9

Operations

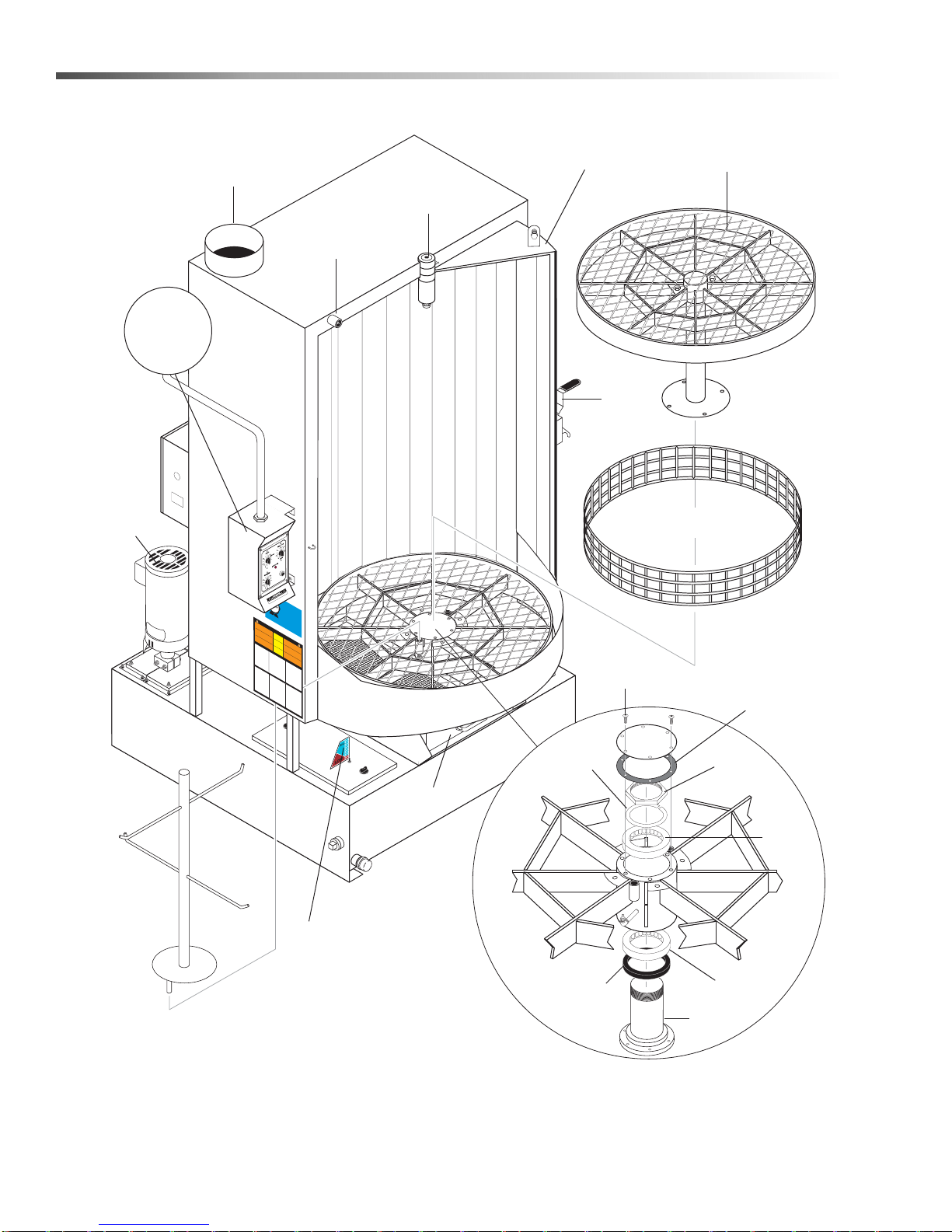

Component Identification - Rear View

KEEP

DRY

ATTENTION

USE ONLYCUDA APPROVED

DETERGENTSTO EX TEND

LABORWARRANTYTO1-YEAR!

