table of Contents

Chapter 1 General Information

23

Chapter 2 Introduction

Chapter 3 Installation

Important information………………………………………………………...……....3

Area of application…………………………………………………………...……….3

Installation considerations………………………………………………...………....3

Notes on safety…………………………………………….……..…………………..4

Product feature……………………...…………………………………..……….…...5

Inlet / outlet runs…………………………………………..…….………………..…..5

Flow conditioner……………………………………………………………………....6

Pipe requirements……………………………………………...……….…………....7

Installation…………………………………………………………………...………...7

Wiring……………………………………………………...…………..……………..10

Connection diagram…………………………………………………………...……10

Connecting DS 300 ………………………………………...……...………..…..…11

Connecting analogue / pulse outputs………………………………….……….…12

Connecting HART………………………………………………...………….…..…12

Connecting Modbus …………………….……………………...…………….....…12

Connecting MBus ………………………………...………...…………………...…13

Chapter 4 Operation

Chapter 5 Trademarks………………….………………...……......……...….

21

Chapter 6 Warranty………………………………………………………..…..

21

Startup…………………………………………………...………...……..……...…..14

Display…………………………………………………...……………………..……14

Configuration…………………………………………………...…….………..….…15

Bluetooth…………………………………………………...……………………..….16

Service Kit…………………………………………………...…………………....…16

Technical data…………………………………………………...……………..…...17

Measuring…………………………………………………...………...………....….17

Dimensions …………………………………………………...…………………..…20

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

The operating instructions must be read in full and carefully ob-

served before starting up the device. The manufacturer cannot be

held liable for any damage which occurs as a result of non-

observance or non-compliance with this manual.

Should the device be tampered with in any manner other than a

procedure which is described and specified in the manual, the war-

ranty is cancelled and the manufacturer is exempt from liability.

CS Instruments is not liable for errors which may have slipped into

this operating manual.

The CS flow meter VA 452 works based on the thermal mass flow

principle and is to be used for measuring the mass flow of gases.

The device can be configured to measure pure gases (e.g. CO2, N2,

O2, Ar etc.) or gas mixtures (e.g. air, natural gas). It is used to meas-

ure gas/air consumption, control and monitor flow rates.

Any use other than that described here compromises the safety of

persons and the entire measuring system and is, therefore, not per-

mitted.

The manufacturer is not liable for damage caused by improper or

non-designated use.

Important

information

Area of

application

322

Installation

and operation

The measuring device must only be installed, connected, commis-

sioned and maintained by qualified and authorized specialists (e.g.

electrical technicians) in full compliance with the instructions in this

manual, the applicable norms, legal regulations and certificates

(depending on the application).

The measuring device may only be modified or repaired if such work

is permitted in this instruction manual.

In order to achieve and maintain the accuracy stipulated in the tech-

nical data, the sensor must be installed according to the instructions

in this manual.

Unhindered flow characteristics are achieved if the sections in front

of the sensor (inlet) and behind the sensor (outlet) are sufficiently

long, absolutely straight and without obstructions such as edges,

seams, bends etc.

Careful attention must be paid to the design of the outlet section as

obstructions can cause counter-flow turbulence as well as turbu-

lence in the direction of the flow.

1. General information

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

•

VA 452 is designed to meet state-of-the-art safety require-

ments, has been tested, and left the factory in a condition in

which it is safe to operate. Relevant regulations and European

standards have been observed.

•

The wiring of the device has to be done correctly in accord-

ance with the wiring diagrams.

•

Observe the technical data on the nameplate!

•

Do not exceed the pressure range of 4.0 MPa.

•

Observe permissible storage, transport and operating tempera-

tures.

•

VA 452 for use in hazardous areas are labeled accordingly on

the nameplate. Relevant national regulations must be ob-

served when operating the device in hazardous areas. Ob-

serve the installation regulations, connection data and safety

instructions provided in the Ex documentation must be ob-

served.

Notes on

safety

4 21

CS provides a warranty for this product of 24 months covering the

material and workmanship under the stated operating conditions

from the date of delivery.

Please report any findings immediately and within the warranty

time guaranteed by us.

Excluded from this warranty is damage caused by improper use

and non-adherence to the instruction manual.

The warranty is also cancelled once the measuring instrument has

been opened provided this is not described in the instruction man-

ual for maintenance purposes. This is also the case if the serial

number has been changed, damaged or removed.

If in addition to the warranty service necessary repairs, adjust-

ments or similar are carried out, the warranty services are free of

charge but there is a charge for other services such as transport

and packing costs. Other claims, especially those for damage

occurring outside the instrument are not included unless responsi-

bility is legally binding.

Warranty

HART®

Registered trademark of HART Communication Foundation, Austin,

USA

MODBUS®

Registered trademark of the MODBUS Organization

MBUS®

Registered trademark of the MBUS Organization

Bluetooth®

Registered trademark of the Bluetooth Organization

Trademarks

6. Warranty

5. Trademarks

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

5

Product

features

•

Direct measurement of mass flow and standard flow without

the need of pressure compensation

•

Wide range of tube sizes are supported with insertion type

for big tubes and inline types for small tubes

•

No moving parts, non clogging

•

All parts which come into contact with the measurement

medium are made of stainless steel 316L.

•

Robust metal enclosure suitable for out-door applications in

harsh environment

•

Wireless Bluetooth interface for commissioning on site

•

Display showing flow rates, consumption, medium tempera-

ture and diagnostic results

•

2 analogue outputs (4-20 mA) and 1 pulse output

•

Available options:

•

Fieldbus interface: HART, Modbus, MBus

•

Hazardous approval ATEX: II 2 G Ex IIC T4

•

2-directional measurement

•

Flow conditioning

20

inlet / outlet

runs

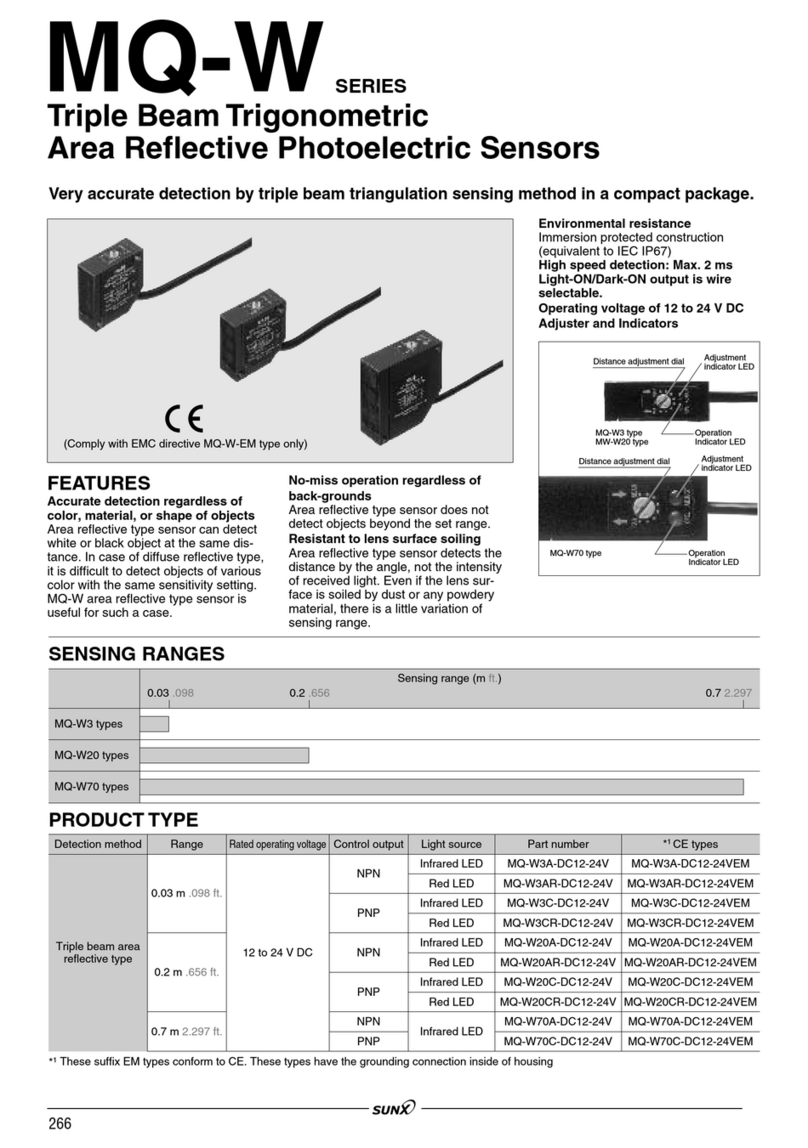

Thermal mass flow meters are sensitive disturbances in the flowing

gas stream (e.g. vortex formation). As a general rule, the installed

sensor should always be installed as far away as possible from any

flow disturbances . Further information can be found in ISO Standard

14511.

