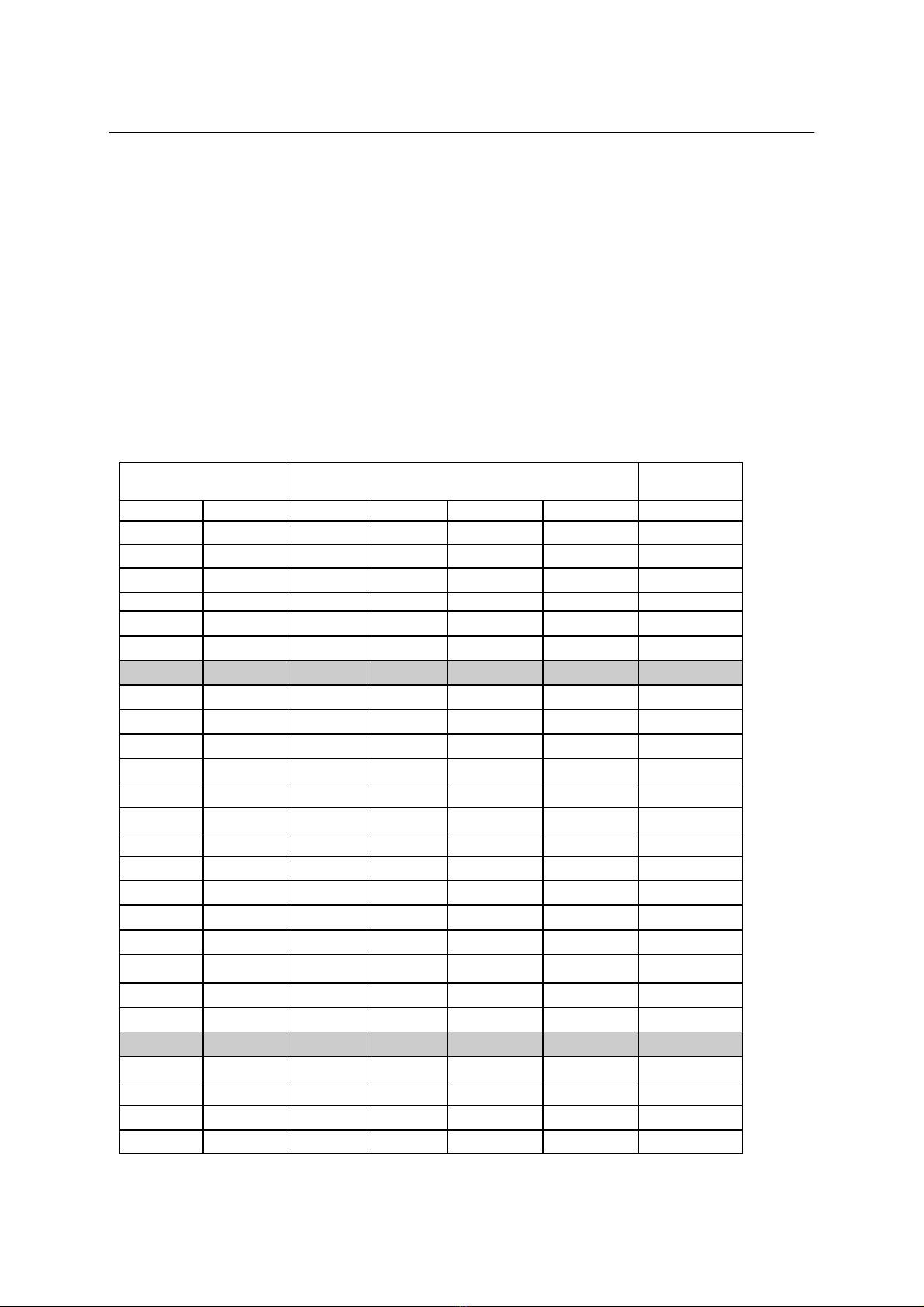

14 V5-02-2010

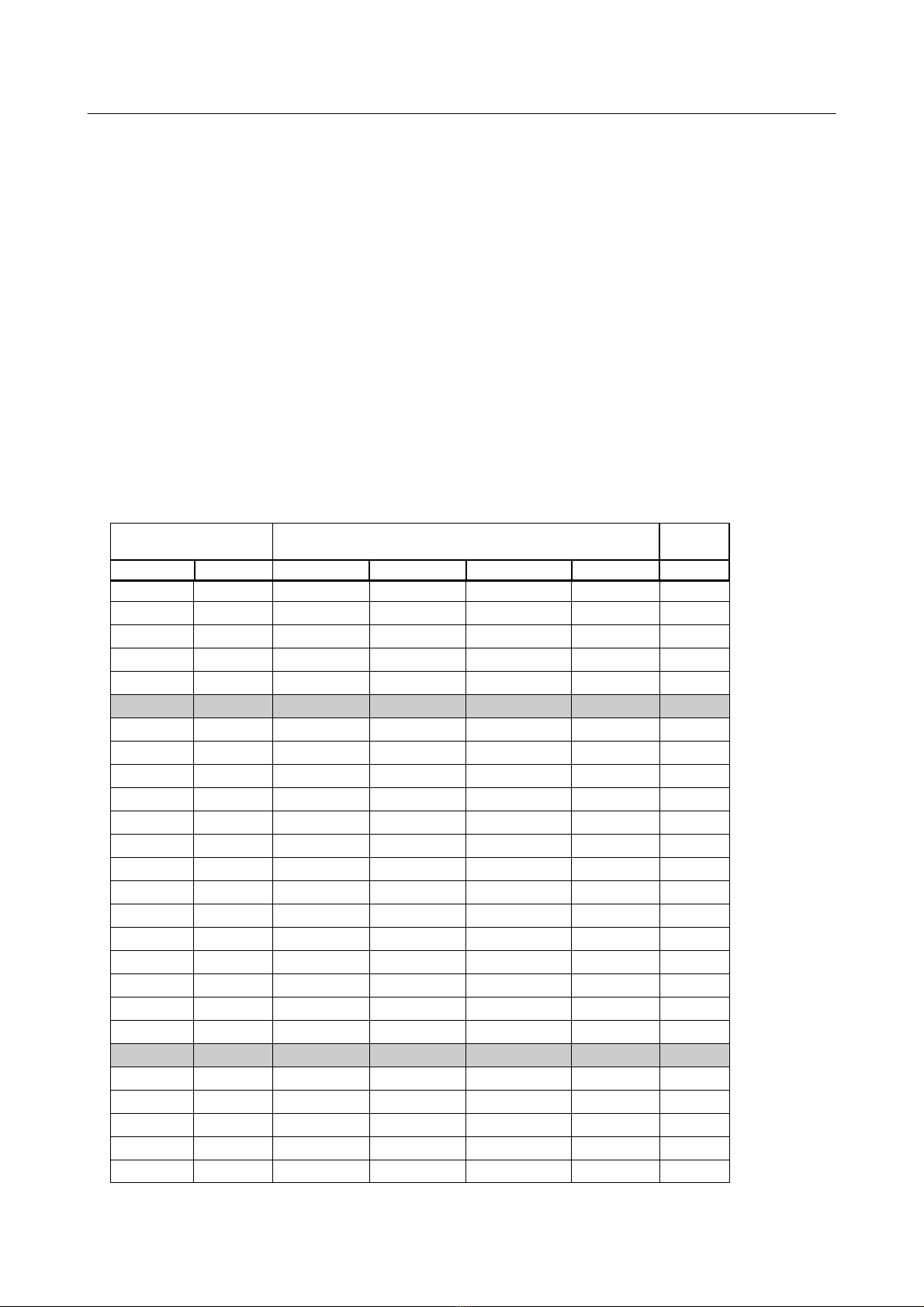

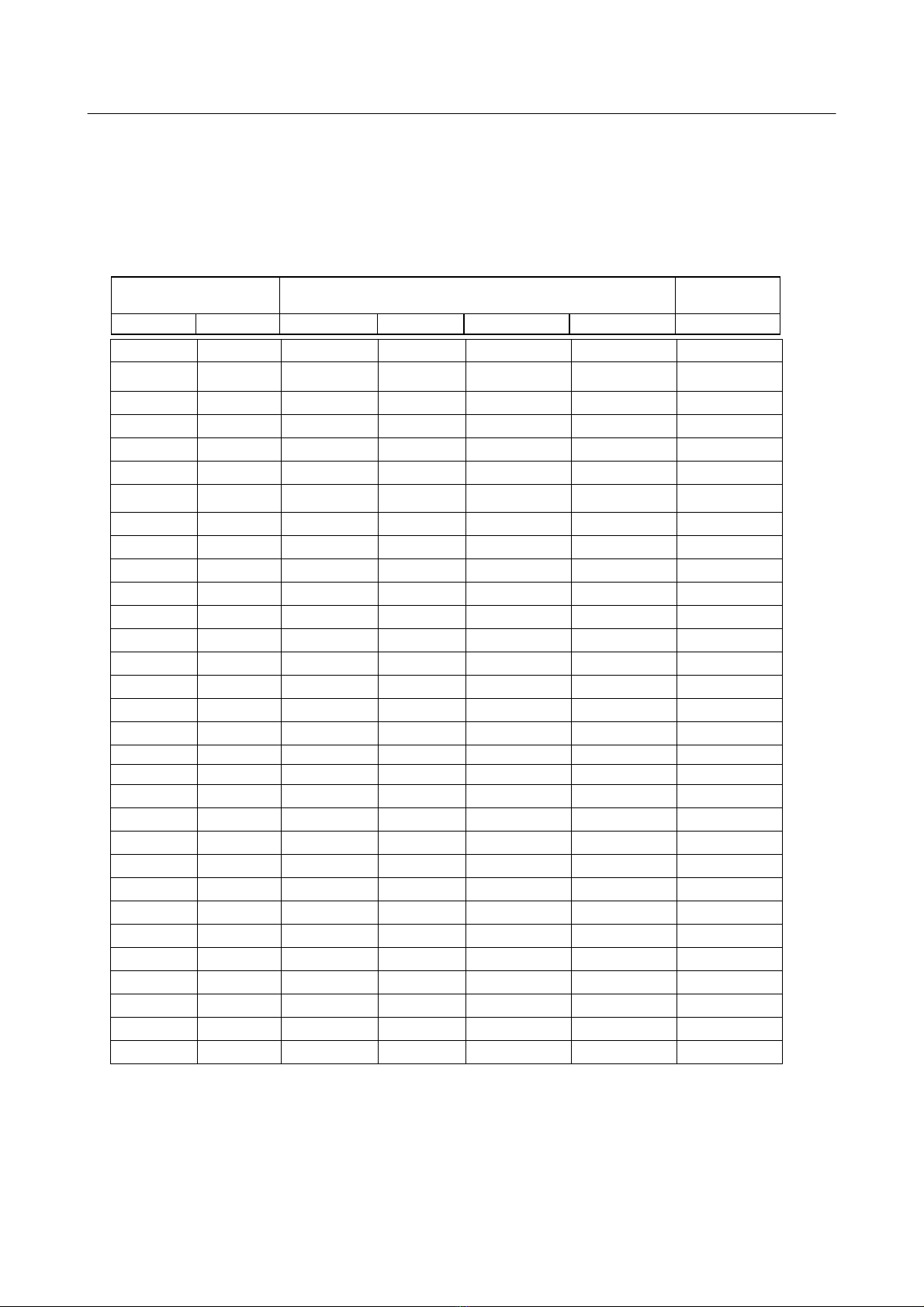

Measuring ranges depending from the inner diameter of the pipe

MEASURING RANGES HIGH SPEED

The sensor VA 400 - high speed version with or without display, has a maximum measuring

range of 224.0 m/sec. The flow rate is programmed to:

Inner diameter: 53.1 mm

This corresponds with an analogue output 4… 20 mA of

0… 1450.06 m³/h 0… 24.17 m³/min 0… 24167.64 l/min 0…402.79 l/sec 0… 224.0 m/sec.

In case of the version with display the inner diameter 25.00 has to be set first if the sensor is used in

other pipes, e. g. 1", 25 mm.

