CS Instruments VD 500 User manual

VD 500 English V1.07 Seite 1 von 40

Instruction manual

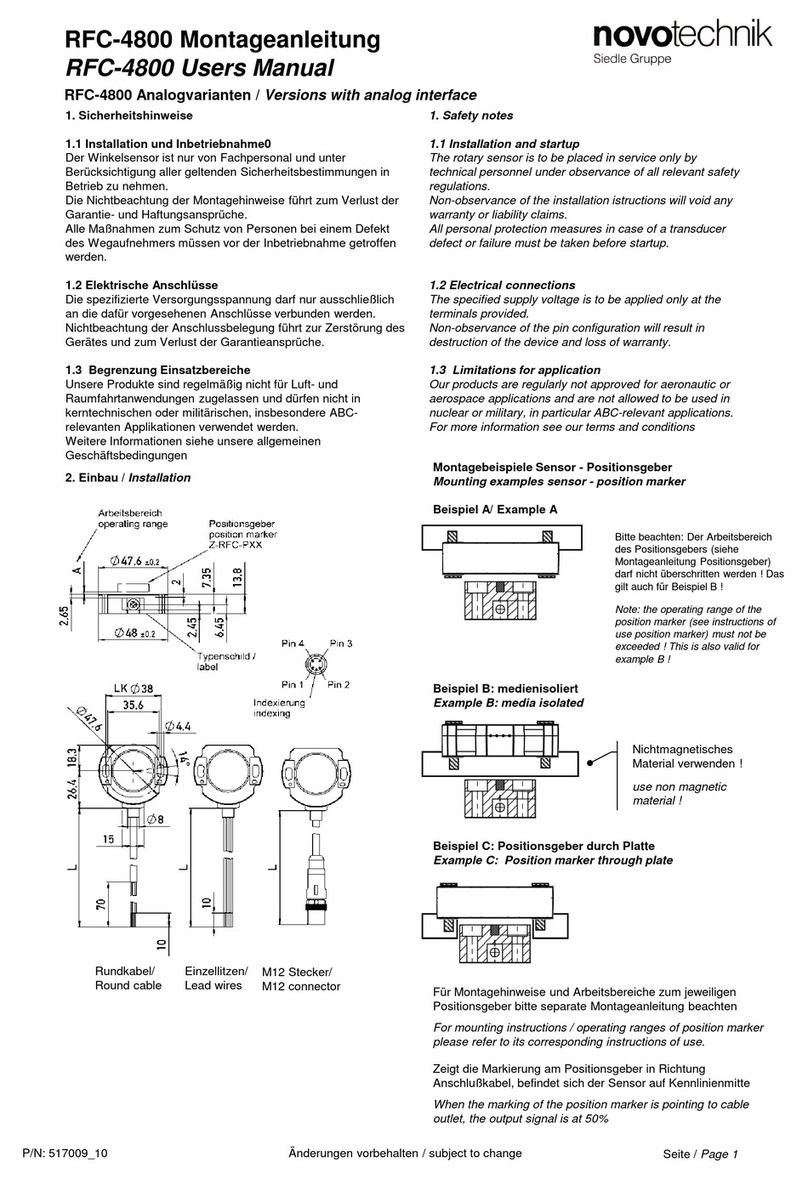

Flow sensor VD 500

with Display, 4 ... 20 mA and Pulse output (galv. isolated)

Stationary and mobile

flow and consumption measurement for compressed air and gases

www.cs-instruments.com

EN - English

Sales Office South

Zindelsteiner Straße 15

D-78052 VS-Tannheim

DEUTSCHLAND

Tel.: +49 (0) 7705 978 99-0

Fax: +49 (0) 7705 978 99-20

Sales Office North

Gewerbehof 14

D-24955 Harrislee

Deutschland

Tel.: +49 (0) 461 700 20 25

Fax: +49 (0) 461 700 20 26

Table of Content

VD 500 English V1.07 Seite 2 von 40

II. Table of content

II. Table of content......................................................................................................... 2

1Intended use.................................................................................................................. 4

2Safety instructions........................................................................................................ 4

3Instruments description ............................................................................................... 5

4Technical data............................................................................................................... 6

5Installation..................................................................................................................... 7

5.1 Pipe/tube requirements ......................................................................................................... 7

5.2 Inlet / outlet runs .................................................................................................................... 7

5.3 Installation VD 500................................................................................................................. 8

5.3.1 ½“ welded nipple with ball valve ½“ ................................................................................... 8

5.3.2 Spot drilling collar with ball valve....................................................................................... 8

5.4 Installation of the Sensor...................................................................................................... 9

5.4.1 Mounting VD 500 onto the ball valve................................................................................. 9

5.4.2 Installation angle for locations that potentially hold water ............................................... 10

5.5 Display Head Position ......................................................................................................... 10

6Commissioning............................................................................................................11

6.1 Zero Point Adjustment......................................................................................................... 11

6.2 4… 20 mA Analogausgang.................................................................................................. 11

7Measuring ranges........................................................................................................12

7.1 Maximum Flow ranges „High speed“ ................................................................................ 13

7.2 Maximum Flow ranges „Ultra speed“ ................................................................................ 14

8Dimension ....................................................................................................................15

9Electrical wiring ...........................................................................................................16

9.1 Modbus RTU, 4..20mA, Pulse or MBus.............................................................................. 16

9.2 Ethernet (optional PoE) ...................................................................................................... 17

