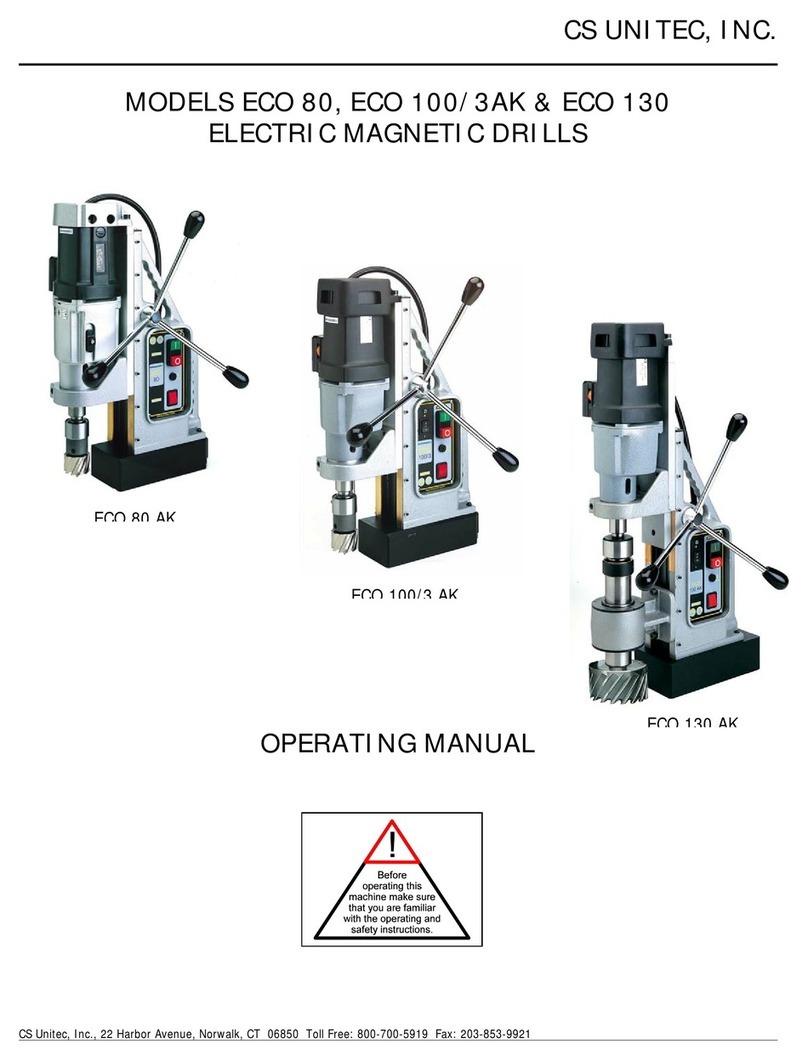

CS Unitec 2-1903-0010 User manual

Instruction Manual

Air Drill

2-1903-0010, 2-1924-0010, 2-1932-0010

This Instruction Manual was written to provide the user with information about the safe

operation and maintenance of C.S UNITEC air drills. Read this manual thoroughly and

become completely familiar with your air drill before using it.

Table of Contents

Safety alert symbols used in this manual.....................................................1

Safety Precautions to be taken when using air drills...................................2

When installing or changing drills or tappers...............................................2

Pictorial nomenclature................................................................................. 3

Instructions for use...................................................................................... 3

Specications.............................................................................................. 4

Maintenance and inspection........................................................................4

Repair...........................................................................................................4

C.S UNITEC Ofces..................................................................................... 4

Safety alert symbols used in this manual

This instruction manual uses the following safety alert symbols. When

you see those symbols in the text, follow the safety message to avoid

personal injury or death.

WARNING: Failure to follow the instructions in the message

might cause a serious accident or death.

CAUTION: Failure to follow the instructions in the message

may cause personal injury or damage to the air tool.

!

!

1/4

2/4

!WARNING

Read this manual thoroughly and become completely familiar

with the air drill before using it. We don’t take responsibility

for an accident or malfunction caused by misuse or improper

operation.

Keep this manual as a ready reference for anyone who may use

the air drill.

If this instructions manual is missing or any warning missing or

defaced (damaged or illegible), replace with a new one. The

instructions manual and label are available through your local

C.S UNITEC dealer.

If the air drill is to be leased, loaned, or sold to anyone, this

manual must be with the air drill.

The air drill is an air tool designed for drilling holes with a

drill. Do not use the air drill for purposes other than specied;

otherwise an accident may result.

It is recommended to install a lter, a pressure reducing valve

and an oiler at the air inlet port.

Do not use an air pressure of higher than 0.6 MPa. Otherwise,

the internal parts or chuck may be damaged, causing an

accident.

Use accessories in a proper manner. If you have any question

about how to use them, contact their respective manufacturers

or dealers. Misuse of accessories can cause an accident.

Before starting operation, remove all tools used for installation

of a tool from the air drill. Tools may y off and cause injury.

If you have any question about the products or the description

in this manual, contact us or your local C.S UNITEC dealer.

WARNING

Safety precautions to be taken when

using air drills - BEFORE USE

Lock the work securely. Otherwise, the work might y,

causing a serious accident.

