CSA XLC 420 User manual

CSA waterworks line

Upstream pressure sustaining/relief pilot

operated automatic control valve

Mod. XLC 420

Rev. 1 –12/2014

XLC 420

2

For further information please consult us at: www.comeval.es

Personnel involved in the installation or maintenance of valves should always be alert

to potential emission of water and pipeline material, and take the necessary safety

precautions. Always wear the suitable protection like helmets, gloves, googles, when

dealing and handling hazardous pipelines and valves.

Introduction

This manual will provide you with the information to properly install and maintain CSA automatic

control valves XLC 400 series. The contents and the procedure are intended for technicians in

charge of CSA valves only, prior to a theoretical and practical training by CSA qualified personnel

only.

Safety

All safety messages in the instruction manual are flagged with the following symbol meaning

danger, caution and warning. This means and makes reference to procedures that may lead to

equipment and system damage and to severe injury or death for the personnel involved.

Inspection

Your valve XLC series has been packaged to provide protection during shipment, however it can

be damaged during transport. Please carefully inspect the unit for damages or discrepancies with

the order upon arrival and report a claim immediately before unloading the goods.

Parts

Recommended spare parts for each components are listed on the respective assembly drawings

depicted on the following pages. These parts should be stocked to minimize delays in case of

malfunction. When ordering spare parts please make reference to the assembly drawing and

identification plate present on the valve.

XLC 420

3

For further information please consult us at: www.comeval.es

Contents

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Handling and Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Set up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Fusion/Powder Coated Valves - - - -- - - - - - - - - - - -- - - - - - - - - - - -- - - - - - - - - - - 8

Disassembly- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - 9

Interventions on the main XLC 400- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - 13

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

XLC 420

4

For further information please consult us at: www.comeval.es

Description

The pilot operated control valve XLC 400 series Mod. 420 is designed to automatically sustain and

relief a upstream pressure value, regardless of variation in demand and upstream pressure

fluctuations.

Picture 1

2

1

4

56

3

7

8

9

XLC 420

5

For further information please consult us at: www.comeval.es

Lifting the valve in the wrong way may cause malfunctioning, emission of water

spurts, injuries to the personnel and permanent damages of the valve.

Handling and storage

Lifting the valve improperly may damage it and the equipments around. It is mandatory not to

fasten the valve around the circuit, fittings, pipes, solenoids or position indicators. Valves must be

lifted only by cables, chains, located around the body, through the flanges holes or eyebolts.

During hoisting always consider that the center of mass depends on the circuitry and pilots

installed.

If installation will be delayed place the valve indoors in a secure watertight storage. Should that be

unavailable use a vermin proof rain cover around the valve to keep off rain , mud , humidity. Place

the valve on a solid and well drained surface base to prevent moisture, flood from reaching the

body.

XLC 420

6

For further information please consult us at: www.comeval.es

Using the valve with extreme low flow rate and/or excessive differential pressure

conditions may cause pulsations and instability. Please make reference to the

recommended flow and pressure charts or contact CSA for assistance with the proper

sizing.

Installation

The automatic control valve XLC 400 must be always installed in a horizontal position with the

bonnet upwards. Smaller valves, (up to 150 mm) can be installed in a vertical pipe shouldn’t be

unavoidable. Prior to that consult us and specify the orientation in the order. A stable and non

pulsating source of pressure is necessary for the proper performance of CSA control valves,

whose minimum pressure is displayed on the technical brochure and always 0,5 bar on the pilot in

addition to the headloss produced during working conditions.

Gate valves or other sectioning devices must be installed upstream and downstream of

CSA control valves to allow for maintenance.

The operating fluid must be free of air, air valves (CSA Mod. FOX 3F AS combination anti-

slam) should be installed downstream and upstream. This to avoid the accumulation of air

pockets during working conditions, allow air discharge during pipe filling and entrance in

case of pipe burst and draining.

A suitable by-pass should be provided for servicing of the valve without interrupting the

flow. For the by-pass sectioning do not use standard gate valve, likely to get damaged

during modulation, but rely on globe pattern gate valves and/or CSA direct acting pressure

sustaining / relief valves Mod. VSM.

If not included in the order install pressure gauges upstream and downstream if necessary,

a flow measurement device is always recommended to make sure hydraulic conditions

remain within the values used for sizing.