Please observe the following recommended minimum values with

regard to the inlet and outlet runs.

2. Introduction

Dimensions

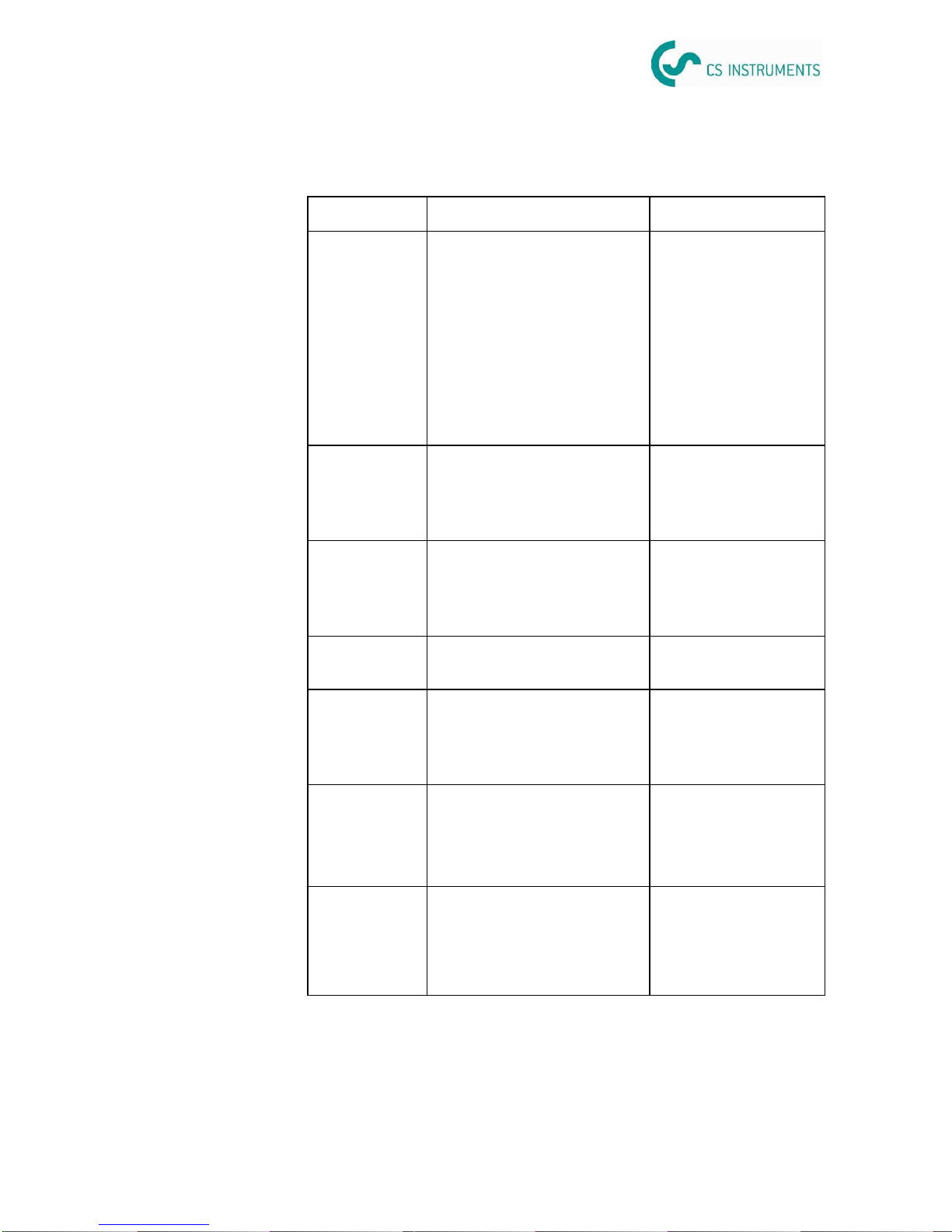

Pipe

nominal

size

[inch]

Outer diameter x

thickness/[inner dia]

[mm]

L

total

length

[mm]

L1

inlet

length

[mm]

H

total

height

[mm]

H1 from

pipe

center to

casing

top [mm]

1/2" Ø21.3 x 2.6/[Ø16.1] 300 210 247.65 200.15

3/4" Ø26.9 x 2.6/[Ø21.7] 475 275 252.65 200.15

1" Ø33.7 x 3.2/[Ø27.3] 475 275 257.65 200.15

1 ¼" Ø42.4 x 3.2/[Ø36.0] 475 275 270.15 200.15

1 ½" Ø48.3 x 3.2/[Ø41.9] 475 275 275.15 200.15

2" Ø60.3 x 3.6/[Ø53.1] 475 275 282.65 200.15

2 ½" Ø76.1 x 3.6/[Ø68.9] 475 275 300.55 208.05

3" Ø88.9 x 4.0/[Ø80.9] 475 275 314.45 214.45

DN

DN15

DN20

DN25

DN32

DN40

DN50

DN65

DN80

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

6 19

Flow

conditioner

In areas where the required inlet / outlet rungs can not be achieved

it’s recommended to use a flow conditioner upstream of the sensor.

This will reduce the minimum inlet run to 5-8 x D.

Pressure loss calculation:

DP = K * v

2

* ρ

DP: Pressure loss [hPa or mbar]

K: Constant = 0.008

v: Actual velocity of gas at conditioner inlet [m/s]

ρ: Density of gas [kg/m3]

conditioner

gasket

gasket

Device type: Slave

Polling address: 1 to 15

Bus address can be set through software

Physical interface: BELL 202

Protocol version: V5.2

Tag: VA 452

Tag description: FLOW METER

Frame/parity/Stop: 8, O, 1

HART

Device type: Slave

Address range: 1 to 247

Bus address can be set through software

Physical interface: RS485 in accordance with EIA/TIA-485

standard

Baudrates: 1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200 Baud

Transm. mode: ASCII, RTU

Response times: Direct data access = 0 to 255 ms (can be con

figured)

Modbus

MBus

Approvals

Certificates

CE mark: The measuring system is conform with the

statutory requirements of the EC Directives.

CS Instruments has successful tested the

device and affixed the CE mark.

Ex approval: CS Instruments provides a separate

documentation.

Other

Standards

EN 60529 Protection by housing (IP code)

IEC/EN 61326 EMC- requirements

ISO 14511 Thermal mass flowmeters.

NAMUR NE 43 Standardization analogue outputs

Device type: Slave

Address range: 1 to 251

Bus address can be set through software

Physical interface: Meter-Bus, EN1434-3

Baudrates: 300, 2400, 9600 Baud

Frame/parity/Stop: 8, E, 1

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

718

Installation

1. Orientation

Pipe

requirements

At all times good installation practice should be followed:

•

Clean pipes and flange welded joints

•

Correctly sized gaskets

•

Correctly aligned flanges and gaskets

•

Use seamless pipes immediately upstream of the flowme-

ter.

•

Use of pipes that match in regards of the internal diameter

next to the flowmeter. Avoid any disturbance or miss-

alignment greater than 1 mm.

•

Anything that disturbs the smoothness of the internal pipe

wall (see figure below) should be eliminated; the goal

should be a smooth uninterrupted internal surface. For

further information please refer to ISO 14511.