The analogue output for 1" can be taken from the table below: 4… 20 mA =

0… 295.30 m³/h 0... 4.92 m³/min 0… 4921.62 l/min 0… 82.03 l/sec 0… 224.0 m/sec.

In case of the version with display please adjust the respective inner diameter (see page 21).

Inner diameter

of the pipe Flow

(final value of measuring range) max.

Inch mm m³/h m³/min l/min l/s m/s

1/4" 6.0 11.40 0.19 190.00 3.17 224.0

10.0 36.42 0.61 606.96 10.12 224.0

15.0 94.05 1.57 1567.53 26.13 224.0

1/2" 16.1 110.16 1.84 1835.96 30.60 224.0

3/4" 21.7 215.33 3.59 3588.77 59.81 224.0

1" 25.0 295.30 4.92 4921.62 82.03 224.0

26.0 321.11 5.35 5351.77 89.20 224.0

27.3 356.85 5.95 5947.52 99.13 224.0

28.5 391.48 6.52 6524.74 108.75 224.0

30.0 437.20 7.29 7286.64 121.44 224.0

1 1/4" 32.8 528.75 8.81 8812.49 146.87 224.0

36.0 643.52 10.73 10725.32 178.76 224.0

36.3 655.12 10.92 10918.73 181.98 224.0

1 1/2" 39.3 774.73 12.91 12912.18 215.20 224.0

40.0 803.59 13.39 13393.14 223.22 224.0

41.8 881.96 14.70 14699.41 244.99 224.0

43.1 941.21 15.69 15686.78 261.45 224.0

45.8 1068.14 17.80 17802.30 296.71 224.0

2" 50.0 1282.52 21.38 21375.40 356.26 224.0

51.2 1346.48 22.44 22441.40 374.02 224.0

53.1 1450.06 24.17 24167.64 402.79 224.0

54.5 1529.41 25.49 25490.17 424.84 224.0

57.5 1712.89 28.55 28548.16 475.80 224.0

60.0 1869.63 31.16 31160.58 519.34 224.0

64.2 2148.38 35.81 35806.27 596.77 224.0

Referred to DIN 1945/ISO 1217 (20 °C, 1000 mbar) and compressed air