A strainer with suitable basket and mesh should be installed ahead of the valve to protect

internal components from debris, particles and foreign material.

Sufficient space should be provided around the valve for disassembly.

Check direction of flow and make sure it is according to the marking on the valve’s casting.

Make sure the flanges and pipes connection are according to the valve’s standard. The

nuts and bolts setting has to be conducted in the proper way, gradual and symmetrical, in

order not to produced additional stress and deformation.

During handling be sure not to damage the glass of the position indicator, if present.

XLC 420

7

For further information please consult us at: www.comeval.es

The set up and valve regulation has to be carried out by qualified personnel only, or

directly from CSA service. Improper actions can lead to permanent damages to the

valve, its internal components and system equipments along with possible injuries of

the people involved.

The difference in pressure generated by the valve during the pressure

sustaining/relief function will produce a thrust proportional to the pressure itself.

Anchorage blocks and way of preventing valve’s movement or shifting need to be

taken into account.

Set up

For the proper set up of XLC 400 Mod. 420 reader is advised to use the following points (rif. picture

1 on page 4).

Make sure the isolation ball valves of the circuitry (2-3-4) are fully open

The valve is at first isolated from the main line as both sectioning devices, upstream and

downstream, are closed.

Unless a specific setting has been required in the order remove the hood from the pilot (6)

and turn clockwise the screw to increase the spring force in the cover almost completely.

The upstream set pressure depends on the pilot setting and it is proportional to the charge

of the spring. Regulation chart are available on request. Doing so the valve will be brought

to the closed position as the upstream set point would become higher than the incoming

pressure.

Slowly operate on the upstream gate valve to open it by 30 %, leaving the downstream

sectioning device completely closed.

Pressure will enter the valve’s body, circuitry and bonnet pushing down the diaphragm and

mobile block against the obturator and inducing the valve’s closure

Remove the air entrapped in the bonnet, during the operation, by means of the air release

device located on top of the position indicator (7) leaving it flowing for at least 20 seconds.

Open completely the upstream gate valve

Slowly open the downstream gate valve, to a maximum of 40% of the stroke, act on the

spring on the pilot decompressing it to generate some flow through the valve and allow for

some time to react, this depends on how big is the system downstream and on the

variations in demands.

Having generated the flow it means that the upstream pressure set point has reached the

incoming pressure value.

XLC 420

8

For further information please consult us at: www.comeval.es

Valves epoxy painted using FBT requires washers flat washers to be installed on the

flanges connections to prevent the paint from cracking or chipping.

Regulations of pilots has to be carried out slowly to avoid unwanted pulsations and

pressure surges. Always leave enough time for the system to balance, in case of

doubts and problems allow for some flow through the by-pass to stabilize the line and

call CSA technical support.

Slowly act on the regulation screw on the pilot (6) turning it clockwise to limit the flow

increasing the upstream pressure to be sustained or anticlock wise to increase the flow

reducing the upstream pressure to be sustained , the variation in pressure depends on the

spring range used, and can vary from 0,47 bar to 0,95 bar per revolution with the most

common springs used. Please consult us for more details.

Once the valve has reached the desired value set the locking nut and place the hood on top

of the pilot. Open the downstream gate valve completely then and check once again the

pressure gauge and the flow meters.

The unit flow control device GR.I.F.O. is exclusive from us and contains needle valves, filter

and check valves used for the proper valve’s stability and regulation. If present do never

change the settings before consulting with our technical support.

Valves epoxy painted FBT

Maintenance

CSA automatic control valves XLC 400 series have been designed with a sturdy and reliable

construction to minimize servicing and possible malfunctioning. However we recommend to inspect

them at least twice per year releasing the air accumulated inside the bonnet and checking the

strainer inside the GR.I.F.O, if present, or placed as a separate entity in the circuitry. We

recommend a thorough inspection and maintenance with complete disassembly every 4 years,

according to the following instructions.

XLC 420

9

For further information please consult us at: www.comeval.es

MSM –Upstream pressure sustaining/relief pilot

The upstream pressure sustaining/relief pilot

is a diaphragm operated valve, spring

loaded and direct acting, that can be

installed basically in any position.

The function is nothing but to sustain or

relief the upstream pressure regardless of

flow rate and pressure variations.