3. Installation

Accuracy

Uncertainty: 1.5% of reading + 0.3% of full scale

Repeatability: 0.25 % of reading

Stated uncertainty at:

Ambient / process temperature: 23 °C ± 3 °C

Ambient / process humidity: <90%, no condensation

Process pressure: 0.6 MPa

Response /

Sampling

Response time: T

95

< 5 seconds

Sampling rate: 5 samples per second

Display is refreshed every 0.5 seconds

Outputs are refreshed every 0.2 seconds

Process

connection

R thread (ISO 7-1), Flange EN 1092-1

All parts in contact with the medium are of stainless steel 316L

Power supply

16 - 30 VDC, 7 W

Environment

conditions

Ambient temp.: -30 … +65 °C (non display version)

-25 … +65 °C (display version)

Storage temp.: -40 … +65 °C

Protection: IP 67

Shock resistance: IEC 60068-2-31

Vibration resist.: IEC 60068-2-6

EMC: IEC / EN 61326

Operating

conditions

Medium temp.: -40 … +100 °C

Pressure loss: < 3 hPa (4” pipe)

Medium pressure: -0.1 … 4.0 MPa

Analogue

output

Active / passive selectable, galvanic isolated

Active: 4 to 20 mA, RL < 400 Ω

Passive: 4 to 20 mA; supply voltage 1 ! 30 V DC, RL <

500 Ω

for HART: RL ≥250 Ω

Uncertainty: < 0.3% of reading

Resolution: 0.005 mA

Pulse/Alarm

output

NO switch, no polarity required, galv. isolated

Max rating: 30 VDC, 200 mA

Pulse width: 10 … 100 msec (depending on flow rate)

Communication Distance: < 3m (depend on environment)

Device name: VA 452 + s/n (Can be edited)

Bluetooth

DN 15 (1/2”), DN 20 (3/4”), DN 25 (1”), DN 32 (1 ¼”),

DN 40 (1 ½”), DN 50 (2”), DN 65 (2 ½”), DN 80 (3”)

Tube size

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

8 17

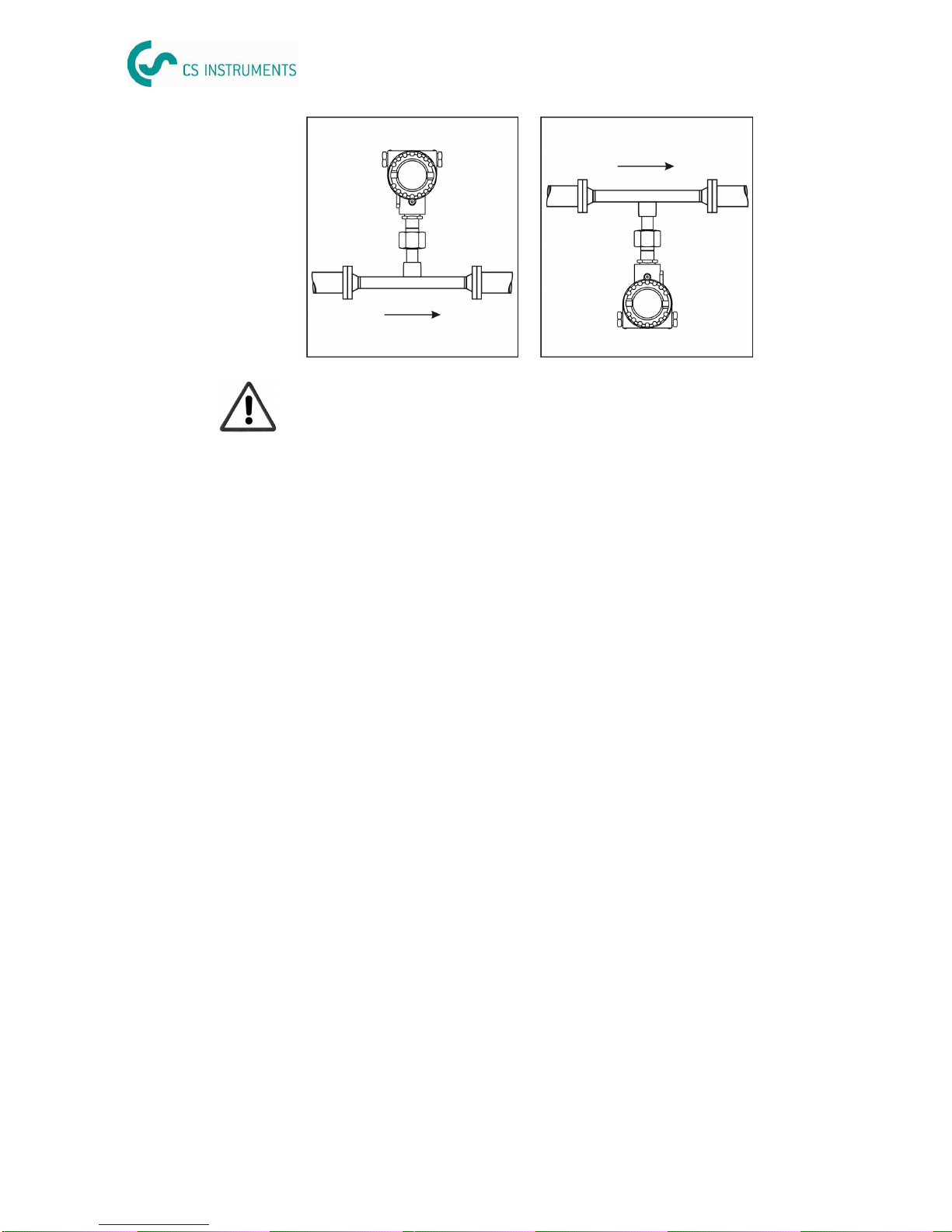

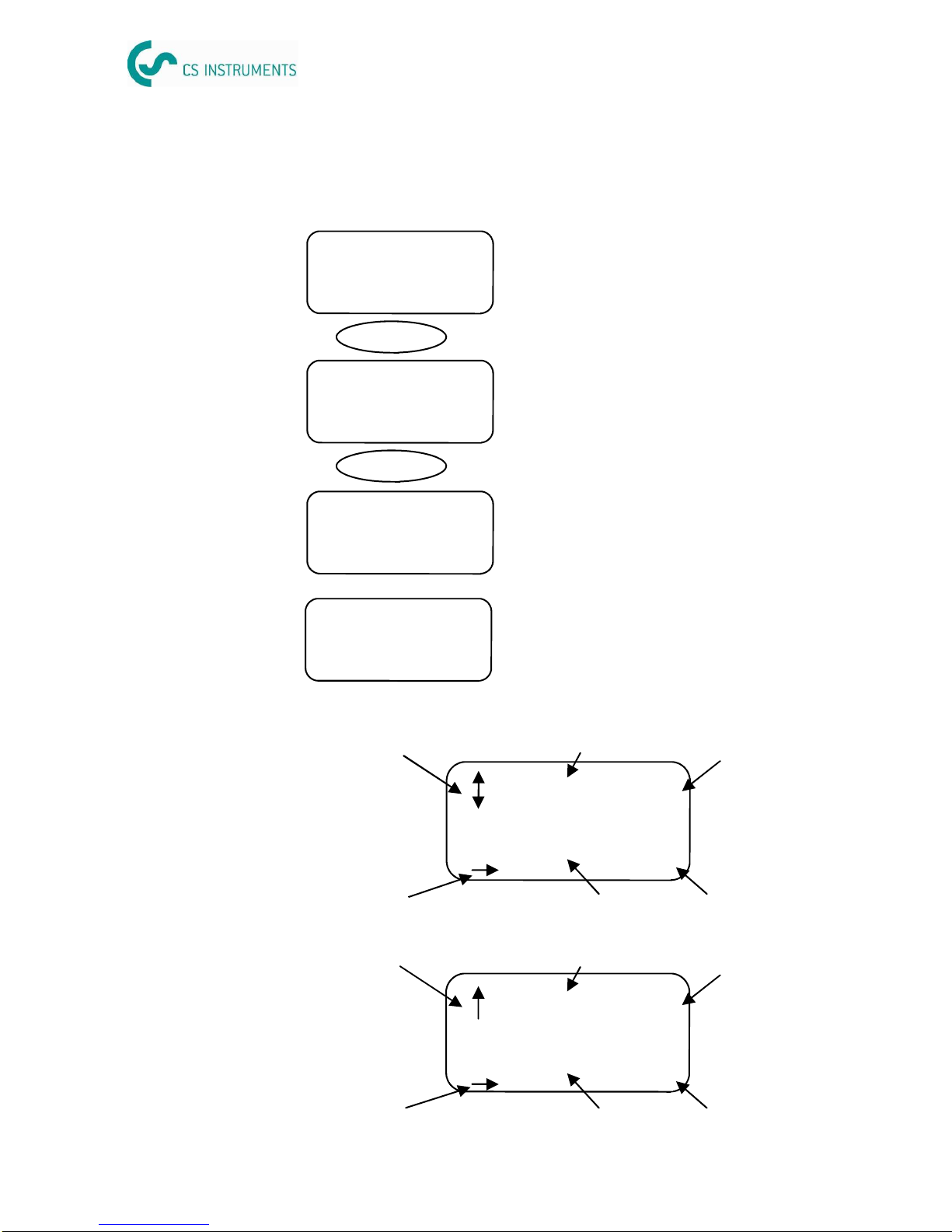

The unit can be installed in any position in the piping. In the case of

wet/dirty gases, upward flow is recommended in vertical pipes to

minimize condensation/contamination on or around the sensing

element. In particular, where free condensation can occur (e.g. Bio-

gas) the sensor should be orientated to prevent water collecting on

or around the sensing elements (e.g. do not install the sensor at a

low point in the installation without adequate drainage).

