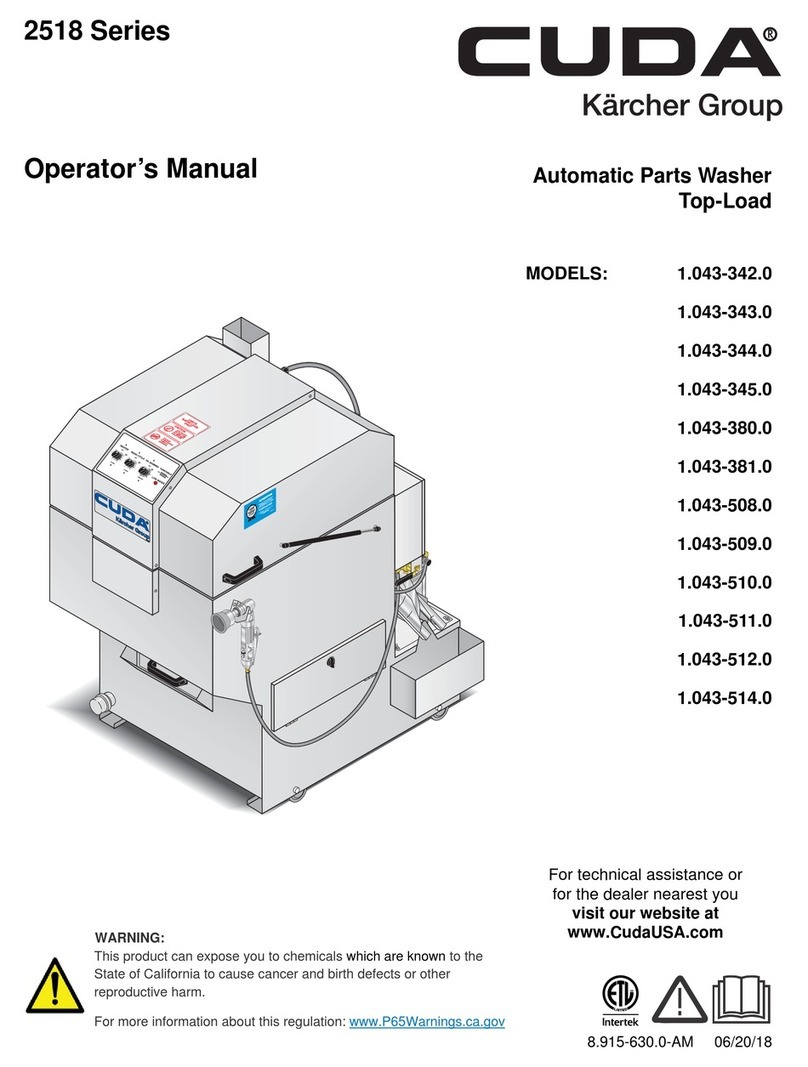

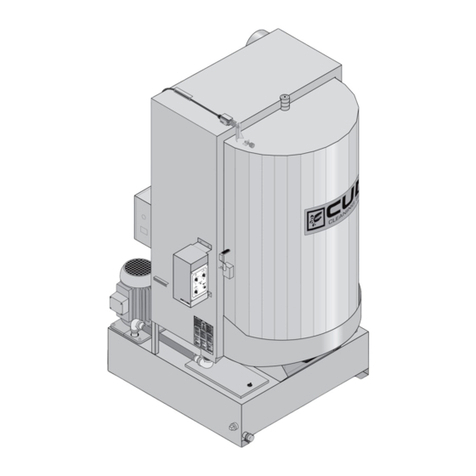

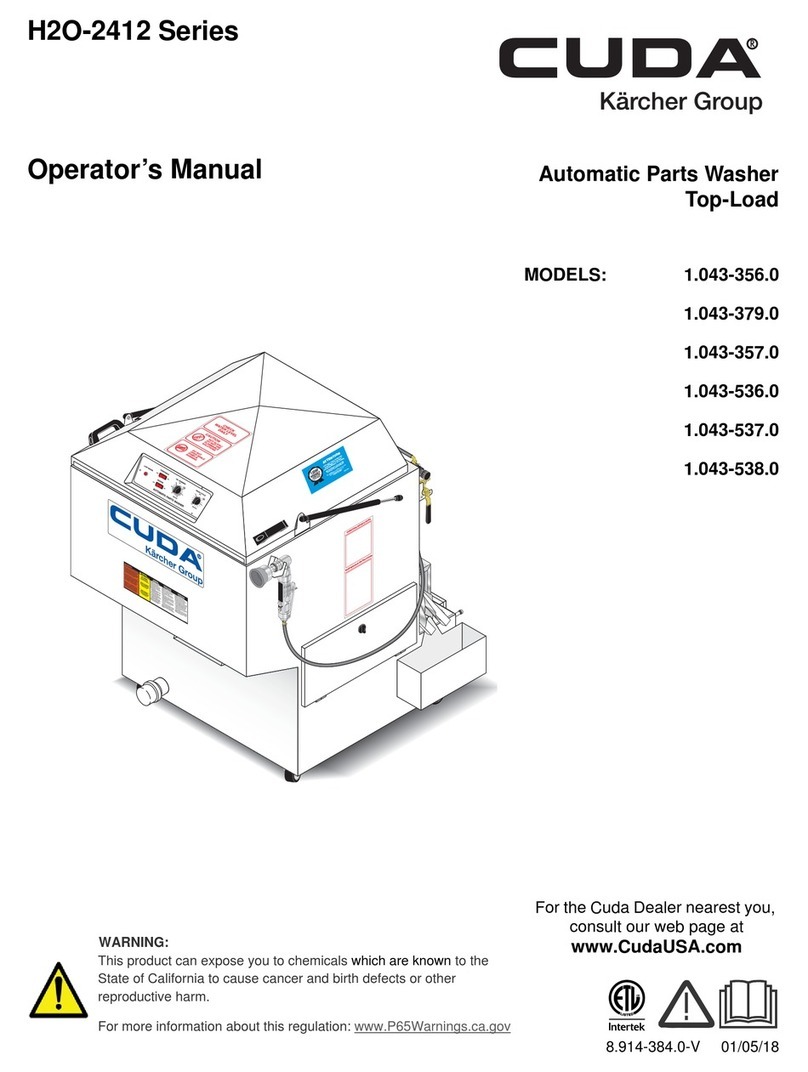

7248 Series

Operator’s Manual Automatic Parts Washer

Front-Load

MODELS 1.043-516.0

1.043-517.0

1.043-518.0

For the Cuda Dealer nearest you,

consult our web page at

www.CudaUSA.com

9.801-712.0 - BB 03/29/21

WARNING:

This product can expose you to chemicals which are known to the

State of California to cause cancer and birth defects or other

reproductive harm.

For more information about this regulation: www.P65Warnings.ca.gov

Thisisaheated parts cleaner.Useonlynonflammable, non-

combustible,water-basedcleaningcompoundsin this machine.

Donotfillorcontaminate with anyflammable or combustible

materialsuchasgasoline,alcohol,mineralspirits,etc.Drainparts

tobecleaned of anycombustibleor flammable material before

placinginsidecabinet.Failuretoobserve thiswarningwill create

anextremelyhazardouscondition.

Estees unlimpiadorde partes que se calienta.Utilice sola-

menteenestamáquinacomponentes delimpieza baseagua,no

inflamablesynocombustibles.Nollenarocontaminar con algún

materialinflamablecomo,gasolina,alcohol,esencias minerales,

etc.Drenelaspartesaser limpiadas decualquier combustibleo

