Table of Content

VA 521 EN V1.20 Page 4o 39

9Operation......................................................................................................................15

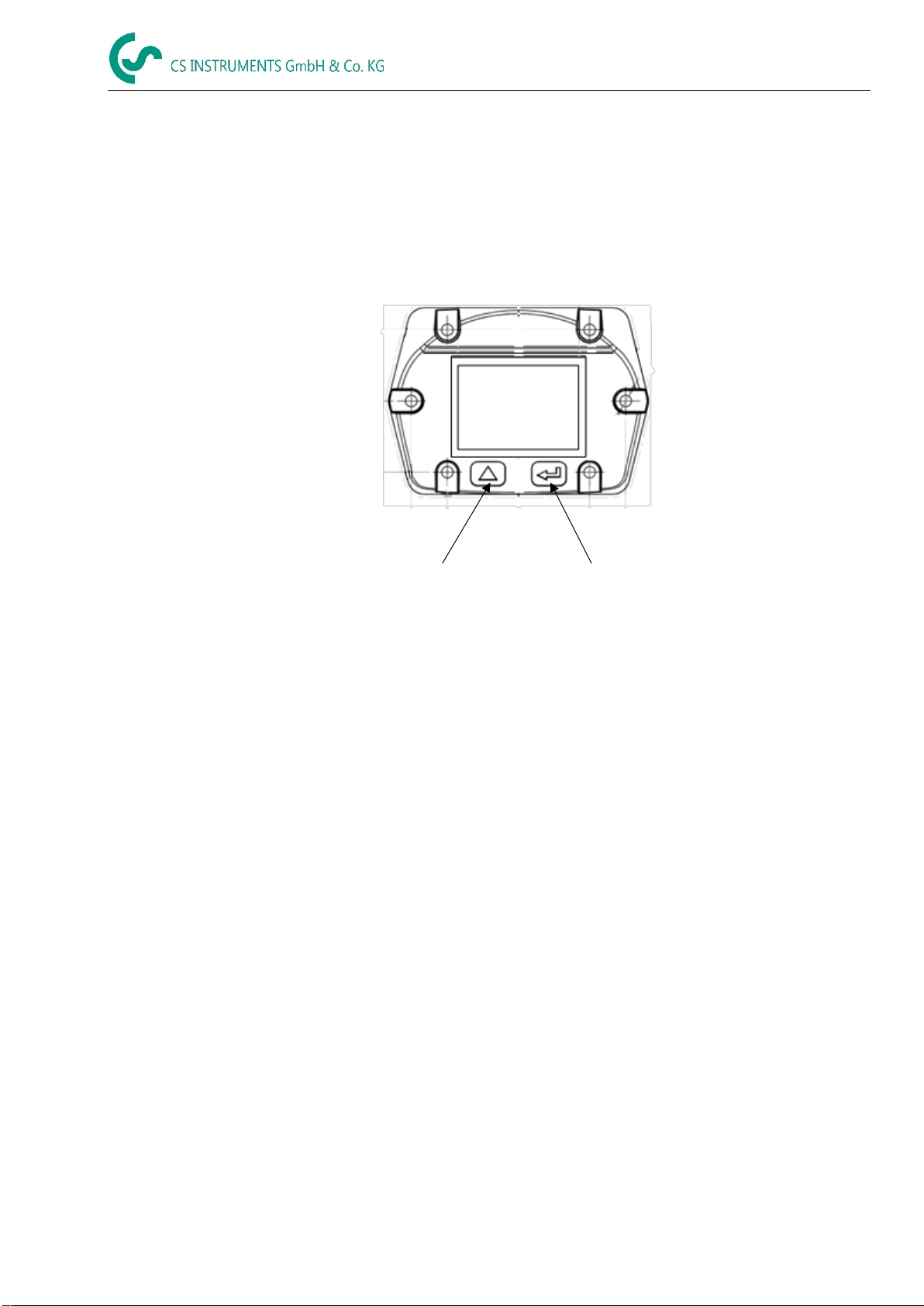

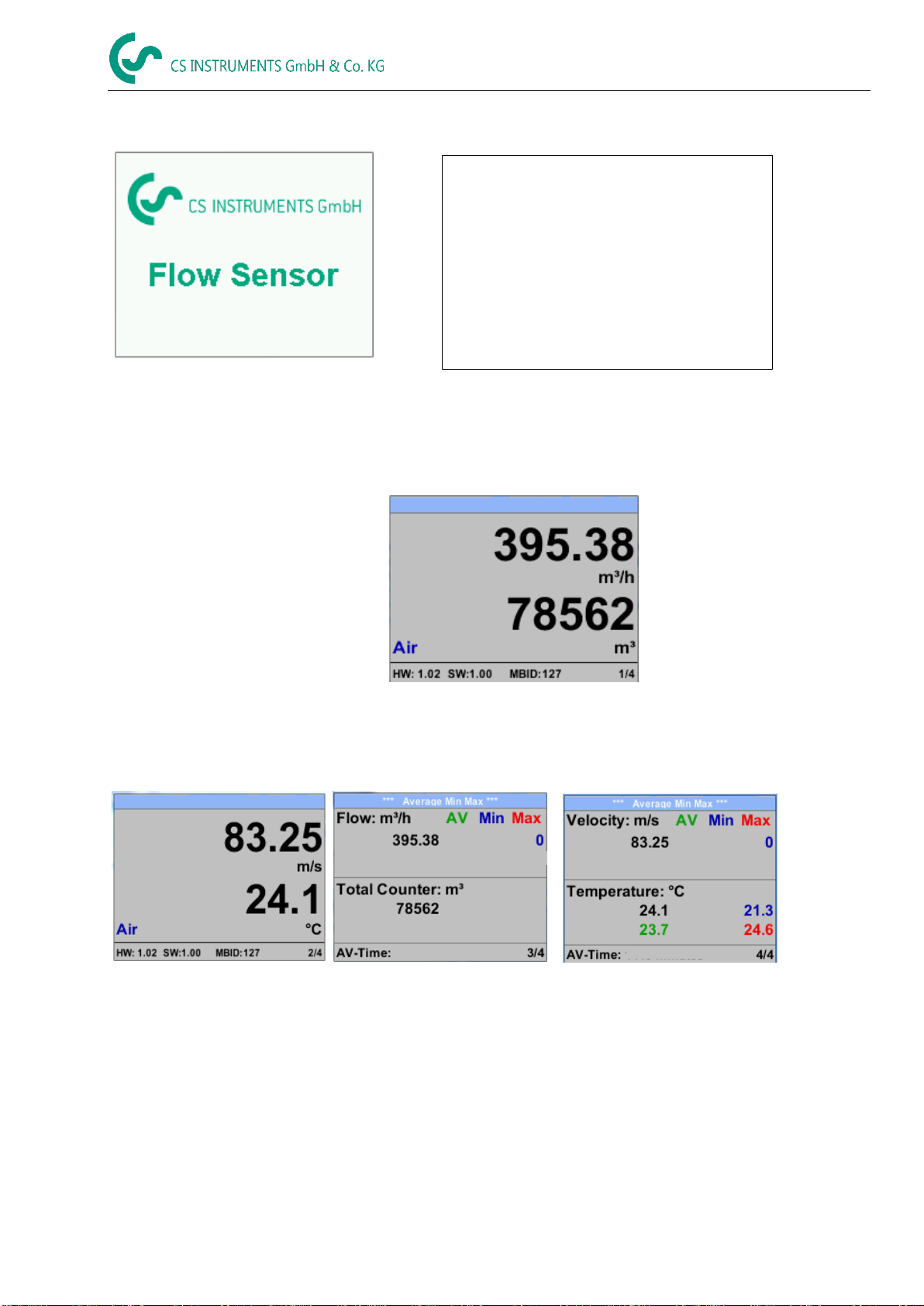

9.1 Initialization .......................................................................................................................... 16

9.2 Main menu ............................................................................................................................ 16

