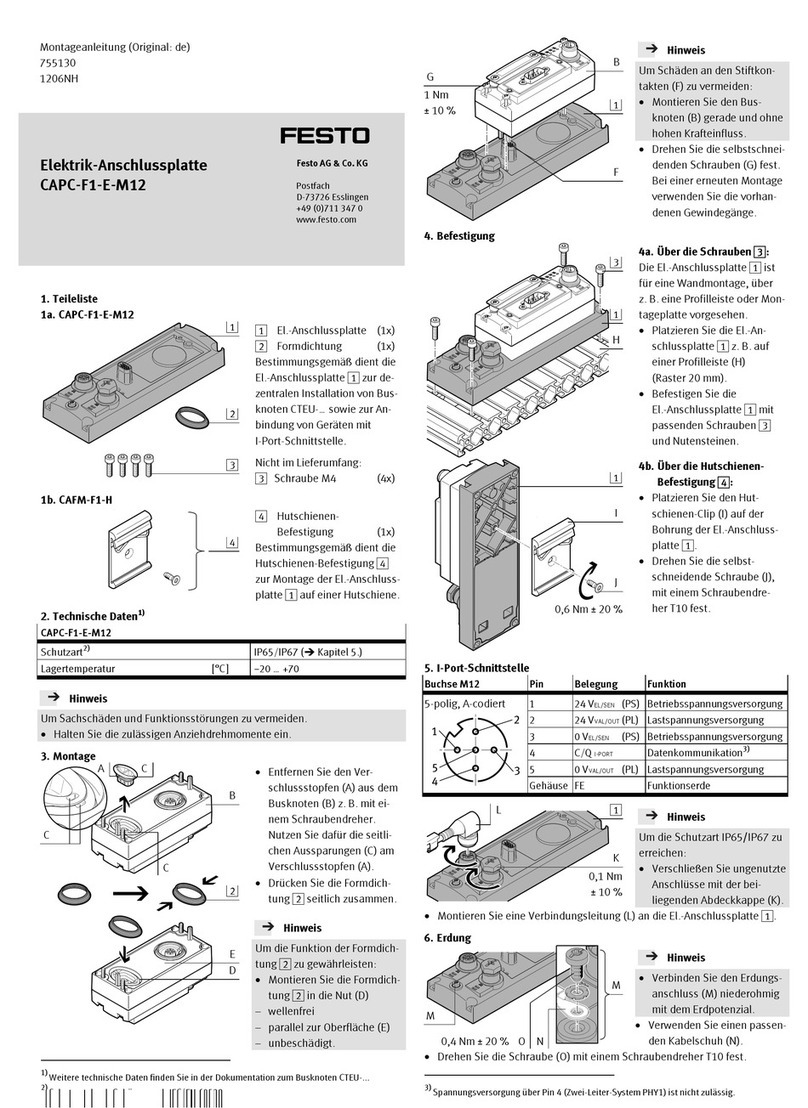

4.2 Pneumatic installation

Connect tubes to the pneumatic

connections 2(retract)/

3(extend).

Seal unused connections with

blanking plugs.

Observe the tightening torque:

DADM-EP-G6-10

Tightening torque 0,5 Nm.

DADM-EP-G6-16

Tightening torque 2 Nm.