Operation

The valve is normally opened thanks to the

force exerted by the spring over the

diaphragm, that is opposed to the upstream

pressure applied directly below it.

When the upstream pressure exceeds the

force of the spring the obturator is pushed up

closing the passage through the pilot and

therefore leading the pressure towards the

main chamber and allowing for the valve to

throttle, which will result in a pressure

increase because of the head loss created

between the valves inlet and outlet.

We obtain the regulation by acting on the

screw (21), i.e. clockwise to increase the

pressure and counter-clockwise to decrease

it.

Disassembly

It is not necessary to remove the pilot from

the circuit for the disassembly. Instead use

the enclosed picture which indicates the

numbers specified here below to perform the

operations.

1- Remove the hood of the pilot (4) loosen

the tightening nut (36) and turn the lead

screw (21) anticlockwise, until the spring is

completely unloaded.

2- Remove the screws (33) holding the cover

(20).

3- Separate the cover, the spring (35) and

the spring guide (7).

22

28

39

27

11

40

33

36

10

26

25

29

04 21

12

35

20

07

16

31

30

41

17

XLC 420

10

4- Separate the intermediate body (29) from the lower body (22) paying attention not to damage

the o-ring (30)

5- Check the surface of the seat (31) making sure it hasn’t been damaged or scratched

6- Holding the gasket container (39), using an aluminum vise or with buffers in order not to damage

or scratch the material, with a monkey wrench 13 unscrew the tightening nut (12) to remove the

upper flat (10) and the diaphragm (11).

7- With a monkey wrench 24 remove the lower tap (16) and clean it checking for possible dirt or

debris , pay attention not to damage the o-ring (17)

8- Check the plane gasket (28) and, if damaged, contact us for further assistance.

Inspection and repair

During these operations carefully check every detail to find damage, in particular the

diaphragm and the sealing seat gasket. The pilot is very sturdy and the materials are

designed to guarantee many years of working conditions for which, generally, it is

sufficient to remove the deposits and make sure to keep the metallic internal components

properly lubricated. If that is not enough we strongly recommend you to contact us technical

support or order the maintenance kit.

Reassembly

To reassembly the pilot you have to repeat, obviously in reverse sequence, the same steps

specified in the dismantling phase, while paying attention to:

- Not to exert excessive torque on the locking nuts and upper flats so as not to wear the internal

components, please contact us for any doubt related to the torque required to perform the

operation.

- Insert the o-rings back to their position properly lubricated

- Set the screws tight using a criss-cross pattern

XLC 420

11

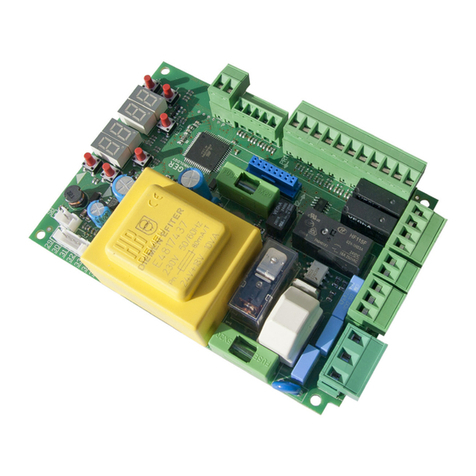

GR.I.F.O. 3 –3/8″ PN 25

The “GR.I.F.O.” (Integrated Group Filter Orifices) is a CSA unit flow control device that

includes all the necessary functions, needed for the proper regulation and stability of the main

valve. Its compact design makes the entire circuitry easy to be maintained, simple and intuitive yet

allowing a tremendous range of regulations compared to other solutions on the market.

It is completely manufactured in stainless steel AISI 303 and contains :

- a fine mesh filter in AISI 304 (8) to protect the pilot circuit from possible dirt, maintained simply by

unscrewing the tap (9).

- the intervention also called reaction speed regulator* (4) of the main valve, and the opening (3)

and closing (2) speed regulators* of the valve’s main chamber, independent one from the other,

obtained by CSA fine adjustment needle valves.

TEL.+39 0524 523978

SALSOMAGGIORE TERME(PR)

GR.I.F.O.-3 G3/8 PN25

VELOCITA' CHIUSURA VELOCITA' APERTURA

CLOSING SPEED OPENING SPEED

ORIFIZIO CALIBRATO

ADJUSTABLE ORIFICE

www.csasrl.it

14 2

4

3

7

13

6

8

9

10

19

1

11 12

5

16

18

17

15

XLC 420

12

-replaceable check valves placed upstream of every regulator to limit the flow and control

the acceleration during the valve opening and closing.