Ensure that the direction arrow on the sensor matches the direction

of flow .

2. Display orientation

The display version of VA 452 can be rotated in both directions

270°. For this purpose the the nut at the top of the shaft has to be

opened fully. Then pull up the metal casing and rotate it in the de-

sired direction. It can be rotated in 90°steps in both directions. A

metal pin locks the position. When the desired position is achieved,

press down the metal casing onto the shaft so that the metal pin can

insert into the position hole. Tighten up the nut.

Technical

data

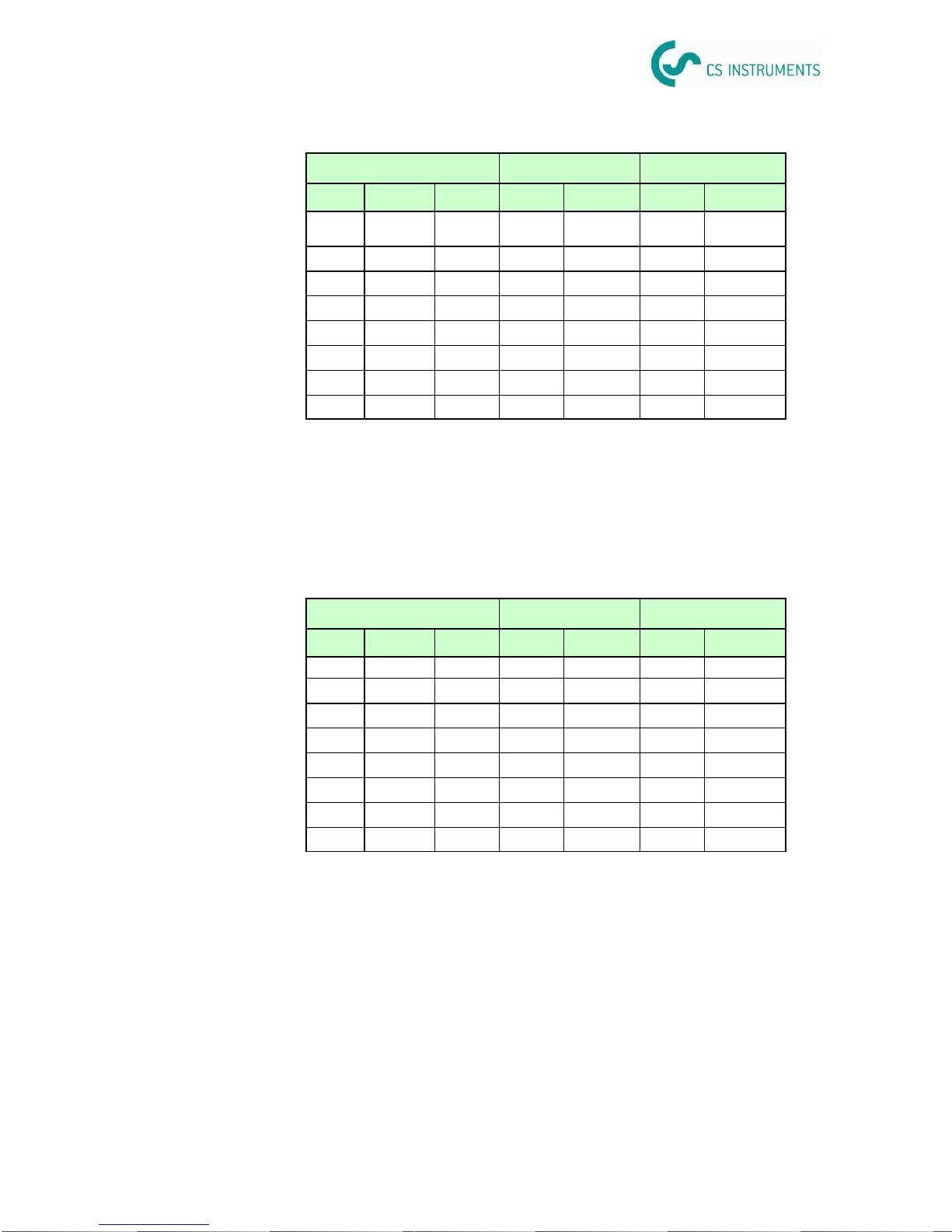

Measuring

range

Pipe sm

3

/h kg/h

Inch DN mm Min Max Min Max

1" DN25 27.3 0.6 147.7 0.7 175.5

1 1/4" DN32 36.0 1.1 266.3 1.3 316.5

1 1/2" DN40 41.9 1.5 366.7 1.7 435.9

2” DN50 53.1 2.4 600 2.9 713

2 1/2" DN65 68.9 4.1 1027 4.9 1220

3” DN80 80.9 5.7 1424 6.8 1693

3/4” DN20 21.7 0.4 89.1 0.4 105.9

1/2” DN15 16.1 0.2 45.6 0.2 54.2

Volumetric flow is stated at 1000 hPa and 20 °C

VA 452 can measure from zero flow onwards, the stated minimum

flow is only required for achieving the specification. Flow rates above

the maximum flow can not be measured.

Standard range calibration:

Pipe sm

3

/h kg/h

Inch DN mm Min Max Min Max

1" DN25 27.3 1.2 294.7 1.4 350.3

1 1/4" DN32 36.0 2.1 531.5 2.5 631.7

1 1/2" DN40 41.9 2.9 731.9 3.5 869.9

2” DN50 53.1 4.8 1198 5.7 1423

2 1/2" DN65 68.9 8.2 2049 9.7 2435

3” DN80 80.9 11.4 2841 13.5 3377

3/4” DN20 21.7 0.7 177.8 0.8 211.4

1/2” DN15 16.1 0.4 100.0 0.4 108.1

Max range calibration:

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

16 9

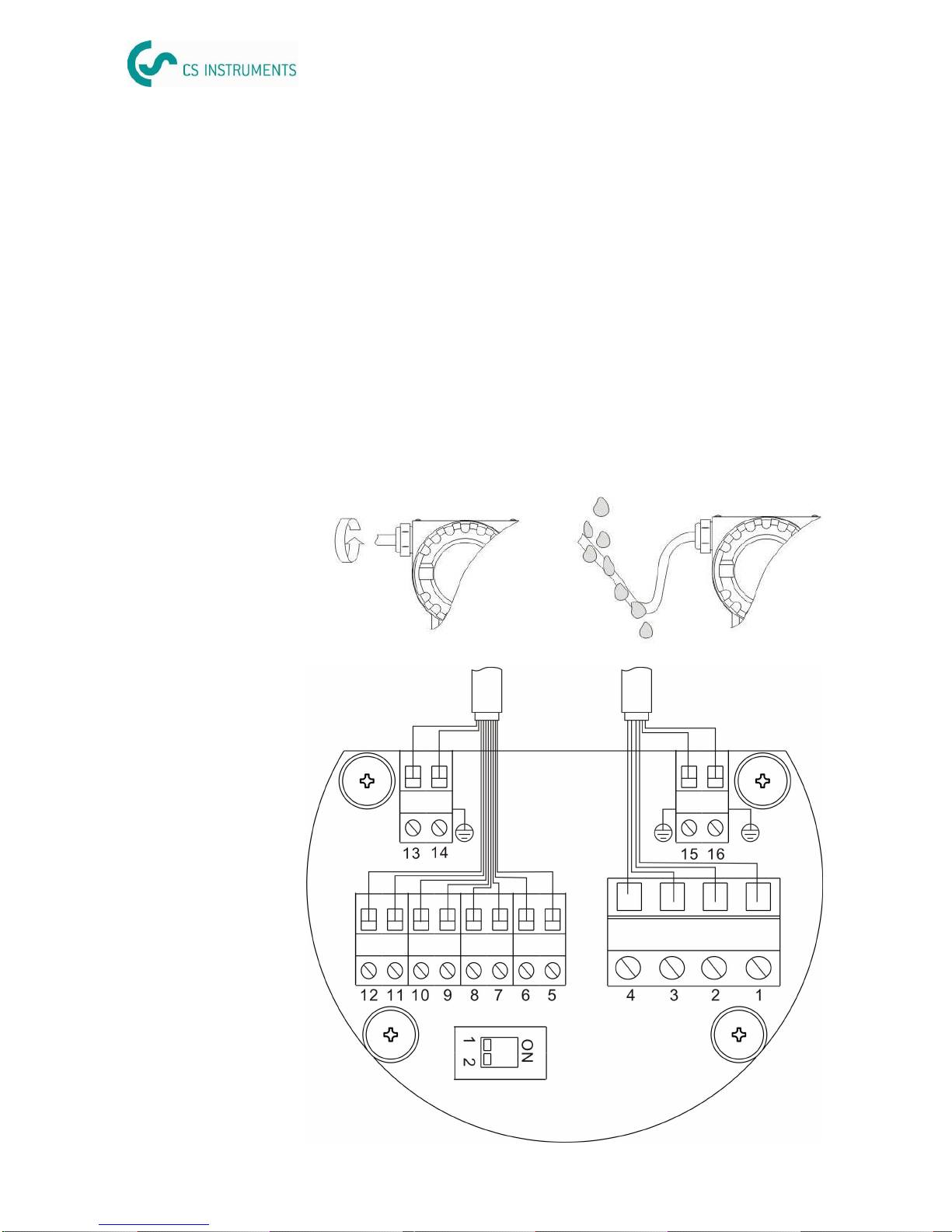

3. Protect sensor tip

The sensor unit can be removed from the measuring section for

example for cleaning or service / calibration. To protect the sensor

during transportation we recommend to use a sensor protection cap

as indicated in the picture below.

Please contact our local service for sensor protection cap.

Sensor head can be rotated in 90°steps through the screw nut

Power

supply

PC VA 452

Bluetooth

Power

supply

PC VA 452Service

Kit

Bluetooth

Bluetooth provides a convenient way of configuring the sensor with-

out the hazel of cable connections. VA 452 needs to be powered up.

Ensure that the distance between VA 452 and PC is no more that 5

meter and the PC Bluetooth antenna should point roughly in the

direction of the display (front part). Please follow the instruction in

the service software and the help file.

Service Kit

The diagram above shows the connection when using the optional

service kit (0554 2005). Please ensure that also in this case the

power supply of either VA 452 or of the service kit is connected

(USB port is not supplying enough power).

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

10 15

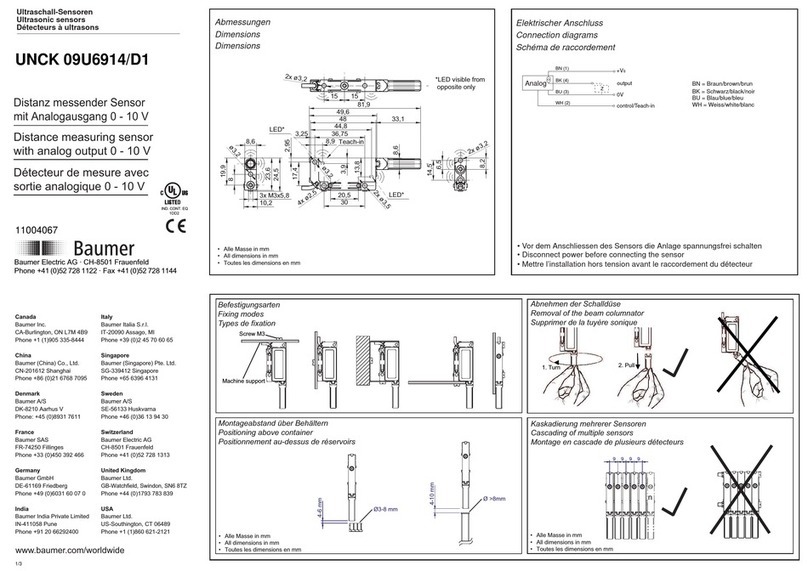

When installing the cables please consider following points:

•

Keep the stripped and twisted lengths of cable shield as

short as possible.

•

Screen and ground the signal lines

•

Install the measuring device that the cable entries do not

point upwards.

•

Do not remove the seal from the cable entry.

•

Unused cable entries must be closed with closers.

•

Cable outer diameter should be between 6 and 8 mm

•

Single wire cross section area should be between 0.25 …

0.75 mm

2

•

The thread size for the cable glands is M20 / 1.5

Wiring

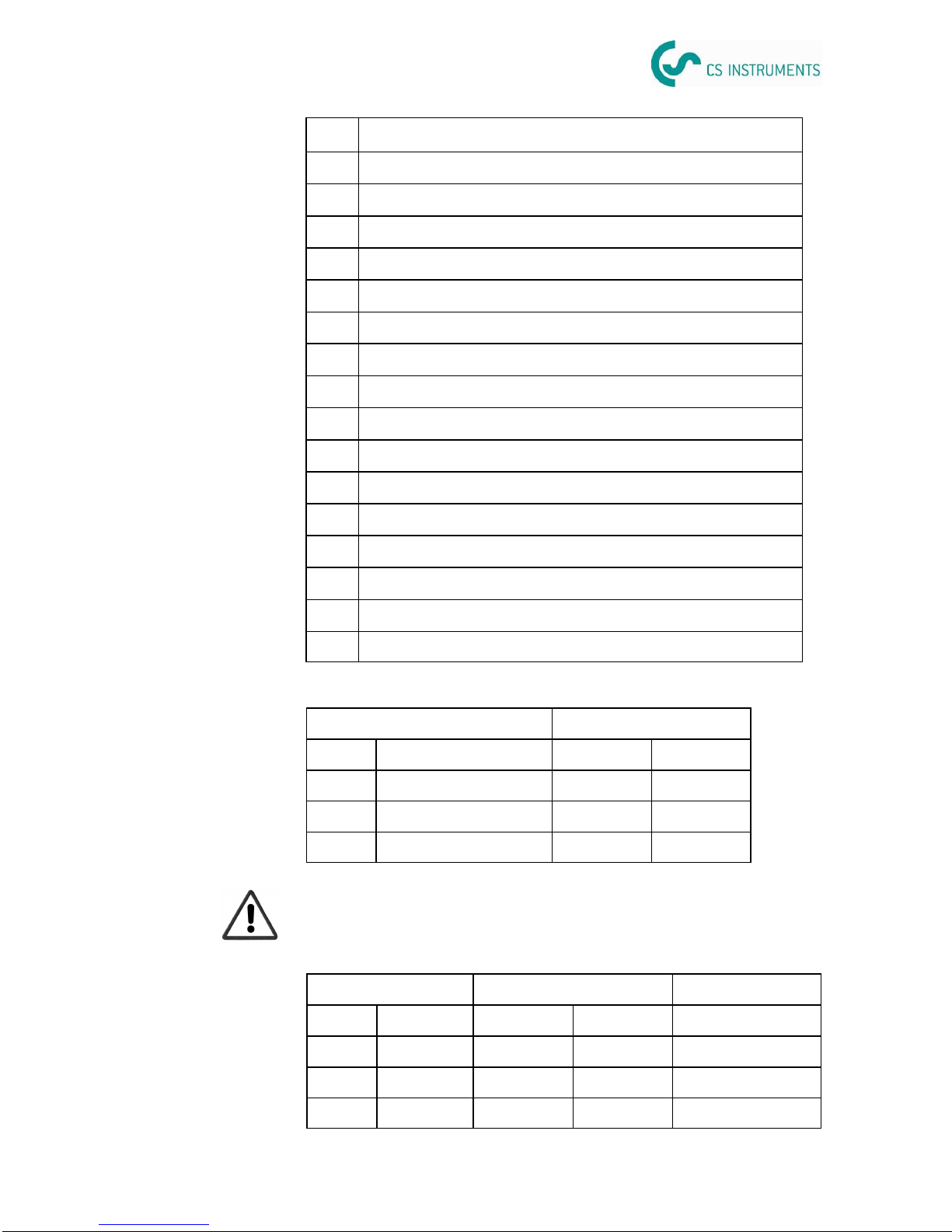

Connection

diagram

Configuration

Configuration settings have to be done through the service software

which is included in the scope of delivery. The service software can

be isntalled on any PC with windows operating system. To

communicate with the sensor the PC needs to have a Bluetooth

interface. Alternativly a service kit can be used which cis as option

Area Available settings Default

Measurement Tube diameter

Flow unit

Consumption unit

Reference conditions

Gas type selection

Consumption counter

Operation pressure

Flow direction

54.0

m

3

/h

m

3

P

S

= 1000 hPA

T

S

= 20 °C

Air

0 m

3

0.6 MPa

Standard

Analogue

output 1 Measurement channel

Scaling

Active / passive

Flow

4 mA: 0 m

3

/h

20 mA: max flow

Active

Pulse output Pulse / Alarm

Pulses per consumption unit Pulse

1

HART Fieldbus address

Manufacturer ID

Device type code

0

255

0

Modbus Device address

Baudrate

Framing/parity/Stop bit

Transmission mode

1

19200

8, E, 1

RTU

MBus Address

Manufacturer code

Baudrate

Access Number

0

END

300

0

Analogue

output 2 Measurement channel

Scaling

Active / passive

Medium Temp.