Table of Content

VD 500 English V1.07

Seite 3 von 40

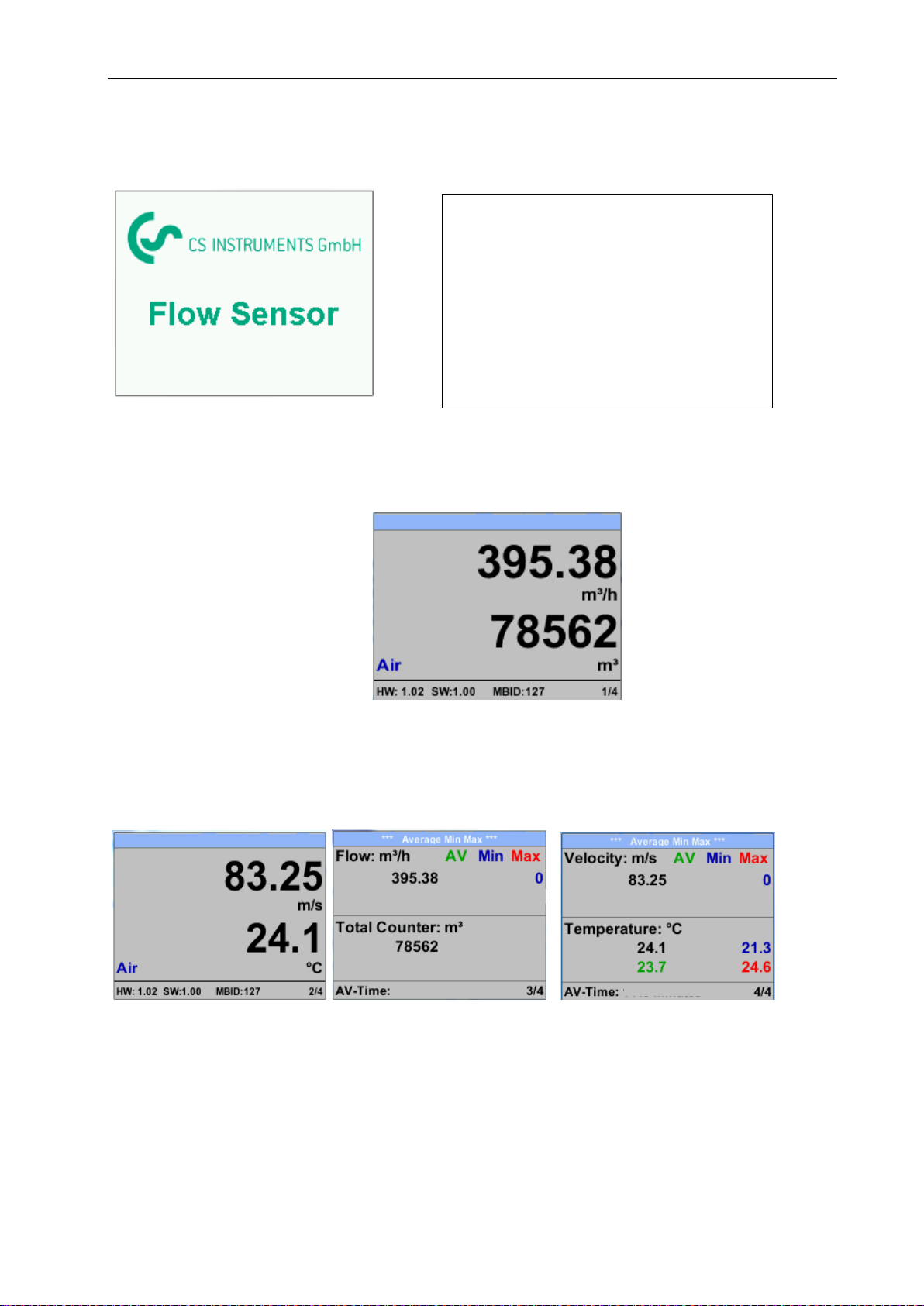

10 Operation...................................................................................................................18

10.1 Initialization .......................................................................................................................... 19

10.2 Main menu ............................................................................................................................ 19

10.3 Settings................................................................................................................................. 20

10.3.1 Sensor Setup................................................................................................................... 21

10.3.1.1 Input / change tube diameter.................................................................................... 21

10.3.1.2 Input / change consumption counter ........................................................................ 22

10.3.1.3 Definition of the units for flow, velocity, temperature and pressure ......................... 22

10.3.1.4 Definition of the reference conditions....................................................................... 23

10.3.1.5 Setting of Zeropoint and Low-flow cut off................................................................. 25

10.3.2 Modbus Settings.............................................................................................................. 26

10.3.2.1 Modbus RTU Setup.................................................................................................. 26

10.3.2.2 Modbus TCP (Optional)............................................................................................ 27

10.3.2.2.1 Network Setup DHCP........................................................................................... 27

10.3.2.2.2 Network Settings static IP..................................................................................... 28

10.3.2.2.3 Modbus TCP Settings........................................................................................... 29

10.3.2.3 Modbus Settings Register (2001…2005) ................................................................ 30

10.3.2.4 Values Register (1001 …1500) ................................................................................ 30

10.3.3 Pulse /Alarm..................................................................................................................... 32

10.3.3.1 Pulse output.............................................................................................................. 32

10.3.4 User Setup....................................................................................................................... 33

10.3.4.1 Password.................................................................................................................. 33

10.3.4.2 Language.................................................................................................................. 33

10.3.4.3 Display / Touch......................................................................................................... 34

10.3.5 Advanced......................................................................................................................... 34

10.3.6 4 -20mA ........................................................................................................................... 35

10.3.7 VD 500 Info...................................................................................................................... 37

10.4 MBus...................................................................................................................................... 37

10.4.1 Default Settings communication...................................................................................... 37

10.4.2 Default values transmitted ............................................................................................... 37

11 Status / Error messages...........................................................................................38

11.1 Status messages.................................................................................................................. 38

11.2 Error messages.................................................................................................................... 39

12 Maintenance..............................................................................................................40

13 Re-Calibration...........................................................................................................40

14 Spare parts and repair..............................................................................................40

15 Calibration.................................................................................................................40

16 Warranty....................................................................................................................40

Safety Instructions

VD 500 English V1.07 Seite 4 von 40

1 Intended use

The VD 500consumption sensor is used for continuous flow measurements, based on a dynamic

pressure / differential pressure measurement.

The VD 500 consumption sensor is designed and constructed exclusively for the intended purpose

described here and may only be used accordingly.

The user must check whether the instrument is suitable for the selected application. It must be

ensured that the medium is compatible with the wetted parts. The technical data listed in the data

sheet are binding.

Improper handling or operation outside the technical specifications is not permitted. Claims of any kind

based on improper use are excluded.

2 Safety instructions

Please read carefully before starting the device!

Warning:

Do not exceed the pressure range of 16 bar.

Over 10 bar we recommend using the high-pressure protection for a safe installation and removal.

Observe the measuring ranges of the sensor!

Overheating destroys the sensor.

Observe the admissible storage and transportation temperature as well as the permitted operating

temperature (e.g. protect the instrument from direct insolation).

Always observe the direction of flow when positioning the sensor!

The safety ring at the sensor head must always remain undamaged and sit correctly in the destined

slot.

The screwed fixture must be pressure tight.

The adapter sleeve must be tightened with a torque of 20 to 30 Nm.

It is necessary to avoid condensation on the sensor element or water drops in the measuring air as

they may cause faulty.

The values of the inlet and outlet sections must not fall below the specified minimum values as this

causes increased deviations in the measuring results.

The manufacturer cannot be held liable for any damage that occurs because of non-observance or

non-compliance with these instructions. Should the device be tampered with in any matter other than a

procedure, which is described and specified in the manual, the warranty is cancelled and the

manufacturer is exempt from liability.

The device is destined exclusively for the described application.

CS Instruments GmbH offers no guarantee for the suitability for any other purpose and is not liable for

errors that may have slipped into this operation manual. CS Instruments GmbH is also not liable for

consequential damage resulting from the delivery, capability or use of this device.

We offer you to take back the instruments of the instruments family VD 500 which you would like to

dispose of.

Qualified employees from the measurement and control technology branch should only carry out

adjustments and calibrations.

!

Instruments description

VD 500 English V1.07 Seite 5 von 40

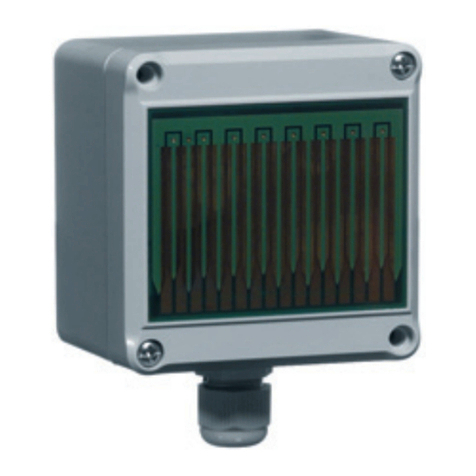

3Instruments description

The VD 500 is a compact consumption counter for compressed air and gases.

Special features:

- Optimum accuracy due to compact design

- Intgrated Display showing Flow, consuption, velocity and temperature

- Input inner tube diameter via display keys

- Units free selectable. m³/h, m³/min, l/min, l/s, kg/h, kg/min, kg/s, cfm

- Modbus RTU (RS485) Interface

- Analogoutput 4..20mA

- Pulse output galv. isolated.

CS Instruments Service Software

- Analogaoutput 4...20 mA scaleabler

- Selection of gas type (Air, Nitrogen, Argon, Nitrous oxide, CO2, Oxygen, Natural gas)

- Read out Service data

- Sensordiagnose

Technical data

VD 500 English V1.07 Seite 6 von 40

4Technical data

Measurement: Flow, Consumption, Velocity and Pressure

Reference: Standard settings ex works:

DIN 1945, ISO 1217 at 20°C and 1000 mbar

other standards can be adjusted by Display keys (optional)

or means of the CS Service Software.

