2

E.04.99 • G. 08.08.19

Overview ........................................................................................................... 3

General information / safety information .................................................................................... 3

Checking scope of delivery and connection data....................................................................... 3

Operating instructions ................................................................................................................ 3

Instruction of operating personnel.............................................................................................. 3

Maintenance and customer service ........................................................................................... 3

Key for code designation ........................................................................................................... 4

Technical specifications ............................................................................................................. 4

Installation ......................................................................................................... 5

Installing flange and burner........................................................................................................ 5

Checking electrode setting......................................................................................................... 5

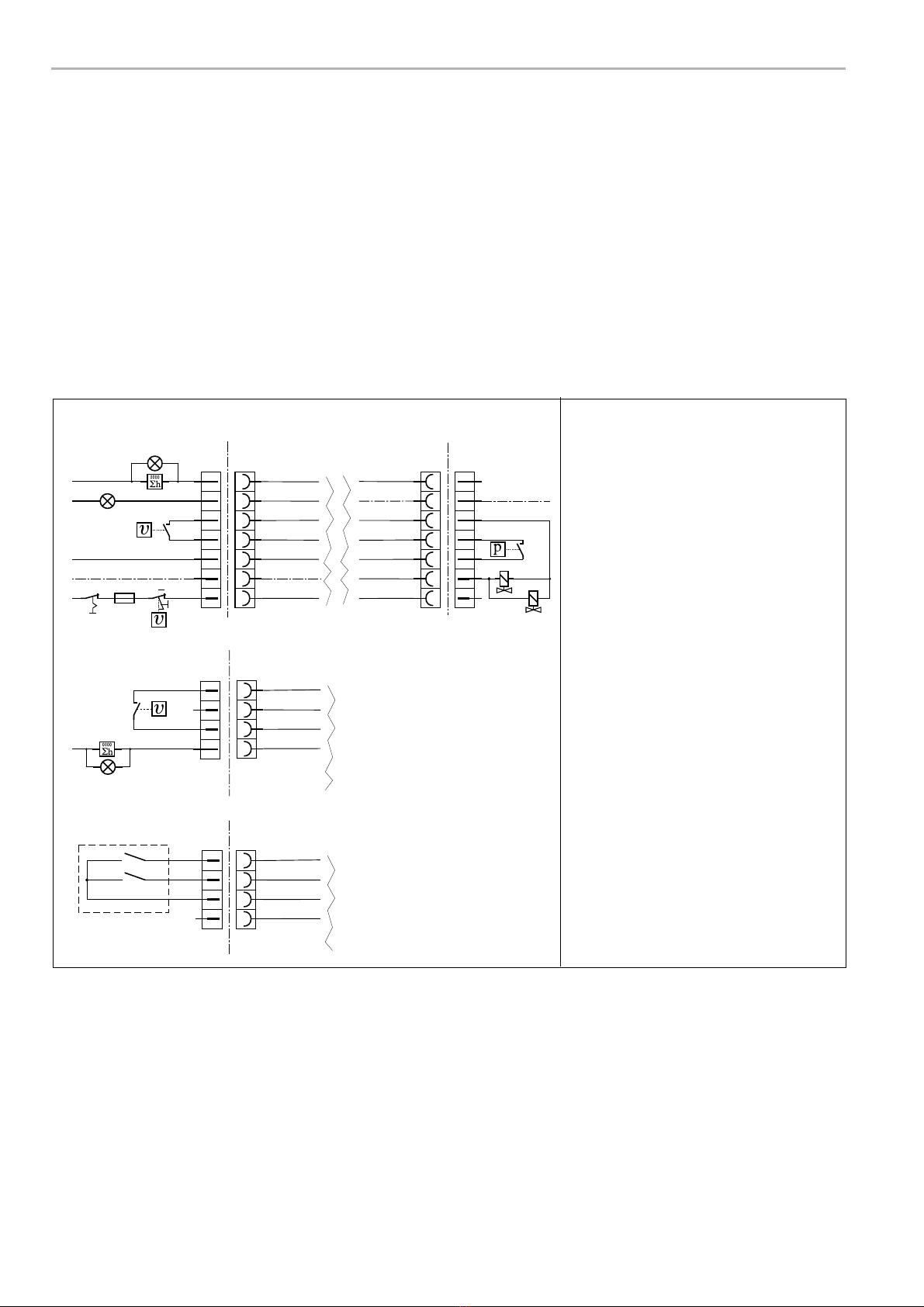

Installing gas assembly.............................................................................................................. 5