Fig. 5

2

3

3

2

Possible activation of a DADM in conjunction with DGSL

DADM DGSL

Fig. 6

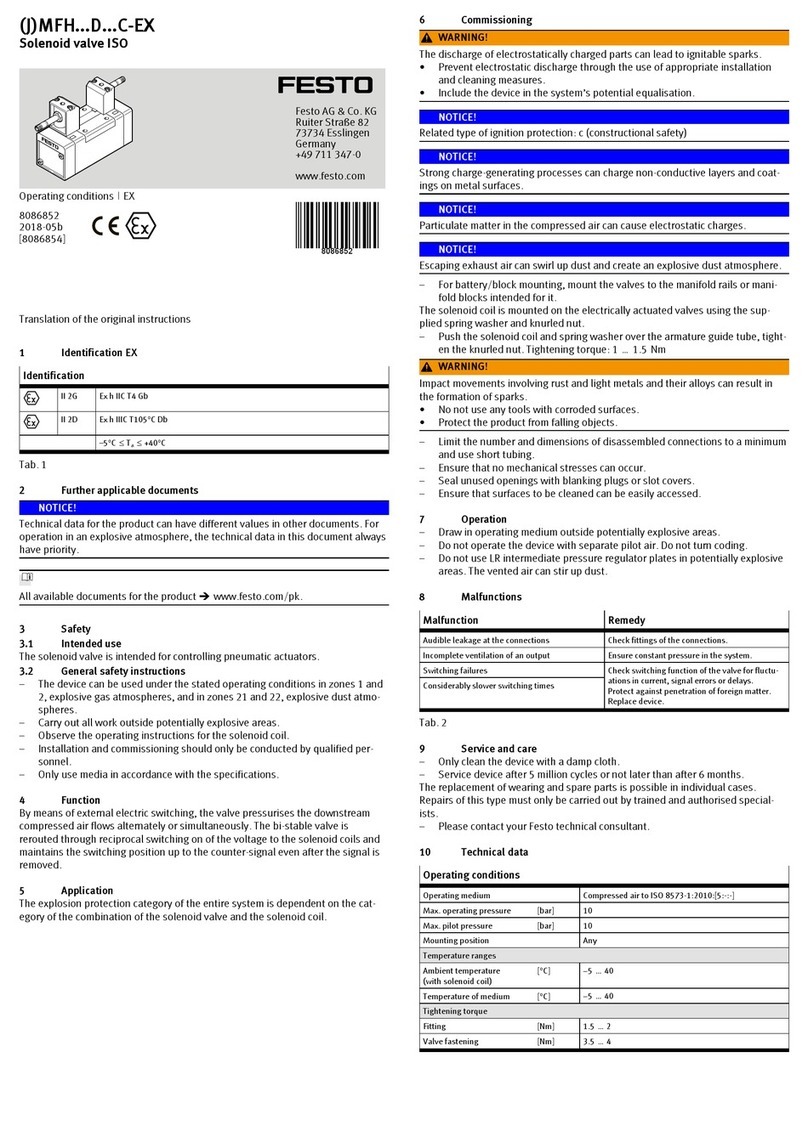

4.3 Electrical installation

For sensing the stop lever positions:

Use proximity switches with

longitudinal cable exit in accordance

with the our catalogue

(èwww.festo.com/catalogue).

Place the cylinder switches in the

slots 6of the intermediate-position

module.

Fig. 7

6

Fasten the cylinder switches in the end positions to be sensed.

Make sure here that there is a gap of minimum 10 mm from ferromagnetic parts.

5 Commissioning

Warning

Fingers can be pinched when the stop lever retracts.

Make sure that nobody can place his/her hand in the positioning range of the

stop lever and that there are no objects in its path.

Note

Malfunctioning can occur if excessive loads are applied to the stop lever.

Make sure that the following points are always observed:

– the stop lever must be retracted/advanced at the correct time

– briefly switch off pressure to the linear drive for retracting the stop lever or

pressurize on both sides.

Complete the commissioning, observing the notes in the operating instructions

as follows:

1. Push the slide of the linear drive by hand into the end position from which move

ment is to be made to the intermediate position.

2. Pressurize the linear drive such that the end position approached under point 1

is maintained.

3. Pressurize the port 3on the intermediate position module to extend the stop

lever. The stop lever extends.

4. Start a test run in accordance with the operating instructions for the linear drive

at low cycle rate and at low impact speed.

5. Accelerate the payload at the drive in steps until the later operating speed is

reached.

The slide of the linear drive must not strike hard against the intermediate-posi

tion module.