Selectable Units: m³/h (Standard settings ex- factory)

m³/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min, kg/s, °C, °F

Measuring principle: Differential pressure

Sensor: Pressure, NTC

Measuring medium: Air, gases

Operating temperature: -20 ... 70°C housing

Medium temperature: -30 ... 180°C probe tube

Relative humidity for

measuring medium: < 95 % r.H (no condensation on the sensor element allowed)

Operating pressure: up to 20 bar

Power supply: 18 to 36 VDC

Power consumption: max. 5W

Digital output: RS 485 (Modbus RTU)

Optional: MBus, Ethernet (PoE)

Analog output: 4...20 mA (see tables page 13 -18),

max. burden < 500 Ohm

Pulse output: pulse output potential free (dry contact)

passive: max. 48Vdc, 150mA

1 pulse pro m³ resp. pro l,

Valency adjustable with the display keys

Accuracy: ± 1,5 % m.v.*, ± 0,3 % f.s. (20..224m/s)*

± 1,5 % m.v (>224 m/s)

Display: optional TFT 1.8“ Resolution 220 x 176

Mounting thread: G ½“, optional ½” NPT

Material: Stainless steel 1.4301 / 1.4404

Protection class IP65

‘* m.v. = measured values

f.s. = full scale

Installation

VD 500 English V1.07 Seite 7 von 40

5 Installation

5.1 Pipe/tube requirements

•Correctly sized gaskets

•Correct aligned flanges and gaskets

•Diameter mismatch at the pipe junctions should be avoided but must be less than 1mm. For

further information see ISO 14511

•Ensure clean pipes after installation

•.

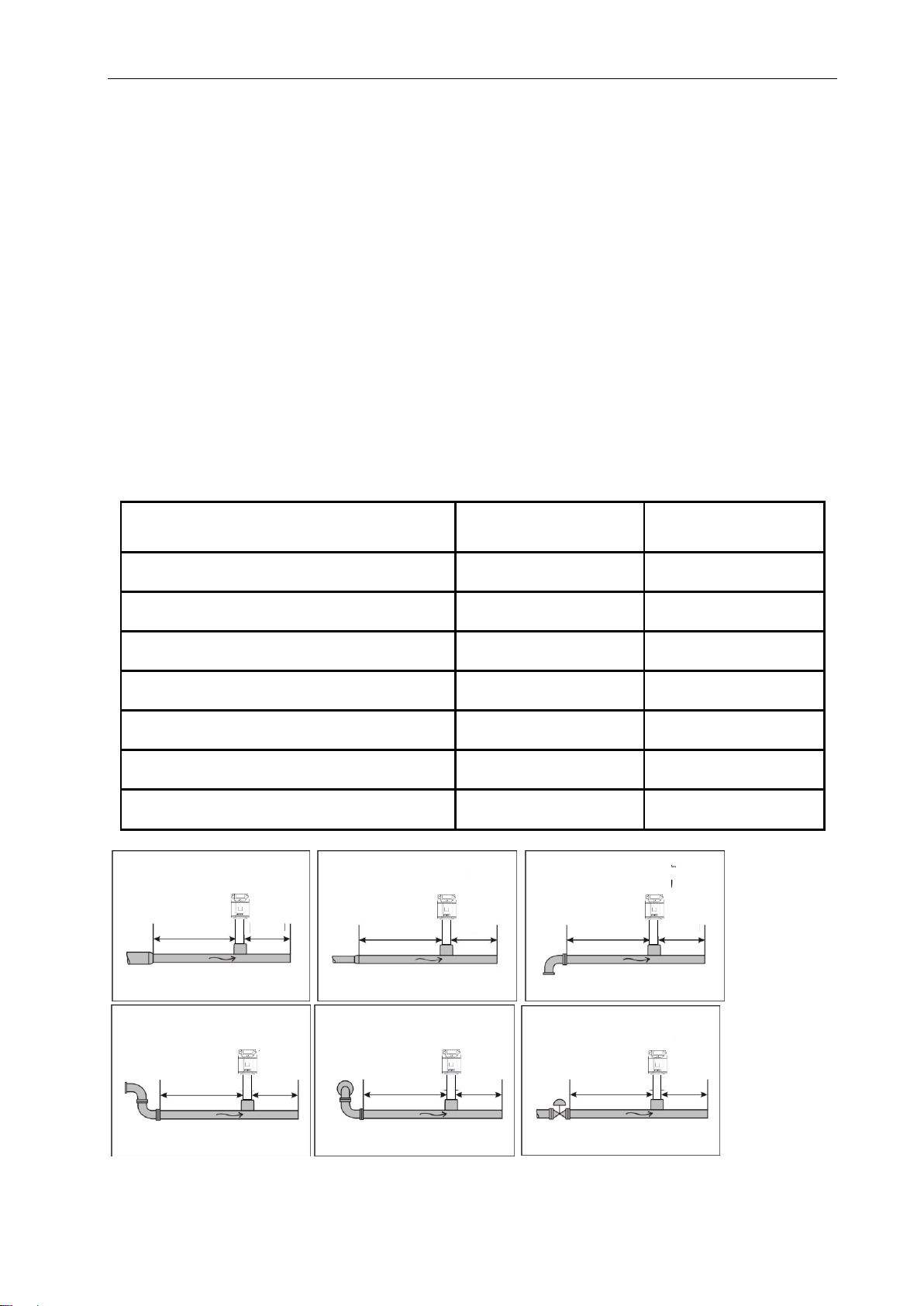

5.2 Inlet / outlet runs

In order to maintain the accuracy stipulated in the data sheets, the sensor must be inserted in the centre

of a straight pip e section with an undisturbed flow progression.

An undisturbed flow progression is achieved if the sections in front of the sensor (inlet) and behind the

sensor (outlet) are sufficiently long, straight and without any obstructions such as edges, seams, curves

etc.

Therefore, it is necessary to ensure the recommended inlet and outlet runs.

Table Inlet / Outlet runs

Flow obstruction before the measurement

section

Min length

Inlet run (L1)

Min length

Outlet run (L2)

Slight curve

(elbow < 90°)

12 x D

5 x D

Reduction

(Pipe narrows to the measurement section)

15 x D

5 x D

Expansion

(Pipe expands to the measurement section)

15 x D

5 x D

90° elbow or T-piece

15 x D

5 x D

2x elbow á 90°

in einer Ebene

20 x D

5 x D

2x elbow á 90°

3-dimensional

35 x D

5 x D

Control valve

45 x D

5 x D

15 x D 5 x D

15 x D 5 x D15 x D

15 x D 5 x D

20 x D 5 x D

35 x D 5 x D

5 x D45 x D

The values represent the min. lengths. In case the min. inlet / outlet runs could not be ensured, it must be

expected to get increased or significant deviations of the measurement values.