materialinflamable antes deintroducir enel gabinete.Si

descuidaobservarestasprecauciones,pueden crearse condicio

-

nesextremadamentepeligrosas.

Cenettoyeurdepiècesest chauffé.Utiliserdans cetappareil

seulementdesnettoyeursàbase d’eau, non combustibles et non

inflammables.Nepasyajouteroucontaminer avec des matériaux

combustiblestels:gasoline,alcool,etc.Viderles piècescontenant

desmatériauxcombustiblesou inflammables avantde les placer

àl’intérieurducabinet.Nepasobserver ces avertissements peut

créerdessituationsrisquées.

HOTWATER

Beforeopeninglid,wait5

secondstoallowspray

arm/turntabletostop

spinning.

AGUA

CALIENTE

Antesdeabrirla tapa,

espere5segundospara

quelabarrarotatoriase

detenga.

EAUCHAUDE

Avantd’ouvrirlecouvert,

attendez5secondes pour

permettreaubrasvaporisa

-

teur/plaquetournante

d’arrêter

detourner.

WARNING

PRECAUCION/ADVERTISSEMENT

CAUTION

CUIDADO/ATTENTION

OPERATINGINSTRUCTIONSINSTRUCCIONESDEOPERACION INSTRUCTIONSD’OP

ÉRATION

IMPORTANT:Beforeoperatingthismachine,

completelyfamiliarizeyourselfwithinstruction

manualprovided.Onlyauthorizedandproperly

instructedindividualsshouldoperate this machine.

Beforeloadingpartsonto turntable/basket, becer

-

tainthepumpisoff and not running and the wash

solutionsareatoperating temperature.

