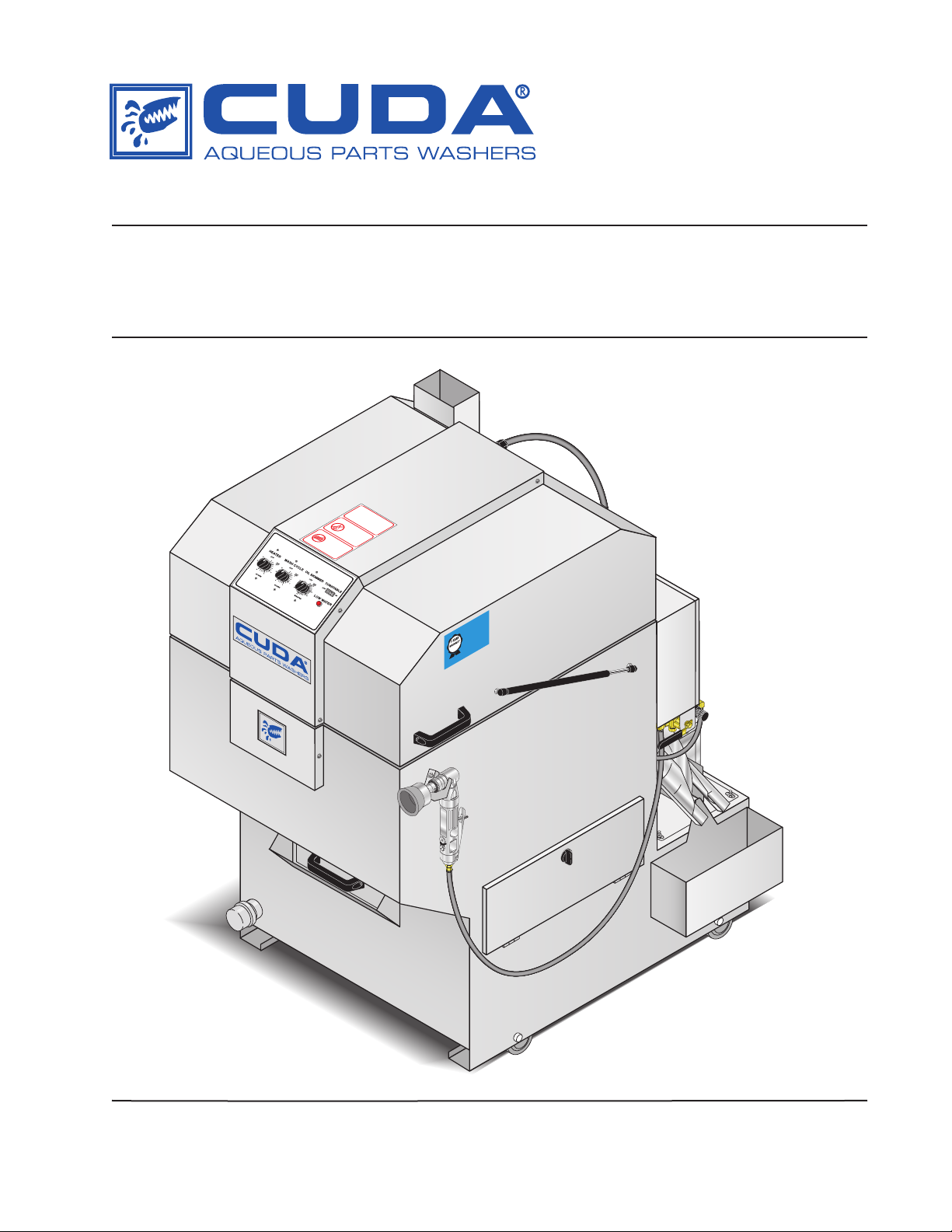

CUDA 2518 • 8.915-630.0 • Rev. 7/13

5

PARTS WASHER OPERATOR’S MANUAL

This manual is intended as a guide for safely install-

ing, operating and maintaining your automatic parts

washer system.

We reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding

of the manufacturer’s operating instructions and warn-

ings before using this machine. Warning information

should be emphasized and understood. If the operator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with

the operator in the operator’s native language by the

purchaser/owner, making sure that the operator com-

prehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and se-

rial number. Use only identical replacement parts.

This machine is to be used only by trained

operators.

GENERAL SAFETY

INFORMATION

CAUTION:To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Read the owner’s manual

thoroughly. Failure to follow in-

structions could cause a mal-

function of the parts washer

and result in death, serious

bodily injury and/or property

damage.

