CSiSC PSiSC HD-58124 User manual

HD-58124

Toilet Partition Installation

Manual

PHONE: 803-252-3020

FAX: 803-256-7769

www.psisc.com

803-252-3020

2

ATTENTION

DO NOT MIX

FASTENER PACKS

EACH FASTENER PACK HAS THE NECESSARY

BOLTS, BARRELS AND SCREWS TO INSTALL

THE RESPECTIVE PANEL, PILASTER OR DOOR.

TORX HEAD BITS ARE PACKED IN THE EXTRA

FASTENER PACKS.

www.psisc.com

803-252-3020

3

TABLE OF CONTENTS

STEP PAGE

1 TOOLS REQUIRED................................... 4

2 GETTING STARTED ................................. 5

3 MARK THE PARTITION LAYOUT............. 6

4INSTALL THE PANELS............................. 8

5INSTALL THE WALL PILASTER

5A USING ‘Z’ BAR ANCHORING SYSTEM .......... 10

5B USING STANDARD LEVELING DEVICE......... 12

6INSTALL THE PILASTERS ..................... 14

7 INSTALL THE HEADRAIL ....................... 17

8 ATTACH THE DOORS ............................ 18

9 ATTACH THE DOOR HARDWARE ........ 20

10 ADJUSTABLE ALUMINUM PILASTERS. 22

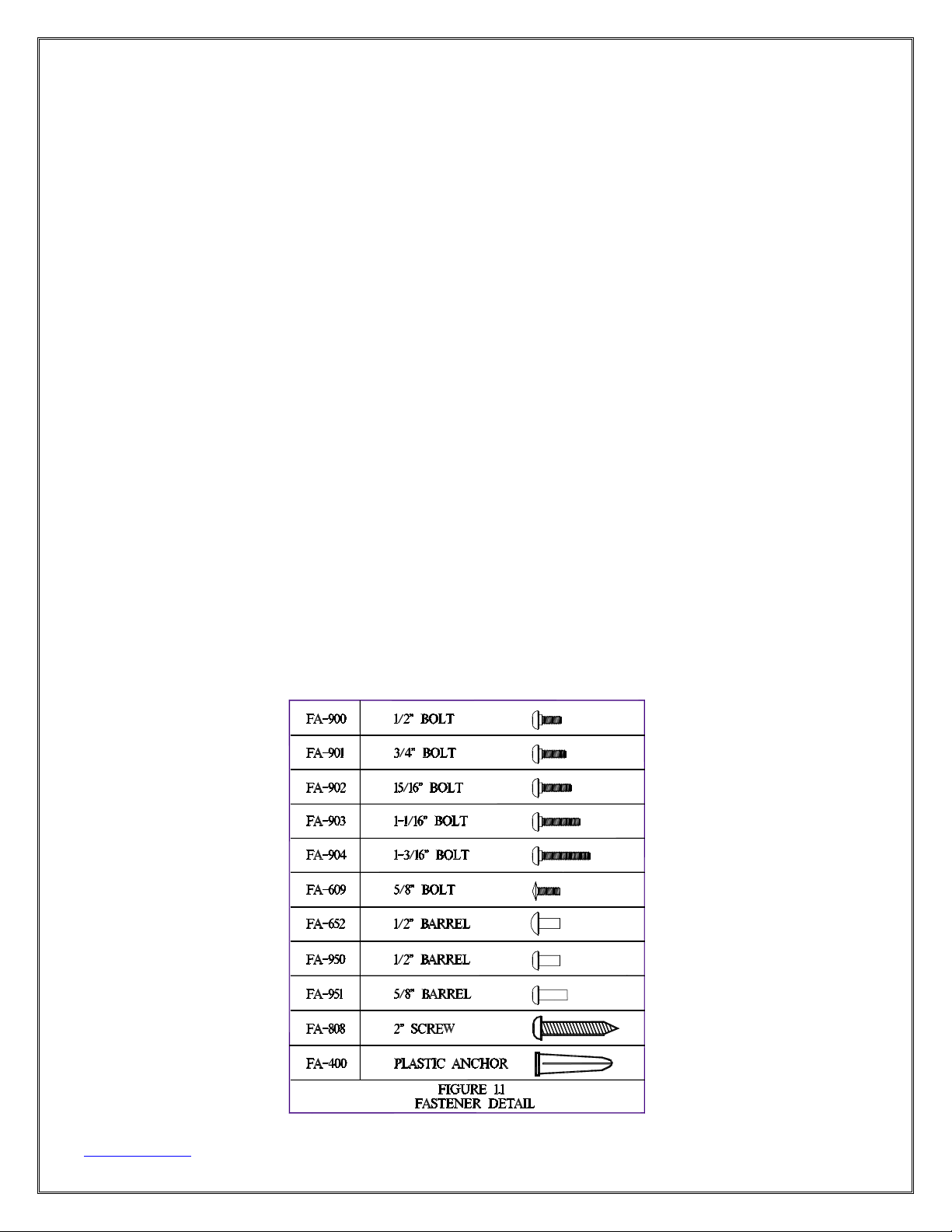

11 BOLT AND BARREL SIZES .................... 23

www.psisc.com

803-252-3020

4

1 TOOLS REQUIRED

xTAPE MEASURE

x4 FOOT LEVEL

xRATCHET TYPE BIT DRIVER (torx head bits supplied)

xFLAT HEAD SCREWDRIVER

xPHILLIPS HEAD SCREWDRIVER

x1 WAY SCREWDRIVER

xTWO 9/16" OPEN END WRENCHES

xHAMMER

xTWO 12" BLOCKS

xDRILL

xROTARY HAMMER DRILL

xHACKSAW

x5/16" CARBIDE TIPPED HAMMER DRILL BIT

x5/8" CARBIDE TIPPED HAMMER DRILL BIT

x1/4" HIGH SPEED STEEL DRILL BITS

xCHALK BOX

www.psisc.com

803-252-3020

5

2 GETTING STARTED

2.1 Find the packing list in the box marked “Packing List”

2.2 Check delivered materials and make sure no parts are

damaged or missing.

2.3 Check dimensions in each bathroom against the shop

drawings marked “For Field Use”. Make notes of

differences.

2.4 Clear bathrooms to provide workroom.

Thank you for choosing partitions from Partition Systems Inc. of South

Carolina. We appreciate your business. At Partition Systems, we strive to

provide the industry’s best partitions with comprehensive installation

guides.

