Sporlan OROA-5 Installation and maintenance instructions

Head Pressure Control Valves

OROA-5, ORI-6-65/225H, ORI-10-65/225-H, ORD-4

INSTALLATION INSTRUCTIONS

To ensure proper performance, head pressure control valves

must be selected and applied correctly. This is covered thor-

oughly in Bulletin 90-30. However, proper installation proce-

dures are equally important.

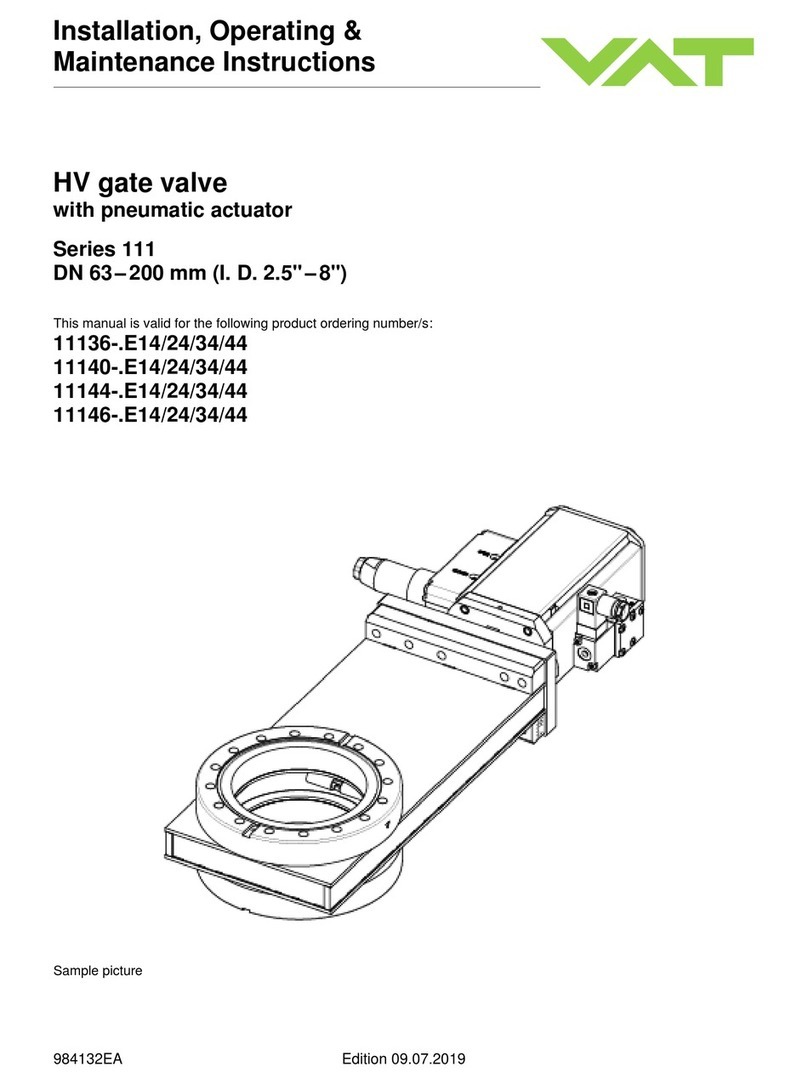

VALVE LOCATION/PIPING SUGGESTIONS — The

OROA, ORI and ORD valves can be installed in horizontal

or vertical lines – whichever best suits the application, and

permits easy accessibility of all valves. Consideration should

be given to locating these valves so they do not act as an oil

trap and so solder cannot run into the internal parts during

brazing. Precautions should also be taken to install the valves

with the flow in the proper direction.

The ORI valve CANNOT be installed in the discharge

line for any reason.

Figures 1 and 2 are piping schematics only to illustrate the

general location of the OROA, ORI, and ORD valves in

the system. Sporlan recommends that recognized piping

references be consulted for assistance in piping procedures.

Sporlan is not responsible for system design, or for misap-

plication of its products. If these valves are applied in any

manner other than described in this bulletin, the Sporlan

warranty is void.

In most cases, the valves are located at the condensing unit.

When the condenser is remote from the compressor, the usual

location is near the compressor. In all cases, it is important

that some precautions be taken in mounting the valves. It is

suggested that they be adequately supported to prevent exces-

sive stress on the connections. Discharge lines are a possible

source of vibrations and gas pulsations, which may result in

fatigue in tubing, fittings, and connections. The severity of

discharge gas pulses differs with each system. On some appli-

cations it may be necessary to dampen the pulses to protect

the ORD-4 internal parts. Pulsations are best handled by a

good muffler placed as close to the compressor as possible.

