3

I

CTC Termination Box solutions allow for the monitoring of remotely mounted

vibration sensors, which would otherwise be restricted to human access due to

safety considerations.

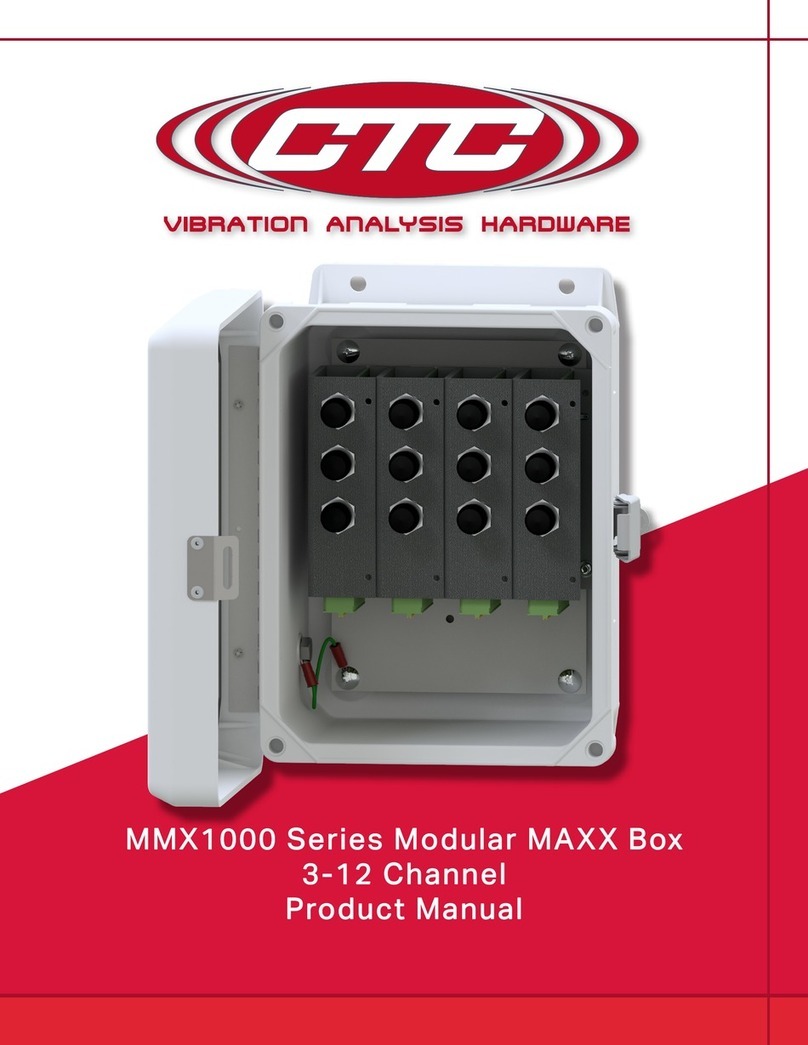

MX102 Series Termination Box Overview: Four to 12 sensor inputs (four to 12

measurement channel outputs), fiberglass enclosure

The MX102 Termination Box is a common cable connection point for bringing

multiple sensor cables into a central location for routine data collection with

portable data collectors.

The MX102 Termination Box is used to convert the two-conductor input wiring

of up to 12 remotely installed accelerometers or piezo velocity sensors to a

dedicated BNC for each sensor. Wiring from each sensor is connected to the

outputs via quick-connect or screw terminal blocks. Each terminal block includes

inputs for positive, negative and shield. The shield drain wire is earth grounded

via a ground stud that is mounted to the side of the fiberglass enclosure.

Rated for NEMA 4X (IP66), the MX102 can withstand harsh environments

including temperatures ranging from -58°F to 180°F (-50°C to 82°C). The box is

also resistant to hose-directed fluid and corrosion. A snap latch is installed on

the door allowing the box to be sealed from the elements when not in use.