MIXDETERGENTS 1 LB (1/2 KG) PER

5-GALLONS(15 LITERS) OF WATER

ForCUDA Approved Detergents visit

http://www.cudausa.comor

call888-319-0882

9.807-513.0

90-DAYLABOR WARRANTY

EXTENDSTO 1-YEAR

WITHEXCLUSIVE USE OF

CUDADETERGENTS

LIMITED

Thisisaheatedparts cleaner.Useonlynonflammable,non-

combustible,water-basedcleaningcompoundsinthismachine.

Donot fillorcontaminatewitha

nyflammableorcombustible

materialsuchasgasoline,alcohol,mineralspirits,etc.Drainparts

tobe cleaned of anycombustibleorflammablematerialbefore

placinginsidecabinet.Failuretoobservethiswarningwillcreate

anextremelyhazardouscondition.

Esteesun limpiadordepartesque secalienta.Utilicesola-

menteenestamáquinacomponentesdelimpiezabaseagua,no

inflamablesynocombustibles.Nollenarocontaminarconalgún

materialinflamablecomo,gasolina,alcohol,esenciasminerales,

etc.Drenelaspartesa ser limpiadasde cualquier combustible o

materialinflamableantesdeintroducir enelgabinete.Si

descuidaobservarestasprecauciones,puedencrearsecondicio-

nesextremadamentepeligrosas.

Cenettoyeurdepiècesestchauffé.Utiliserdanscet appareil

seulementdesnettoyeursàbased’eau, non combustiblesetnon

inflammables.Nepasyajouteroucontamineravec desmatériaux

combustiblestels:gasoline,alcool,etc.Viderlespiècescontenant

desmatériauxcombustiblesouinflammablesavantdelesplacer

àl’intérieurducabinet.Nepasobservercesavertissementspeut

créerdessituationsrisquées.

HOTWATER

Beforeopeninglid,wait5

secondstoallowspray

arm/turntableto stop

spinning.

AGUA

CALIENTE

Antesdeabrir la tapa,

espere5 segundos para

quelabarra rotatoriase

detenga.

EAUCHAUDE

Avantd’ouvrirlecouvert,

attendez 5 secondes pour

permettreaubras vaporisa-

teur/plaquetournanted’arrêter

detourner.

WARNING

PRECAUCION/ADVERTISSEMENT

CAUTION

CUIDADO/ ATTENTION

OPERATINGINSTRUCTIONSINSTRUCCIONESDE OPERACIONINSTRUCTIONSD’OPÉRATION

IMPORTANT:Beforeoperatingthismachine,

completelyfamiliarizeyourselfwith instruction

manualprovided.Onlyauthorized andproperly

instructedindividualsshouldoperate this machine.

Beforeloadingpartsonto turntable/ basket, be cer-

tainthepumpisoffandnotrunningandthe wash

solutionsareatoperatingtemperature.

1.Filltankwithwaterand cleaningsolution.

Waterlevelshouldbe2"belowthe accessdoors.

Checkdaily.

2.Programheatertimerfor desiredperiodof

operation.Allowtimefor unit topreheatcleaning

solution.

3.Opendoor/lidandplacearticles to becleanonto

basket/turntable.Becertainno partsprotrude

throughthebottomor beyondthesidesofthe

basket/turntable.Donotexceedthespecified

heightorweightlimitfor this spraywashcabinet.

4.Closedoor/lidandlatchsecurely.Withmachine

settowash, turn“washcycle”timer to the desired

cleaningtime.Pumpwill startand run until time

hasexpired.

5.Beforeopeningthe door/lid,turnwash cycle timer

offandwait5 secondsfor machineto stop spin-

ning.Thiswillallow steam toescapethe cabinet

andexcesswater to drainfrom yourparts.

IMPORTANTE:Antesde oparar elequipo,familiarícesecom-

pletamenteconelmanualdeoperaciónquese incluye. Solo

personalautorizadoydebidamente capacitadodebeoparar

ésteequipo.Antesde abrirla puerta/cubierta olaspiezasde

cargasobrelatornamesa/canasta,asegúresedequelabomba

estéapagaday sin funcionar, yque lassoluciones de limpieza

esténatemperaturadefuncionamiento.