Hold the air drill rmly and prepare for reaction force. Reaction

force changes abruptly when the drill penetrates through the

work. Avoid operating a large air tool alone; otherwise, its

reaction torque may whack you.

Do not make jerky starts of the air drill. There is danger of

causing an accident or malfunction of the machine. Operate the

starting switch slowly.

WARNING

Safety precautions to be taken when

using air drills - DURING USE

!

!

!WARNING

Wear protective glasses. Use any other appropriate protective

gear such as ear plugs and protective shoes.

Check the rotating direction of the direction lever before starting

the air drill. If the air drill rotates in the direction you don’t expect,

you might get injured. Make sure to stop the air drill before

switching over the rotating directions.

Use caution not to get burned. The head tool such as a drill is

very hot immediately after use. Do not touch it inadvertently.

Securely tighten the air hose connection if any looseness is found

during operation. If the air hose comes off during operation, it

will jump, and may cause an accident.

!CAUTION

When the air drill is not provided with an oiler, add approximately

0.5 ml of turbine oil (ISO VG32 or equivalent) through the air

supply port, before and after operation. Then allow the air drill to

run without load for 2 to 3 seconds, with care not to allow dirt or

dust into the system. Unlubricated operation may cause the air

drill to fail to operate normally, thus resulting in an accident.

When the air drill is provided with an oiler, add turbine oil (ISO

VG32 or equivalent) and adjust the drip rate of oil to a few drips

per minute. Unlubricated operation may cause the air drill to fail

to operate normally,l thus resulting in an accident.

Before starting each shift, drain the tank or air lter. Air

containing a lot of water will cause the malfunction of the air drill

or result in an accident.

Use caution not to allow the entrance of dirt into the unit when

connecting the air hose. Failure to protect the unit against the

entrance of foreign matter may cause the malfunction of the air

drill or an accident. Before connecting the air hose to the air drill,

idle the machine until no dirt or water comes out of it, and wipe

away any dirt or dust from the air hose connection area.

Safety precautions to be taken when

using air drills - WHEN INSTALLING

OR CHANGING DRILLS

Remove the air hose before removal and installation of a tool

such as a drill.

If the air drill starts rotating unintentionally, it may cause an

accident. When any protective device (such as coupler) is not

equipped which automatically shuts off the air, close the main

cock, operate the machine once to discharge the air remaining

inside the air hose before removing it. Otherwise, the air

hose can jump about due to the remaining air pressure when

disconnected.

WARNING

!

3/4

Pictorial Nomenclature

!WARNING

Use the proper head tool (drill chuck, drill socket, or drill) that meets the requirements

(dimensions) of your air tool.

Use of any improperly sized head tool may result in an accident.

Install the head tool such as a drill securely.

Poor installation of the head tool such as a drill may cause an accident, malfunction of the air

drill or premature service life of the socket.

When installing the drill to a large air tool (see the gure below), loosen the feed handle by

turning counterclockwise approximately 10mm from its fully clockwise (tightened) position.

A drill comes off when the feed handle is turned (tightened) fully clockwise.

Please make sure to remove oil or dust on taper part both of unit and drill chuck when you

install drill chuck (or drill) into the body.

If not, it will be at risk of coming off.

2-1903-00010 2-1924-0010, 2-1932-0010

Safety precautions to be taken when

using air drills - WHEN INSTALLING

OR CHANGING DRILLS - CON’T

Instructions For Use

FOR SMALL AIR TOOLS :

1.) Hold the tool with both hands.

2.) Press the tip of the drill vertically against the place where a

hole is to be drilled.

3.) Push the lever slowly to rotate the drill. When the lever is

released, the drill will stop

FOR LARGE AIR TOOLS:

1.) Normally hold the air tool by two persons - one holding the

holder; the other the grip. Reaction torque may whack you

if the air tool is held by yourself. Use of an auxiliary tool as

shown on the next page allows for safer and easier operation.

2.) Press the tip of the drill vertically against the place where a

hole is to be drilled.

3.) Grip Type - Turn the grip slowly counterclockwise (R

position) to rotate the drill clockwise. The the grip is returned

to the neutral position (zero position), the drill will stop rotating.

When the grip is turned clockwise (L position), the drill will

rotate counterclockwise.

one y

4/4

Example of auxiliary tool for use with a large air tool

Type (Wood)

Capacity

(Drill

Diameter)

Chuck

Style

Max.

Free

Speed

Overall

Height

Weight Shank

Center

to Side

Distance

Feed

Length

Hose

Inlet

Thread

Hose

Size

Air Cons.

IN r.p.m IN LBS IN IN NPT IN CFM

2-1903-0010 1"1/2"Wood 750 17 1/2"14 1/2 1 1/2 2 1/4 3/8 1 39

2-1924-0010 2"1/2"Wood 700 18 1/2"24 3/4 1 3/4 4 1/2 1 50

2-1932-0010 3"1/2"Wood 380 18 1/2"14 1/2 1 1/2 2 1/4 3/8 1 50

Morse taper shank type (Large air tool)

Maintenance and Inspection

Make sure to perform maintenance and inspection at regular

intervals. It is recommended to perform maintenance and

inspection at intervals of either a total number of tightening of

100,000 operations or one year, whichever comes rst.