4 mA: -50 °C

20 mA: 200 °C

Active

In order to fully utilize ethe functionality of VA 452 a configuration is

required. There are various paramters which need to be set in the flow

meter. The table below gives an overview about the available settings.

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

1114

Connecting

DS 300

DS 300 is connected to VA 452 through a 3 pole cable.

VA 452 DS 300

Pin Signal Pin Pin

4 SDI I-3 G-6

2 V+ I-1 G-8

3 V- I-4 G-7

DS 300 has 2 inputs (I and G) for flow / dew point sensors.

If there are more than 1 VA 452 to be connected to DS 300 a sepa-

rate power supply has to be used for at least one of the VA 452,

since DS 300 can only supply one VA 452 flow sensor.

VA 452 DS 300 Ext. 24 VDC

Pin Signal Pin Pin

4 SDI I-3 G-6

2 V+ N.C. N.C. 24V+

3 V- I-4 G-7 24V-

Startup

Initializing...

2 sec.

Software: 1.31

Hardware: 1.20

The version with display will startup in the sequence as described

below.

1345.6

12345670

m

3

/h

2 sec.

Software and hardware version

VA 452 will then show the actual online

values of flow and total consumption.

After reset the sensor has a warm-up

time of about 20 seconds., during this

time the flow rate is zero.

m

3

M: 43.6 °C

A: 25.7 °C

E: 00 00 00 00

Every 5 seconds the display will show the

medium and the ambient temperature

together with an error code. The error

code information is helpful for service

engineers .

Display

Flow unit

Consumption unit10 digit consumption

6 digit flow

Flow direction

Overflow indication

12345.6

1234567890

m

3

m

3

/h

4. Operation

Flow unit

Consumption unit10 digit consumption

6 digit flow

Flow direction

Alarm indication

12345.6

1234567890

m

3

m

3

/h

Pin Signal description

1 Ground for SDI

2 V+

3 V-

4 SDI

5 Direction input D1 (flow switch)

6 Direction input D2 (flow switch)

7 Pulse output P1 / Alarm switch A1

8 Pulse output P2 / Alarm switch A2

9 Current output channel 1 - / HART bus

10 Current output channel 1 + / HART bus

11 Current output channel 2 - / MODBUS data + / MBUS M1

12 Current output channel 2 + / MODBUS data - / MBUS M2

13 Ground for MODBUS cable

14 Earth

15 Earth

16 Earth

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

12 13

Connecting

analogue /

pulse outputs

VA 452 in the standard configuration comes with 2 analogue outputs

and 1 pulse output. All signals are electrically isolated. The analogue

output can be used as an active output—current is sourced through

the positive connection pin—or passive. In the passive configuration

a current signal is modulated onto the external signal voltage.

Pin Signal Description

12 Analog 2 I+ Positive signal output

11 I- Negative signal output

10 Analog 1 I+ Positive signal output

9 I- Negative signal output

7 Pulse P1 No polarity required

8 P2 No polarity required

Connecting

HART

Pin Signal Description

10 Analog 1 I+ / HART+ Positive signal output

9 I- / HART- Negative signal output

The HART signal is modulated on analogue output 1. In case VA

452 is used in a multi drop configuration (more than 1 slave on the 4-

20 mA line) the analogue output can not be used anymore.

Connecting

Modbus

The version with Modbus comes with one analogue output

and one pulse output.

Pin Signal Description

11 Modbus Data+ RS-485

12 Data- RS-485

10 Analog 1 I+ Positive signal output

9 I- Negative signal output

7 Pulse P1 No polarity required

8 P2 No polarity required

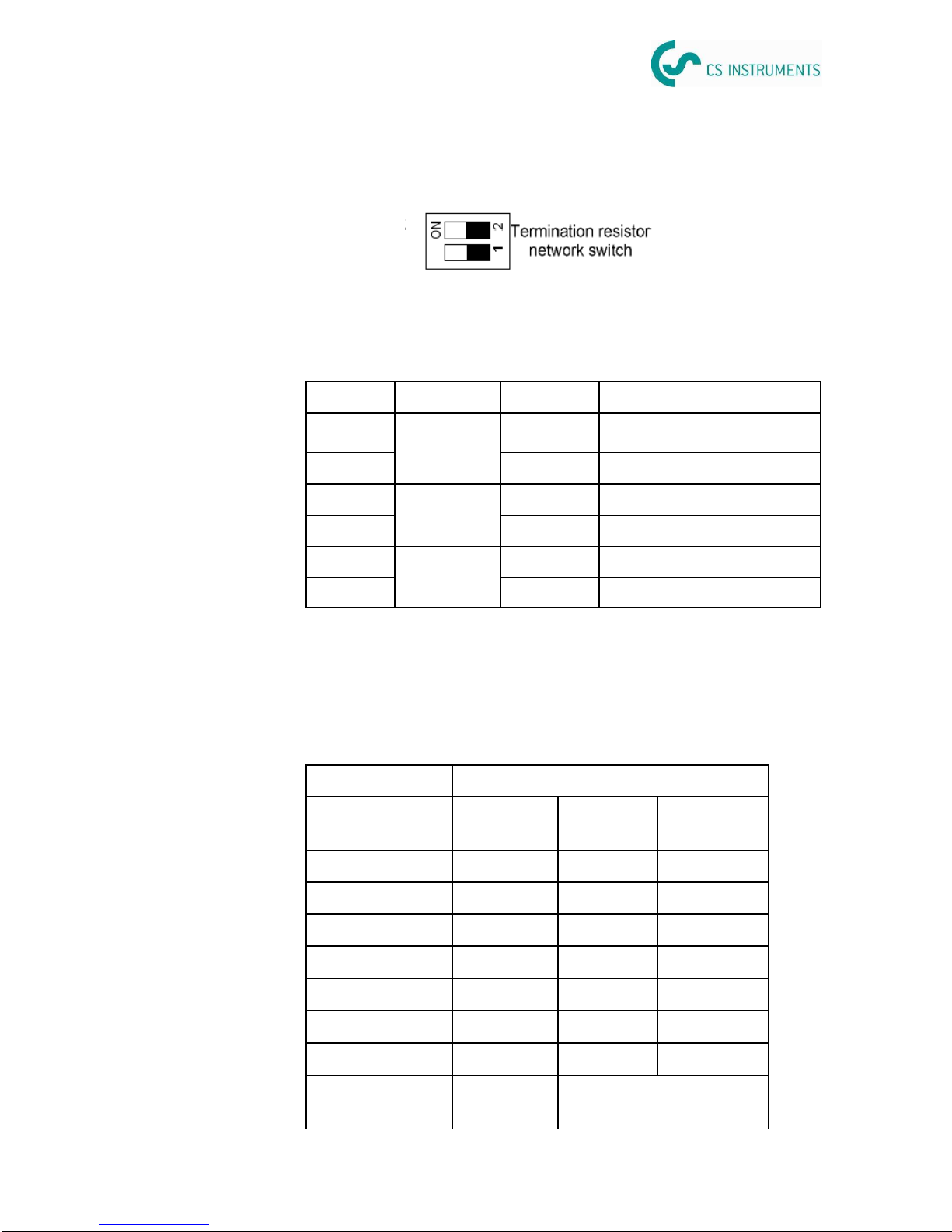

Modbus requires to activate terminal resistors at the last device on

the bus system. For this purpose the DIP switches on the connector

board should be set to “ON” position.

Connecting

MBus

The version with MBus comes with one analogue output and one

pulse output.

Pin Signal Description

11 MBus M1 MBus

12 M2 MBus

10 Analog 1 I+ Positive signal output

9 I- Negative signal output

7 Pulse P1 No polarity required

8 P2 No polarity required

Pulse output

The maximum number of pulses per second is limited to 45 pulse

per second. As a result depending on the flow rate and the selected

consumption unit the maximum flow rate is limited to the values in

the table below..

