3

I

CTC modular MAXX box solutions allow for the monitoring of remotely mounted

vibration sensors, which would otherwise be restricted to human access due to

safety considerations.

MMX2000 Series Modular MAXX Box Overview: 3-12 Channel boxes, stainless

steel enclosure

The MMX2000 3-12 channel enclosure is a common cable termination point for

bringing in a variety of sensor applications including single axis, biaxial, triaxial,

and dual output (vib/temp) sensors for routine data collection with portable data

collectors.

The MMX2000 Series offers convenient three position quick connect terminal

blocks for terminating the sensor of your choice.

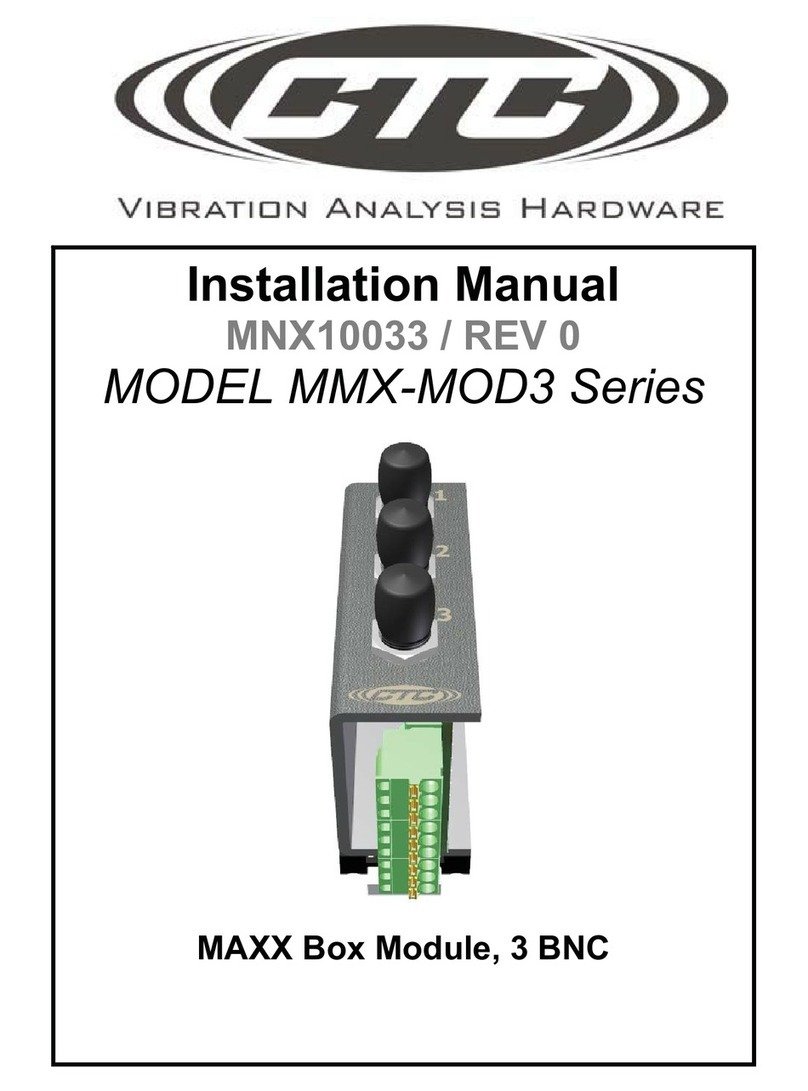

Setup of DIP Switches

In addition to the most popular application of single axis sensors the MMX-MOD3

modules can be setup to provide grouped signals from a Dual Output sensor,

triaxial or biaxial style sensor that share the “common” conductor. By adjusting

the dip switches, the common connection can be shared between inputs 1 & 2,

2 & 3, for dual outputs and between inputs 1 & 2 for biaxial sensors or 1, 2, & 3

for triaxial sensors. This eliminates the need to insert jumper wires between the

different inputs within the module. The switches are displayed further on in this

manual. Note: All modules are set at “Commons OPEN” at factory.