Vibrations from moving parts of the compressor are best

isolated by flexible loops or coils (discharge lines 1/2” or

smaller), or flexible metal hoses for larger lines.

For best results, the hoses should be installed as close to

the compressor shut-off valves as possible, and mounted

horizontal and parallel to the crankshaft or vertically upward.

The hoses should never be mounted horizontal and 90° from

the crankshaft. A rigid brace should be placed on the outlet

end of the hose to prevent vibrations beyond the hose.

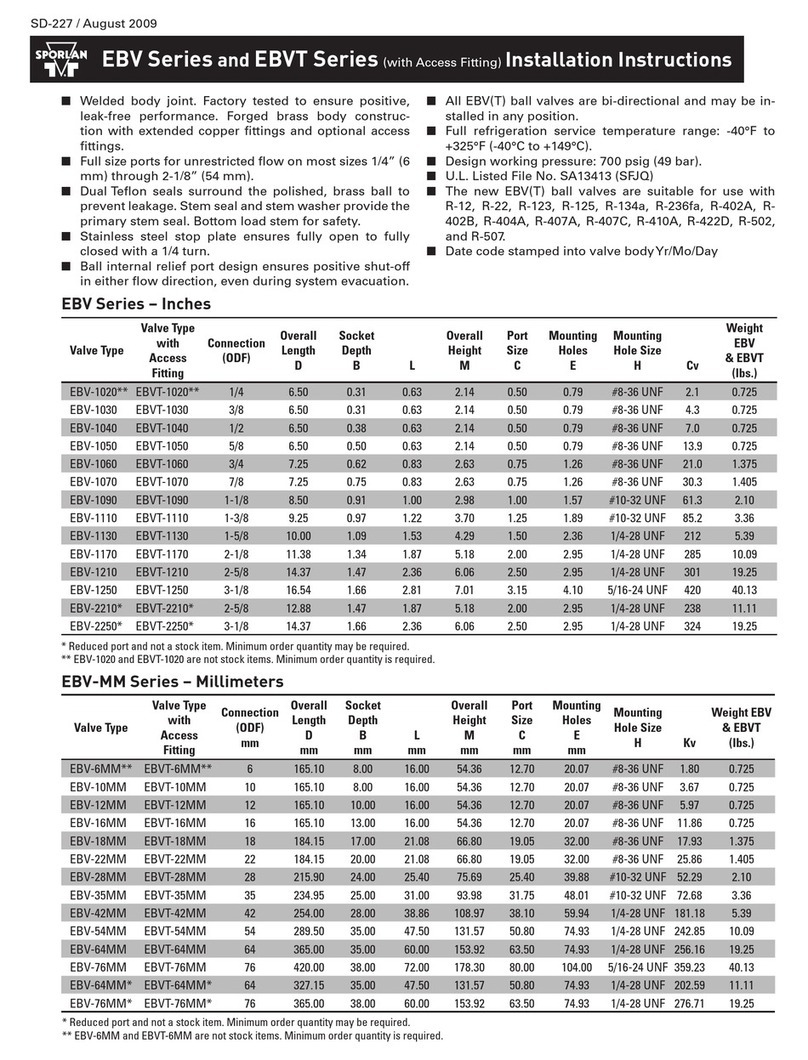

The inlet connections on the OROA-5, ORI-6 and ORI-10

valves should be sized the same as the outlet of the condenser

where possible. The ORD-4 is available with 5/8” ODF and

7/8” ODF solder connections. On systems with discharge

lines smaller than 5/8” OD, the bypass line can be the same

size as the discharge line and the ORD-4 connections can be

bushed down. If the system capacity is greater than any of

the head pressure control valves ratings, these valves can be

applied in parallel.

CAUTION: When the head pressure control valves are fac-

tory installed and capped for future hook-up in the field, any

holding charge in the condensing unit and valve assembly

should be bled off from all sides of the valves before remov-

ing the caps. This will prevent the caps from blowing off due

to any trapped refrigerant.