- an upstream outlet not filtered protected by a cap 1/8 G

- an upstream pressure outlet filtered, 1/8 G, protected by an air valve.

- The adjustment is normally done in the factory although it is possible to modify it on the spot, in

order to find the optimal regulation according to the function required.

Herewith enclosed are the optimal values for the most common XLC applications expressed in

terms of revolutions, starting from the fully closed position and turning anticlockwise.

The regulators are needle valves designed by us and the rotation permits to obtain a specific

passage. For example the regulation 3 means that, starting from the complete closed needle

(turned clockwise), unscrewing 3 turns in opening you will get the indicated regulation.

Maintenance

The “GRIFO” is particularly sturdy, extremely simple and reliable so it does not require

maintenance but we strongly advise to proceed regularly, at least twice per year, with a clearing of

the filter from dirt and deposits, simply by unscrewing the tap (9) and washing the mesh. This

procedure can be carried out without interrupting the flow through the main valve, and simply by

isolating the main circuit by means of the isolation ball valve and removing the pressure right

upstream of the GRIFO.

Type

Reaction

speed

Opening

speed

Closing

speed

XLC 410

3

1

5

XLC 412

3,5

4

4

XLC 420

3

3

4

XLC 430

3

1

5

Others

Please contact us for informations.

XLC 420

13

Interventions on the main XLC 400 valve

In case of malfunctioning or defects, that

can be found on the main valve, is possible to

intervene without removing the product

from the pipeline. The defects can be either

internal and external.

The external defects mainly concerns the

pilot circuit and are not related to the main

body of the XLC 400 control valve.

The internal defects concern the mobile

block, or the deterioration of the internal

components.

Problems can be summed up in three

categories:

a) the valve is blocked, the mobile block

does not move;

b) the mobile block moves but the valve

does not react because the diaphragm is

damaged.

c) the diaphragm is OK but the valve does

not close or leakages is reported.

The possible causes lead

to:

defects on the

diaphragm;

defects on the movements of the

mobile

block;

friction caused by

deposits and

corrosion;

problems on the

gaskets;

defects on the sealing

seat.

15

13

21

14

17 16 118 4

10 5

9

3

7

2

8

11

12

20

19

6

N. Component Material

1

2

3

4

5

6

7

8

9

Body

Cap

Position indicator

Pressure outlet tap

Upper flat o-ring

Obturator o-ring

Indicator stem

Main shaft

Guide ring

GJS 450-10 or GJS 500-7

10 Spring

11 Locking nut

12 Upper flat

13 Diaphragm

14 Obturator

15

16

17

18

19

20

21

Plane gasket

Gasket holder

Seat

Seat o-ring

Studs

Nuts

Washers

St. steel/Ni-plated brass

AISI 302

AISI 303/AISI 304/AISI 316

AISI 304/AISI 316

AISI 304/AISI 316

GJS 450-10 or GJS 500-7

AISI 316

NBR/EPDM/Viton

NBR/EPDM/Viton

AISI 303

AISI 303/AISI 316

Bronze/AISI 303/AISI 316

AISI 303/AISI 316

Painted st./AISI 304/316

Neoprene-nylon

St. st./paint. st./GJS 450-10/500-7

NBR

AISI 303/AISI 316

NBR/EPDM/Viton

AISI 304/AISI 316

XLC 420

14

Problems solving

Problem

Cause

Solution

The main

valve

doesn’t

close

The gate valves are

closed

Open the gate

valves

The ball valves of the circuit are

closed

Open the ball

valves

There is no pressure inside

the

main chamber

Check the pressure coming

into the

circuit

The diaphragm is damaged ( see

the

following section “checking the

diaphragm”)