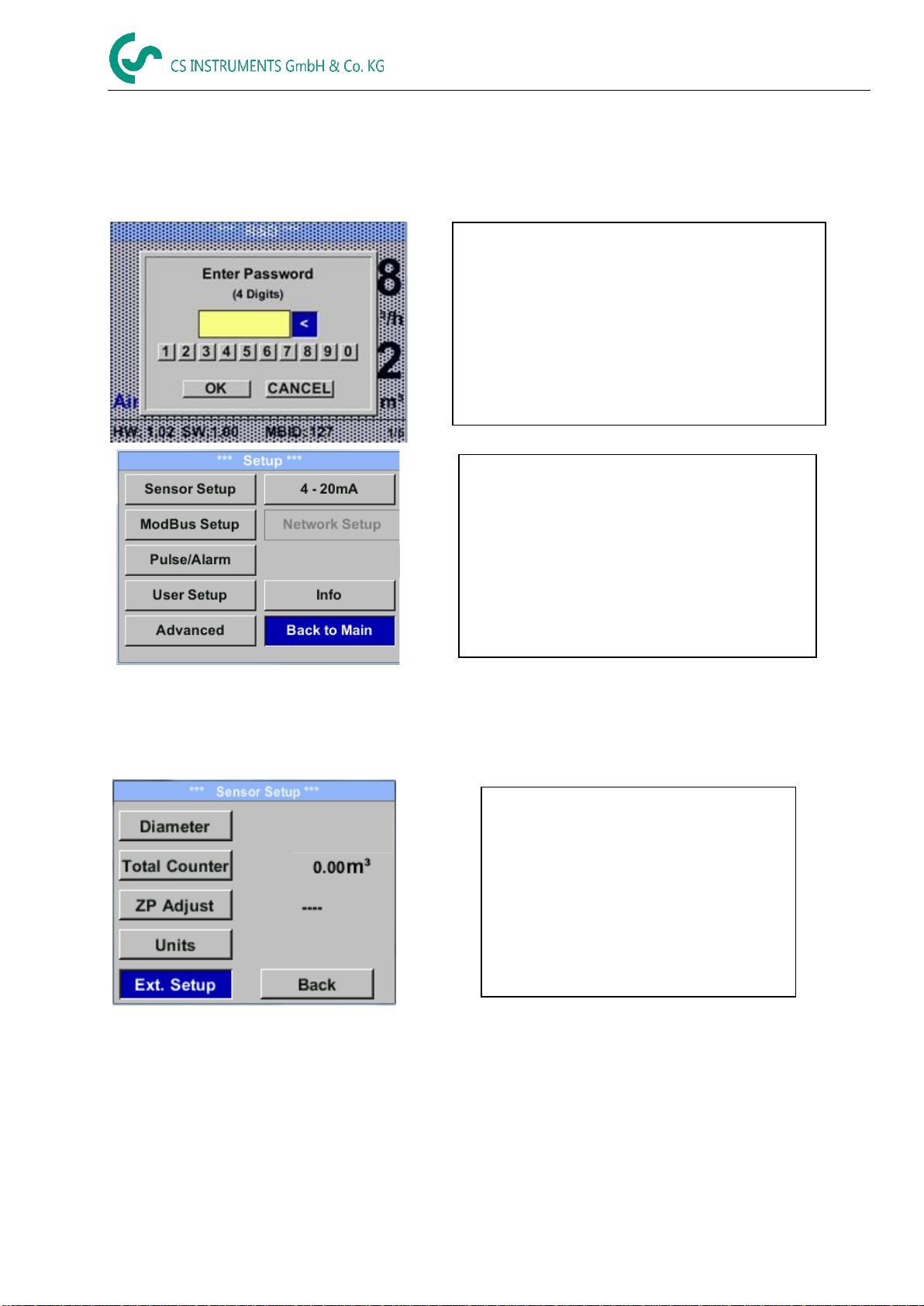

9.3 Settings................................................................................................................................. 17

9.3.1 Sensor Setup................................................................................................................... 17

9.3.1.1 Input / change tube diameter.................................................................................... 17