1.Filltankwithwater and cleaning solution.

Waterlevelshouldbe2"belowthe accessdoors.

Checkdaily.

2.Programheatertimerfordesiredperiodof

operation.Allowtimeforunit top reheatclean ing

solution.

3.Opendoor/lidandplace articles to be clean onto

basket/turntable.Becertainnopartsprotrude

throughthebottomor beyondthesides of the

basket/turntable.Donotexceedthespecified

heightorweightlimit for this spraywashcabinet.

4.Closedoor/lidandlatchsecurely.Withmachine

settowash,turn“wash cycle”timer to t he desired

cleaningtime.Pumpwillstar t andrun until time

hasexpired.

5.Beforeopeningthedoor/lid, turn wash cycle timer

offandwait5secondsformachineto stop spin

-

ning.Thiswillallowsteam to escapethe cabinet

andexcesswaterto drainfrom yourparts.

IMPORTANTE:Antesdeopararel equipo,familiarícesecom-

pletamenteconelmanual deoperación que se incluye.Solo

personalautorizadoydebidamente capacitado debe oparar

ésteequipo.Antesdeabrirla puerta/cubierta o las piezas de

cargasobrelatornamesa/canasta, asegúrese de que labomba

estéapagadaysin funcionar,y que las soluciones de limpieza

esténatemperaturade funcionamiento.

1.Lleneeldepósitocon agua y la solución paralimpieza.El

niveldelaguadebe estar 2" por debajode las puerta de ac

-

ceso.Verifiqueelnivel diariamente.

2.ProgrameelT

emporizadordelcalentadorparael período de

operacióndeseado.Dejepasarun tiempo para que la unidad

precalientelasoluciónpara limpieza.

3.Abralapuerta/tapay coloque las piezas a lavar en lator

-

namesa/canasta,asegúresedeque ninguna pieza so-

brepaseelfondoniel perímetrode la to rnamesa.No exceda

loslimitesespecificadosdepeso y altura para el gabinete de

lavado.

4.Cierrelapuerta/tapayasegure el candado.Conla máquina

enposicióndelavar,ajusteeltemporizador de “ciclo de

lavado”altiempodeseado.Labombaarrancaráyfuncionará

duranteeltiemposeleccionado.

5.Antesdeabrirla puerta/cubierta, apague eltemporizador del

ciclodelavadoyespere 5 segundos pa ra que la máquina

dejedegirar.Estopermitirá que elvapor salga del gabinete y

elexcesodeagua drene de las piezas.

IMPORTANT:Avantd’utilisercettemachine,familiarisez

-

vouscomplètementaveclemanueld’instruction fourni.Cette

machinedevraitêtreutilisée seulement pardu personnel

autoriséetformé.Avantl’ouverturedelaporte/ducouvercle

ouduchargementdespièces sur la tabletournante/le panier,

s’assurerquelapompe est en positionarrêt et ne fonctionne

pasetqueles solutions de lavage sontà températurede

fonctionnement.

1.

Remplirleréservoird’eauetd’unesolution de nettoyage.

Leniveaud’eau doitsetrouverà 5 cm (2 po) sous les

portes d’accès.Vérifierquotidiennement.

2.

Programmerleminuteriede chauffage de l’appareil pour

lapériodedefonctionnement souhaitée. Prévoirdu temps

pourquel’appareilpréchauffela solution de nettoyage.

3.

Ouvrirlaporte/couvertetplacez lesarticles àêtre lavé

surlepanier/plaquetournante.Assurez-vousqu’iln’y est

aucunepiècedépassantlepainer oudansle fond au-delà

dupainer/plaquetournante.

4.Fermezlaporte/couvertet verrouillez de façon sécuritaire.

Lamachineprêtepourle lavage, tournez le minuteur “wash

cycle”autempsde lalavagedésiré.La pompe fonctionnera

jusqu’àcequetempssélectionnésoit écoulé.

5.

Avantd’ouvrirlaporte/lecouvercle,mettre la minuteriedu

cycledelavageàl’arrêt et attendre pendant 5 secondes que

l’appareils’arrêtedetourner.Cela permettra à lavapeur de

s’échapperducabinetetàl’excès d’eau de s’écoulerdevos

pièces.

WARNING

PRECAUCION/ADVERTISSEMENT

• Machinemustbeconnected to a properly sized

lockabledisconnect.

• Installationmustcomplywith NEC code.

• Forsupplyconnection,usewiresacceptable for

atleast90degrees C.

• Donotusebelow grade floor or grade level.

Thefollowingscheduleisbasedonaverageuse.

Higherusagemayrequiremorefrequentmainte

-

nance.