Installation

VD 500 English V1.07

Seite 8 von 40

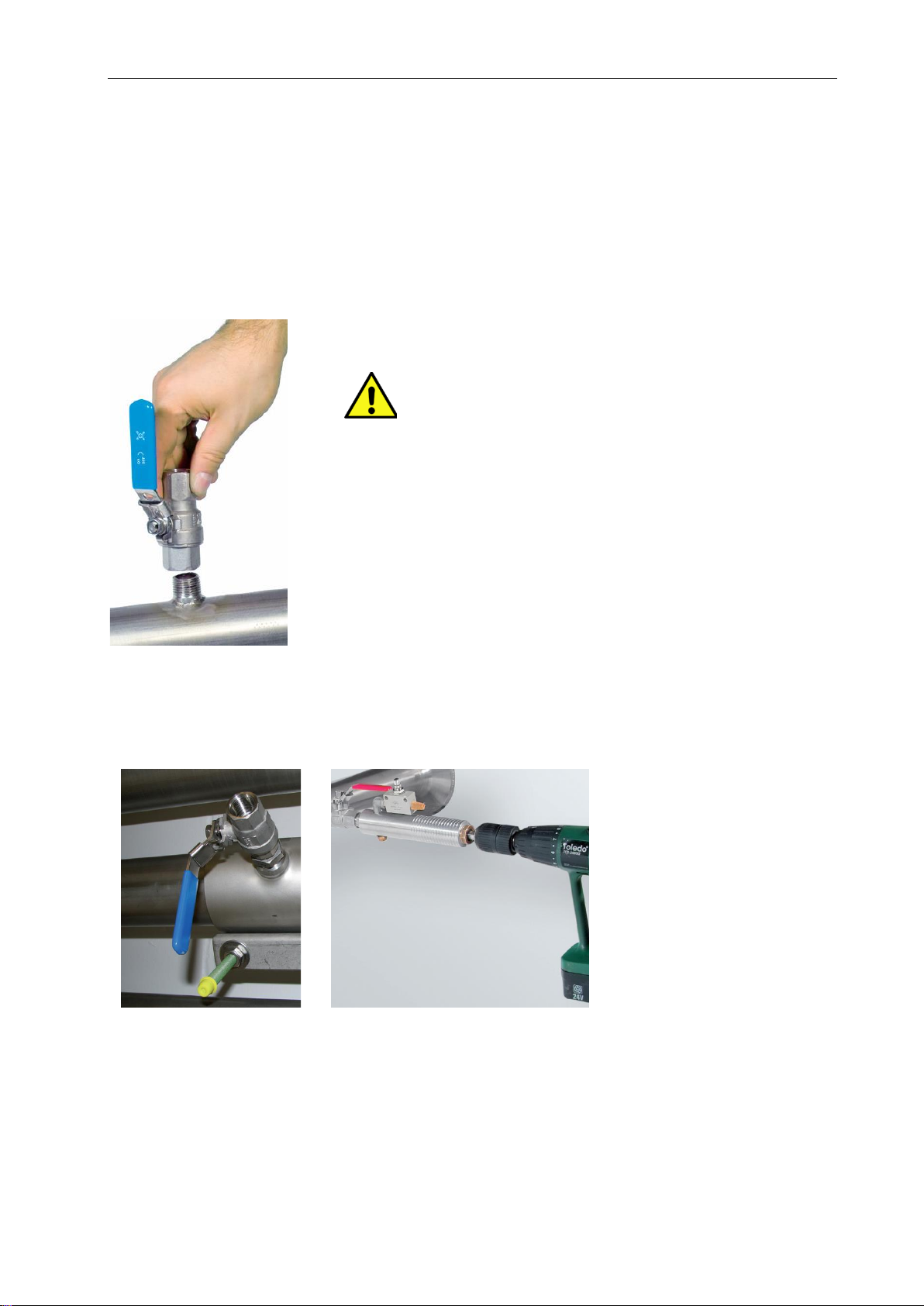

5.3 Installation VD 500

The installation of the sensor is done via a ball valve ½ ".

If no valid measuring point with a ball valve ½ " is available there are following ways to set up a

measuring point.

5.3.1 ½“ welded nipple with ball valve ½“

5.3.2 Spot drilling collar with ball valve

In case the system could not be shut down, means to be set depressurized, there could be used the CS

spot drilling collar (Order-No. 0530 1108) and drilling jig (Order-No. 0530 1108) to drill through the ball

valve.

Important:

Ensure that the system is in shut down, ie. depressurized.

Note for installation with ball valve

Ball valve R 1/2“, DN 15

Passage ball valve: Minimum Ø15 mm

Installation

VD 500 English V1.07

Seite 9 von 40

5.4 Installation of the Sensor

5.4.1 Mounting VD 500 onto the ball valve

•Assembly is carried out by inserting the connection thread with gasket. (G1/2“

thread, SW 32) into the ball valve with ½"internal thread.

The sensor has be tighten by hand as far as possible and then tighten with

stipulated torque of 25-30 Nm.

It must be ensured that the installation is pressure-tight.

•The sensor is then inserted to the required immersion depth (sensor tip in the

middle of pipe) and aligned according to the direction of the airflow.

A depth scale engraved on the probe tube, a flow alignment arrow and an

aligning device will be of help for you.

Once the sensor has been aligned the adapter sleeve must be tighten with

stipulated torque of 20-30Nm (SW 17).

Attention: Alignment of the sensor must not be modified when tightening the connection thread and

adapter sleeve. In this case, please check the immersion depth and alignment again and

correct it if necessary. The angular deviation should not be greater than 2° in relation to

ideal position as otherwise the measuring accuracy will decrease.

Calculation mounting depth: Alignment flow direction

Mounting depth = X + Y

dA = outer diameter

X = dA / 2

y

dA

x

160

170

180

Installation depth

Engraved depth scale for

accurate installation

Safety ring

Adapter sleeve

Connection thread

Sensor alignment

A max. angle deviation of ±2° is permitted to ensure correct

measured values..

