8

Operations

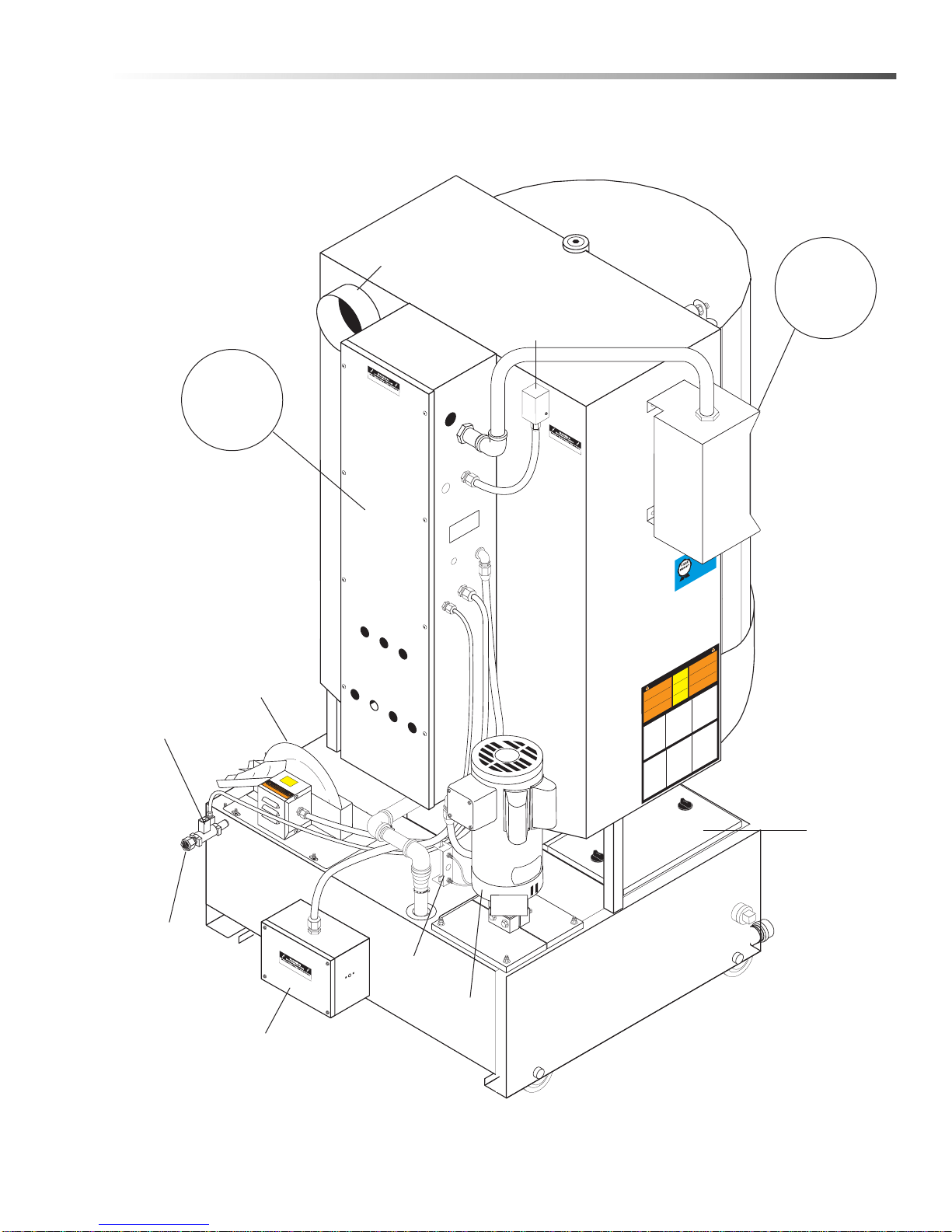

Component Identification - Front View

Cuda 2840 Operator’s Manual 8.930-370.0 -AU

ATTENTION

USEONLY CUDA APPROVED

DETERGENTSTO EXTEND

LABORWARRANTYTO1-YEAR!