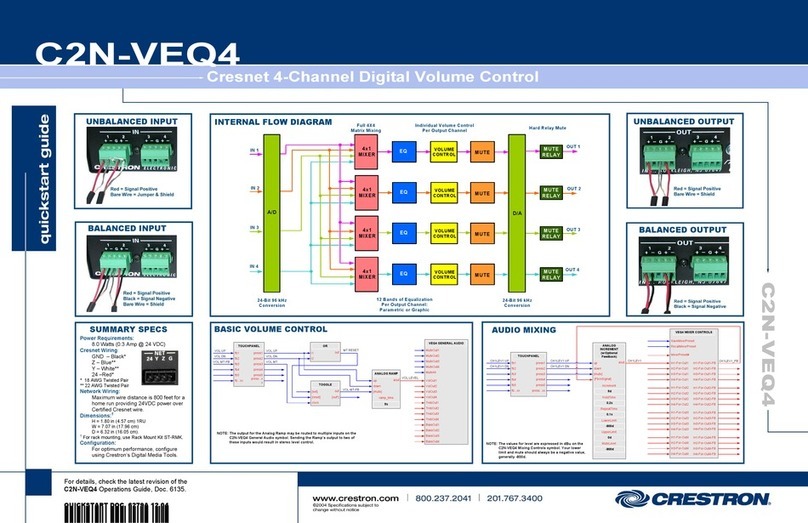

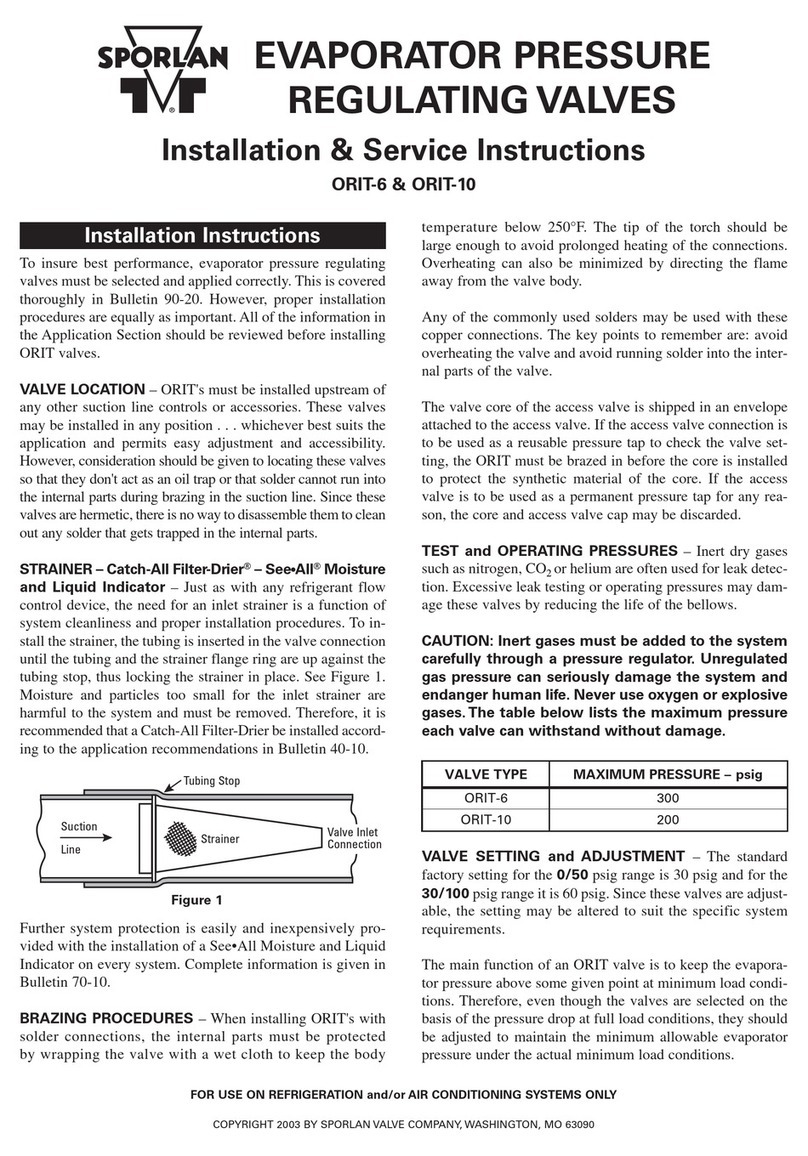

VALVE STRAINERS – Catch-All®filter-driers –

See·All®moisture and liquid indicator — Just as with

any refrigerant flow control device, the need for an inlet

strainer is a function of system cleanliness and proper instal-

lation procedures. When the strainer is used with the ORI,

the tubing is inserted in the valve connection until the tubing

and strainer flange ring are up against the tubing stop, thus

locking the strainer in place. See Figure 3. In order for the

strainer to seat properly against the tubing stop of the OROA

condenser connection, the strainer is inserted into the tubing.