It is advisable to disassemble and adjust the air drill at regular

intervals. To keep the performance and avoid an unexpected

accident, it is advisable to ask a specialist to disassemble and

adjust the air drill at regular intervals. Record and store the

results of measurements taken with a C.S UNITEC torque meter

as well as torque data after bolt tightening.

WARNING

!

Unauthorized modication or repair can cause an accident.

We don’t take any responsibility for an accident or malfunction

if the air drill is modied or repaired by the user himself. The

repair, disassembly, and adjustment must be left to your local

C.S UNITEC dealer.

WARNING

!

Repair

C.S UNITEC Ofces

For any additional information required, please refer to your local C.S UNITEC dealer of the

following C.S UNITEC ofces:

22 Harbor Ave

Norwalk, CT 06850

Tel: (800)-700-5919

Fax: (203)-853-9921

www.csunitec.com

This manual suits for next models

2

Other CS Unitec Drill manuals

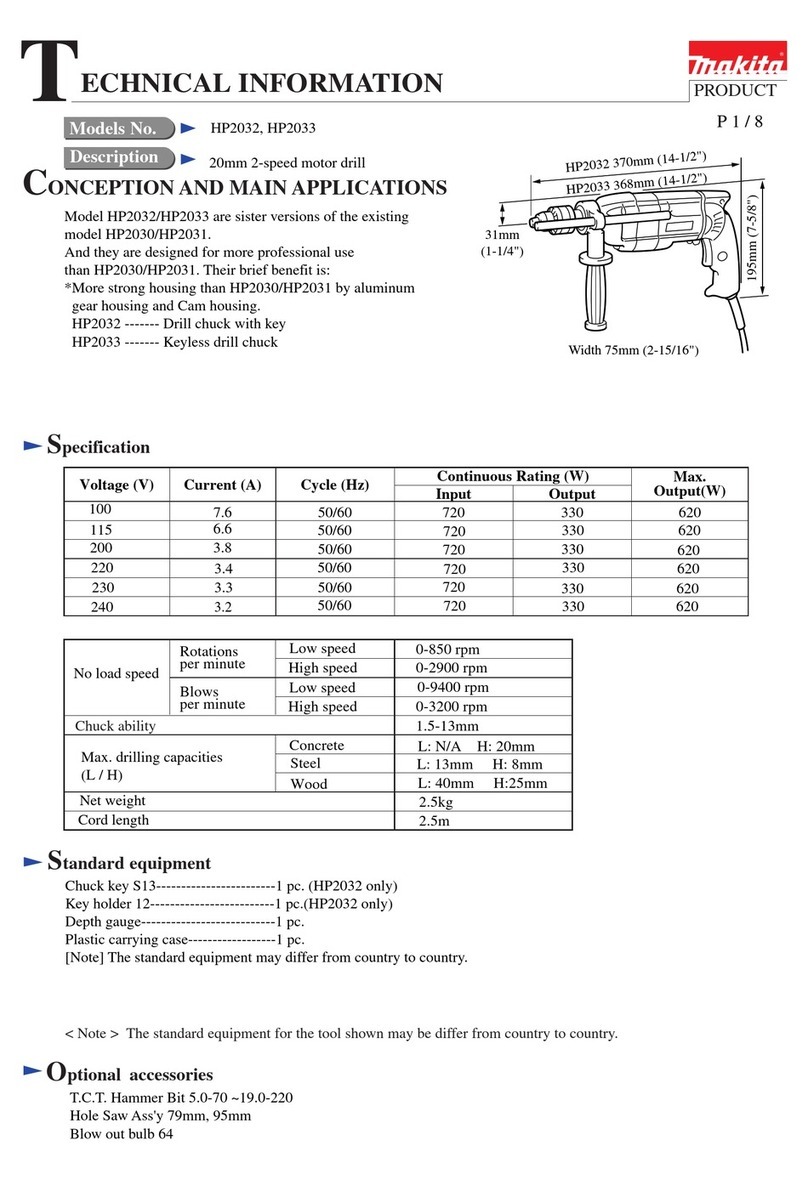

Popular Drill manuals by other brands

Bosch

Bosch Professional GSR 1800 Li Original instructions

Sealey

Sealey SD800.V2 instructions

RED ROOSTER

RED ROOSTER 10RDS-4000 manual

Craftsman

Craftsman 315.101300 owner's manual

Baier Elektrowerkzeuge

Baier Elektrowerkzeuge BDB 829 Translation of the original instruction manual

Ferm

Ferm HDM1037 Original instructions

Porter-Cable

Porter-Cable FLEX BBT 9.6 instruction manual

Hitachi Koki

Hitachi Koki DV16V instruction manual

Bosch

Bosch Professional GWB 10,8-LI Original instructions

Hilti

Hilti SF 2-A manual

Mafell

Mafell BST 650S Translation of the original operating instructions

Wolfcraft

Wolfcraft 3406000 Translation of the original operating instructions