If you need assistance, have questions or comments; contact our customer

service department at:

Customer Service

Partition Systems Inc. of South Carolina

PO Box 181, Columbia, SC 29202

(803) 252-3020, Fax: (803) 252-6030

Partition Systems International of South Carolina

825 Garland St.

Columbia, SC 29201

www.psisc.com

803-252-3020

6

3 MARK THE PARTITION LAYOUT

3.1 Establish and mark the center of the panels across the

back wall according to shop drawings. For end-panels and

alcove-panels mark the outer edge. (See fig.3.1)

3.2 Establish and mark the panel-brackets on the back wall

18” and 64” from the finished floor.

3.3 Establish and mark the wall-pilaster location on the side

wall according to shop drawings. (See fig.3.1)

3.4 Establish and mark the pilaster-brackets on the side wall

18” and 64” from the finished floor.

3.5 Establish and mark the outer edges of each pilaster from

the back and side walls according to shop drawings. (See

fig.3.1)

3.6 Mark and drill holes for the floor fasteners.

3.6.1 For leveling devices mark 5/8” in from the end of the

pilaster(s), centered from front to back. Drill a 2” deep hole

in the floor with a 5/8" bit.

3.6.2 For shoe/heel place the shoe on the floor centered between

the outer edges of the pilaster Using the shoe as a template,

mark the holes. Drill a 2” deep hole in the floor with a 5/16"

bit. (See fig.5-B.1)

3.7 Mark wall bracket mounting holes using the brackets as a

template. Center and level the brackets before marking

(See fig.3.1). For end-panels and alcove-panels use the

outer edge.

3.8 Drill 5/16" holes for wall brackets.

3.9 Insert plastic anchors (FA-400) into holes.

3.10 Secure wall and pilaster brackets with 2” stainless steel

screws (FA-808).(See fig.3.2)

www.psisc.com

803-252-3020

7

www.psisc.com

803-252-3020

8

4 INSTALL THE PANELS

4.1 Place a 12" high support in position to hold up the panels.

(see fig. 4.1)

4.2 Set the panel on the support and slide the panel into the

wall brackets until the bottom is ½” from the wall.

4.3 Drill the bottom bracket hole through the panel with a ¼”

drill bit and secure with a ½" bolt (FA-900) and a ½" barrel

(FA-950).

4.4 Level the top of panel.

4.5 Drill the top bracket hole with a ¼” drill bit and secure with

a ½" bolt (FA-900) and a ½" barrel (FA-950).

4.6 Repeat steps 4.1 through 4.5 for each panel.

www.psisc.com

803-252-3020

9

www.psisc.com

803-252-3020

10

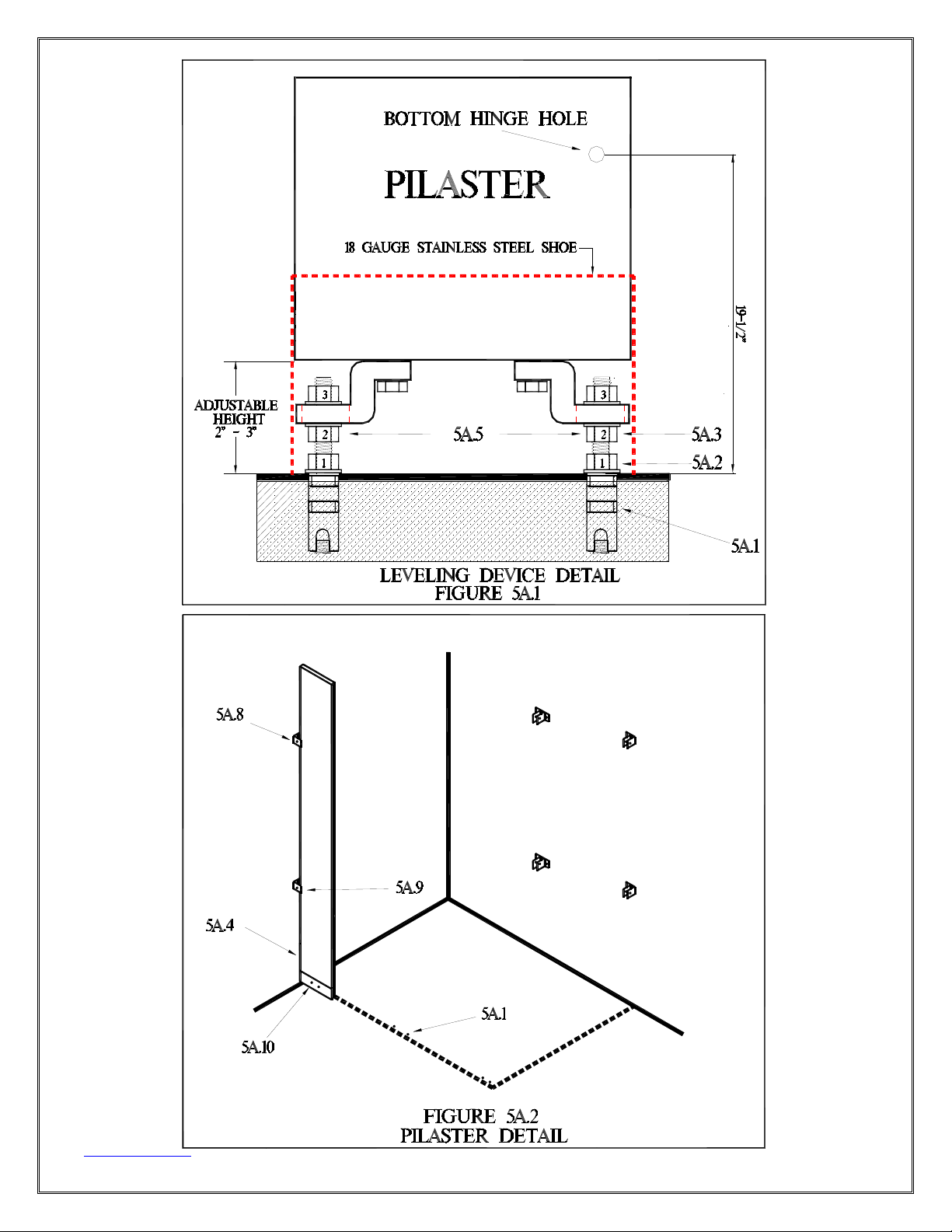

5 INSTALL THE WALL PILASTER

5A USING ‘Z’ BAR ANCHORING SYSTEM

5A.1 Place a lead anchor into the floor holes from step 3.6.