The tubing is then inserted into the valve connection, thus

locking the strainer in place. See Figure 4.

© Copyright 2016 by Sporlan Division, Parker Hannifin, Washington, MO

FOR USE ON REFRIGERATION and/or AIR CONDITIONING SYSTEMS ONLY

Tubing Stop

Strainer Valve Connection ORI

Tubing Stop

Tubing

Tubing

Strainer

Valve Connection OROA

Condenser

Compressor

Receiver

ORD-4

ORI

Condenser

Compressor

Receiver

OROA

Figure 1

Figure 2 Figure 3

Figure 4

INSTALLATION & SERVICE INSTRUCTIONS

SD-68-52016

Page 2

Moisture and particles too small for the inlet strainer are harm-

ful to the system and must also be removed. Therefore, for

complete system protection, it is recommended that a Catch-

All Filter-Drier be installed in the liquid line according to the

application recommendations given in Bulletin 40-10.

Moisture detection is easily and inexpensively provided with

the installation of a See·All moisture and liquid indicator.

Complete information is given in Bulletin 70-10. Furthermore,

a See·All moisture and liquid indicator at the receiver is

necessary to charge the system properly.

BRAZING PROCEDURES — Any of the commonly used

brazing alloys for high side usage are satisfactory. However,

when soldering or brazing, it is very important that the

internal parts be protected by wrapping the valve with a

WET cloth to keep the body temperature below 250°F for

the OROA and ORI; and, 300°F for the ORD-4. Also, when

using high temperature solders, the torch tip should be large

enough to avoid prolonged heating of the copper connections.

And, always direct the flame away from the valve body.

TEST and OPERATING PRESSURES — Excessive leak

testing or operating pressures may damage these valves and

reduce the life of the operating members. For leak detection,

an inert dry gas, such as nitrogen or CO2, may be added to an

idle system to supplement the refrigerant pressure.

CAUTION: Inert gases must be added to the system

carefully through a pressure regulator. Unregulated

gas pressure can seriously damage the system and

endanger human life. Never use oxygen or explosive

gases.

The table below lists the maximum values each valve can

withstand without damage. Precautions must be taken to keep

test or operating pressures below these values.

VALVE SETTINGS and ADJUSTMENT — A complete

discussion on pressure settings is given in the Application

Section of Bulletin 90-30. To determine the proper setting for

a specific system, that section should be reviewed.

Table 1 lists the setting data for the OROA, ORI and ORD

valves. Other ORI settings can be obtained by adjusting the

valves a proportionate amount between those values shown.

The ORD-4-20 setting means that the ORD-4 will start to

open when the pressure difference between the discharge

line and the receiver is 20 psig. This setting is suitable for

all systems where the combined pressure drop through the

condenser, the ORI and connecting piping is less than 14

psi. Therefore, if the ORI is selected for 2 psi ∆P, then the

maximum allowable pressure drop through the condenser is

12 psi. Normally, condenser pressure drop on refrigeration

systems is less than 10 psi. However, many condensers on

air-conditioning systems may have pressure drops up to 25

psi. Therefore, when in doubt, consult with the equipment

manufacturer or, if possible, measure it by reading the dis-

charge pressure at the compressor and the receiver pressure

during full load operation. That is, this reading should be

taken with a normal condensing temperature at full load. For

systems where the condenser pressure drop is higher than

normal, OROA and ORD valves with higher settings are

available upon special request. See Table 4, page 4.

To adjust the ORI valve, remove the cap and turn the adjust-

ment screw with the proper size hex wrench (1/4” for ORI-6

and 5/16” for ORI-10). A clockwise rotation increases the

valve setting while a counter-clockwise rotation decreases

the setting. To obtain the desired setting, a pressure gauge

should be utilized at the compressor discharge service valve

so the effects of any adjustment can be observed. Small

adjustments are recommended to allow the system adequate

time to settle out after each adjustment.