IMPORTANT:Besureelectricalsupplyis OFF be

-

foredrainingsump.Onlyqualifiedpersonnelshould

servicethismachine.

DAIL

Y:

• Checkwaterlevelinthe sump daily. Topping

offthewaterdaily will preventdamage to the

heaterelement.

• Removeandcleandebrisscreen.

• Visuallycheckforpluggednozzles.Remove

andcleanifneeded.Reinstall in the exact origi

-

nalposition.

WEEKL

Y:

•Grease/oildoorhinges.

MONTHL

Y:

• Performvisualcheckofturntabledrivechain.

• Drainwashsolutionfrom sump,removesand/

gritfrombottomof the sump.Careshould be

takentoavoidbendingor damagingheater ele

-

mentduringthecleaning process.

• Whensumphasbeencleanedand refilled with

water,addtherecommendedquantity of deter-

gentforyourmachine.

NOTE:Dissolvecleaningpowderintowarmwater

beforeaddingthemanufacturer’srecommended

amounttothetank.

8.922-402.0

• Lamáquinadebeestar conectada a unenchufe

eléctricodeseguridad.

•Lainstalacióndebecumplir con el código NEC.

•Paralasconexionesdealimentación, usecablea

-

doparaalmenos90 grados centígrados.

Noutilicepordebajo del nivel del piso.

• L’appareildoitêtreconnectéà un sectionneur

verrouillabledetailleappropriée.

• L’installation doitseconformerau code NEC.

• Pourleraccordement de l’alimentation,utiliserdes

fils pouvantaccepteraumoins 90degrés Celsius.

Nepasutiliserun calibre ou un gradeinférieur.

Letableausuivantestfondésur uneutilisation moyenne.

Uneutilisationplusimportante peut exiger un entretien plus

fréquent.

IMPORTANT:S’assurerquele système électrique est à l’arrêt

avantdeviderlerése rvoir.Seul lepersonnel qualifiédoit ré

-

parercetappareil.

QUOTIDIENNEMENT:

•Vérifier quotidiennementleniveau d’eau dansle rés

-

ervoir.Leremplissagequotidiend’eaupermet d’éviter

d’endommagerl’élémentchauffant.

• Démonteretnettoyerlefiltre à débris.

•Vérifiervisuellementsides busessont bouchées/ob-

struées.Démonteretnettoyer,le cas échéant.Réinstaller

danslapositioninitialeexacte.

HEBDOMADAIREMENT:

•Graisser/huilerlespentures/charnièresde la porte.

MENSUELLEMENT:

• Procéderàuncontrôlevisuel de la chaîned’entraînement

delatabletournante.

• Assécherlasolutionde lavagedu r éservoir,et enlever tout

sable/graviersetrouvantaufond.Des précautions doivent

êtreprisespouréviter de plier/courberl’élément chauffant

oudel’endommagerau cours du processus denettoyage.

•Lorsqueleréservoiraéténettoyéetremplid’eau,ajouter la

quantitédedétergentrecommandée pour votreappareil.

NOTE:Biendissoudrelapoudre dans l’eau chaude avant

d’ajouterdansleréservoir.

Elplandemantenimientoquesepresentaacontinuación,está

basadoenunusopromediodelequipo.Unusomás frecuente o

severopuederequerirunmantenimientomásfrecuente.

IMPORTANTE:

Asegúresedequeel sistema eléctrico esté

AP

AGADOantesdevaciarelcárter.Sólopersonal calificado

deberepararestamáquina.

DIARIAMENTE:

• Compruebeelniveldelaguaen el cárter diariamente.

Mantenerelniveladecuado del agua evitará dañarel

elementodelcalentador.

• Retireylimpielosresiduos de lacriba.

• Compruebevisualmentequelas boquillas están instaladas

correctamente.Retireylimpiesies necesario.Reinstaleen

laposiciónoriginalexacta.

SEMANALMENTE:

• Lubriquelasbisagrasdelapuerta.

MENSUALMENTE:

•Realiceunaverificaciónvisualdela cadena de propulsión

delatornamesa.

•Drenelasoluciónde limpieza del cárter, retire del fondo de

cárterlossedimentos.Debe tener cuidado de no doblaro

dañarelelementodelcalentador durante el proceso de

limpieza.

• Unavezqueel cárterestá limpio y relleno de agua,

agreguelacantidadrecomendada de detergente parala

máquina.

NOTA:Disuelvaeldetergenteenaguacalienteantesdeagregar-

loaltanqueenlacantidadrecomendadaporelfabricante.

MAINTENANCEINSTRUCTIONS

INSTRUCCIONESDEMANTENIMIENTODIRECTIVESD’ENTRETIEN

TURNTABLE

JOG