Unit Max flow

Pulses per con-

sumption unit 1 1/10 1/100

m3/h 162,000 1,620,000 16,200,000

m3/min 2,700 27,000 270,000

l/min 2,700 27,000 270,000

cfm 2,700 27,000 270,000

Kg/h 162,000 1,620,000 16,200,000

Kg/min 2,700 27,000 27,0000

Kg/s 45 450 4,500

Default To be configured by ser-

vice software

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

12 13

Connecting

analogue /

pulse outputs

VA 452 in the standard configuration comes with 2 analogue outputs

and 1 pulse output. All signals are electrically isolated. The analogue

output can be used as an active output—current is sourced through

the positive connection pin—or passive. In the passive configuration

a current signal is modulated onto the external signal voltage.

Pin Signal Description

12 Analog 2 I+ Positive signal output

11 I- Negative signal output

10 Analog 1 I+ Positive signal output

9 I- Negative signal output

7 Pulse P1 No polarity required

8 P2 No polarity required

Connecting

HART

Pin Signal Description

10 Analog 1 I+ / HART+ Positive signal output

9 I- / HART- Negative signal output

The HART signal is modulated on analogue output 1. In case VA

452 is used in a multi drop configuration (more than 1 slave on the 4-

20 mA line) the analogue output can not be used anymore.

Connecting

Modbus

The version with Modbus comes with one analogue output

and one pulse output.

Pin Signal Description

11 Modbus Data+ RS-485

12 Data- RS-485

10 Analog 1 I+ Positive signal output

9 I- Negative signal output

7 Pulse P1 No polarity required

8 P2 No polarity required

Modbus requires to activate terminal resistors at the last device on

the bus system. For this purpose the DIP switches on the connector

board should be set to “ON” position.

Connecting

MBus

The version with MBus comes with one analogue output and one

pulse output.

Pin Signal Description

11 MBus M1 MBus

12 M2 MBus

10 Analog 1 I+ Positive signal output

9 I- Negative signal output

7 Pulse P1 No polarity required

8 P2 No polarity required

Pulse output

The maximum number of pulses per second is limited to 45 pulse

per second. As a result depending on the flow rate and the selected

consumption unit the maximum flow rate is limited to the values in

the table below..

Unit Max flow

Pulses per con-

sumption unit 1 1/10 1/100

m3/h 162,000 1,620,000 16,200,000

m3/min 2,700 27,000 270,000

l/min 2,700 27,000 270,000

cfm 2,700 27,000 270,000

Kg/h 162,000 1,620,000 16,200,000

Kg/min 2,700 27,000 27,0000

Kg/s 45 450 4,500

Default To be configured by ser-

vice software

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

1114

Connecting

DS 300

DS 300 is connected to VA 452 through a 3 pole cable.

VA 452 DS 300

Pin Signal Pin Pin

4 SDI I-3 G-6

2 V+ I-1 G-8

3 V- I-4 G-7

DS 300 has 2 inputs (I and G) for flow / dew point sensors.

If there are more than 1 VA 452 to be connected to DS 300 a sepa-

rate power supply has to be used for at least one of the VA 452,

since DS 300 can only supply one VA 452 flow sensor.

VA 452 DS 300 Ext. 24 VDC

Pin Signal Pin Pin

4 SDI I-3 G-6

2 V+ N.C. N.C. 24V+

3 V- I-4 G-7 24V-

Startup

Initializing...

2 sec.

Software: 1.31

Hardware: 1.20

The version with display will startup in the sequence as described

below.

1345.6

12345670

m

3

/h

2 sec.

Software and hardware version

VA 452 will then show the actual online

values of flow and total consumption.

After reset the sensor has a warm-up

time of about 20 seconds., during this

time the flow rate is zero.

m

3

M: 43.6 °C

A: 25.7 °C

E: 00 00 00 00

Every 5 seconds the display will show the

medium and the ambient temperature

together with an error code. The error

code information is helpful for service

engineers .

Display

Flow unit

Consumption unit10 digit consumption

6 digit flow

Flow direction

Overflow indication

12345.6

1234567890

m

3

m

3

/h

4. Operation

Flow unit

Consumption unit10 digit consumption

6 digit flow

Flow direction

Alarm indication

12345.6

1234567890

m

3

m

3

/h

Pin Signal description

1 Ground for SDI

2 V+

3 V-

4 SDI

5 Direction input D1 (flow switch)

6 Direction input D2 (flow switch)

7 Pulse output P1 / Alarm switch A1

8 Pulse output P2 / Alarm switch A2

9 Current output channel 1 - / HART bus

10 Current output channel 1 + / HART bus

11 Current output channel 2 - / MODBUS data + / MBUS M1

12 Current output channel 2 + / MODBUS data - / MBUS M2

13 Ground for MODBUS cable

14 Earth

15 Earth

16 Earth

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

10 15

When installing the cables please consider following points:

•

Keep the stripped and twisted lengths of cable shield as

short as possible.

•

Screen and ground the signal lines

•

Install the measuring device that the cable entries do not

point upwards.

•

Do not remove the seal from the cable entry.

•

Unused cable entries must be closed with closers.

•

Cable outer diameter should be between 6 and 8 mm

•

Single wire cross section area should be between 0.25 …

0.75 mm

2

•

The thread size for the cable glands is M20 / 1.5

Wiring

Connection

diagram

Configuration

Configuration settings have to be done through the service software

which is included in the scope of delivery. The service software can

be isntalled on any PC with windows operating system. To

communicate with the sensor the PC needs to have a Bluetooth

interface. Alternativly a service kit can be used which cis as option

Area Available settings Default

Measurement Tube diameter

Flow unit

Consumption unit

Reference conditions

Gas type selection

Consumption counter

Operation pressure

Flow direction

54.0

m

3

/h

m

3

P

S

= 1000 hPA

T

S

= 20 °C

Air

0 m

3

0.6 MPa

Standard

Analogue

output 1 Measurement channel

Scaling

Active / passive

Flow

4 mA: 0 m

3

/h

20 mA: max flow

Active

Pulse output Pulse / Alarm

Pulses per consumption unit Pulse

1

HART Fieldbus address

Manufacturer ID

Device type code

0

255

0

Modbus Device address

Baudrate

Framing/parity/Stop bit

Transmission mode

1

19200

8, E, 1

RTU

MBus Address

Manufacturer code

Baudrate

Access Number

0

END

300

0

Analogue

output 2 Measurement channel

Scaling

Active / passive

Medium Temp.

4 mA: -50 °C

20 mA: 200 °C

Active

In order to fully utilize ethe functionality of VA 452 a configuration is

required. There are various paramters which need to be set in the flow

meter. The table below gives an overview about the available settings.

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

16 9

3. Protect sensor tip

The sensor unit can be removed from the measuring section for

example for cleaning or service / calibration. To protect the sensor

during transportation we recommend to use a sensor protection cap

as indicated in the picture below.

Please contact our local service for sensor protection cap.

Sensor head can be rotated in 90°steps through the screw nut

Power

supply

PC VA 452

Bluetooth

Power

supply

PC VA 452Service

Kit

Bluetooth

Bluetooth provides a convenient way of configuring the sensor with-

out the hazel of cable connections. VA 452 needs to be powered up.

Ensure that the distance between VA 452 and PC is no more that 5

meter and the PC Bluetooth antenna should point roughly in the

direction of the display (front part). Please follow the instruction in

the service software and the help file.

Service Kit

The diagram above shows the connection when using the optional

service kit (0554 2005). Please ensure that also in this case the

power supply of either VA 452 or of the service kit is connected

(USB port is not supplying enough power).

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

8 17

The unit can be installed in any position in the piping. In the case of

wet/dirty gases, upward flow is recommended in vertical pipes to

minimize condensation/contamination on or around the sensing

element. In particular, where free condensation can occur (e.g. Bio-

gas) the sensor should be orientated to prevent water collecting on

or around the sensing elements (e.g. do not install the sensor at a

low point in the installation without adequate drainage).

Ensure that the direction arrow on the sensor matches the direction

of flow .

2. Display orientation

The display version of VA 452 can be rotated in both directions

270°. For this purpose the the nut at the top of the shaft has to be

opened fully. Then pull up the metal casing and rotate it in the de-

sired direction. It can be rotated in 90°steps in both directions. A

metal pin locks the position. When the desired position is achieved,

press down the metal casing onto the shaft so that the metal pin can

insert into the position hole. Tighten up the nut.