NOTE: Even though the ORI valve is selected on the basis

of the full load conditions or summer operation, it should be

adjusted to maintain the desired condensing pressure when-

ever the ambient is below 70°F.

REFRIGERANT CHARGE AND CHARGING

PROCEDURES — When this method of head pressure con-

trol is utilized on a system, there must be enough refrigerant

to flood the condenser at the lowest expected ambient and

still have enough charge in the system for proper operation.

A shortage of refrigerant will cause hot gas to enter the liquid

line and the expansion valve, and refrigeration will cease.

Secondly, the receiver must have sufficient capacity to hold

at least all of the excess liquid refrigerant in the system, since

it will be returned to the receiver when high ambient condi-

tions prevail. If the receiver is too small, liquid refrigerant

will be held back in the condenser during the high ambient

conditions and excessively high discharge pressures will be

experienced.

CAUTION: All receivers must utilize a pressure relief device

according to the applicable standards or codes (e.g. ARI

Standard 495).

The charging instructions described on page 3 use average val-

ues. The exact charge required will vary with unit design and

piping. These instructions are intended to provide assistance to

the service technician where specific charging instructions for

the condensing units involved are not available.

Charging Procedure:

1. Before starting the system, charge approximately 2-1/2

lbs. per ton of liquid refrigerant into the receiver or

enough refrigerant to provide a liquid seal in the receiver.

2. Put refrigerant vapor into the suction side to break the

vacuum.

3. Start the system and charge to a clear See·All moisture

and liquid indicator.

Table 1

Valve Type Maximum Rated

Pressure - psig

OROA 450

ORI-6-65/225-H 450

ORI-10-65/225-H 450

ORD-4 680

Valve

Type

Standard Factory

Setting for

Refrigerants

12 & 134a

Setting For Refrigerants

22, 404A & 507

Pressure

Setting

psig

Depth of

adjusting

nut from

top of

Spring

Housing

Pressure

Setting

psig

Depth of

adjusting

nut from

top of

Spring

Housing

Turns IN

from

Refrigerant

12 Setting

OROA 100 - 180 - -

ORI-6 120 1/4” 200 1/2” 3

ORI-10 120 3/8” 200 3/4” 5

ORD-4-20 20 - 20 - -

CAUTION: Bubbles in the See·All don’t necessar-

ily indicate a shortage of charge, especially when it is

located downstream of other liquid line components

and/or remotely from the receiver. When satisfied with a

clear See·All (or that any bubbles are caused by reasons

other than a shortage of charge), the system is correctly

charged for the charging ambient.

4. The extra winter charge (as calculated below) is now

weighed into the receiver.

To determine the extra charge required, calculate the total

length of tubing in the condenser including the equivalent

length for return bends. See Table 2. Then multiply the total

length in feet by the number of pounds per foot for the proper

refrigerant and condenser tube size from Table 2.

Example: R-12 system with 1170 equivalent feet of 1/2 inch

tubing in the condenser.

1170 x .110 = 130 pounds

The amount of refrigerant calculated using Table 2 must

be corrected since the condenser might be already partially

flooded especially if charging is being done at low ambients.

Table 3 provides information on percentage of condenser to

be flooded at various ambients for high, medium and low

suction condensing units. To determine the extra charge,

determine the difference in percentage between the charg-

ing ambient and the minimum winter ambient and multiply

the figure by the pounds of refrigerant calculated before.

Example: High Suction Condensing Unit, 40°F evaporating

temperature

-20°F Minimum Winter Ambient .79

50°F Charging Ambient –.40

.39

130 x .39 = 51 lbs. of extra charge

These calculations do not take into account cylinder unload-

ing. Additional charge will be required. For more complete

charging recommendations, see Sporlan Bulletin 90-30-1.

There are several possible causes for system malfunction

with “refrigerant side” head pressure control and these may

be difficult to isolate from each other. As with any form of

system trouble-shooting, it is necessary to know the existing

operating temperatures and pressures before system problems

can be determined. Once the actual malfunction is estab-

lished, it is easier to pinpoint the cause and then take suitable

corrective action. The following chart lists the most common

malfunctions, the possible causes, and the remedies. Since

the OROA, ORI and ORD are hermetic valves and cannot be

disassembled for inspection and/or replacement of parts, they

must be replaced if they become inoperative.