Replace the

diaphragm

The mobile block is stuck due to

corrosion,

deposits,

cavitation

Clean the main shaft

and replace all

the

components affected by

deposit or

corrosion

The mobile block is stuck due to

stones,

pebbles, trapped

inside

the

main body

Remove the material from

the

valve

The plane gasket of the obturator of

the main valve and/or of the pilot is

ruined

Replace the plane

gaskets

The sealing seat is

ruined

Replace the sealing

seat

The main

valve

doesn’t

open

The gate valves are

closed

Open the gate

valves

The ball valves of the circuit are

closed

Open the ball

valves

There is no pressure on the main

supply

line

Check the upstream

pressure

The pilot set point is higher than the

incoming pressure value

Reduce the upstream

pressure set point by turning

the screw anticlockwise to

generate the opening

The mobile block is stuck due to

stones,

pebbles, debris that remain

trapped

inside

the

valve

Clean the main shaft

and replace all

the

components affected by

deposit or

corrosion

XLC 420

15

1) Checking the diaphragm

In order to verify if the diaphragm has suffered any damage simply proceed as follows:

a) slowly close the upstream and downstream gate valves;

b) close all the ball valves of the circuit;

c) completely open the air vent valve from the position indicator, if the latter is not present

the fitting of the isolation valve on the chamber;

d) open the upstream gate valve slowly but not completely little by little so that the pressure enters

the main valve body.

The water that flows will raise the mobile block and the membrane therefore, the air vent will

discharge the remaining water trapped inside the main valve bonnet.

When all the water of the main chamber has been expelled (this operation could take a few

minutes and is related to the DN of the valve as well as the opening percentage of the upstream

gate valve) if the membrane is not damaged, the flow will come to an end and you can be sure the

cause of the problem has to be found somewhere else.

On the contrary if the flow keeps going the diaphragm is surely damaged or the nut fixing the

membrane to the shaft is not tightened enough, therefore intervene accordingly, simply by

replacing the diaphragm or setting the nut tight.

Warning: remember to close the upstream gate and decrease all the remaining pressure inside

the valve before removing the bonnet.

Movement of the mobile block

In order to verify the proper movement of the mobile block to proceed as follows: isolate the main

chamber closing the two isolation ball valves on the upstream and downstream side of the valve’s

body, and open the drain port located on top of the position indicator. In this way you will relief the

pressure out of the valve’s bonnet.

Attention: with this operation we will basically open the valve completely, therefore no regulation

will be performed. Make sure to avoid dangerous consequences of the pressure system onto which

the valve is acting.

When the main valve is completely opened mark the glass of the indicator to the

corresponding position.

Now close leave the isolation ball valve downstream and open the correspondent upstream, also

close the air release valve on the position indicator. The main valve will close.

Verify that the valve closes following the movement downwards of the indication rod (a slowing

down in the final phase is normal and caused by the bending and adjustment of the diaphragm).

When the valve is closed, mark the glass of the indicator to the corresponding position and verify

that the movement of the rod is like the one indicated below, if different, then means that there is

something preventing the proper movement of the mobile group and please contact us

immediately.

DN in mm

50

65

80

100

125

150

200

250

300/400

Stroke in mm

15

18

21

27

27

43

56

70

84

XLC 420

16

The clogging can be located between the seat and obturator if the indication rod is in closed

position and the flow continues, or between the sealing seat and cap if the valve does not reach

the complete opening. Before proceeding to dismantling the cover, it is suggested to do some

manual opening and closing operations putting the main chamber under pressure and discharging

it. This operation proved to be enough in some situations to flush the dirt downstream. If not take

the cover apart.

3) Friction of the shaft

One of the more frequent causes of the mobile group movement obstruction are the

corrosion and deposits on the main shaft causing friction. They can be due to particles (conveyed

from the water) or to limestone deposits (for extremely hard water) that in the long run cause the

jamming of the main shaft on the guiding devices, because of the high friction value.

Should that be the case simply proceed to a proper cleaning leaving it in a muriatic acid solution

5% as long as necessary, shouldn’t that be sufficient then proceed with a fine abrasive cloth until

the deposit is completely removed.

4) Plane gasket

The valve must close watertight once the pressure has entered the main chamber and if we have

enough pressure to do it which is at least 0,5 bar acting on the pilot in addition to headloss during

outflow, if that doesn’t happen proceed with the inspection of the plane gasket performance

assuring the closure between the obturator and the sealing seat.

5) Sealing seat

One more reason that could be responsible for the improper closure of the valve may be the

sealing seat, occurring in case of dirt and deposits or damaged due to cavitation. In these cases

we must proceed with an accurate inspection to clean the component by means of sandpaper

then polish it, if the problem can’t be solved on the spot please contact us technical support for

immediate assistance.