Technical

data

Measuring

range

Pipe sm

3

/h kg/h

Inch DN mm Min Max Min Max

1" DN25 27.3 0.6 147.7 0.7 175.5

1 1/4" DN32 36.0 1.1 266.3 1.3 316.5

1 1/2" DN40 41.9 1.5 366.7 1.7 435.9

2” DN50 53.1 2.4 600 2.9 713

2 1/2" DN65 68.9 4.1 1027 4.9 1220

3” DN80 80.9 5.7 1424 6.8 1693

3/4” DN20 21.7 0.4 89.1 0.4 105.9

1/2” DN15 16.1 0.2 45.6 0.2 54.2

Volumetric flow is stated at 1000 hPa and 20 °C

VA 452 can measure from zero flow onwards, the stated minimum

flow is only required for achieving the specification. Flow rates above

the maximum flow can not be measured.

Standard range calibration:

Pipe sm

3

/h kg/h

Inch DN mm Min Max Min Max

1" DN25 27.3 1.2 294.7 1.4 350.3

1 1/4" DN32 36.0 2.1 531.5 2.5 631.7

1 1/2" DN40 41.9 2.9 731.9 3.5 869.9

2” DN50 53.1 4.8 1198 5.7 1423

2 1/2" DN65 68.9 8.2 2049 9.7 2435

3” DN80 80.9 11.4 2841 13.5 3377

3/4” DN20 21.7 0.7 177.8 0.8 211.4

1/2” DN15 16.1 0.4 100.0 0.4 108.1

Max range calibration:

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

718

Installation

1. Orientation

Pipe

requirements

At all times good installation practice should be followed:

•

Clean pipes and flange welded joints

•

Correctly sized gaskets

•

Correctly aligned flanges and gaskets

•

Use seamless pipes immediately upstream of the flowme-

ter.

•

Use of pipes that match in regards of the internal diameter

next to the flowmeter. Avoid any disturbance or miss-

alignment greater than 1 mm.

•

Anything that disturbs the smoothness of the internal pipe

wall (see figure below) should be eliminated; the goal

should be a smooth uninterrupted internal surface. For

further information please refer to ISO 14511.

3. Installation

Accuracy

Uncertainty: 1.5% of reading + 0.3% of full scale

Repeatability: 0.25 % of reading

Stated uncertainty at:

Ambient / process temperature: 23 °C ± 3 °C

Ambient / process humidity: <90%, no condensation

Process pressure: 0.6 MPa

Response /

Sampling

Response time: T

95

< 5 seconds

Sampling rate: 5 samples per second

Display is refreshed every 0.5 seconds

Outputs are refreshed every 0.2 seconds

Process

connection

R thread (ISO 7-1), Flange EN 1092-1

All parts in contact with the medium are of stainless steel 316L

Power supply

16 - 30 VDC, 7 W

Environment

conditions

Ambient temp.: -30 … +65 °C (non display version)

-25 … +65 °C (display version)

Storage temp.: -40 … +65 °C

Protection: IP 67

Shock resistance: IEC 60068-2-31

Vibration resist.: IEC 60068-2-6

EMC: IEC / EN 61326

Operating

conditions

Medium temp.: -40 … +100 °C

Pressure loss: < 3 hPa (4” pipe)

Medium pressure: -0.1 … 4.0 MPa

Analogue

output

Active / passive selectable, galvanic isolated

Active: 4 to 20 mA, RL < 400 Ω

Passive: 4 to 20 mA; supply voltage 1 ! 30 V DC, RL <

500 Ω

for HART: RL ≥250 Ω

Uncertainty: < 0.3% of reading

Resolution: 0.005 mA

Pulse/Alarm

output

NO switch, no polarity required, galv. isolated

Max rating: 30 VDC, 200 mA

Pulse width: 10 … 100 msec (depending on flow rate)

Communication Distance: < 3m (depend on environment)

Device name: VA 452 + s/n (Can be edited)

Bluetooth

DN 15 (1/2”), DN 20 (3/4”), DN 25 (1”), DN 32 (1 ¼”),

DN 40 (1 ½”), DN 50 (2”), DN 65 (2 ½”), DN 80 (3”)

Tube size

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

6 19

Flow

conditioner

In areas where the required inlet / outlet rungs can not be achieved

it’s recommended to use a flow conditioner upstream of the sensor.

This will reduce the minimum inlet run to 5-8 x D.

Pressure loss calculation:

DP = K * v

2

* ρ

DP: Pressure loss [hPa or mbar]

K: Constant = 0.008

v: Actual velocity of gas at conditioner inlet [m/s]

ρ: Density of gas [kg/m3]

conditioner

gasket

gasket

Device type: Slave

Polling address: 1 to 15

Bus address can be set through software

Physical interface: BELL 202

Protocol version: V5.2

Tag: VA 452

Tag description: FLOW METER

Frame/parity/Stop: 8, O, 1

HART

Device type: Slave

Address range: 1 to 247

Bus address can be set through software

Physical interface: RS485 in accordance with EIA/TIA-485

standard

Baudrates: 1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200 Baud

Transm. mode: ASCII, RTU

Response times: Direct data access = 0 to 255 ms (can be con

figured)

Modbus

MBus

Approvals

Certificates

CE mark: The measuring system is conform with the

statutory requirements of the EC Directives.

CS Instruments has successful tested the

device and affixed the CE mark.

Ex approval: CS Instruments provides a separate

documentation.

Other

Standards

EN 60529 Protection by housing (IP code)

IEC/EN 61326 EMC- requirements

ISO 14511 Thermal mass flowmeters.

NAMUR NE 43 Standardization analogue outputs

Device type: Slave

Address range: 1 to 251

Bus address can be set through software

Physical interface: Meter-Bus, EN1434-3

Baudrates: 300, 2400, 9600 Baud

Frame/parity/Stop: 8, E, 1

0970 0042 VA 452 English, V1.9, 13.08.13 0970 0042 VA 452 English, V1.9, 13.08.13

Flow sensor VA 452 Flow sensor VA 452

5

Product

features

•

Direct measurement of mass flow and standard flow without

the need of pressure compensation

•

Wide range of tube sizes are supported with insertion type

for big tubes and inline types for small tubes

•

No moving parts, non clogging

•

All parts which come into contact with the measurement

medium are made of stainless steel 316L.

•

Robust metal enclosure suitable for out-door applications in

harsh environment

•

Wireless Bluetooth interface for commissioning on site

•

Display showing flow rates, consumption, medium tempera-

ture and diagnostic results

•

2 analogue outputs (4-20 mA) and 1 pulse output

•

Available options:

•

Fieldbus interface: HART, Modbus, MBus

•

Hazardous approval ATEX: II 2 G Ex IIC T4

•

2-directional measurement

•

Flow conditioning

20

inlet / outlet

runs

Thermal mass flow meters are sensitive disturbances in the flowing

gas stream (e.g. vortex formation). As a general rule, the installed

sensor should always be installed as far away as possible from any

flow disturbances . Further information can be found in ISO Standard

14511.

Please observe the following recommended minimum values with

regard to the inlet and outlet runs.

2. Introduction

Dimensions

Pipe

nominal

size

[inch]

Outer diameter x

thickness/[inner dia]

[mm]

L

total

length

[mm]

L1

inlet

length

[mm]

H

total

height

[mm]

H1 from

pipe

center to

casing

top [mm]

1/2" Ø21.3 x 2.6/[Ø16.1] 300 210 247.65 200.15

3/4" Ø26.9 x 2.6/[Ø21.7] 475 275 252.65 200.15

1" Ø33.7 x 3.2/[Ø27.3] 475 275 257.65 200.15

1 ¼" Ø42.4 x 3.2/[Ø36.0] 475 275 270.15 200.15

1 ½" Ø48.3 x 3.2/[Ø41.9] 475 275 275.15 200.15

2" Ø60.3 x 3.6/[Ø53.1] 475 275 282.65 200.15

2 ½" Ø76.1 x 3.6/[Ø68.9] 475 275 300.55 208.05

3" Ø88.9 x 4.0/[Ø80.9] 475 275 314.45 214.45

DN

DN15

DN20

DN25

DN32

DN40

DN50

DN65

DN80

Other manuals for VA 452

1

Table of contents

Other CS Instruments Accessories manuals

CS Instruments

CS Instruments VA 550 User manual

CS Instruments

CS Instruments Vortex VX 570 User manual

CS Instruments

CS Instruments VD 500 User manual

CS Instruments

CS Instruments VA 521 User manual

CS Instruments

CS Instruments FA 550 User manual

CS Instruments

CS Instruments VA 500 User manual

CS Instruments

CS Instruments VA 525 User manual

CS Instruments

CS Instruments VA 570 User manual

CS Instruments

CS Instruments VA 500 User manual

CS Instruments

CS Instruments VA 400 User manual