Indication flow direction

Installation

VD 500 English V1.07

Seite 10 von 40

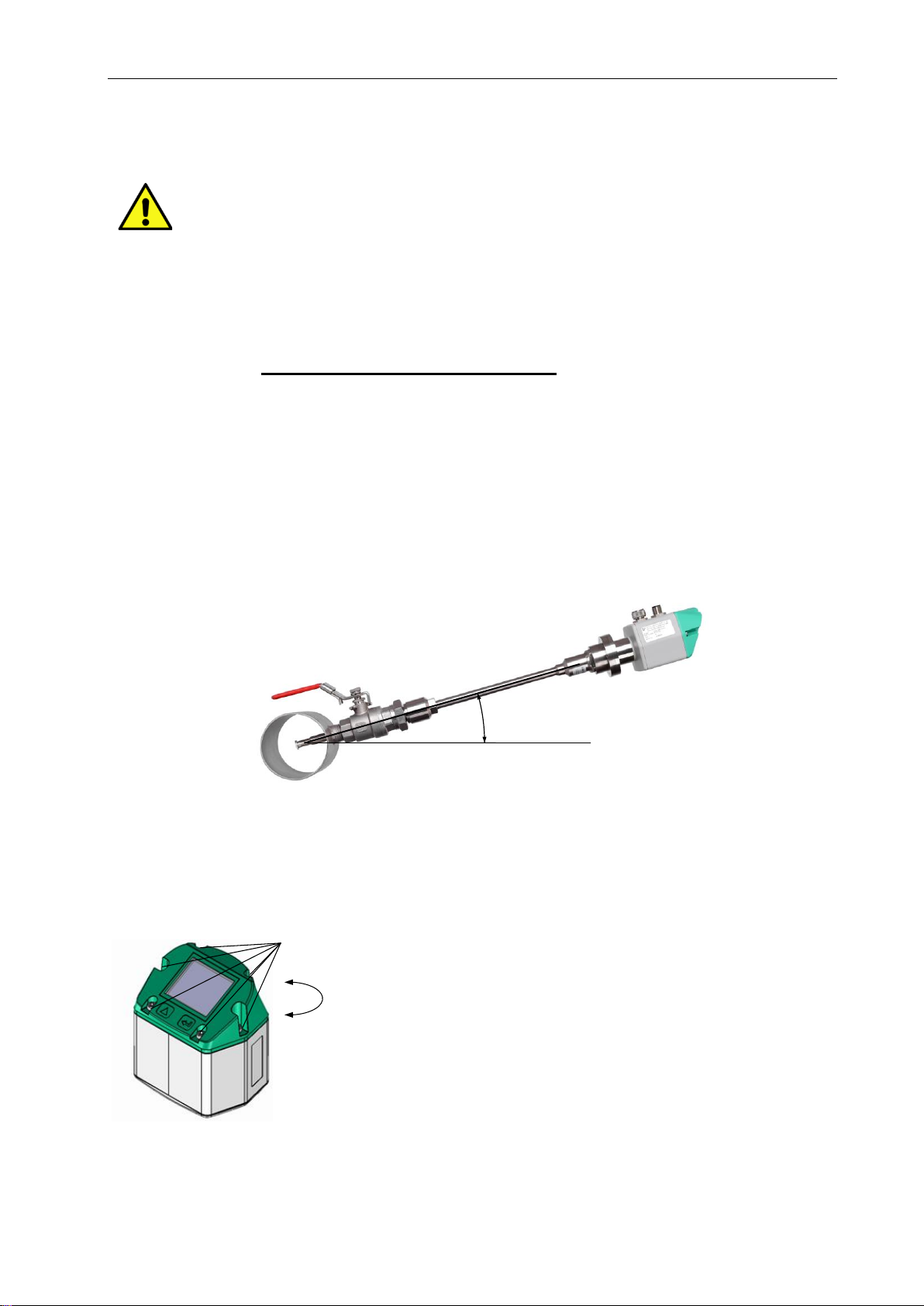

5.4.2 Installation angle for locations that potentially hold water

Location that potentially hold water should be avoided !

•It is recommended to install the VD 500 at an angle of 15 degrees (see

picture).This allows condensate or water to drip off in the event that it is

present.

•Installations in risers are basically possible.

•Not permitted installation of the VD 500:

oupside down sensor installation as condensate / water may no longer

drain off.

oAn installation from above (vertical) is also not permitted as water

penetration leads to measurement errors.

oAn installation in downpipes

15,0 °

5.5 Display Head Position

The Position of the Display head is twistable by 180 e.g. in

case of reverse flow direction.

For this purpose the 6 fastening screws are to be released

and the display head rotated 180°.

Caution:

It must be ensured that the connection plugs are still plugged

and the gasket is installed correctly.

Fastening screws

Commissioning

VD 500 English V1.07 Seite 11 von 40

6 Commissioning

The consumption sensor VD 500 measures the flow velocity (differential pressure principle) in the

center of the pipe.

6.1 Zero Point Adjustment

In order to achieve the required measurement accuracy, a zero point adjustment of

the sensor must first be carried out at the start of the measurement.

•To do this, pull the sensor out completely to the stop.

•Then start the zero point calibration on the sensor.

Main menu →Sensor settings→Zero point, see also chapter 10.3.1.5

Carrying out the zero point adjustment again is recommended every 180 days!

6.2 4… 20 mA Analogausgang

➢VD 500 with Display with 4… 20 mA analogue- and pulse output

Please enter inner diameter of the pipe!

Values indicated in the display:

Actual value in m³/h, m³/min etc.

Counter in m³, l, cf

as well as pulse output, 1 pulse per m³, l, cf

are calculated according to the set diameter. Please take the analogue value for flow rate

4. 20 mA from the tables on pages 13 - 14

4 mA always corresponds with the starting value 0 m³/h, 0 m³/min. The final value 20 mA can be taken

from the tables on pages 13 -17.

Example VD 500 High Speed version:

1“ with inner diameter 25,0 mm: 4mA = 0 m³/h 20 mA = 295 m³/h

2“ with inner diameter 53,1 mm: 4mA = 0 m³/h 20 mA = 1450 m³/h

➢VD 500 without Display with 4… 20 mA analogue- and pulse output

No adjustments are necessary at the consumption sensor.

The respective final values for the flow rate can be taken from the tables on the pages xx - xx.

Analogue start value 4 mA is always set as scaling value 0 m³/h, 0 m³/min etc.

Analogue end value 20 mA is the final value, see tables pages 13 –17..

Example VD 500 High Speed -Version:

1“ with inner diameter 25,0 mm: 4mA = 0 m³/h 20 mA = 295 m³/h

2“ with inner diameter 53,1 mm: 4mA = 0 m³/h 20 mA = 1450 m³/h

Measuring ranges

VD 500 English V1.07 Seite 12 von 40

7Measuring ranges

The consumption sensor VD 500 is available in 2 different versions:

•High Speed–Version max. measuring range of 224.0 m/s

•Ultra Speed –Version max. measuring range of 600.0 m/s

The sensors are programmed to pipe inner diameter of 53,1 mm.

Measuring range Analogoue output Scaling

•High Speed –Version 0 ...1450 m³/h 4mA =0 m³/h, 20mA = 1450 m³/h

•Ultra Speed –Version 0 ...2114 m³/h 4mA =0 m³/h, 20mA = 2114 m³/h

In case of use in other inner pipe diameter the diameter, using the display version, the diameter has to be

set first.

The corresponding scale values for the respective version could be found in sections 5.1 to 5.3.

Example:

Pipe 1“, Inner diameter 25mm Measuring range Analogoue output Scaling

•High Speed –Version 0 ...295 m³/h 4mA =0 m³/h, 20mA = 295 m³/h

•Ultra Speed–Version 0 ...430 m³/h 4mA =0 m³/h, 20mA = 430 m³/h

For changing the inner pipe diameter and adjusting the 4…20mA scaling, please refer to chapter

“Operation”.

Please note:

The area outside the pipe (environment of the sensor) is not allowed to be an explosive area. (Ex area) .

Measuring ranges

VD 500 English V1.07

Seite 13 von 40

The end values refer to application-typical conditions of 7 bara + 50°C.

The end values of the consumption sensor VD 500 depend on temperature and pressure and change

with changing operating conditions..

7.1 Maximum Flow ranges „High speed“

Inner diameter

of the pipe

Flow

(final value of

measuring range in

Nm³/h)

Max

Inner diameter

of the pipe

Flow

(final value of measuring

range in Nm³/h)

Max.

Inchl

mm

Air2)

Air 3)

m/s

Inch

mm

Air2)

Air 3)

m/s

3/4"

21,7

215

198

224,0

3"

80,0

3364

3097

224,0

1"

25,0

295

272

224,0

82,5

3582

3297

224,0

26,0

321

296

224,0

84,9

3794

3492

224,0

27,3

357

328

224,0

90,0

4268

3929

224,0

28,5

391

360

224,0

4"

100,0

5276

4856

224,0

30,0

437

402

224,0

107,1

6059

5577

224,0

1 1/4"

32,8

529

487

224,0

110,0

6391

5883

224,0

36,0

644

592

224,0

5"

125,0

8263

7606

224,0

36,3

655

603

224,0

133,7

9453

8701

224,0

1 1/2"

39,3

775

713

224,0

6"

150,0

11913

10965

224,0

40,0

804

740

224,0

159,3

13436

12367

224,0

41,9

886

816

224,0

182,5

17656

16251

224,0

43,1

941

866

224,0

190,0

19137

17614

224,0

45,8

1068

983

224,0

8"

200,0

21230

19540

224,0

2"

50,0

1283

1180

224,0

206,5

22632

20831

224,0

51,2

1346

1239

224,0

10"

250,0

33211

30568

224,0

53,1

1450

1335

224,0

260,4

36075

33204

224,0

54,5

1529

1408

224,0

12"

300,0

47881

44070

224,0

57,5

1713

1577

224,0

309,7

51027

46966

224,0

60,0

1870

1721

224,0

339,6

61356

56473

224,0

64,2

2148

1977

224,0

400,0

85122

78347

224,0

2 1/2"