5A.2 Screw a 3/8" x 3½” threaded rod into the lead anchor. Place a

3/8" flat washer and 3/8" nut onto the rod and tighten with a 9/16"

wrench to secure the lead anchor.

5A.3 Place a second 3/8" nut and 3/8” flat washer onto the threaded

rod. Move the nut half way down the rod. (See figure 5A.1)

5A.4 Place the wall-pilaster onto the threaded rod and slide it into the

wall mounted pilaster-brackets.

5A.5 Adjust the 3/8" nut to raise (lower) the pilaster until the bottom

hinge hole is 19½” off the finished floor. (See figure 5A.1)

5A.6 Place the pilaster shoe onto the pilaster and place the pilaster

onto the threaded rod. Place a third washer and nut onto the

threaded rod.

5A.7 Set the bottom gap between the wall and the pilaster according

to the shop drawings. Tighten the top nut to secure the pilaster.

5A.8 Level the pilaster. Drill the top pilaster bracket hole with a ¼”

drill bit. Secure with a ½” bolt (FA-900) and a 5/8" barrel (FA-951).

5A.9 Drill the bottom bracket hole. Secure with bolt and barrel.

5A.10 Drill through the shoe and pilaster. Secure with a ½” bolt (FA-

900) and a 5/8" barrel (FA-951).

www.psisc.com

803-252-3020

11

www.psisc.com

803-252-3020

12

5 INSTALL THE WALL PILASTER

5B USING STANDARD LEVELING DEVICE

5B.1 Mount the shoe/heel to the floor with 2” stainless steel

screws (FA-808).

5B.2 Place the pilaster into the shoe/heel and slide the wall-

pilaster into the wall brackets.

5B.3 Using the Leveling Bolt in the bottom of the pilaster raise

(lower) the pilaster to where the bottom hinge hole is 19½”

off the finished floor. (See figure 5B.2)

5B.4 Place the pilaster into the shoe/heel. Slide the pilaster into

the wall brackets. (See figure 5B.1)

5B.5 Set the bottom gap between the wall and the pilaster

according to shop drawings.

5B.6 Drill the bottom bracket hole through the pilaster with a ¼”

drill bit. Secure with a ½” bolt (FA-900) and a 5/8" barrel.

(FA-951)

5B.7 Check level and drill the top hole through the pilaster with a

¼” drill bit. Secure with a ½” bolt (FA-900) and a 5/8" barrel.

(FA-951)

5B.8 Drill ¼” hole(s) through the shoe, heel and pilaster. Secure

the shoe with ½" bolts (FA-900) and 5/8" barrels. (FA-951)

www.psisc.com

803-252-3020

13

www.psisc.com

803-252-3020

14

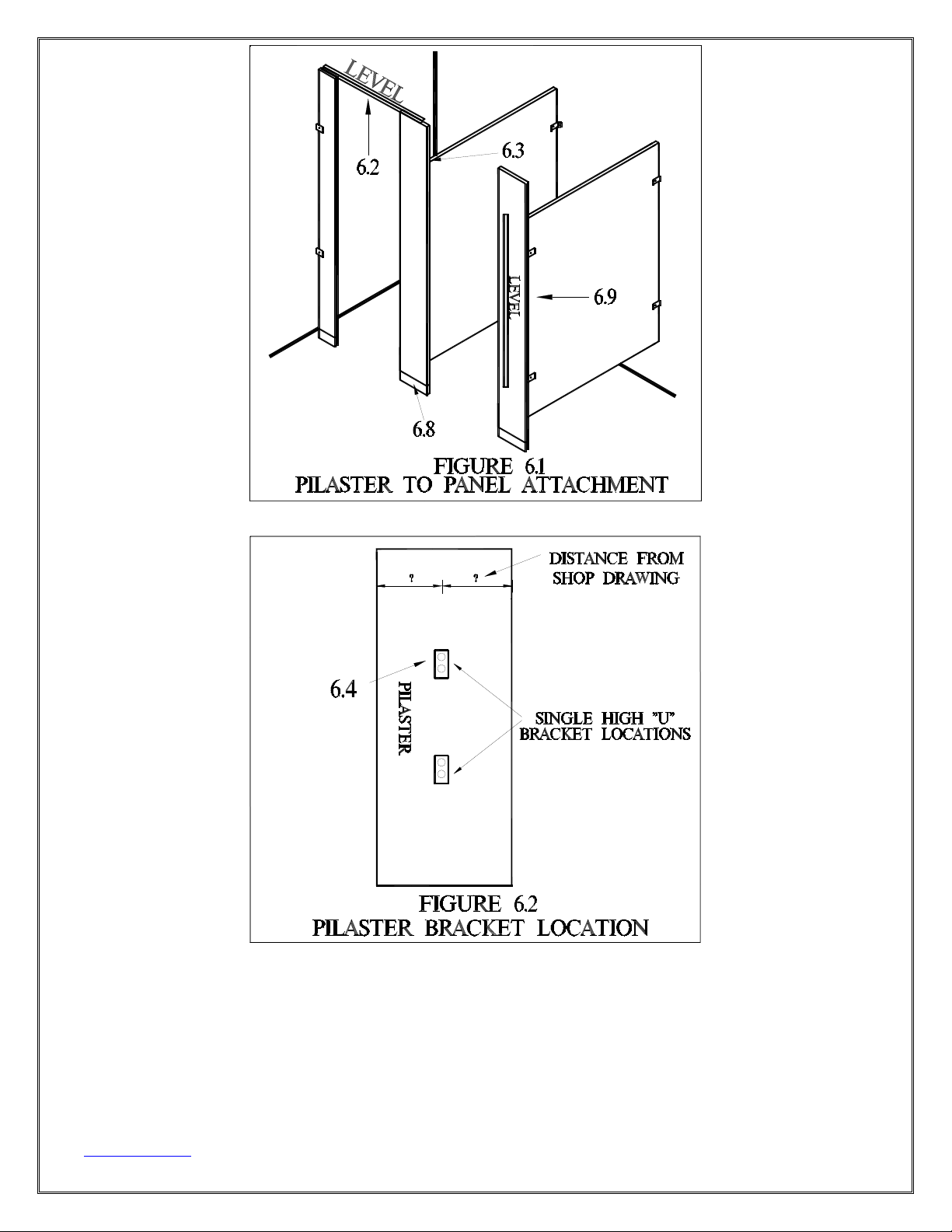

6 INSTALL THE PILASTERS

6.1 Prepare the pilaster floor fasteners. For leveling device follow

steps 5A.1 through 5A.3. For shoe & heel follow step 5B.1.