2. Improper installation could cause serious injury

to the machine. All installations must comply with

local codes. Contact your electrician, plumber,

utility company or the selling distributor for specific

details.

3. The machine can only operate on the type of electri-

cal power indicated on the electrical specifications

tag. Operating the machine on any other power

supply will permanently damage the motors.

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE.

WARNING: Electrical shock

could cause serious injury or

death.

4. Install the machine in compli-

ance with the National Electric

Code, connect it to a properly

sized lockable disconnect and

ground the machine using

the grounding stud inside the

main electrical panel.

5. While operating the machine, keep all electrical

panels in place and securely fastened at all times.

6. Disconnect the machine completely from the out-

side power source before servicing.

WARNING: Hot, high pressure

cleaning solution could cause

serious injury.

7. Do not operate the machine

with the lid or door open and

do not override the safety

switch.

8. After the machine stops, wait

10 seconds before opening

the lid or door.

WARNING: Always wear ap-

proved eye protection and pro-

tective clothing while operating

machine.

9. Always wear rubber gloves

when loading and unload-

ing the machine or servicing

components in the processing

chambers or sumps.

WARNING: Slips and falls could cause serious

injury.

10. Maintain an unobstructed work area around the

machine and keep the floor free of water, oil, grease

or other foreign substances.

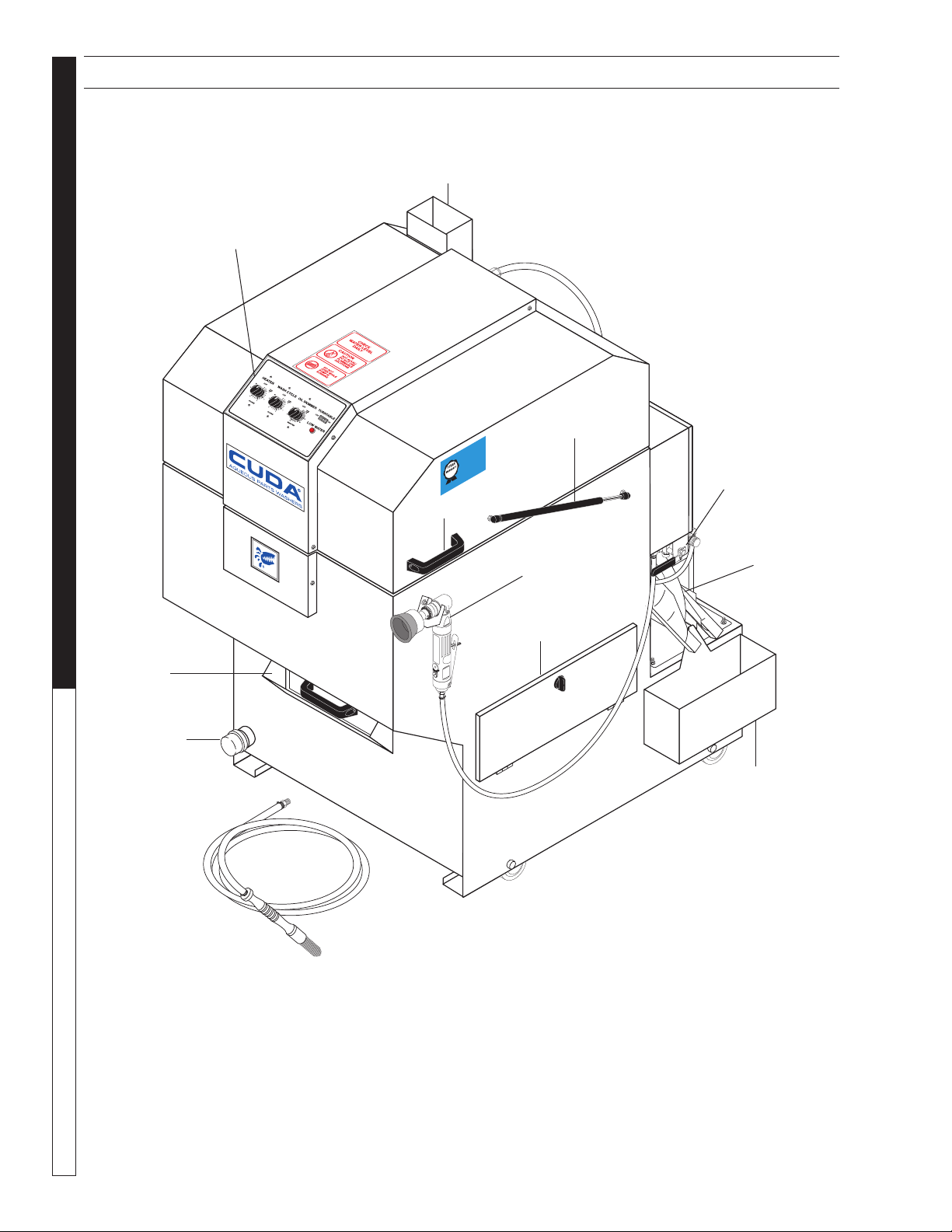

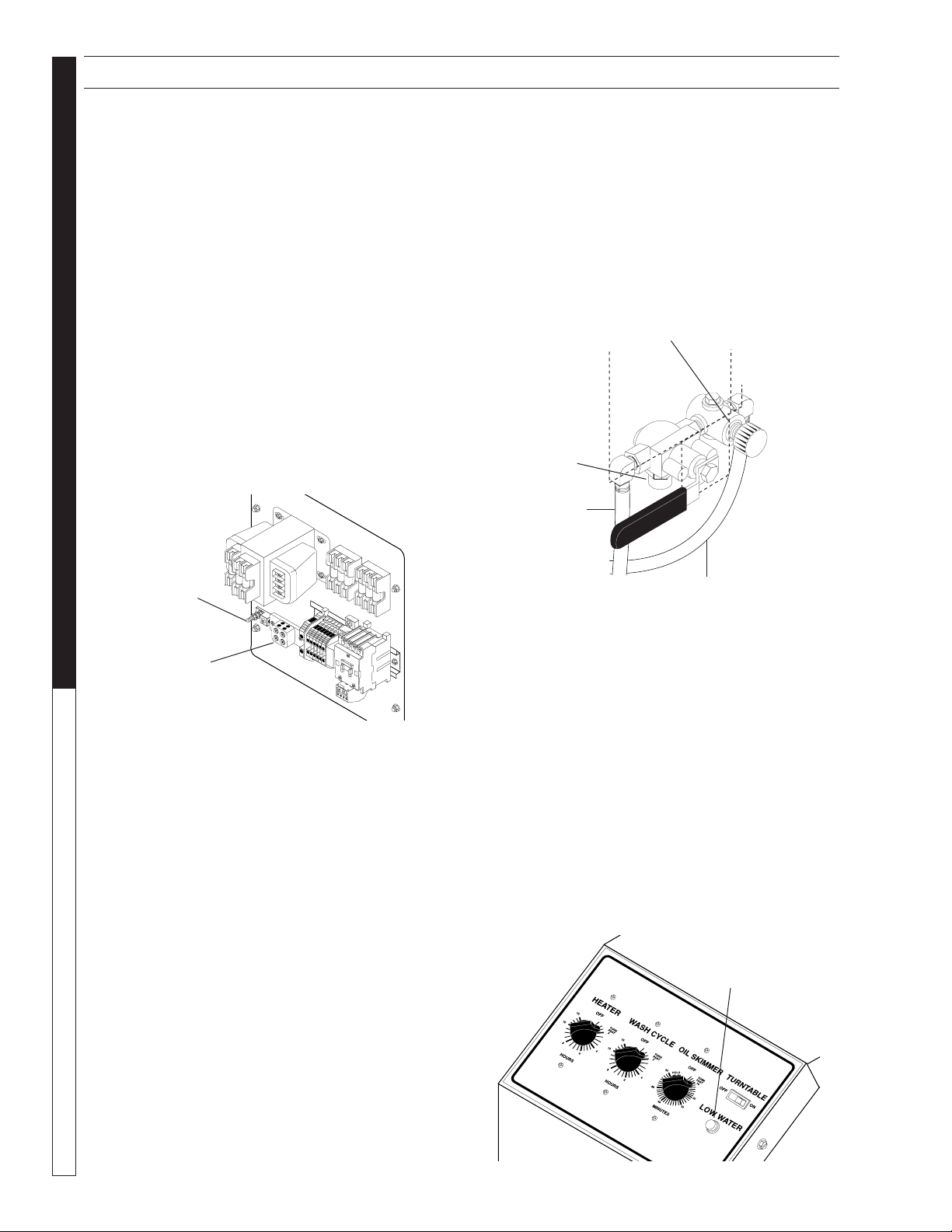

This automatic parts washer is designed to operate

safely and efficiently with a minimum of required mainte-

nance. Before you begin to install and use the machine,

please familiarize yourself with the major components.

HIGH PRESSURE

SPRAY CAN PIERCE

SKIN AND TISSUES.

PROTECTIVE

EYE WEAR AND

CLOTHING MUST

BE WORN.

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

INTRODUCTION