65,0

2205

2029

224,0

500,0

133003

122417

224,0

70,3

2589

2383

224,0

600,0

191524

176281

224,0

71,1

2648

2437

224,0

700,0

260685

239938

224,0

76,1

3041

2799

224,0

800,0

340487

313388

224,0

900,0

430929

396632

224,0

1000,0

532011

489669

224,0

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring ranges

VD 500 English V1.07

Seite 14 von 40

7.2 Maximum Flow ranges „Ultra speed“

Inner diameter

of the pipe

Flow

(final value of

measuring range in

Nm³/h)

Max

Inner diameter

of the pipe

Flow

(final value of

measuring range in

Nm³/h)

Max

Inchl

mm

Air2)

Air 3)

m/s

Inchl

mm

Air2)

Air 3)

m/s

3/4"

21,7

578

531

600,0

3"

80,0

9012

8286

600,0

1"

25,0

791

727

600,0

82,5

9595

8822

600,0

26,0

860

791

600,0

84,9

10162

9344

600,0

27,3

956

879

600,0

90,0

11433

10512

600,0

28,5

1048

964

600,0

4"

100,0

14132

12994

600,0

30,0

1171

1077

600,0

107,1

16229

14922

600,0

1 1/4"

32,8

1416

1302

600,0

110,0

17120

15741

600,0

36,0

1724

1585

600,0

5"

125,0

22134

20351

600,0

36,3

1755

1614

600,0

133,7

25321

23282

600,0

1 1/2"

39,3

2075

1908

600,0

6"

150,0

31910

29340

600,0

40,0

2152

1979

600,0

159,3

35990

33091

600,0

41,9

2374

2183

600,0

182,5

47293

43484

600,0

43,1

2521

2318

600,0

190,0

51260

47131

600,0

45,8

2861

2631

600,0

8"

200,0

56865

52285

600,0

2"

50,0

3435

3158

600,0

206,5

60621

55738

600,0

51,2

3607

3316

600,0

10"

250,0

88958

81793

600,0

53,1

3884

3571

600,0

260,4

96628

88845

600,0

54,5

4097

3767

600,0

12"

300,0

128252

117922

600,0

57,5

4588

4218

600,0

309,7

136680

125690

600,0

60,0

5008

4605

600,0

339,6

164345

115130

600,0

64,2

5755

5291

600,0

400,0

228004

209670

600,0

2 1/2"

65,0

5906

5430

600,0

500,0

356256

327610

600,0

70,3

6934

6376

600,0

600,0

513009

471758

600,0

71,1

7092

6521

600,0

700,0

698262

642116

600,0

76,1

8145

7489

600,0

800,0

912017

838682

600,0

900,0

1154271

1061458

600,0

1000,0

1425026

1310441

600,0

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Dimensions

VD 500 English V1.07 Seite 15 von 40

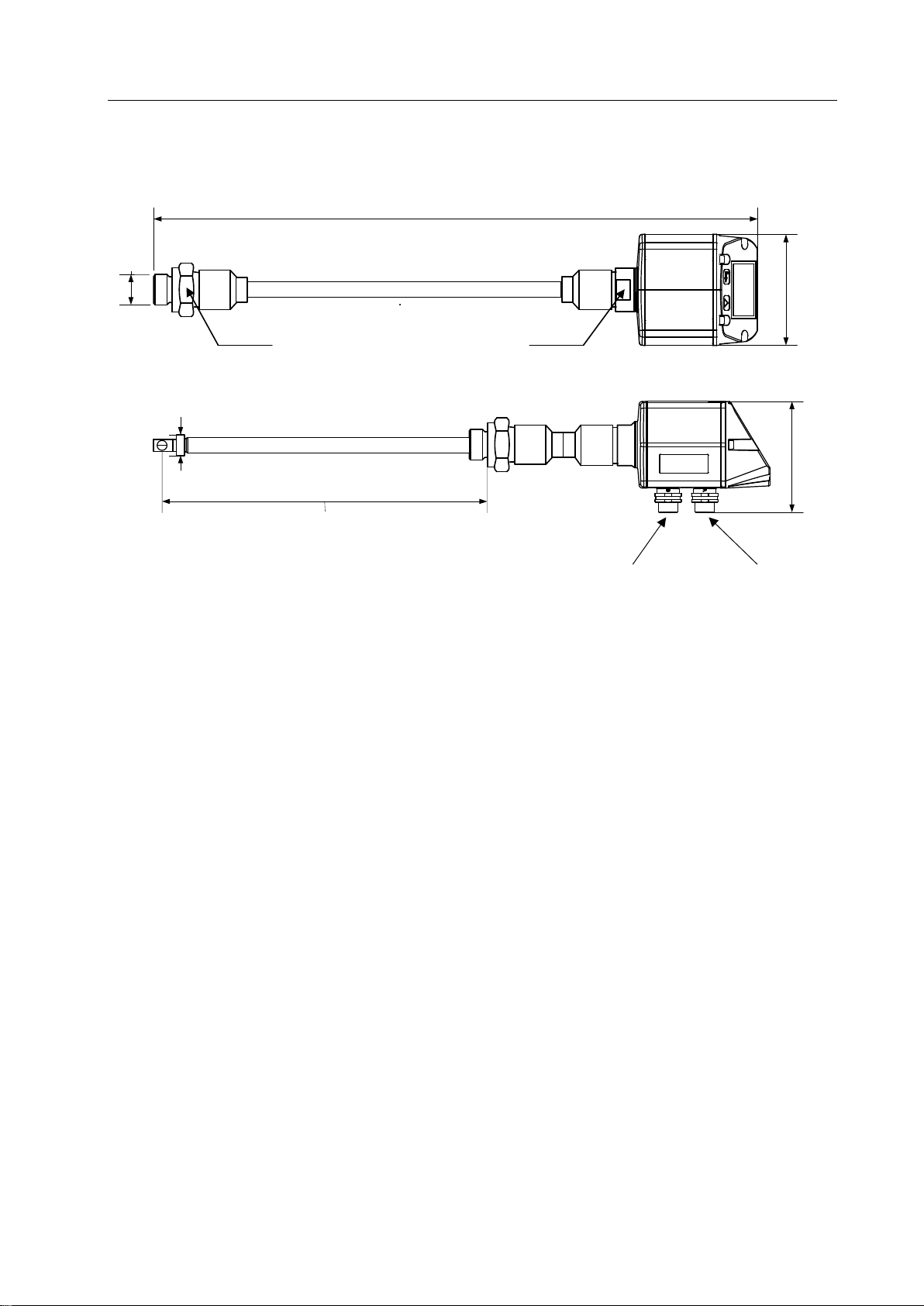

8Dimension

416,0 (Standard Schaft 220mm)

76,5

G ½“

(ISO 228/1)

SW 32 SW 27

75,0

220 mm(Standard)