6.2 Place the pilaster onto the leveling device (or heel) and level the

top of the pilaster with the pilaster at the wall.

6.3 On the back of the pilaster mark the center of the panel

according to shop drawings. (See fig 6.2)

6.4 Mark the pilaster where the brackets will be located at 18” and

64” off the floor for shoe/heel, 17” and 63” for leveling device.

6.5 Place the pilaster-to-panel brackets onto the pilaster where the

marks are made. Mark the mounting holes. (see fig 6.2)

6.6 Drill ¼” holes through the pilaster and secure the pilaster-to-

panel brackets with ½" bolts (FA-900) and 5/8" barrels (FA-951).

6.7 Place the shoe onto the pilaster and place the pilaster onto the

leveling device (or shoe/heel). Slide the panel into the bracket.

6.8 Secure the pilaster.

6.8.1 For ‘Z” bar anchoring system, place a 3/8" washer and nut onto the

threaded rods and tighten to secure the pilaster.

6.8.2 For standard leveling device drill level top of pilaster with pilaster at

wall, drill a ¼” hole through the shoe and the pilaster. Secure with ½"

bolts (FA-900) and 5/8" barrels (FA-951).

6.9 Level the pilaster front and drill through the top panel bracket

hole. Secure the panel with a ½" bolt (FA-900) and ½" barrel. (FA-

950). Drill and secure the remaining panel bracket hole(s).

6.10 Repeat steps 6.2 through 6.9 for each pilaster.

6.11 For leveling devices secure the shoes. Drill a ¼” hole through

the pilaster. Secure the shoes with ½" bolts (FA-900) and 5/8"

barrels. (FA-951)

www.psisc.com

803-252-3020

15

SEE SHOP DRAWINGS FOR DISTANCE BETWEEN

PILASTERS BEFORE FASTENING PILASTERS TO FLOOR.

www.psisc.com

803-252-3020

16

7 INSTALL THE HEADRAIL

7.1 Measure and cut the front headrail to the appropriate length. For

large openings, cut the headrail as long as possible with the cut in

the center of a pilaster.

7.2 Lay the headrail on top of the pilasters and using the headrail

bracket as a template attach to wall using the supplied fasteners.

7.3 Drill a ¼” hole through the headrail bracket, headrail and the wall-

pilaster. Secure with a 15/16" bolt (FA-902) and 5/8" barrel (FA-

951).

7.4 For each pilaster, measure and mark the door opening width

according to shop drawings. Drill a ¼” hole through the headrail

and the pilaster. Secure with a ¾” bolt (FA-901) and a 5/8" barrel

(FA-951). See the notes to determine how many holes to drill.

7.5 For in-corner and free-standing configurations place an end-cap

and a corner headrail bracket onto the end of the headrail. Drill a

¼” hole through the headrail bracket, headrail and pilaster.

Secure with a 15/16" bolt (FA-902) and 5/8" barrel (FA-951).

7.6 Measure from the top of the panel to the bottom of the corner

headrail bracket.

7.7 Measure, mark and secure a headrail bracket on the wall at the

height measured in step 7.6.

7.8 Measure from the back wall to the corner headrail bracket. Cut a

piece of headrail to fit between the two brackets. Drill a ¼” hole

through the headrail and bracket and secure with 15/16" bolts (FA-

902) and 5/8" barrels (FA-951).