1.Lleneeldepósito conagua yla soluciónparalimpieza.El

niveldelaguadebeestar2"pordebajo de las puerta de ac-

ceso.Verifiqueelniveldiariamente.

2.ProgrameelTemporizadordel calentadorparael períodode

operacióndeseado.Dejepasarun tiempo paraque la unidad

precalientelasoluciónparalimpieza.

3.

Abralapuerta/tapaycoloquelaspiezasa lavarenlator-

namesa/canasta,asegúresedequeningunapieza so-

brepaseelfondoni el perímetro de la tornamesa.No exceda

loslimitesespecificadosdepesoyalturaparael gabinetede

lavado.

4.Cierrelapuerta/tapayasegureel candado. Conlamáquina

enposicióndelavar,ajusteel temporizadorde“ciclode

lavado”altiempodeseado.Labombaarrancaráyfuncionará

duranteeltiemposeleccionado.

5.Antesdeabrirlapuerta/cubierta,apague el temporizadordel

ciclodelavadoyespere 5 segundos paraque la máquina

dejedegirar.Estopermitiráqueel vapor salga delgabinete y

elexcesode agua drenedelas piezas.

IMPORTANT:Avantd’utilisercettemachine,familiarisez-

vouscomplètementavecle manuel d’instructionfourni.Cette

machinedevraitêtreutiliséeseulementpardupersonnel

autoriséetformé.Avantl’ouverturedela porte/du couvercle

ouduchargementdespiècessurla table tournante/le panier,

s’assurerquelapompeest en position arrêt et ne fonctionne

pasetquelessolutionsdelavagesont à température de

fonctionnement.

1.

Remplirleréservoird’eauetd’unesolutiondenettoyage.

Leniveaud’eaudoitse trouver à5 cm (2po)sousles

portesd’accès.Vérifierquotidiennement.

2.

Programmerleminuterie dechauffagedel’appareil pour

lapériodedefonctionnement souhaitée.Prévoir du temps

pourquel’appareilpréchauffelasolutiondenettoyage.

3.

Ouvrirlaporte/couvertetplacezlesarticles à être lavé

surlepanier/plaquetournante.Assurez-vous qu’iln’yest

aucunepiècedépassantlepainer oudansle fond au-delà

dupainer/plaquetournante.

4.Fermezla porte/couvert et verrouillezde façonsécuritaire.

Lamachineprêtepourle lavage,tournez le minuteur“wash

cycle”autemps dela lavage désiré.Lapompefonctionnera

jusqu’àcequetempssélectionnésoitécoulé.

5.

Avantd’ouvrirla porte/lecouvercle, mettre la minuterie du

cycledelavageàl’arrêtet attendrependant 5 secondes que

l’appareils’arrêtede tourner.Celapermettraàla vapeurde

s’échapperducabinetetàl’excèsd’eaude s’écouler de vos

pièces.

WARNING

PRECAUCION/ADVERTISSEMENT

• Machinemustbeconnectedto aproperlysized

lockabledisconnect.

• InstallationmustcomplywithNEC code.

• Forsupplyconnection,usewiresaccept ablefor

atleast90 degrees C.

• Donot usebelowgrade floor or grade level.

Thefollowingscheduleisbasedonaverageuse.

Higherusagemayrequiremorefrequentmainte

-

nance.

IMPORTANT:BesureelectricalsupplyisOFF be-

foredrainingsump.Onlyqualified personnelshould

servicethismachine.

DAILY:

• Checkwaterlevelinthe sump daily.Topping

offthewaterdaily will preventdamagetothe

heaterelement.

• Removeandcleandebrisscreen.

• Visuallycheckforpluggednozzles.Remove

andcleanifneeded.Reinstallinthe exactorigi-

nalposition.

WEEKLY:

• Grease/oildoorhinges.

MONTHLY:

•Performvisualcheckofturntabledrivechain.