MIXDETERGENTS 1 LB (1/2 KG)PER

5-GALLONS(15 LITERS) OF WATER

ForCUDAApproved Detergents visit

http://www.cudausa.comor

call888-319-0882

9.807-513.0

90-DAYLABORWARRANTY

EXTENDSTO1-YEAR

WITHEXCLUSIVEUSEOF

CUDADETERGENTS

LIMITED

This is aheated partscleaner.Use onlynonflammable,non-

combustible,water-basedcleaningcompoundsin this machine.

Do notfillor contaminate withanyflammableor combustible

materialsuchasgasoline,alcohol,mineralspirits,etc.Drainparts

tob

ec

leanedof anycombustible or flammable material before

placinginsidecabinet.Failureto observe this warningwill create

anextremely hazardous condition.

Este es un limpiador de partesques

ec

alienta.Utilice sola-

menteen estamáquinacomponentes de limpieza baseagua,no

inflamablesynocombustibles. No llenarocontaminar con algún

materialinflamablecomo,gasolina,alcohol, esencias minerales,

etc.Drenelas partes a ser limpiadas de cualquier combustible o

materialinflamable antesde introducir en el gabinete.Si

descuidaobservarestas precauciones,pueden crearsecondicio-

nesextremadamente peligrosas.

Ce nettoyeur de pièces estchauffé. Utiliserdans cetappareil

seulementdesnettoyeursàbased’eau,noncombustibleset non

inflammables.Ne pasyajouter ou contaminer avecdesmatériaux

combustiblestels:gasoline,alcool,etc.Viderlespièces contenant

desmatériauxcombustiblesouinflammables avant de les placer

àl’intérieurdu cabinet.Nepasobservercesavertissements peut

créerdes situations risquées.

HOTWATER

Beforeopening lid,wait 5

secondsto allowspray

arm/turntableto stop

spinning.

AGUA

CALIENTE

Antesde abrir la tapa,

espere5 segundos para

quela barra rotatoria se

detenga.

EAUCHAUDE

Avantd’ouvrir le couvert,

attendez 5 secondes pour

permettreau bras vaporisa-

teur/plaquetournante d’arrêter

detourner.

WARNING

PRECAUCION/ADVERTISSEMENT

CAUTION

CUIDADO/ ATTENTION

OPERATINGINSTRUCTIONS INSTRUCCIONESDE OPERACIONINST

RUCTIONSD’OPÉRATION

IMPORTANT:Beforeoperatingthis machine,

completelyfamiliarizeyourselfwith instruction

manualprovided.Only authorized and properly

instructedindividuals should operate this machine.

Beforeloading parts onto turntable/ basket, be cer-

tainthe pump is off and not running and the wash

solutionsare at operating temperature.

1.Filltank with water and cleaning solution.

Waterlevel should be 2" below the access doors.

Checkdaily.

2.Programheater timer for desired period of

operation.All owtime for unit to preheat cleaning

solution.

3.Open door/lid and place articles to be clean onto

basket/turntable.Becertainno parts protrude

throughthe bottom or beyond the sides of the

basket/turntable.Donot exceed the specified

heightor weight limit for this spray wash cabinet.

4.Closedoor/lid and latch securely.With machine

setto wash,turn“wash cycle”timer to the desired

cleaningtime.Pump will start and run untiltime

hasexpired.

5.Before opening the door/lid, turn wash cycle timer

offand wait 5 seconds for machine to stop spin-

ning.Thiswill allow steam to escape the cabinet

andexcess water to drain fromyour parts.

IMPORTANTE:Antesde opararel equi po,familiarícese com-

pletamentecon el manual de operación que se incluye.Solo

personalautorizado y debidamente capacitado debe oparar

ésteequipo. Antes de abrirla puerta/cubierta o las piezas de

cargasobre la tornamesa/canasta, asegúrese de que la bomba

estéapagada y sin funcionar, y que las soluciones de limpieza

esténa temperatura de funcionamiento.