Pilaster Size # Bolts Location

< 7” 1 Centered

8” – 13” 2 2” from each end

> 14” 3 2” from each end and one centered

www.psisc.com

803-252-3020

17

www.psisc.com

803-252-3020

18

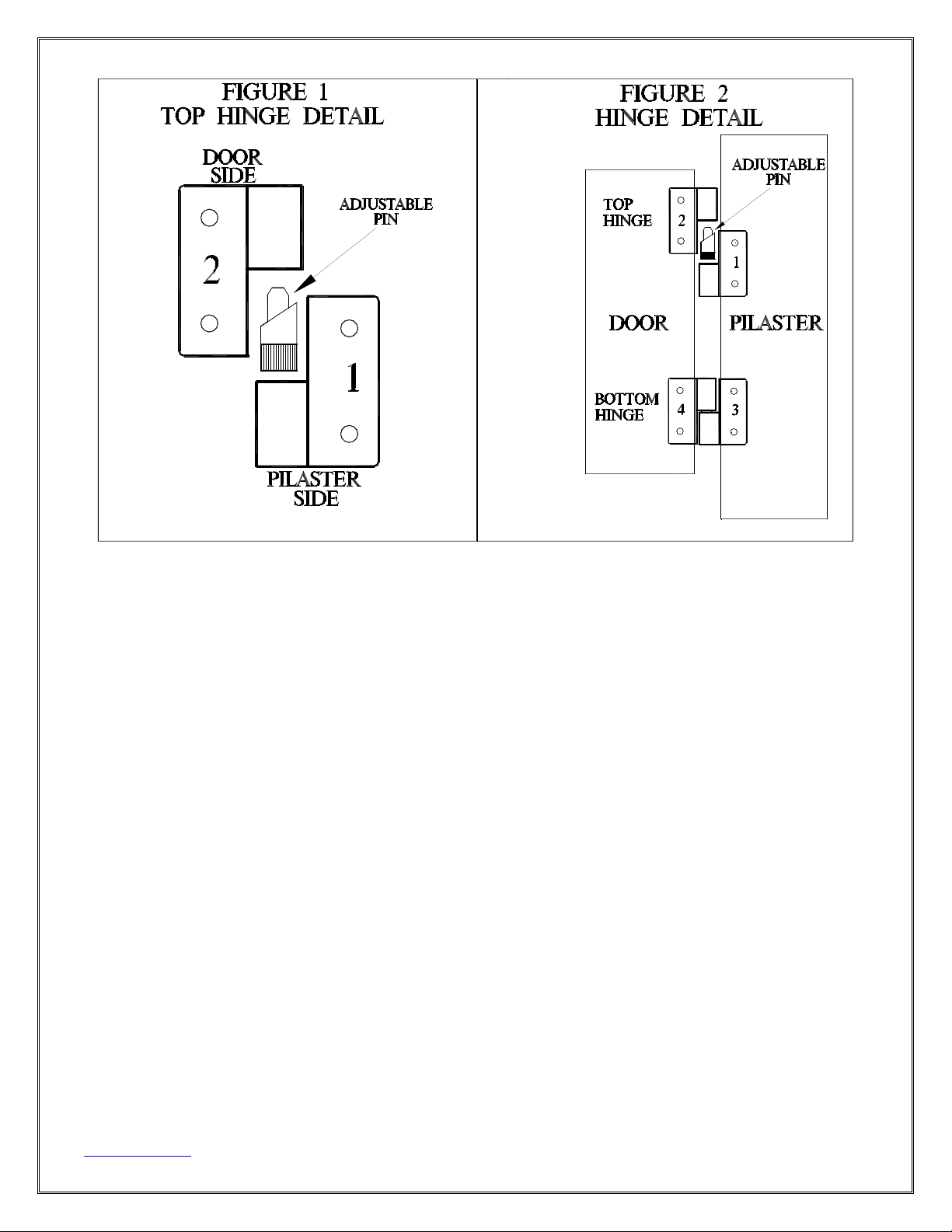

8 ATTACH THE DOORS

8.1 Secure part 1 of the top hinge onto the top of the pilaster

with ½" bolts (FA-900) and 5/8" barrels (FA-951). Keep the

adjustable pin in hinge part 1. (See fig. 1)

8.2 Secure part 2 of the top hinge onto the top of the door with

½" bolts (FA-900) and 5/8" barrels (FA-951). (See fig. 1)

8.3 Secure part 3 of the bottom hinge onto the bottom of the

pilaster with ½" bolts (FA-900) and 5/8" barrels (FA-951). (See

fig. 2)

8.4 Hang the door onto the pilaster.

8.5 Secure part 4 of the bottom hinge to the bottom of the

door using ½" bolts (FA-900) and 5/8" barrels.

www.psisc.com

803-252-3020

19

Notes:

xTo increase or decrease the default door opening reposition the

adjustable pin in the top hinge. The default position is 15oopen.

xFor the best installation place the barrel through the hinge.

xOn inswing doors the hinge is located on the inside of the stall.

On outswing doors the hinge is located on the outside of the stall.

xA right hand inswing hinge (SS-151) is also a left hand outswing

hinge. A left hand inswing hinge (SS-150) is also a right outswing

hinge.

www.psisc.com

803-252-3020

20

9 ATTACH THE DOOR HARDWARE

9.1 Mark the keeper position on the Pilasters.

9.1.1 For surface mounted latches, measure and mark the center of the

keeper 41" above the finished floor.

9.2 Using the keeper as a template, mark and drill ¼” holes through

the pilaster. Secure the keepers using ½” bolts (FA-900) and 5/8"

barrels (FA-951).

9.3 Mount the door latch. Position the surface mounted latches on

the inside of the door so the latch clears the keeper when the

door opens. Using the latch as a template, mark and drill ¼”

holes through the door.

9.3.1 For inswing and outswing doors, secure the latch with ½" bolts (FA-

900) and 5/8" barrels (FA-951).

9.3.2 For outswing doors secure the door pull with ½" bolts (FA-900) and

5/8" barrels (FA-951). Secure the door pull on the outside of the door.

9.4 Mount the coat hook / bumper

9.4.1 For inswing doors place the coat hook / bumper 4” from the top and

outer edge. Mark and drill ¼” holes in the door. Secure the coat

hook / bumper to the inside of the door with 5/8" bolts (FA-609) and ½”

barrels (FA-652).

9.4.2 For outswing doors center the coat hook 4” from the top. Mark and

drill ¼” holes in the door. Secure the coat hook with 5/8" bolts (FA-609)

and ½” barrels (FA-652).

9.4.3 For ADA doors see local specifications for coat hook placement.

(usually 48” from the finished floor)