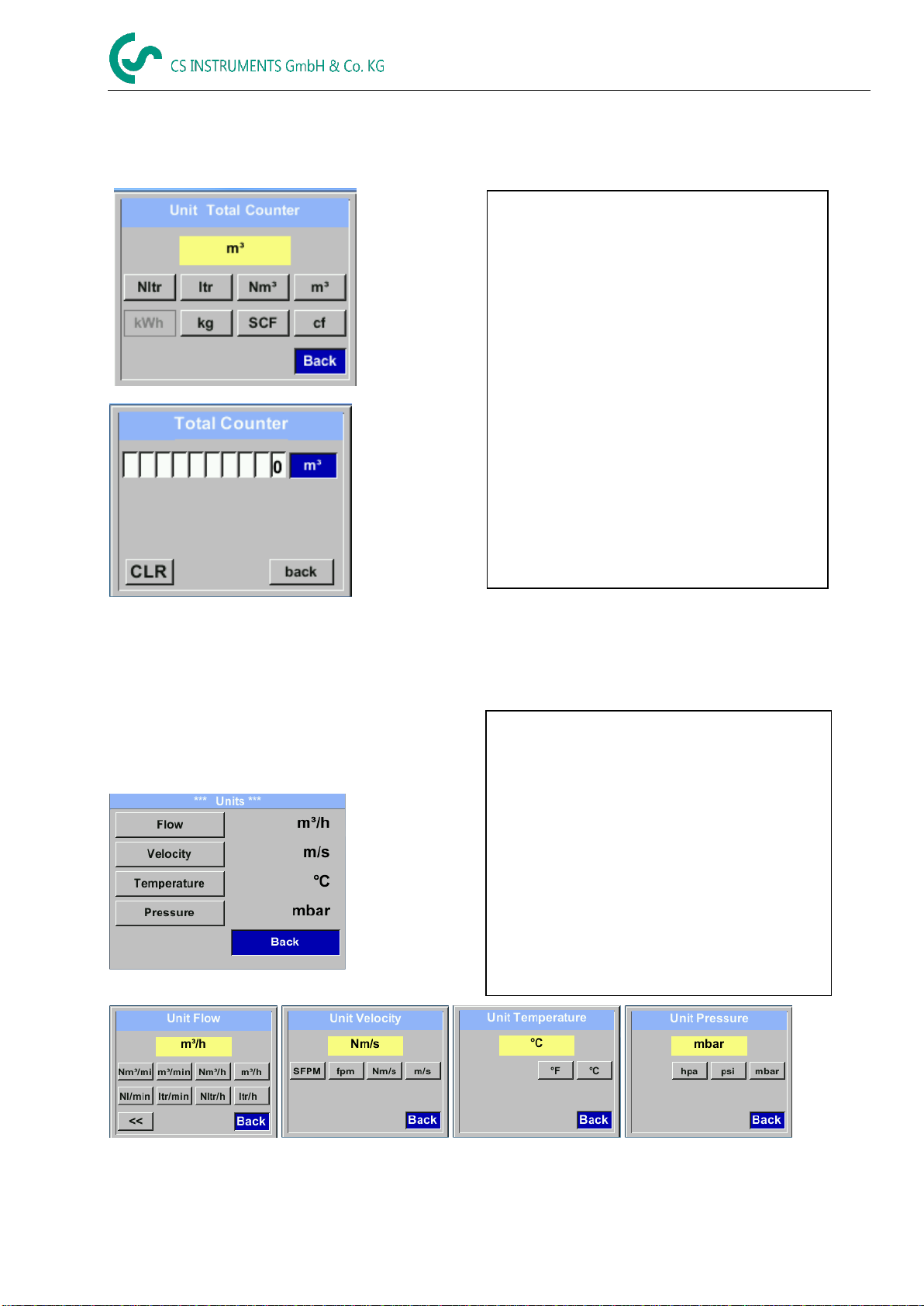

9.3.1.2 Input / change consumption counter........................................................................ 18

9.3.1.3 Definition of the units for flow, velocity, temperature and pressure ......................... 18

9.3.1.4 Definition of the reference conditions....................................................................... 19

9.3.1.5 Setting of Zeropoint and Low-flow cut off................................................................. 21

9.3.2 Modbus RTU Setup ......................................................................................................... 22

9.3.3 Modbus TCP (Optional)................................................................................................... 23

9.3.3.1 Network Setup DHCP............................................................................................... 23

9.3.3.2 Network Settings static IP......................................................................................... 24

9.3.3.3 Modbus TCP Settings............................................................................................... 25

9.3.3.4 Modbus Settings (2001…2005)............................................................................. 26

9.3.3.5 Values Register (1001 …1500) ................................................................................ 26

9.3.4 Pulse /Alarm..................................................................................................................... 28

9.3.4.1 Pulse output.............................................................................................................. 28

9.3.5 User Setup....................................................................................................................... 29

9.3.5.1 Password.................................................................................................................. 29

9.3.5.2 Language.................................................................................................................. 29

9.3.5.3 Display / Touch......................................................................................................... 30