Optional: 120, 160, 300, 400 mm

Ø11,7

Connector plug A

Connector plug B

Electrical wiring

VD 500 English V1.07

Seite 16 von 40

9Electrical wiring

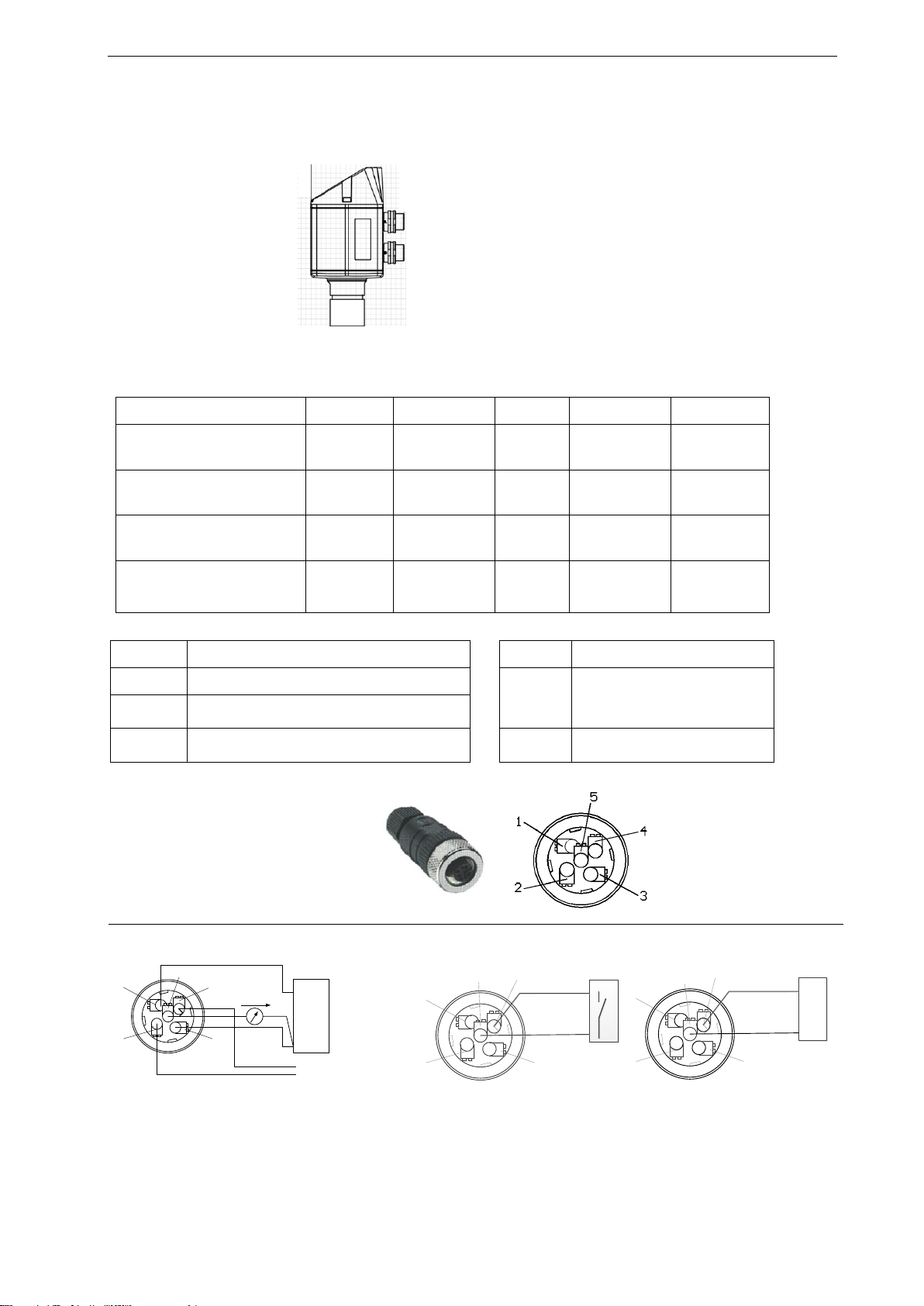

9.1 Modbus RTU, 4..20mA, Pulse or MBus

Attention: Not required connections NC must not be connected to a voltage and/or to

protection earth. Cut and insulate cables.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Connector plug A

+VB

RS 485 (A)

-VB

RS 485 (B)

I+

4..20 mA

Connector plug B

Pulse output (standard)

NC

GND

DIR

Pulse

galv. isolated

Pulse

gavl. isolated

Connector plug B

Option MBus

NC

GND

DIR

MBus

MBus

Colours pulse cables

0553 0106 (5 m)

0553.0107 (10 m)

brown

white

blue

black

grey

Legend:

-VB

Negative supply voltage 0 V

Pulse

Pulse for consumption

+VB

Positive supply voltage 18...36 VDC smoothed

NC

Must not be connected to a voltage

and/or to protection earth. Please

cut and isolate cables.

I +

Current signal 4...20 mA –selected measured

signal

RS 485 (A)

RS 485 (B)

Modbus RTU A

Modbus RTU A

MBus

MBus (reverse polarity protected)

If no connection cable/ pulse

cable is ordered the sensor will

be supplied with a M12

connector plug. The user can

connect the supply and signal

cables as indicated in the

connection diagram.

.

M12 Connector plug

View from back side

(terminal side)

Connector plug A (M12 - A-coding) Connector plug B (M12 - A-coding)

3

4

5

1

2

+ VB

- VB

4 … 20mA

+ -

Grau / Grey

Blau / Blue

Weiss / White

Schwarz / Black

Modbus (B)

Modbus (A)

Braun / Brown

Remark: If the sensor is placed at the end of the Modbus system a termination is required. The sensors have

an internal switchable termination, therefore the 6 fastening screws from the lid are to be released

and set the internal DIP Switch to “On”. It must be ensured that the connection plugs are still plugged

and the gasket is installed correctly.

Alternatively, a 120R resistor can be installed in the plug between pin 2 and pin 4.