Table of contents

Popular Bathroom Fixture manuals by other brands

Spectrum

Spectrum Pfister Saxton LG89-XGL1 Maintenance & Care Guide

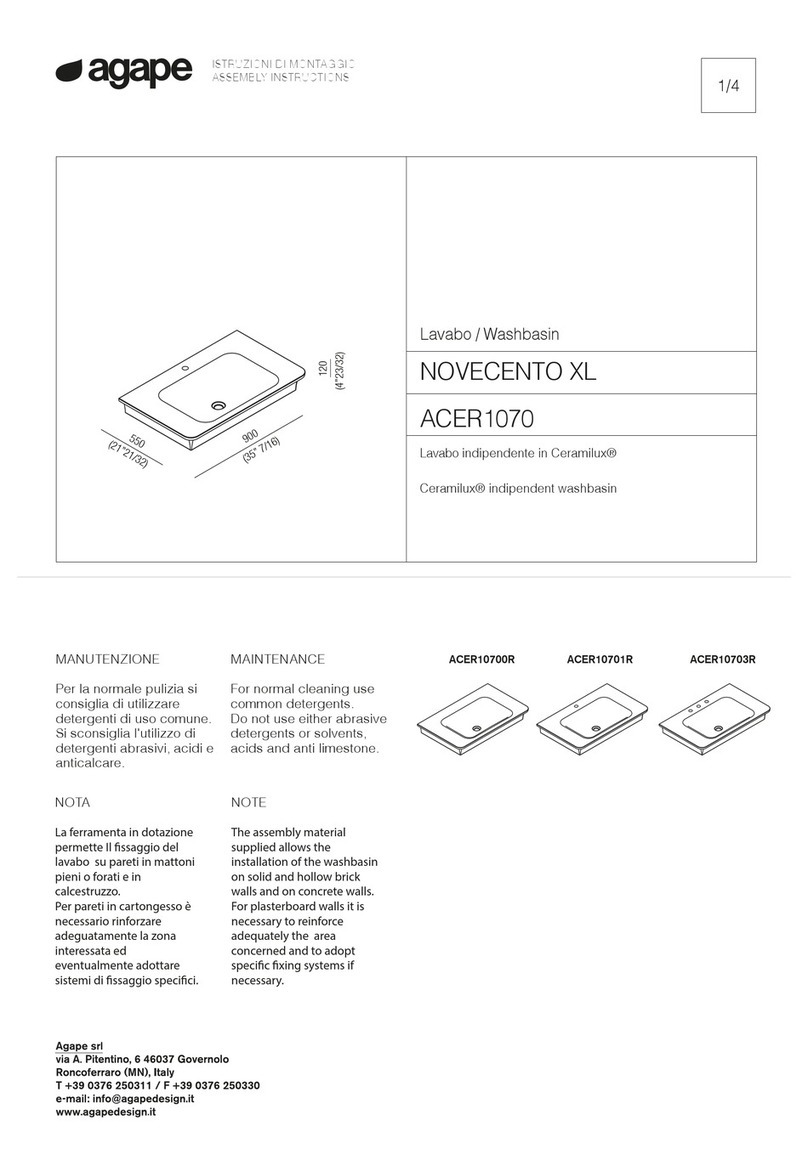

agape

agape Novecento XL ACER1070 Assembly instructions

Spectrum Brands

Spectrum Brands Pfister Zeelan 8P8-WS2-ZLS Maintenance & Care Guide

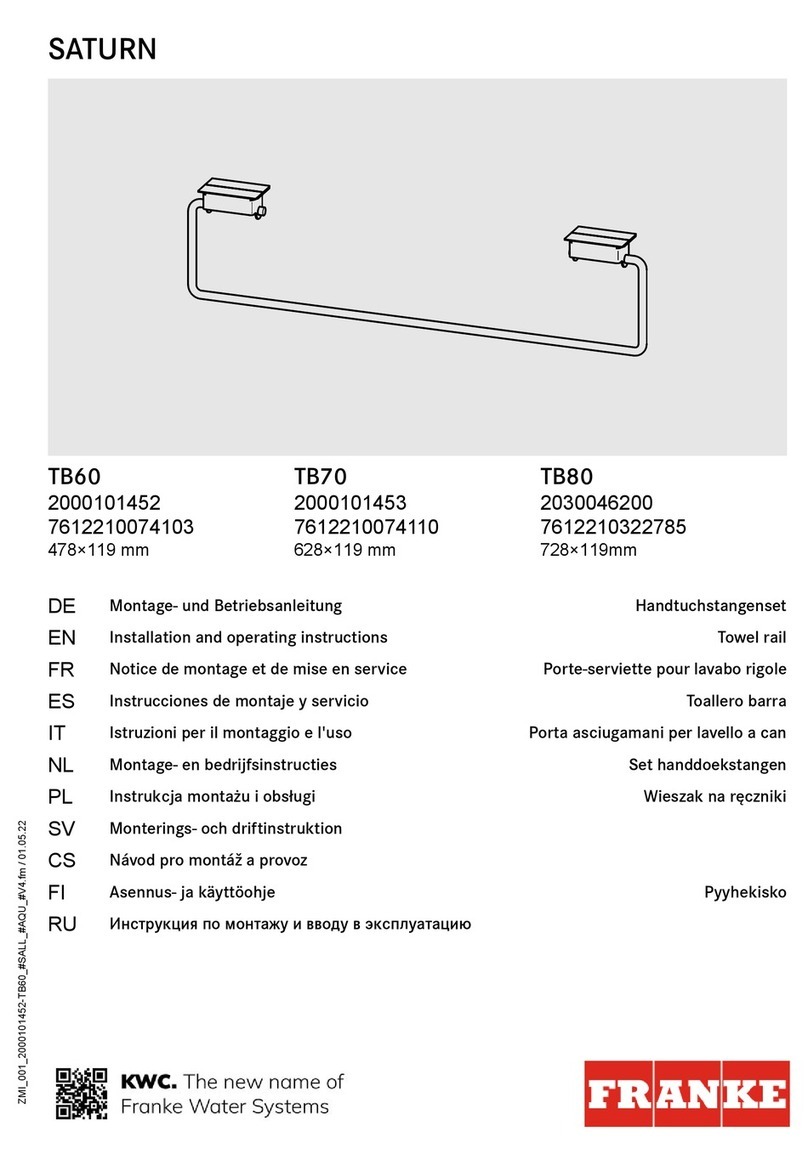