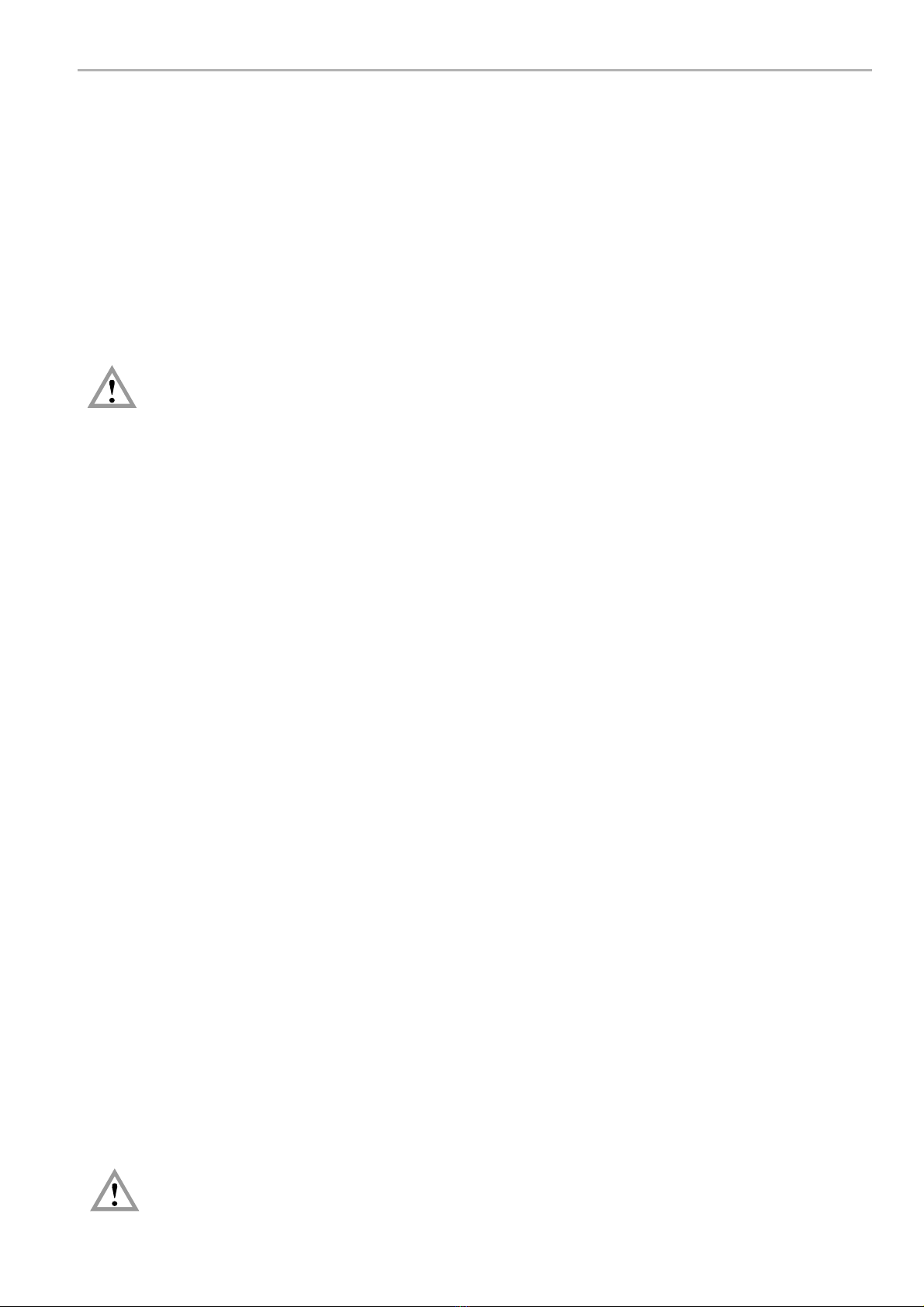

Establishing electrical connections ............................................................................................ 6

Function ............................................................................................................. 7

Control unit LME ........................................................................................................................ 7

Air flow setting, dimension “A”.................................................................................................... 10