3

4

5

1

2

Grau / Grey

Schwarz / Black

Impulsausgang / Pulse output

3

4

5

1

2

Grau / Grey

Schwarz / Black

MBus

Option MBus

Connector plug A

Connector plug B

Electrical wiring

VD 500 English V1.07

Seite 17 von 40

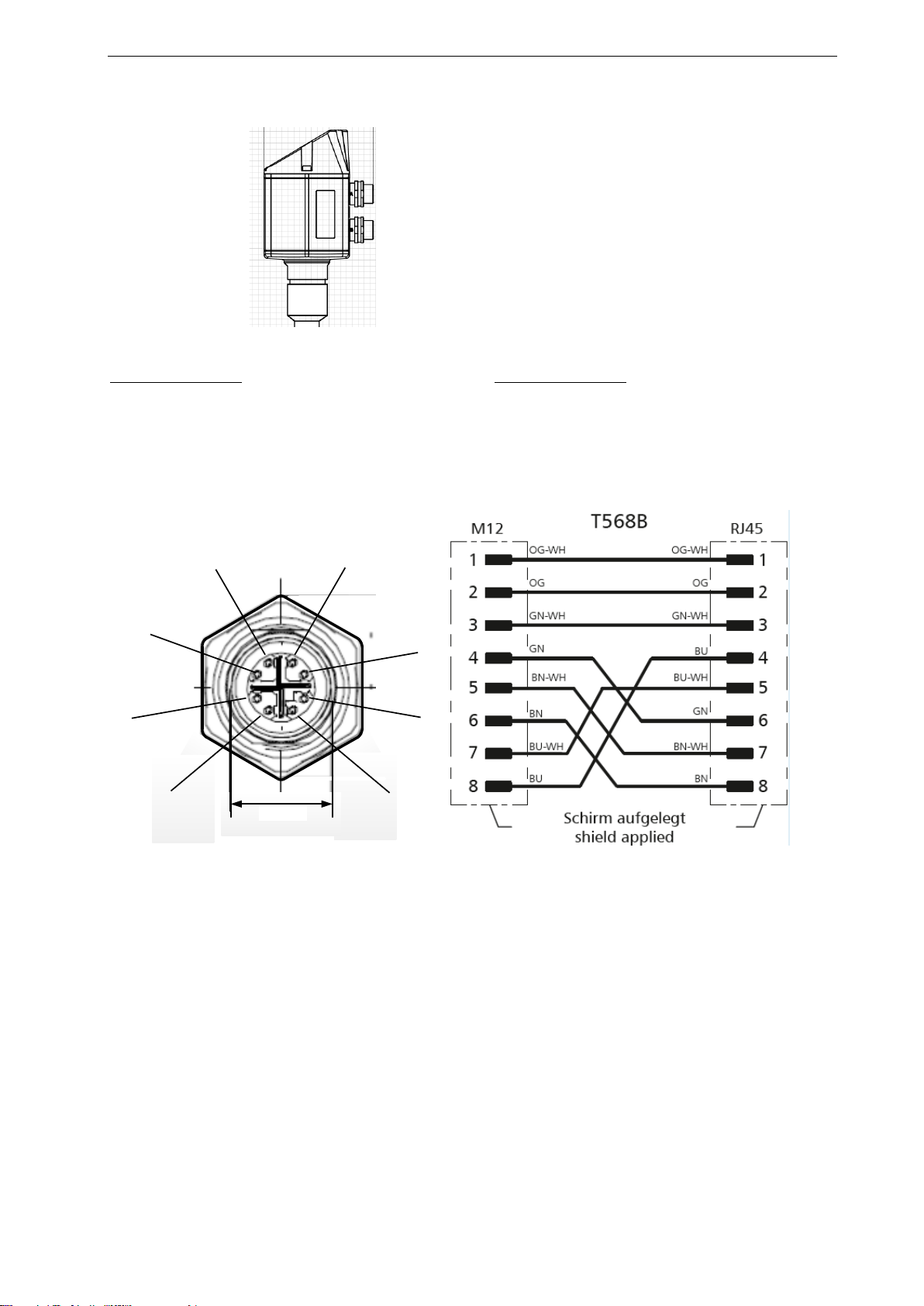

9.2 Ethernet (optional PoE)

Connector plug B Connection cable

M12 x-coded 8 pole M12 x-coded to RJ45

Data LINES: 1,2 und 3,4

PoE LINES: 5,6 und 7,8

2

81

3

5 4

6

7

M12 x 1

Connection cable: Cat 6.

*PoE: Power over Ethernet

- Connector plug B (M12 X-coded 8 pole)

- Connector plug A

Operation

VD 500 English V1.07 Seite 18 von 40

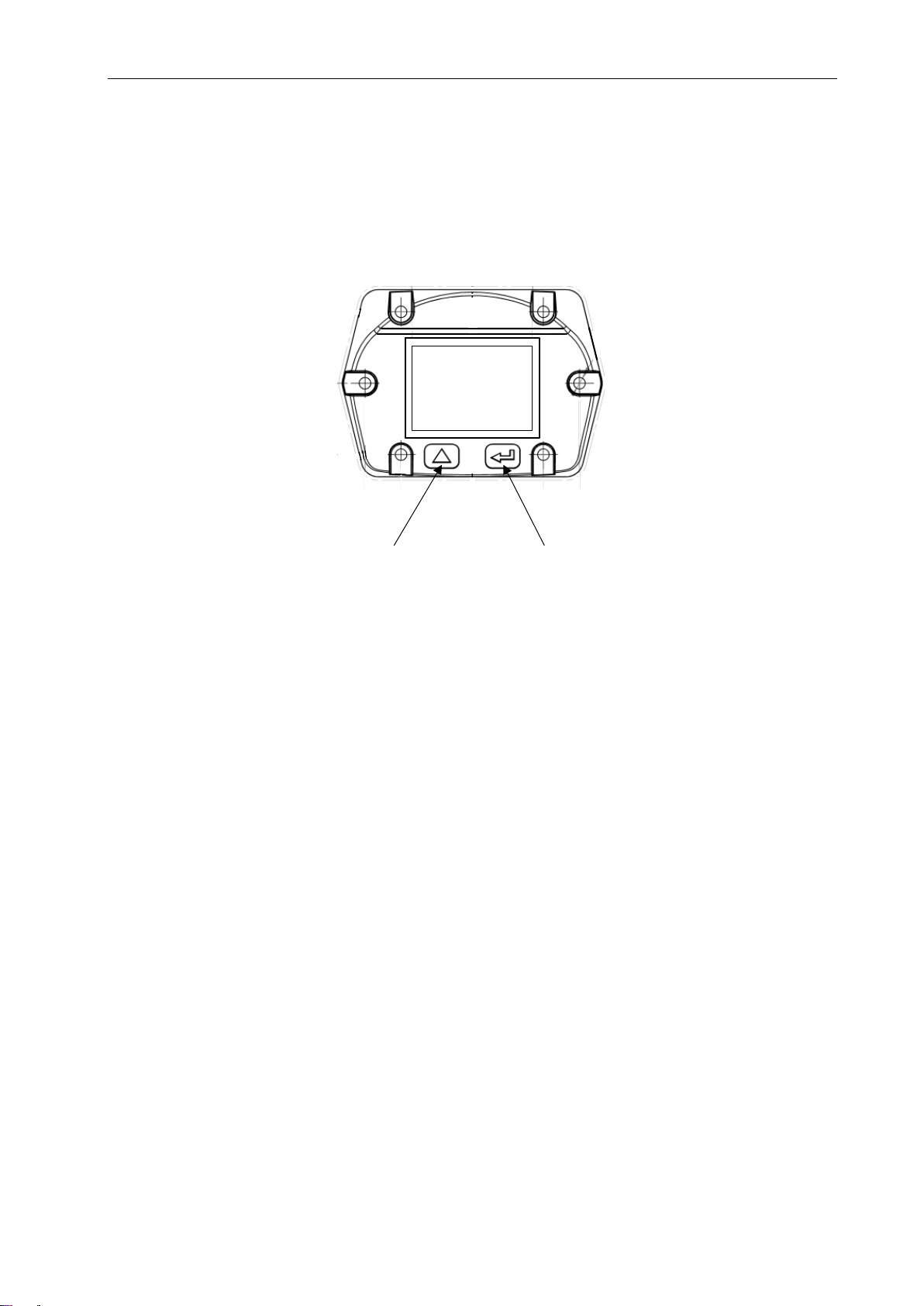

10 Operation

Remark: In version with display only.

“Up“ ( ) “OK“ ( )

The operation of the VD 500 is done by the two capacitive key buttons Up () und Enter ()

Operation

VD 500 English V1.07

Seite 19 von 40

10.1 Initialization

10.2 Main menu

HW Version Page-No.

Gas /

Status Info

SW Version Modbus ID

*** VA 500 ***

Switching to pages 2-4 or back by pressing key „“

*** VA 500 ***

391.23

391

1 minutes

410,34

1 minute

91,3282.46

AV-Time ( Period for average value calculation) could be changed under Sensor Setup.-Advanced–AV-

Time

After switching on the VD 500, the initialized

screen is displayed followed by the main

menu.

*** VD 500 ***

Operation

VD 500 English V1.07

Seite 20 von 40

10.3 Settings

The settings menu could accessed by pressing the key „OK“.

But the access to the settings menu is password protected.

Selection of a menu item or to change a value

is done with the key „“,a final move to the

chosen menu item or takeover of the value

change needs the confirmation by pressing the

key „OK“

Factory settings for password at the time of

delivery: 0000 (4 times zero).

If required the password could be changed at

Setup–User setup-Password.

.

Table of contents

Other CS Instruments Accessories manuals

CS Instruments

CS Instruments VA 500 User manual

CS Instruments

CS Instruments FA 550 User manual

CS Instruments

CS Instruments Vortex VX 570 User manual

CS Instruments

CS Instruments VA 550 User manual

CS Instruments

CS Instruments VA 452 User manual

CS Instruments

CS Instruments VA 400 User manual

CS Instruments

CS Instruments VA 570 User manual

CS Instruments

CS Instruments VA 525 User manual

CS Instruments

CS Instruments VA 500 User manual

CS Instruments

CS Instruments VA 521 User manual