Franke

Franke SATURN TB60 Installation and operating instructions

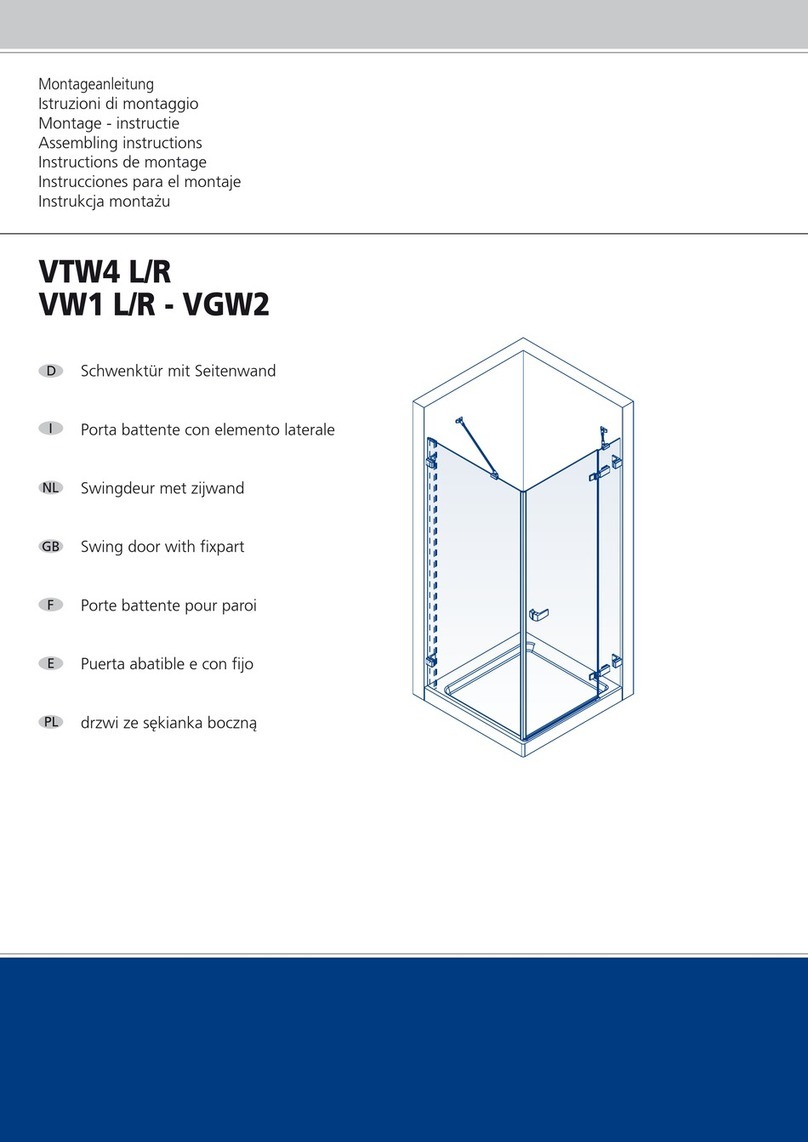

Duka

Duka VTW4 L Assembling instructions

ERGONOMIC

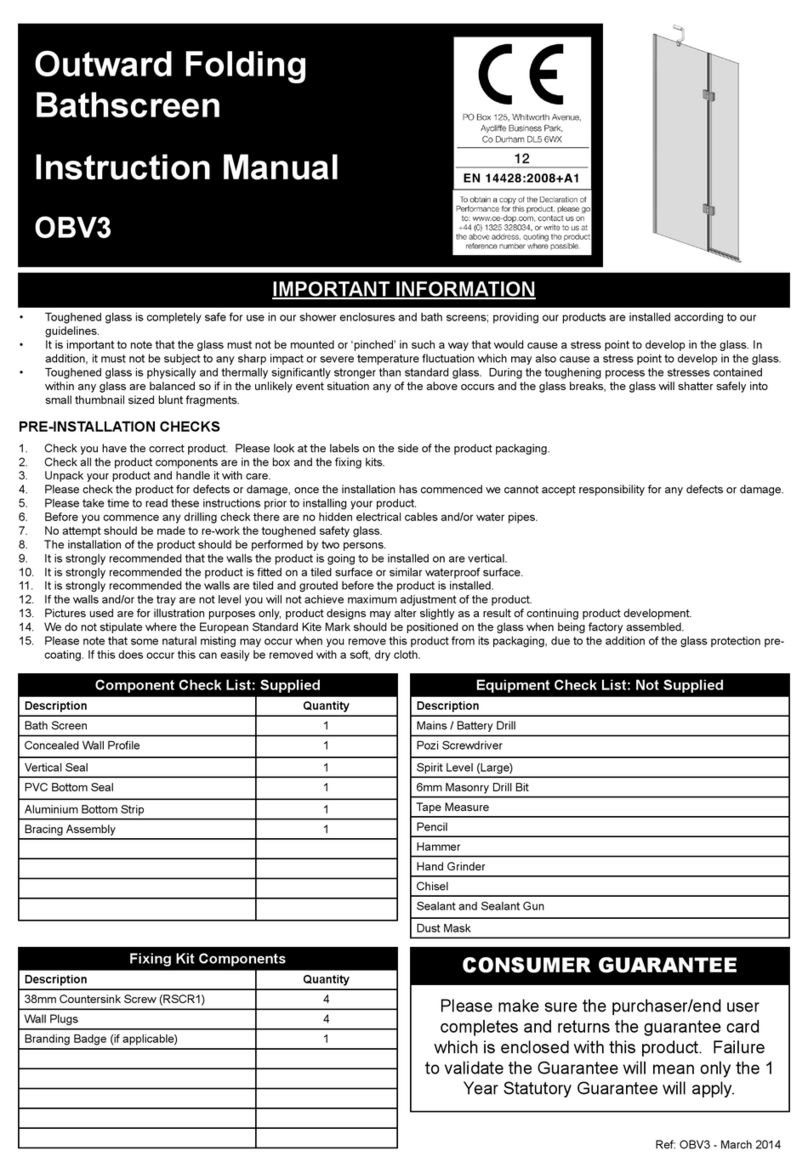

ERGONOMIC OBV3 instruction manual

Orbital Systems

Orbital Systems Oas Standard installation instructions

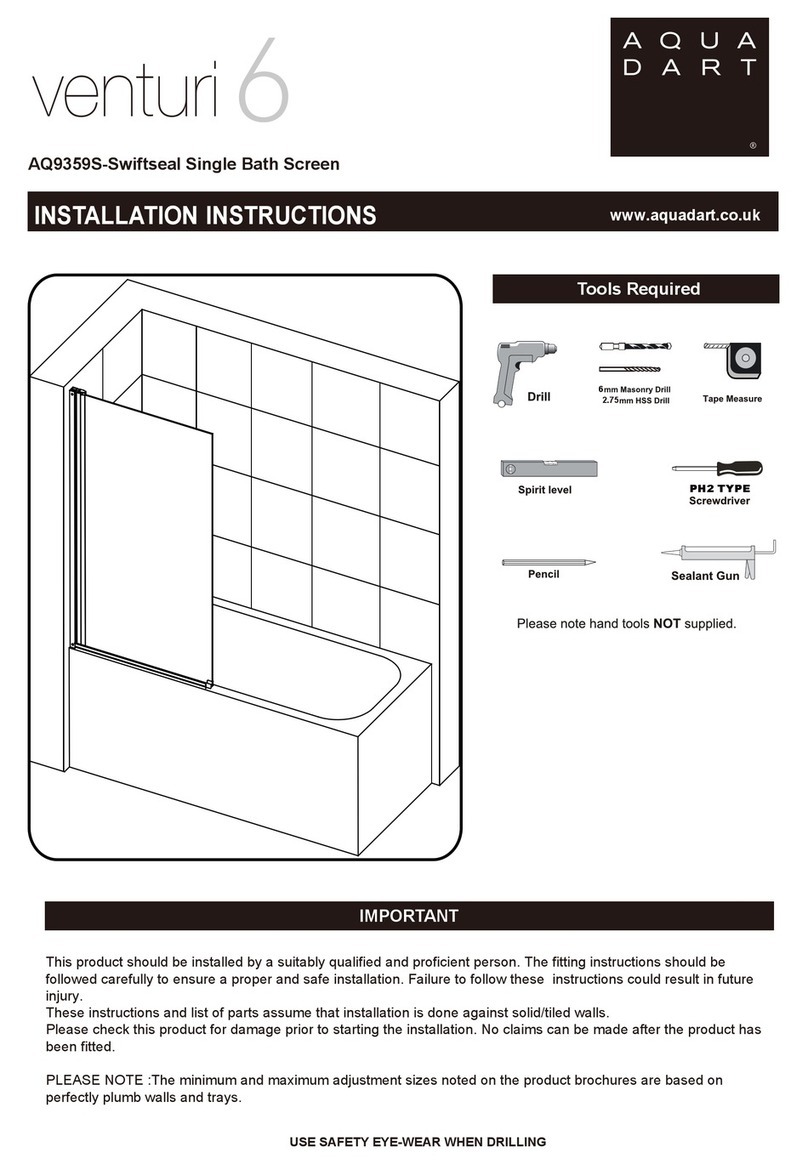