1.Llene eldepósito con agua y la solución para limpieza.El

niveldelagua debe estar 2" por debajo de las puerta de ac-

ceso.Verifiqueelnivel diariamente.

2.ProgrameelTemporizador del calentador para el período de

operacióndeseado.Deje pasar un tiempo paraque launidad

precalientela solución para limpieza.

3.

Abrala puerta/tapa y coloque las piezas a lavar en la tor-

namesa/canasta,asegúrese de que ninguna pieza so-

brepaseel fondo ni el perímetro de la tornamesa.Noexceda

loslimites especificados de peso y altura para el gabinete de

lavado.

4.Cierre la puerta/tapa y asegure el candado.Con la máquina

enposición de lavar, ajuste el temporizador de “ciclo de

lavado”altiempo deseado.La bomba arrancará y funcionará

duranteel tiempo seleccionado.

5.Antesde abrir la puerta/cubierta,apague el temporizador del

ciclode lavado y espere 5 segundos para que la máquina

dejede girar.Esto permitirá que el vapor salga del gabinete y

elexceso de agua drene de las piezas.

IMPORTANT:Avantd’utilisercette machine, familiarisez-

vouscomplètement avec lemanuel d’instruction fourni.Cette

machinedevrait être utilisée seulement par du personnel

autoriséet formé.Avantl’ouverture de la porte/du couvercle

oudu chargement des pièces sur la table tournante/le panier,

s’assurerque la pompe est en position arrêt et ne fonctionne

paset que les solutions de lavage sont à température de

fonctionnement.

1.

Remplirle réservoir d’eau et d’une solution de nettoyage.

Leniveau d’eau doit se trouver à 5 cm (2 po) sous les

portesd’accès.Vérifier quotidiennement.

2.

Programmerle minuterie de chauffage de l’appareil pour

lapériode de fonctionnement souhaitée.Prévoir du temps

pourque l’appareil préchauffela solution de nettoyage.

3.

Ouvrirla porte/couvert et placez les articles à être lavé

surle panier/plaque tournante.Assurez-vous qu’il n’y est

aucunepièce dépassant le painer ou dans le fond au-delà

dupainer/plaque tournante.

4.Fermez la porte/couvert et verrouillez de façonsécuritaire.

Lamachine prête pour le lavage,tournez le minuteur “wash

cycle”autemps de la lavage désiré. La pompe fonctionnera

jusqu’àce que temps sélectionné soit écoulé.

5.

Avantd’ouvrir la porte/le couvercle, mettre la minuteriedu

cyclede lavage à l’arrêt et attendre pendant 5 secondes que

l’appareils’arrête de tourner.Cela permettra à la vapeur de

s’échapperdu cabinet et à l’excès d’eau de s’écouler de vos

pièces.

WARNING

PRECAUCION/ADVERTISSEMENT

• Machinemust be connected to a properly sized

lockabledisconnect.

• Installationmust complywith NEC code.

• Forsupply connection,use wires acceptable for

atleast 90 degrees C.

• Do not use below grade floor or grade level.

Thefollowingscheduleisbasedonaverageuse.

Higherusagemayrequiremorefrequentmainte-

nance.

IMPORTANT:Besureelectrical supply is OFF be-

foredraining sump.Only qualified personnel should

servicethis machine.

DAILY:

• Checkwaterlevel in the sump daily.T

opping

offthe water daily will prevent damage to the

heaterelement.

• Removeand clean debris screen.

• Visuallycheck for plugged nozzles.Remove

andclean if needed.Reinstall in the exact origi-

nalposition.

WEEKLY:

• Grease/oildoor hinges.

MONTHLY:

•Performvisualcheckofturntabledrivechain.

• Drainwashsolution from sump,remove sand/

gritfrom bottom of the sump.Care should be

takento avoid bending or damaging heater ele-

mentduring the cleaning process.