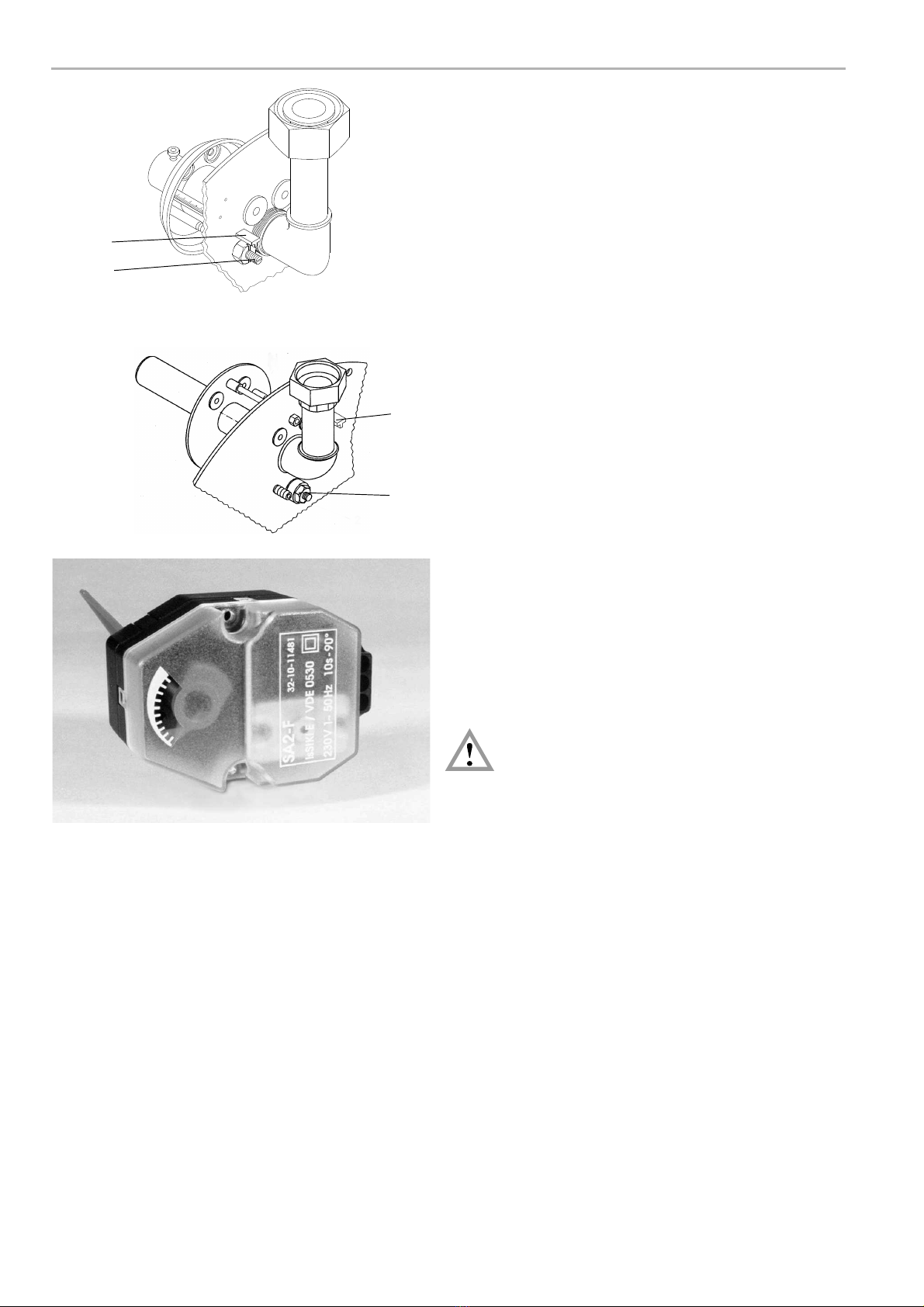

Air flap positioning motor .......................................................................................................... 10

Compact gas unit ...................................................................................................................... 12

Gas pressure monitor ................................................................................................................ 12

Start-up .............................................................................................................. 13

Adjustment tables RG20 ............................................................................................................ 13

Adjustment tables RG30 ........................................................................................................... 15

Adjusting gas burner and boiler ................................................................................................. 17

Calculation principle for gas burner adjustment ......................................................................... 21

Design ............................................................................................................... 23

Exploded drawing and spare parts/parts list RG20.................................................................... 23

Exploded drawing and spare parts/parts list RG30.................................................................... 25

Service instructions/dimensions ........................................................................ 27

Service position.......................................................................................................................... 27

Reference dimensions, ignition and ionisation electrodes ........................................................ 27

Measuring ionisation current ..................................................................................................... 28

Servicing air pressure monitor .................................................................................................. 29

Declaration of conformity ........................................................................................................... 30

Burner overall dimensions / boiler connection dimensions ........................................................ 32

Working ranges .......................................................................................................................... 32