• Drainwashsolutionfromsump,removesand/

gritfrombottom of the sump.Careshouldbe

takentoavoidbending or damagingheater ele-

mentduringthecleaningprocess.

• Whensumphasbeencleanedandrefilledwith

water,addtherecommended quantityof deter-

gentforyour machine.

NOTE:Dissolvecleaningpowderinto warmwater

beforeaddingthemanufacturer’srecommended

amounttothetank.

8.922-402.0

• Lamáquinadebe estar conectadaa unenchufe

eléctricode seguridad.

• Lainstalación debe cumplir con el código NEC.

• Paralasconexiones de alimentación,use cablea-

doparaal menos 90 grados centígrados.

Noutilicepor debajo del niveldel piso.

• L’appareildoitêtreconnecté à un sectionneur

verrouillabledetaille appropriée.

• L’installationdoitse conformer au code NEC.

•Pourle raccordementde l’alimentation,utiliser des

filspouvantaccepteraumoins 90degrésCelsius.

Nepas utiliserun calibre ou un grade inférieur.

Letableausuivant est fondé surune utilisationmoyenne.

Uneutilisationplusimportantepeutexigerun entretien plus

fréquent.

IMPORTANT:S’assurerquelesystèmeélectrique est àl’arrêt

avantdeviderleréservoir.Seullepersonnel qualifiédoit ré-

parercetappareil.

QUOTIDIENNEMENT:

• Vérifierquotidiennementleniveaud’eau dansle rés-

ervoir.Leremplissagequotidiend’eaupermetd’éviter

d’endommagerl’élémentchauffant.

• Démonteretnettoyer le filtre à débris.

• Vérifiervisuellementsidesbusessontbouchées/ob-

struées.Démonteretnettoyer,lecas échéant.Réinstaller

danslapositioninitiale exacte.

HEBDOMADAIREMENT:

• Graisser/huilerlespentures/charnièresde laporte.

MENSUELLEMENT:

• Procéderàuncontrôlevisueldela chaîned’entraînement

delatabletournante.

• Assécherlasolutionde lavagedu réservoir, etenlevertout

sable/graviersetrouvantaufond. Des précautions doivent

êtreprisespour éviter deplier/courberl’élément chauffant

oudel’endommager au cours duprocessusdenettoyage.

•Lorsqueleréservoiraéténettoyéetremplid’eau,ajouterla

quantitédedétergentrecommandéepourvotreappareil.

NOTE:Biendissoudrelapoudredansl’eauchaudeavant

d’ajouterdansleréservoir.

Elplandemantenimientoquesepresentaacontinuación,está

basadoenunusopromediodelequipo.Unusomásfrecuenteo

severopuederequerirunmantenimientomásfrecuente.

IMPORTANTE:Asegúresedequeelsistema eléctrico esté

APAGADOantesde vaciarelcá rter.Sólopersonalcalificado

deberepararestamáquina.

DIARIAMENTE:

• Compruebeelnivel delagua enelcárter diariamente.

Mantenerelnivel adecuado delaguaevitarádañar el

elementodelcalentador.

•Retireylimpielos residuos de la criba.

•Compruebevisualmentequelasboquillasestán instaladas

correctamente.Retireylimpie si es necesario.Reinstale en

laposiciónoriginalexacta.

SEMANALMENTE:

• Lubriquelasbisagrasdela puerta.

MENSUALMENTE:

• Realiceunaverificación visual de lacadena depropulsión

delatornamesa.

• Drenelasolución delimpiezadelcárter, retire del fondo de

cárterlossedimentos.Debetenercuidadode no doblar o

dañarel elementodel calentadordurante el proceso de

limpieza.

• Unavezqueelcárter estálimpio y relleno de agua,

agreguelacantidadrecomendadadedetergente parala

máquina.

NOTA:Disuelvaeldetergenteenaguacalienteantesdeagregar-

loaltanqueenlacantidadrecomendadaporelfabricante.