XLC 420

17

Disassembly

As mentioned before make sure that the gate valves upstream and downstream of the valves have

been properly closed and set tight.

Relieve the pressure of the main chamber simply by closing the isolation valves of the circuit and

opening one of its fittings. Proceed with the removal of the circuitry, in order to facilitate the

intervention on the cover, only after having noted down the layout

Remove the nuts (4) and the washers (5). If the valve has been working for a long time you may

notice that all the parts in contact with the diaphragm will tend to get stuck, in this case simply hit

the lower part of the cover to loosen it by means of a plastic hammer and a chisel driving it

upwards. After that, hoisting the valve vertically using eyebolts. Remove the internal mobile block

and put it into a grip with clamps in soft material such as brass or aluminum, be extremely

careful doing that because the upper and lower main shaft surface responsible of the valve-s

guiding mechanism , if worn or etched, may cause the blocking of the valve due to its bind in the

bearings.

Remove the nut and the washer (10) take off the upper flat (11) the O-rings (21) check the

diaphragm looking for damage and, after having pulled out the plane gasket (13)by means of a

screw driver ( please make sure not to wear the gasket itself or its housing) examine it carefully.

Check the driving bush on the cover (7).

Examine the sealing seat (15) looking for scratches that may affect the proper water tightness and

for possible sign of cavitation.

The sealing seat is made in stainless steel and it usually doesn’t require particular

maintenance, a very important thing though is to guarantee proper cleaning by means of sand

paper.

Up to DN 150 the sealing seat is screwed into the body while for the remaining DN it is set tight by

several screws. To carry out a further inspection and removal of the sealing seat, and in case of

cavitation, please contact our technical support for immediate assistance.

Inspection

After all the components have been dismantled we need to look for any damage caused by wear of

the surface, deposits, corrosion or something else.

It is strongly advised to replace every 4 years all the components made in rubber, responsible for

the water tightness of the valve, such as O-Rings, the diaphragm, the plane gasket.

XLC 420

18

Reassembly

To reassemble do the reverse of the disassembly procedure positioning the main shaft back into

the grip along with all the pieces. It is very important not to forget the O-Ring (21) and to set the

nut tight (10) to assure a proper torque between the diaphragm and the plane gasket. Please be

extremely careful with this step because a nut not properly tight may engender movements making

the mobile block unstable, therefore affecting the valve’s performance.

Put the mobile group back into the valve’s body placing the shaft into the sealing seat guide, make

the holes of the diaphragm match the studs and position the spring (9) under the cover.

Set the nuts tight using a cross over pattern, then put the circuitry back to its original position.

Final inspection

Make sure that the internal mobile block can move without any friction, this can be verified simply

by gradually putting the main chamber under pressure and checking the movement of the

indication rod, as explained before.

Examine the status of the plane gasket simply by checking the perfect water tightness of the

sealing seat. At this point proceed by opening the upstream gate valve full throttle to have the

normal working conditions, check for any leakage through the cover or the nuts, should that

happen set them tighter.

XLC 420

19

We reserve the right to incorporate our latest design and material changes without notice or obligation.

Design features, materials of construction and dimensional data, as described in this manual, are provided for your information only.

