Introduction

Congratulations on your purchase

of the Badger Curb Maker.

The Curb Maker is proudly

manufactured in the USA by Curb

Roller Manufacturing. The Curb

Maker has been manufactured to

provide years of service.

Before using the Curb Maker you

must read and follow this manual

for proper use and set up. You

must also read the DeWalt DCD460

manual.

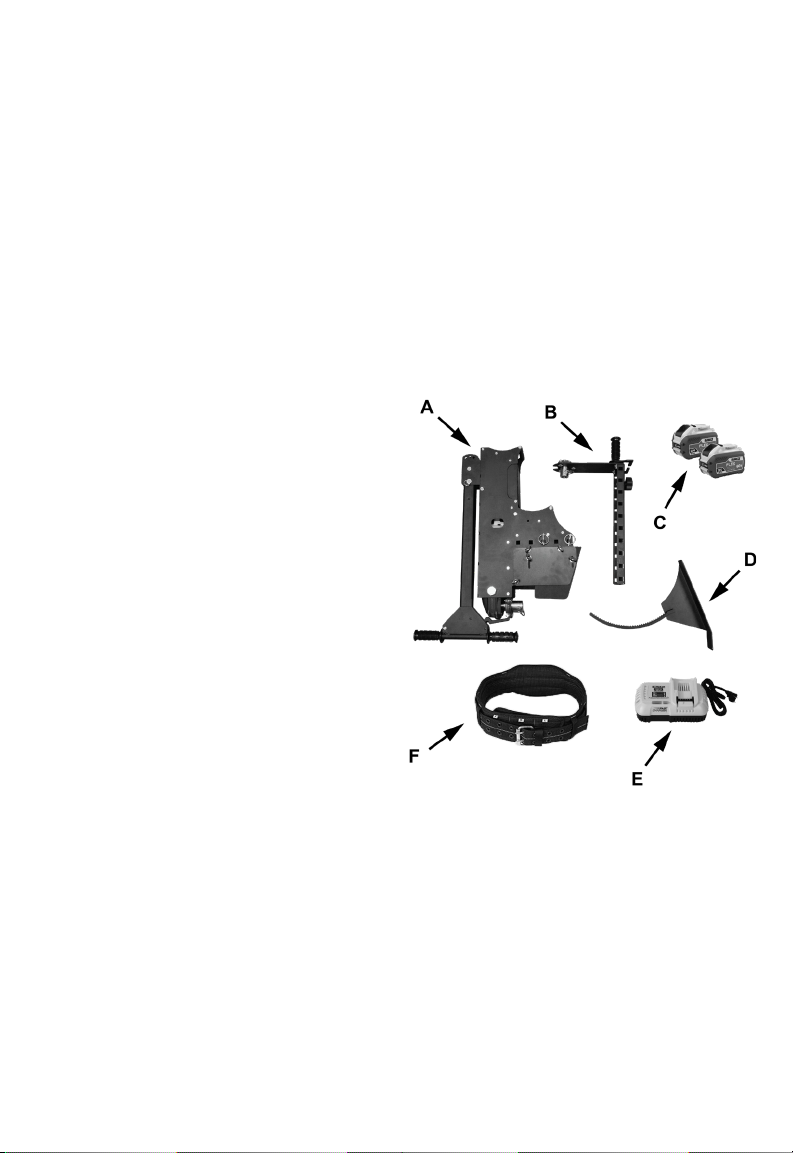

Upon Receipt

Carefully examine your equipment

upon receipt to verify all the

components of your order have

been shipped to you and arrived

undamaged. Report any damage

immediately to the freight carrier

and register any claim. If any

material or manufacturing defects

are discovered, contact a Curb

Roller Mfg. representative at

785-467-3132.

Manufacturer’s Notice

Information provided in this manual

was current as of the issue date.

Curb Roller Mfg. reserves the right

to make design changes without

notice or liability.

Information furnished in this manual

does not include all of the details

of design, production, or variations

of the equipment. It does not cover

all of the possible contingencies

which may emerge during

operation. If special problems arise

or further information is desired,

please contact a Curb Roller Mfg.

representative at 785-467-3132.

This owner’s manual does not

replace, nor does its use release

the owner/operator from observing

all safety codes or operating

limitations as well as any applicable

federal, state, provincial or local

regulations.

1