SERVICE INSTRUCTIONS

Table 3

Table 2

Page 3

Tubing Size

and Thickness

Inches

Equivalent

Length for

Each

Return

Bend-Feet

Refrigerant per Foot of Tubing

Pounds @ -20°F

Refrigerant

12 22 502

3/8 .016 .20 .060 .055 .057

1/2 .017 .25 .110 .102 .106

5/8 .018 .30 .175 .163 .169

Condenser

Ambient

Temperature

°F

Percentage of Condenser to be Flooded

Low Suction Condensing Units Medium Suction Condensing Units High Suction Condensing Units

Evaporating Temperature - °F

-35 -25 -15 -5 0 10 20 30 35 40 45 50

80 27 15 0 0 0 0 0 0 0 0 0 0

70 62 49 35 15 40 24 0 0 0 0 0 0

60 76 65 56 45 60 47 33 17 26 20 10 4

50 83 75 68 60 70 60 50 38 45 40 33 28

40 86 80 74 68 76 68 60 50 56 52 46 42

30 88 84 79 74 80 73 66 59 64 60 55 51

20 90 86 82 78 83 77 72 65 69 66 62 59

0 92 89 86 82 87 83 78 73 76 73 70 68

-20 94 91 88 86 91 87 82 77 80 79 76 73

-40 97 94 92 90 94 89 84 79 83 81 79 77

Malfunction - Low Head Pressure

Possible Cause Remedy

1. Insufficient Refrigerant charge to adequately flood condenser. Add charge.

2. Low pressure setting on ORI. Increase setting.

3. ORI fails to close due to foreign material in valve. Turn Adjustment out so material passes though valve.

If unsuccessful, replace ORI.

4. ORI fails to adjust properly. See 3 above.

Page 4

INSTALLATION PRECAUTIONS

1. See page 2 for safe working pressures.

2. Do not overcharge — see charge and charging

procedures on pages 2 and 3.

3. Be sure that the piping does not allow liquid

refrigerant to be trapped in sections where

hydrostatic pressure can develop.

4. Be sure that the receiver is large enough to hold

the entire charge during “warm” operation.

5. Do not overheat — see brazing procedures on

page 2.

6. “Caution:” on page 1, right column.

7. “Caution:” on page 2, left and right column.

8. “Caution:” on page 3, left column. Bold type indicates pressure range.

*Available on special order ONLY.

WARNING: Serious injury could result from an explosion caused by the rapid expansion of trapped

liquid refrigerant subjected to high temperature. ALWAYS OPEN OR VENT THE SYSTEM BEFORE

APPLYING HEAT TO REMOVE SYSTEM COMPONENTS. Break the element charging cap tube on

valve dome by hand or with a clean cut tool. DO NOT use side cutters, which may seal the opening.

Table 4

SD-68-52016© 2016 Parker Hannifin Corporation

Malfunction - Low Head Pressure (Continued)

Possible Cause Remedy

5. Wrong setting on OROA (e.g. 100 psig on Refrigerant 22

or 404A system).

Replace OROA with valve at correct setting.

6. OROA fails to close due to:

a. Foreign material in valve.

b. Loss of air charge in element.

See below:

a. Cause OROA to open by raising condensing/receiver

pressure above valve setting by cycling condenser fan. If

foreign material does not pass through valve, replace OROA.

b. Replace OROA.

7. ORD fails to open due to:

a. Less than 20 psi pressure drop across ORD.

b. Internal parts damaged by overheating when installed.

See below:

a. Check ORI causes/remedies on page: 2, 3, or 4.

b. Replace ORD

Malfunction - High Head Pressure

Possible Cause Remedy

1. Dirty condenser coil. Clean coil.

2. Air on condenser blocked off. Clear area around unit.

3. Too much refrigerant charge. Remove charge until proper head pressure is maintained.

4. Undersized receiver. Check receiver capacity against refrigerant required to maintain desired

head pressure.

5. Non-condensibles (air) in system. Purge from system.

6. High pressure setting on ORI. Decrease setting.

7. ORI or OROA restricted due to inlet strainer being plugged. Open inlet connection to clean strainer.

8. ORI fails to adjust properly or to open due to foreign material in valve. Turn adjustment out so material passes through valve.

If unsuccessful, replace ORI.