MAINTENANCEINSTRUCTIONS

INSTRUCCIONESDEMANTENIMIENTOD

IRECTIVESD’ENTRETIEN

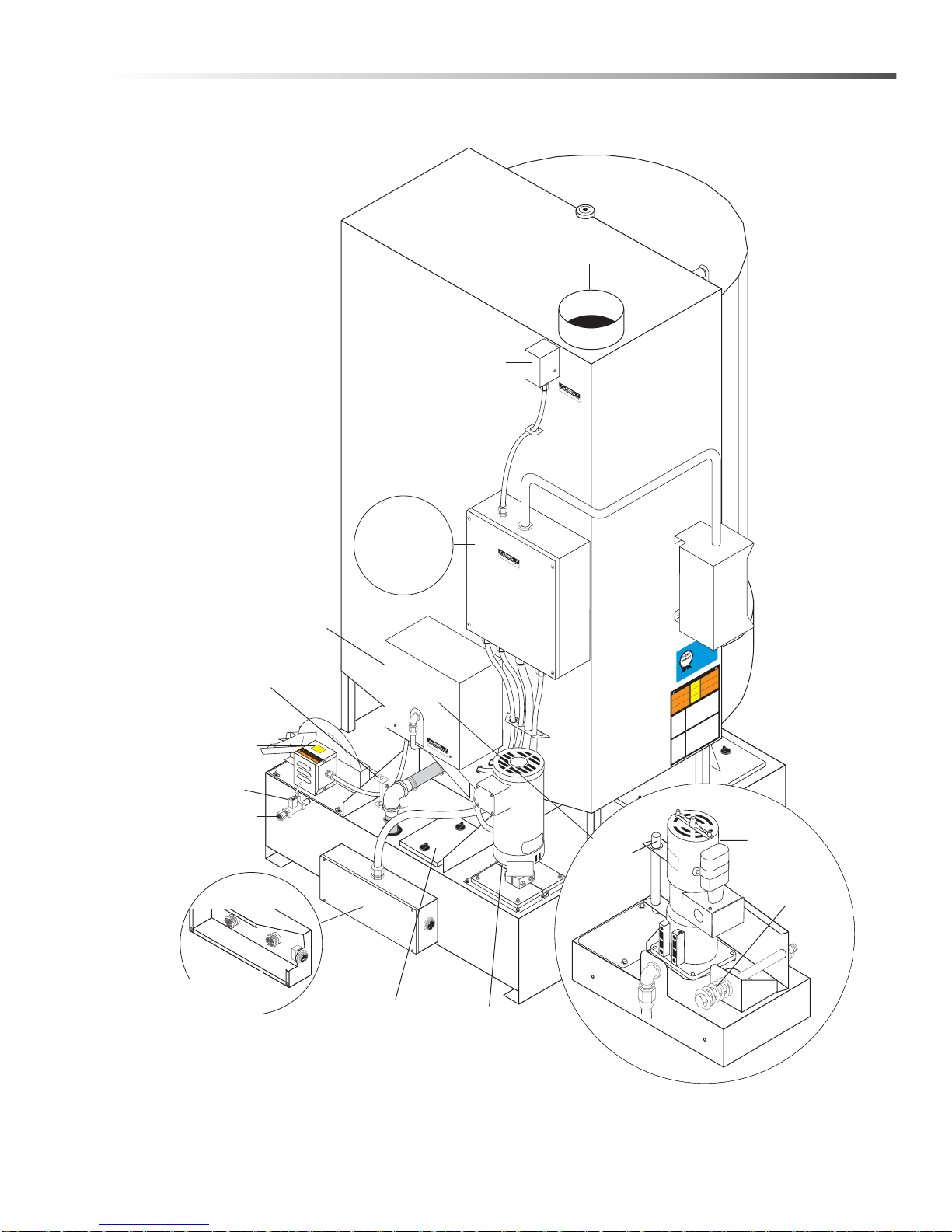

Steam Vent

Door Safety

Switch

Turntable

Drive

Enclosure

For

Detail See

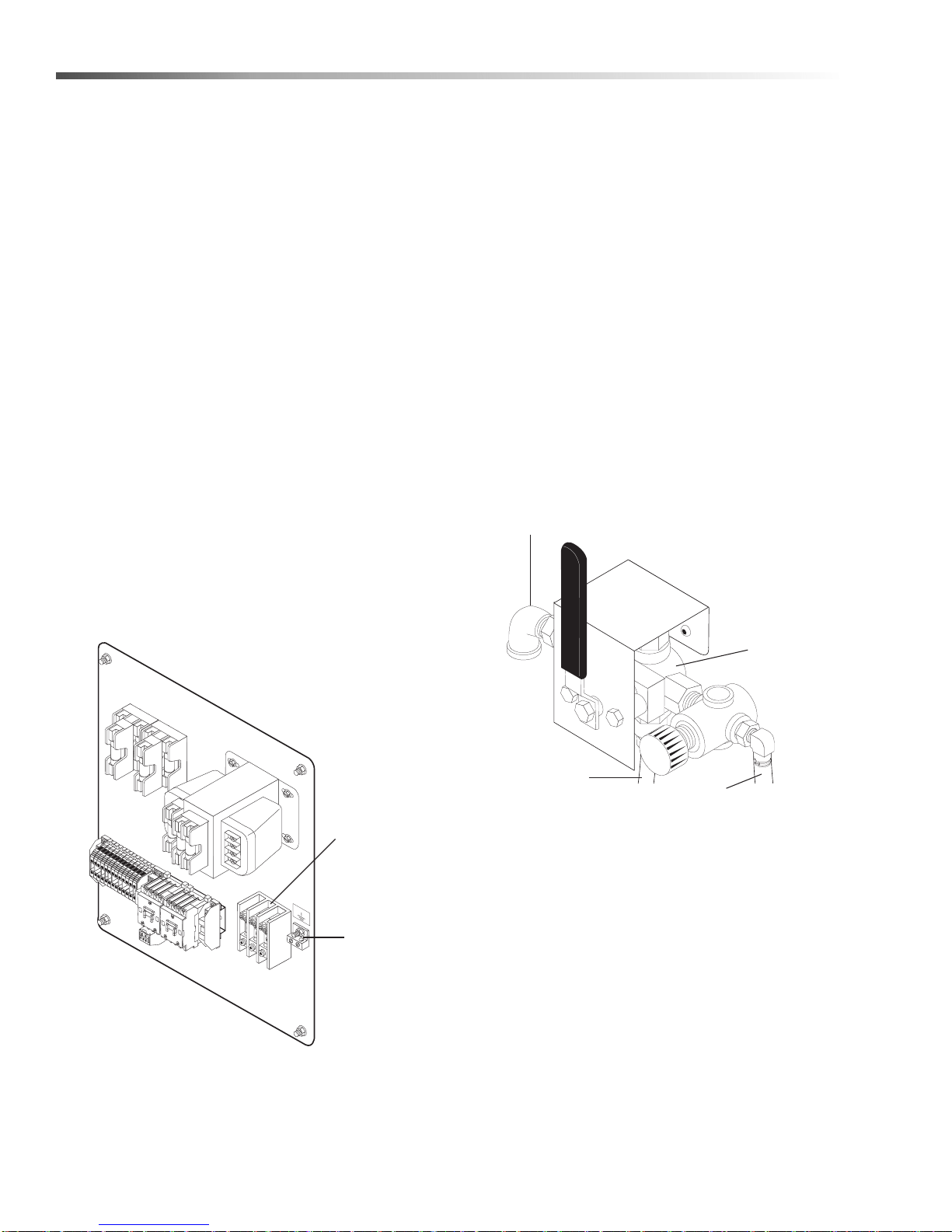

Main Control

Panel Illus.

Fresh Water In

Pump

Sump Cover

Heating

Element &

Thermostat

Enclosure

Low Water

Shut-Off Assy.

Oil Skimmer Assy.

Optional

Solenoid Valve

Drive

Motor

Compression

Spring Assy.

Pivot

Pin

Cuda 4860 Operator’s Manual 8.914-383.0 - U