Table of contents

Other CSA Control Unit manuals

Popular Control Unit manuals by other brands

Emerson

Emerson VAREC 7100B Series Instruction, Operation and Maintenance Manual

DAE

DAE AMR130-v2.0 installation guide

Numatics

Numatics 2005 Series Installation and maintenance instructions

Watts

Watts LF007 Series Installation, maintenance & repair

Inel

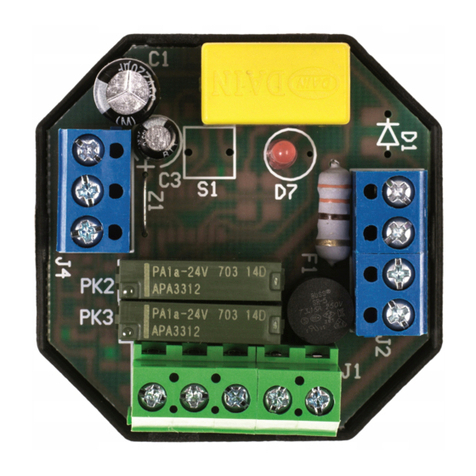

Inel ST-0P Instructions for installation and use

DOLD

DOLD SAFEMASTER BN 5930.48/203 operating instructions

Scully

Scully ST-35C-120 EL Technical manual

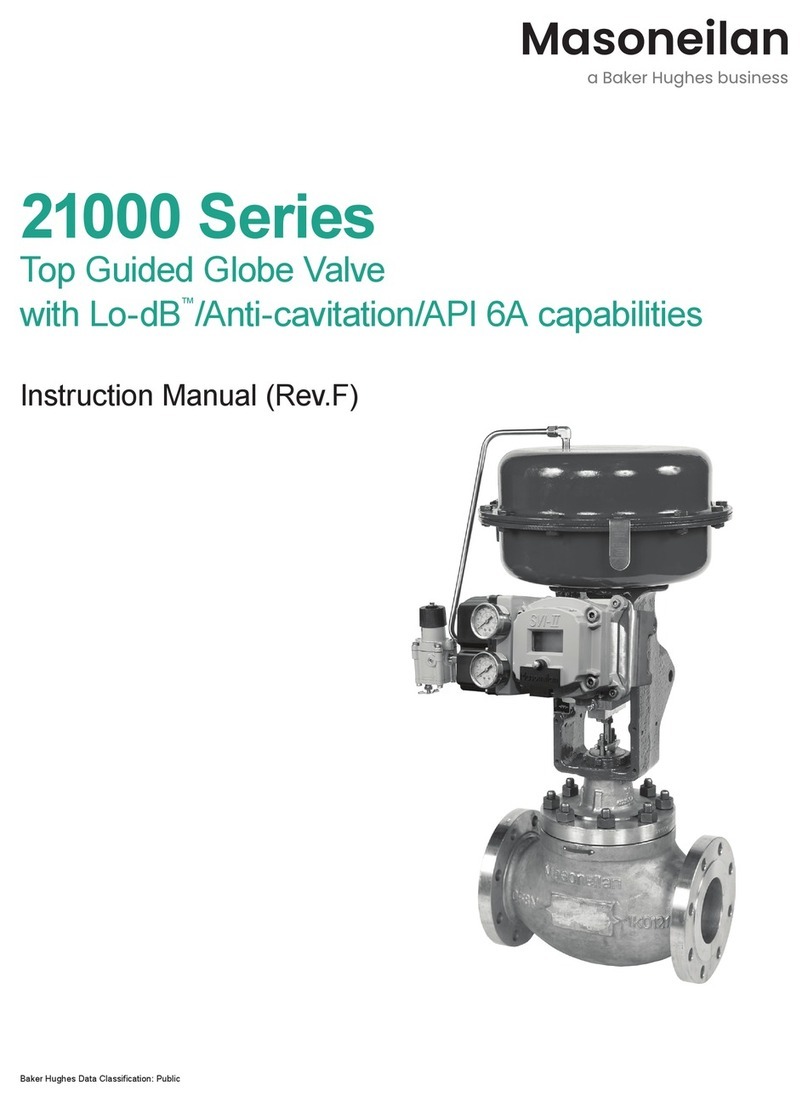

Baker Hughes

Baker Hughes Masoneilan 21000 Series instruction manual

Sporlan

Sporlan OROA-5 Installation & service instructions

CBE

CBE SP5 Series instructions

KONTRONIK

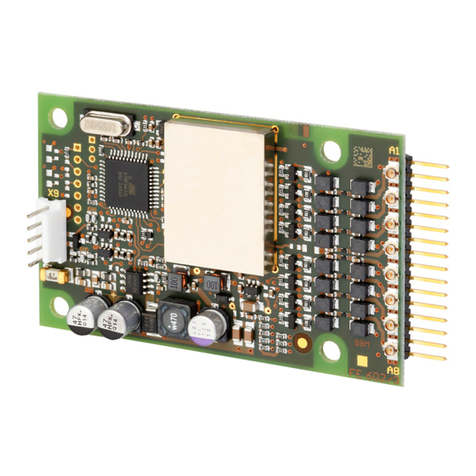

KONTRONIK PIX4000 Operation manual

Feig Electronic

Feig Electronic OBID i-scan ID ISC.M02.M8-B manual