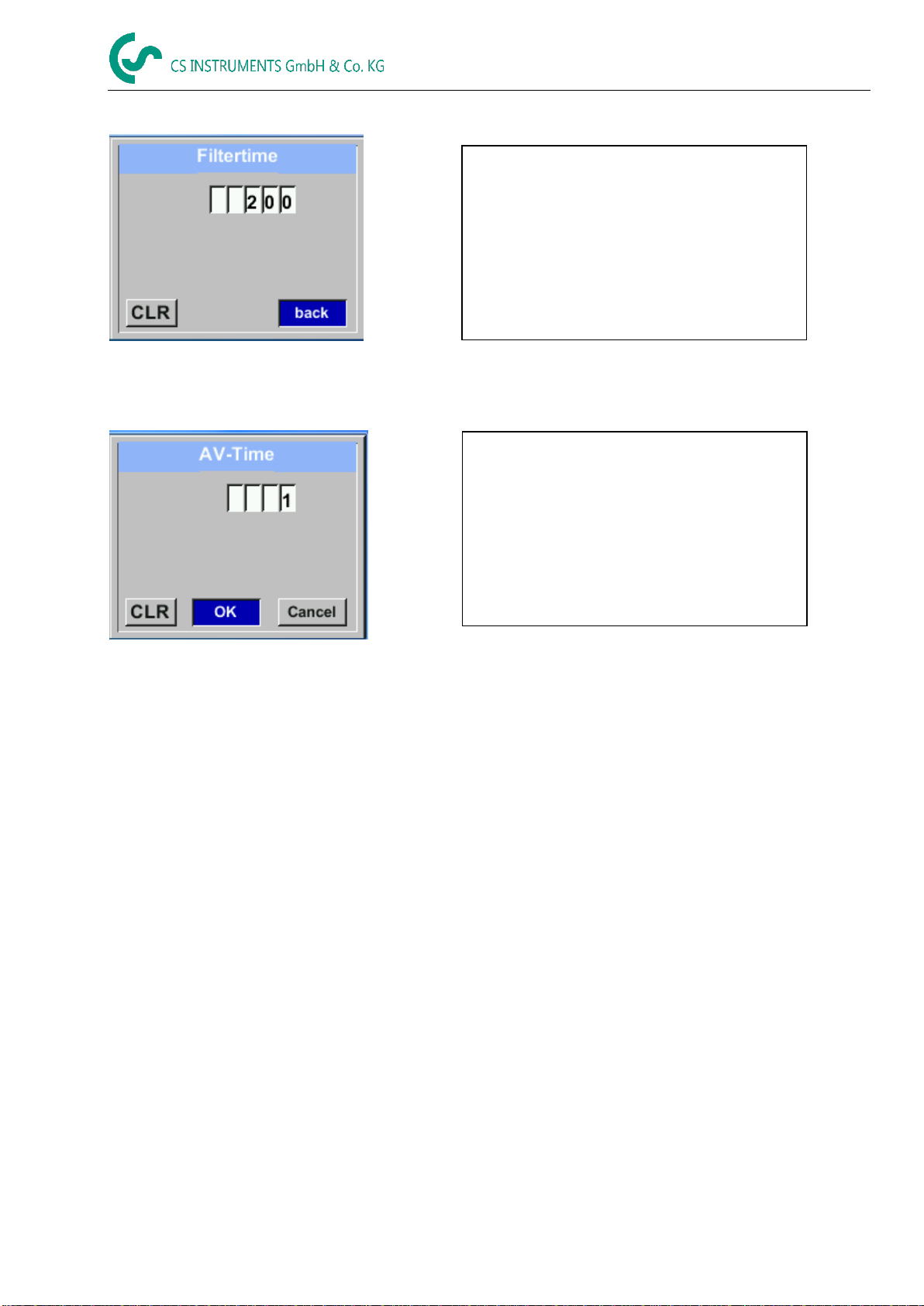

9.3.6 Advanced......................................................................................................................... 30

9.3.7 4 -20mA ........................................................................................................................... 31

9.3.8 VA 521 Info...................................................................................................................... 33

9.4 MBus...................................................................................................................................... 34

9.4.1 Default Settings communication...................................................................................... 34

9.4.2 Default values transmitted............................................................................................... 34

10 Status / Error messages...........................................................................................35

10.1 Status messages.................................................................................................................. 35

10.2 Error messages.................................................................................................................... 36

11 Maintenance..............................................................................................................37

12 Cleaning of the sensor head....................................................................................37

13 Re-Calibration...........................................................................................................37

14 Spare parts and repair..............................................................................................37

15 Calibration.................................................................................................................37

16 Warranty....................................................................................................................37