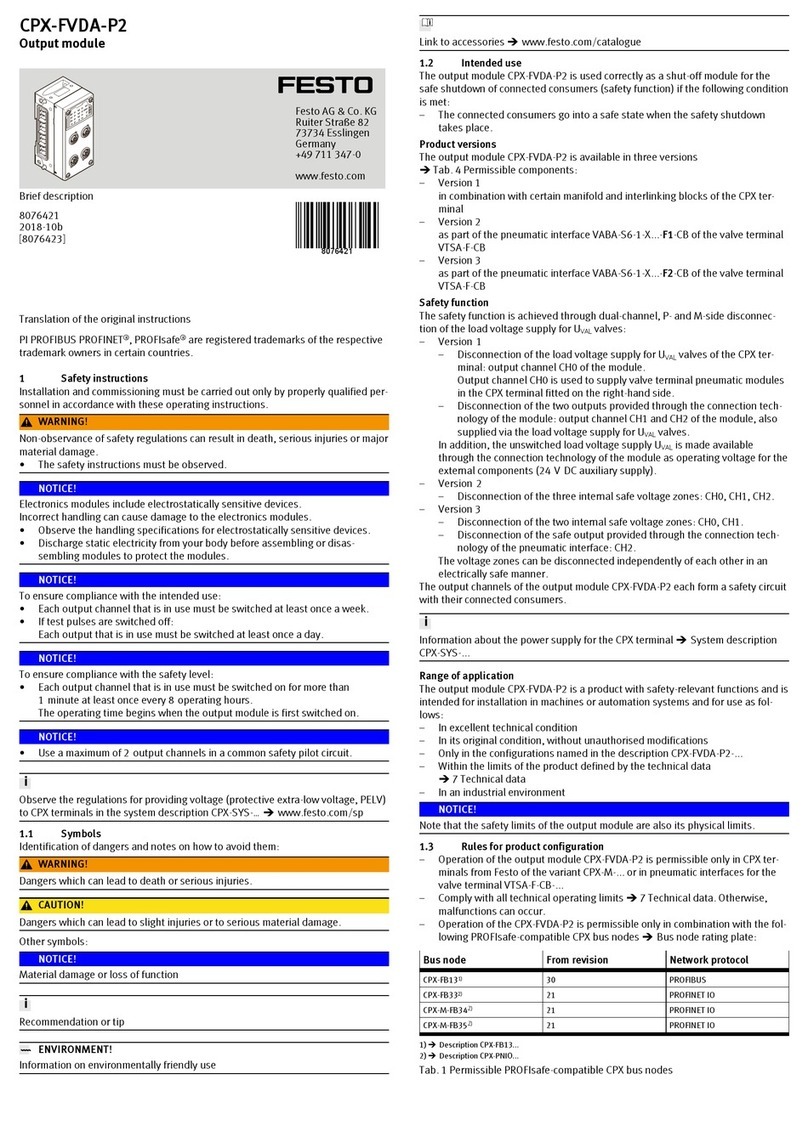

6. If required, adjust the intermediate position by screwing the cushioning com

ponent in or out at the shock absorber retainer DADP-ES-G6 9.

Maintain the unscrewing length X and the permissible tightening torque of the

lock nut (A) (èFig. 9).

7. Terminate the test run.

X(A)

Fig. 8

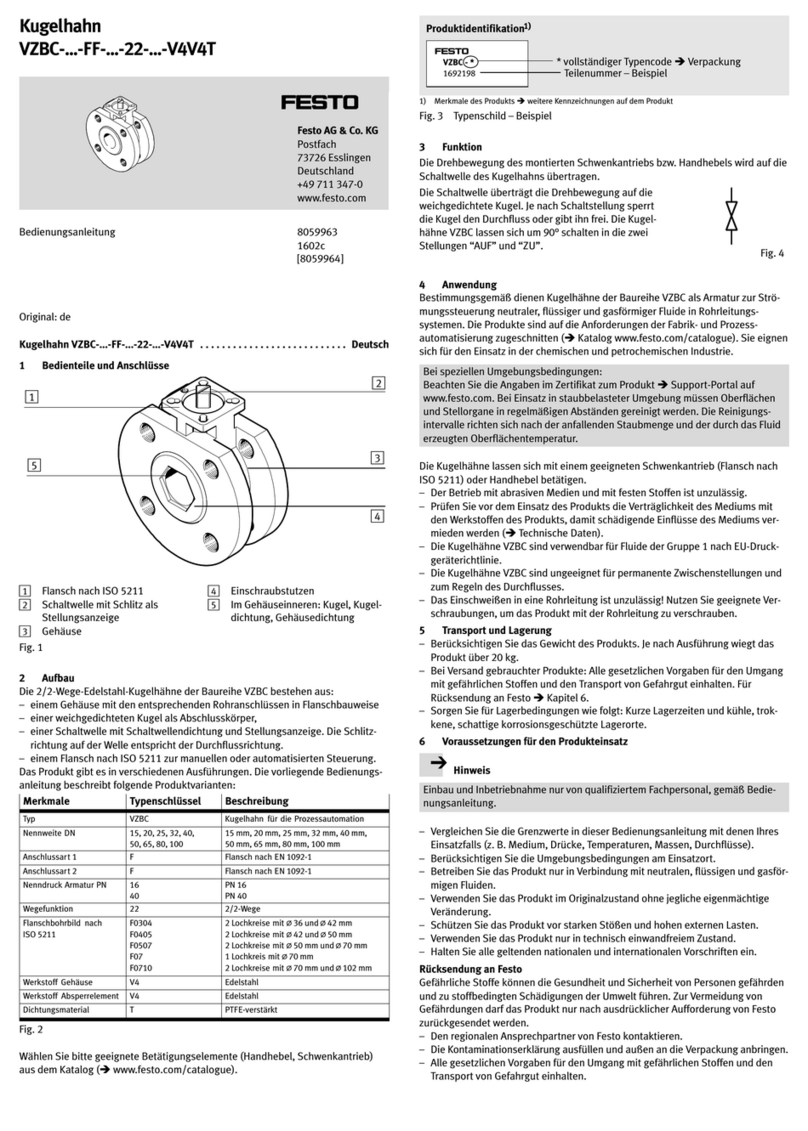

DADP-ES-G6-… 10 16 20 25

Unscrewing length X1)

– with DGSL-...-PA/P1A/Y3A [mm] 0 … 25.5 0 … 39.5 0 … 49.5 0 … 49

– with DGSL-...-EA [mm] 0 … 5.5

Tightening torque (A) [Nm] 3 5 8 20

1) Max. adjustable end-position range

Fig. 9

6 Accessories

Select the corresponding accessories from our catalogue

(èwww.festo.com/catalogue).