Aquadart

Aquadart venturi 6 AQ9359S installation instructions

Mira

Mira Platinum installation guide

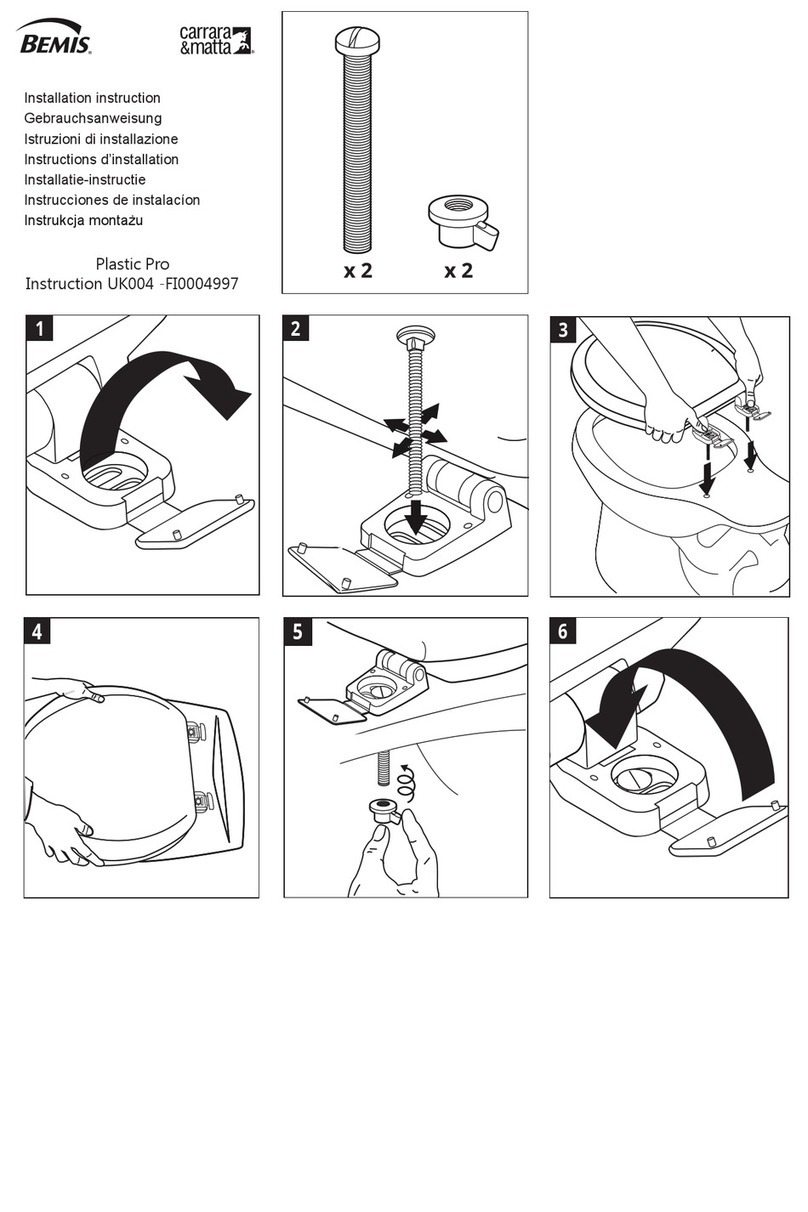

BEMIS

BEMIS Plastic Pro UK004 Installation instruction

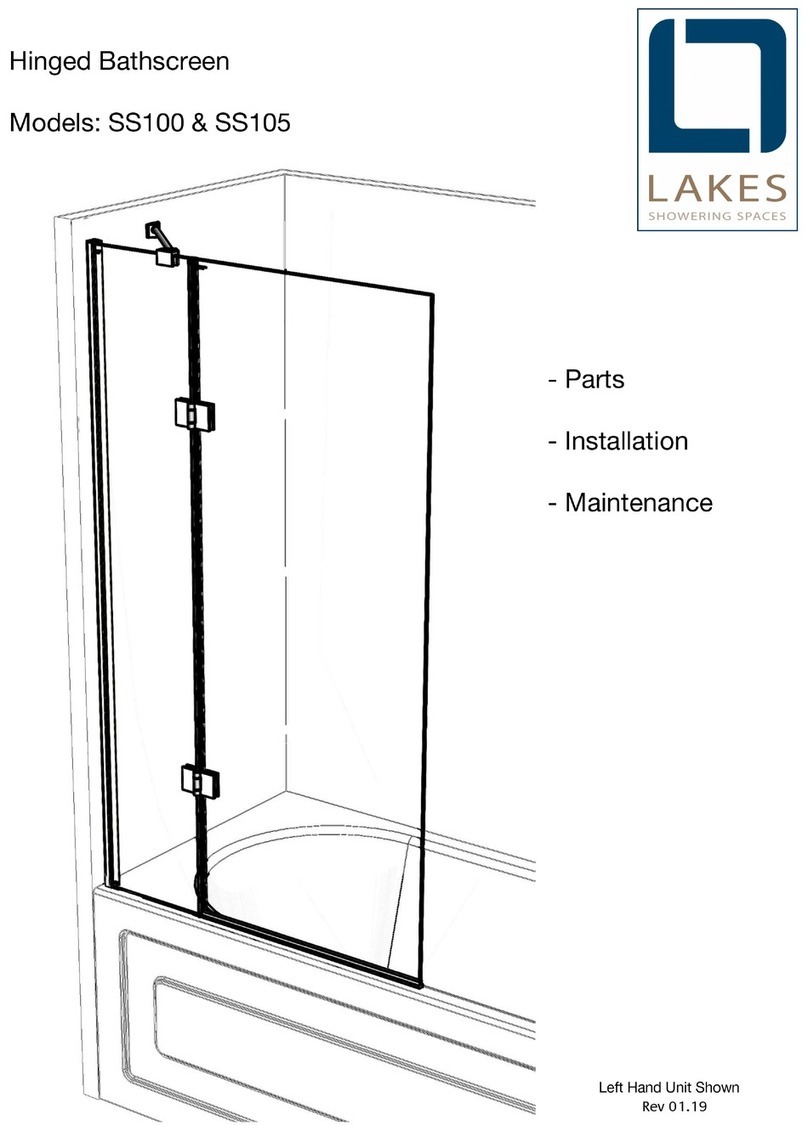

Lakes

Lakes SS100 manual

Hans Grohe

Hans Grohe AXOR Urquiola 11901000 Instructions for use/assembly instructions