• Whensump has been cleaned and refilled with

water,add the recommended quantity of deter-

gentforyour machine.

NOTE:Dissolvecleaning powder into warm water

beforeadding the manufacturer’s recommended

amountto the tank.

8.922-402.0

• Lamáquina debe estar conectada a un enchufe

eléctricode seguridad.

• Lainstalación debe cumplir con el código NEC.

• Paralas conexiones de alimentación,use cablea-

dopara al menos 90 grados centígrados.

Noutilice por debajo del nivel del piso.

• L’appareildoitêtreconnectéà un sectionneur

verrouillablede taille appropriée.

• L’installationdoitse conformer au code NEC.

• Pourleraccordement de l’alimentation,utiliser des

filspouvant accepter au moins 90 degrés Celsius.

Nepas utiliser un calibre ou un grade inférieur.

Letableau suivant est fondé sur une utilisation moyenne.

Uneutilisation plus importante peut exiger un entretien plus

fréquent.

IMPORTANT:S’assurer que le système électrique est à l’arrêt

avantde vider le réservoir.Seul le personnel qualifié doit ré-

parercet appareil.

QUOTIDIENNEMENT:

• Vérifierquotidiennement le niveau d’eau dans le rés-

ervoir.Leremplissage quotidien d’eau permet d’éviter

d’endommagerl’élément chauffant.

• Démonteret nettoyer le filtre à débris.

• Vérifiervisuellement si des buses sont bouchées/ob-

struées.Démonteret nettoyer, le cas échéant.Réinstaller

dansla position initialeexacte.

HEBDOMADAIREMENT:

• Graisser/huilerles pentures/charnières de la porte.

MENSUELLEMENT:

• Procéderà un contrôle visuel de la chaîne d’entraînement

dela table tournante.

• Assécherla solution de lavage du réservoir, et enlevertout

sable/gravierse trouvant aufond.Des précautions doivent

êtreprises pour éviter de plier/courber l’élément chauffant

oude l’endommager au cours du processus de nettoyage.

•Lorsqueleréservoiraéténettoyéetremplid’eau,ajouterla

quantitédedétergentrecommandéepourvotreappareil.

NOTE:Biendissoudre la poudre dans l’eau chaude avant

d’ajouterdans le réservoir.

Elplandemantenimientoquesepresentaacontinuación,está

basadoenunusopromediodelequipo.Unusomásfrecuenteo

severopuederequerirunmantenimientomásfrecuente.

IMPORTANTE:Asegúresede que el sistema eléctricoesté

APAGADOantesde vaciar el cárter.Sólo personal calificado

debereparar esta máquina.

DIARIAMENTE:

• Compruebeel nivel del agua en el cárter diariamente.

Mantenerel nivel adecuado del agua evitará dañar el

elementodel calentador.

• Retirey limpie los residuos de la criba.

• Compruebevisualmente que las boquillas están instaladas

correctamente.Retirey limpie si es necesario.Reinstale en

laposición original exacta.

SEMANALMENTE:

• Lubriquelas bisagras de la puerta.

MENSUALMENTE:

• Realiceunaverificaciónvisual de la cadena de propulsión

dela tornamesa.

• Drenela solución de limpieza del cárter, retire del fondo de

cárterlos sedimentos.Debe tenercuidado de no doblar o

dañar el elemento del calentador durante el proceso de

limpieza.

• Unavez que el cárter está limpio y relleno de agua,

agreguela cantidad recomendada de detergente parala

máquina.

NOTA:Disuelvaeldetergenteenaguacalienteantesdeagregar-

loaltanqueenlacantidadrecomendadaporelfabricante.

MAINTENANCEINSTRUCTIONS

INSTRUCCIONESDEMANTENIMIENTODIRECTIVESD’ENTRETIEN

For Detail

See Control

Panel Illus.

For Detail

See Control

Box Illus.