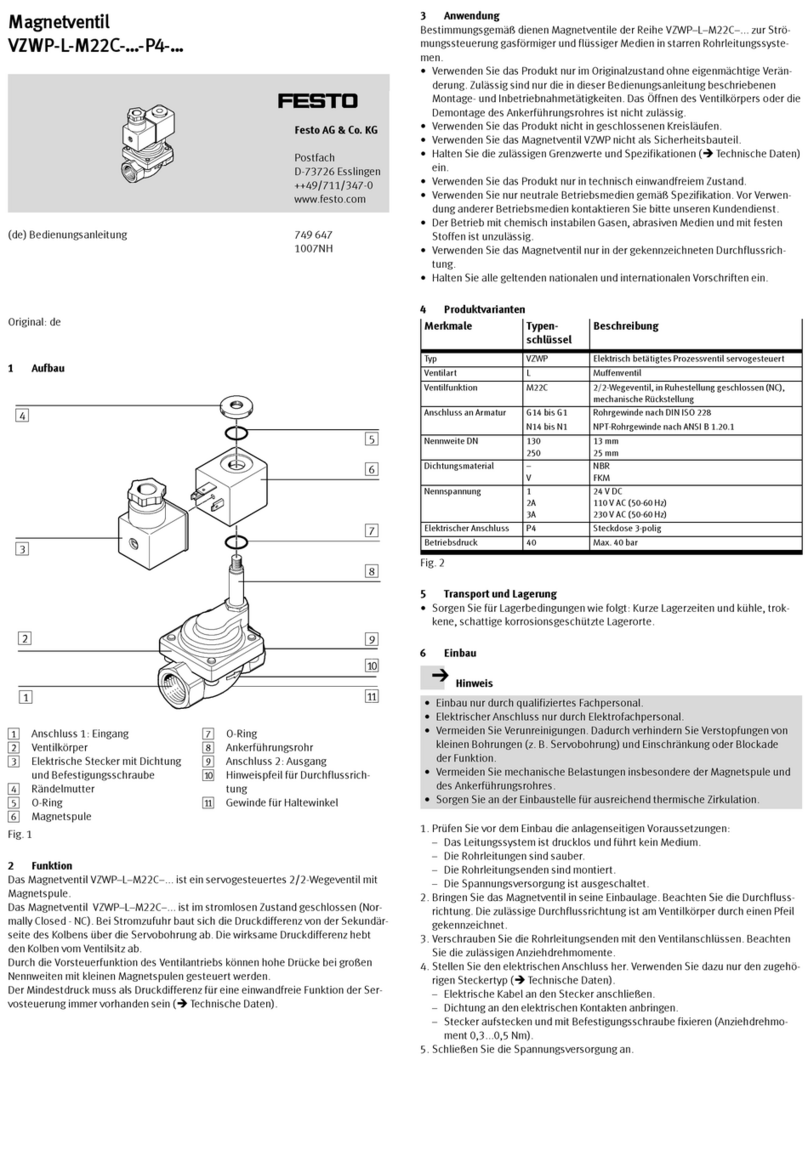

7 Fault clearance

Malfunction Possible cause Remedy

Drive knocks hard in the

intermediate position

Cushioning component defective Replace the cushioning element

Stop element overloaded Reduce the impact speed

Malfunctions in position

sensing

Position of cylinder switches

incorrect

Correct position of cylinder

switches

Incorrect cylinder switch type

used

Use only cylinder switches in

accordance with the catalogue

(èwww.festo.com/catalogue)

Cylinder switch defective Replace cylinder switch

Ferritic parts in the vicinity of

the cylinder switch

Use parts of non-magnetic

materials.

Maintain minimum distance

(è4.3 Electrical installation)

Stop lever does not

retract

Linear drive presses against the

stop lever

Briefly switch off pressure to the

linear drive for retracting the

stop lever or pressurize on both

sides (è5 Commissioning)

Fig. 10

8 Technical data

DADM-EP-G6-… 10 16

Function Double-acting pneumatic cylinder

Mounting position Any

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Operating pressure [bar] 3 … 6

Pneumatic connection M3 M5

Max. impact force [N] 500 1100

Max. impact speed [m/s] 0.8

Maximum swivel time [ms] 150

Max. frequency1) [Hz] 3

Repetition accuracy

with damper DY../P1 [mm] ±0.02

with damper P/E [mm] 0.3

Ambient temperature [°C] 0 … +60

Information on materials

Housing Anodised aluminum

Stop lever High-alloy stainless steel

Screws Galvanized steel

Seals NBR

Weight [kg] 0.17 0.37

1) The max. permissible frequency of the cushioning component used must not be exceeded. High

switching frequencies are not appropriate for continuous operation

Fig. 11