9. Wrong setting on OROA (e.g., 180 psig on Refrgerant 12 system). Replace OROA with valve at correct setting.

10. Bypassing hot gas when not required due to:

a. If ORI, ORD are used and internal parts of ORD are damaged by

overheating when installed.

b. If OROA is used and internal parts are damaged by overheating when

installed.

c. If ORI uses a pressure drop across condenser, associated piping and

ORI exceeds 14 psi under full load conditions.

d. If OROA used and pressure drop across condenser, associated piping

and OROA exceeds 14 psi under full load condition.

See below:

a. Replace ORD.

b. Replace OROA.

c. Reduce pressure drop in piping by using larger ORI or ORI larger valves in

parallel or use ORD with higher setting.

d. Reduce pressure drop by using 2 - OROA in parallel or substitute OROA

with higher ORD setting. See table below.

Maximum Pressure Drop

Between Compressor

and Receiver - psi

Head Pressure

Component Selection

Below 14 OROA-5-100 or -180

ORD-4-20 & ORI

15 - 19 *OROAB-5-100 or -180

*ORD-4-25 & ORI

20 - 24 *OROAC-5-100 or -180

*ORD-4-30 & ORI

25 - 29 *OROAD-5-100 or -180

*ORD-4-35 & ORI

This manual suits for next models

3

Other Sporlan Control Unit manuals

Sporlan

Sporlan ORIT-12 Installation and maintenance instructions

Sporlan

Sporlan EBV Series User manual

Sporlan

Sporlan ORIT-10 Installation and maintenance instructions

Sporlan

Sporlan ESX User manual

Sporlan

Sporlan SDR-4 Quick guide

Sporlan

Sporlan B5D User guide

Sporlan

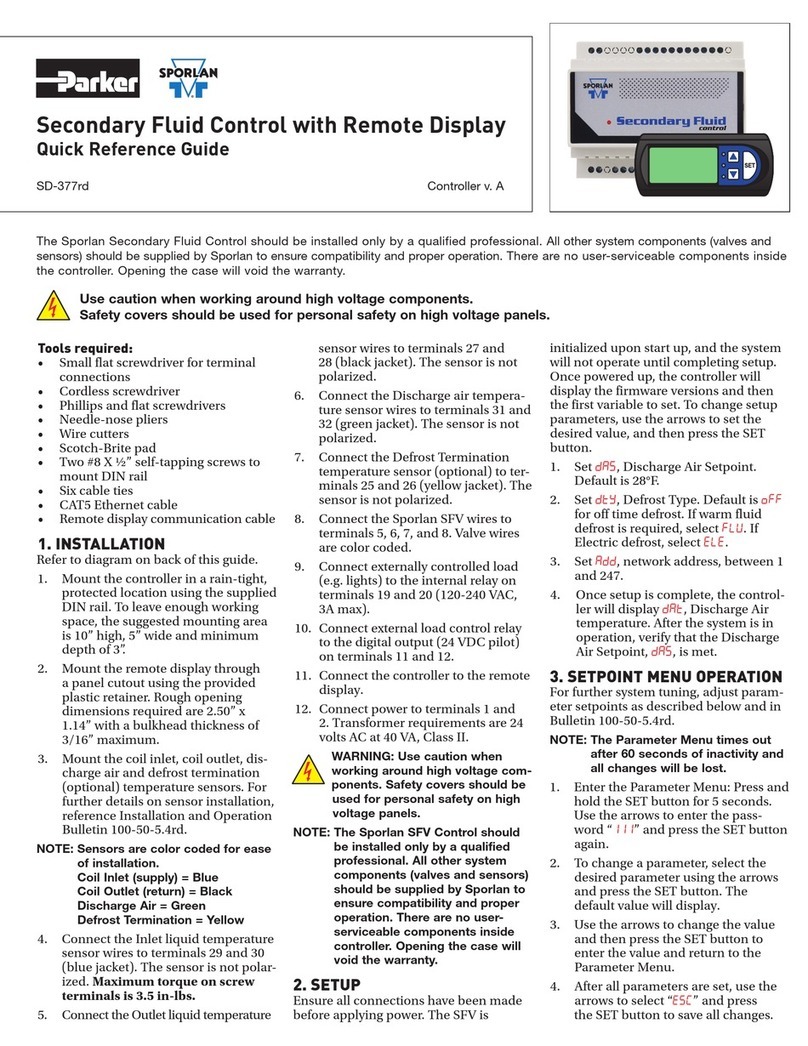

Sporlan Secondary Fluid Control User manual

Sporlan

Sporlan Parker S3C User guide