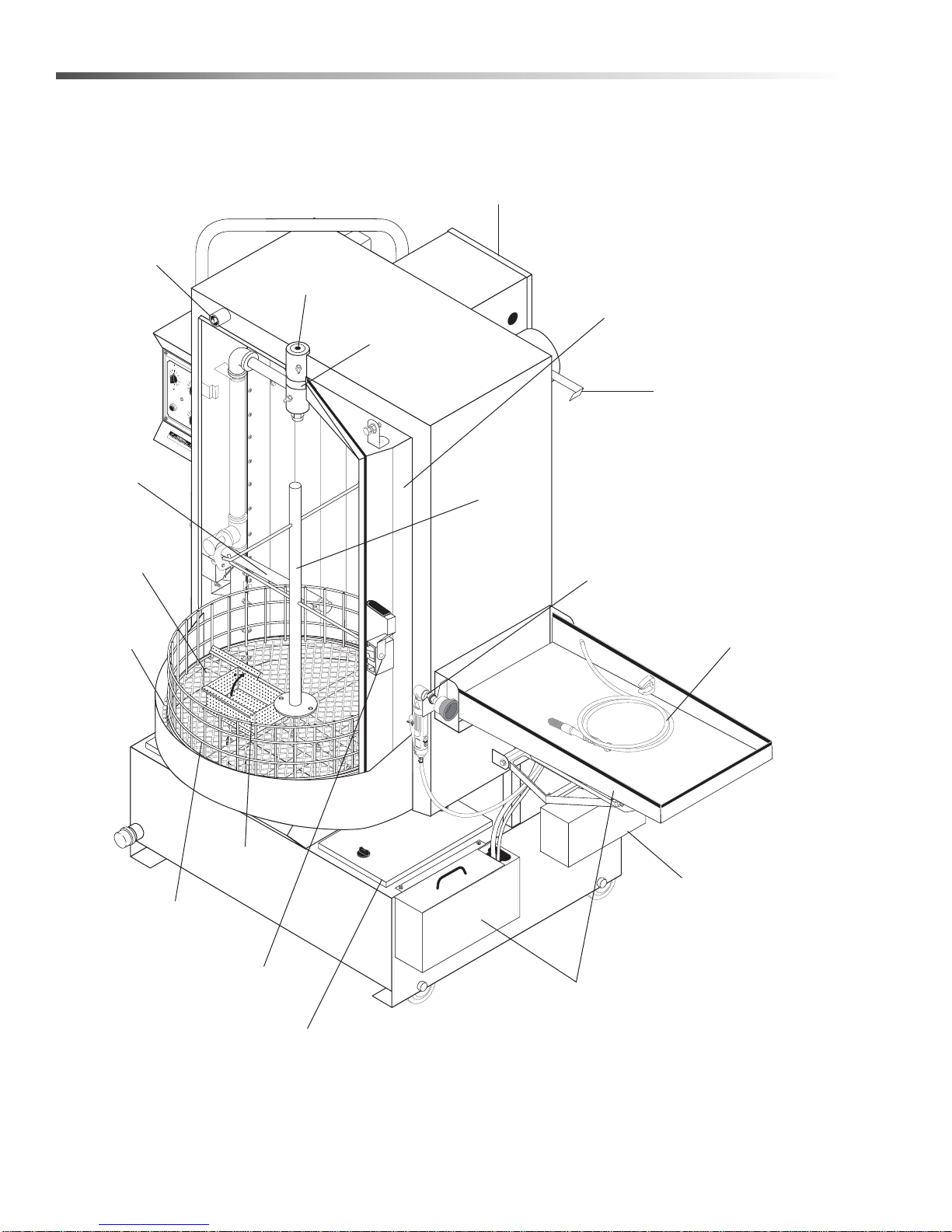

Steam Vent

Door Safety

Switch

Plunger

Revolving

Door Pivot

Assy.

Revolving

Door

Debris

Screen

Sump

Cover

Door Latch

Pump