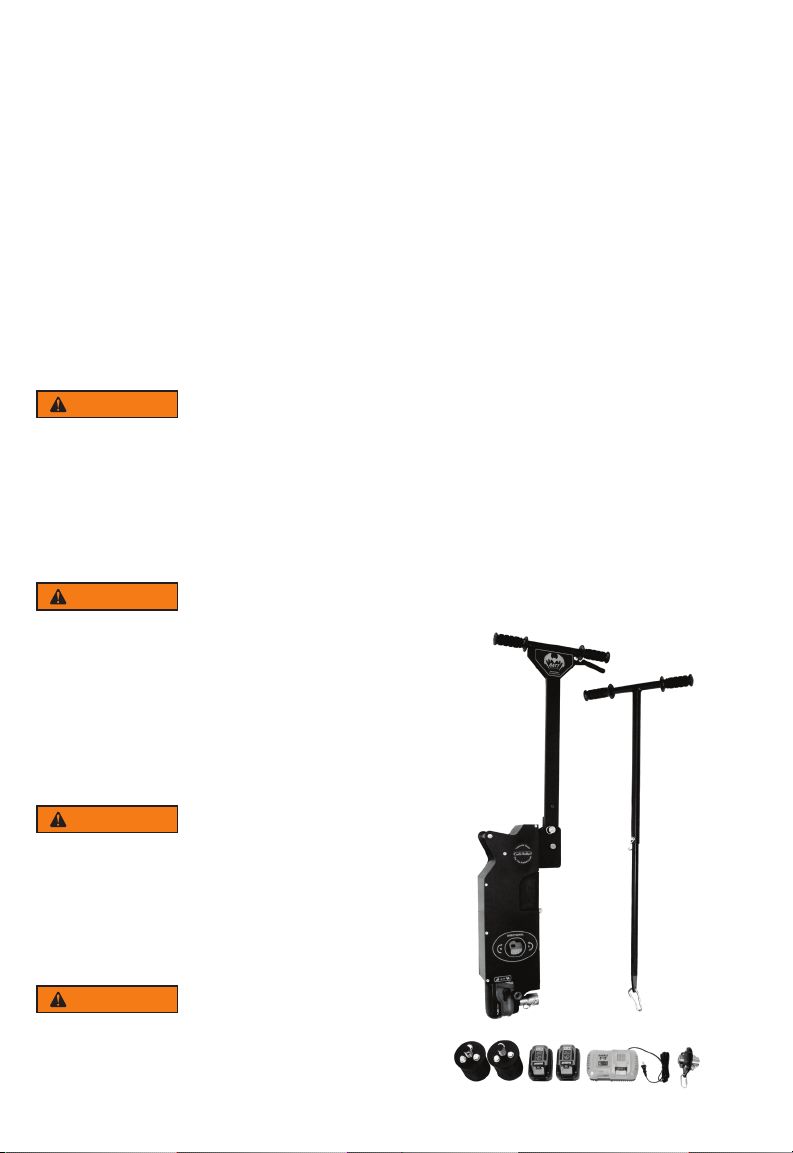

Congratulations on your

purchase of the BATT Screed!

Curb Roller Manufacturing

proudly manufactures the BATT

Screed 6000 in the USA.

Before using the BATT Screed

6000 you must read and follow

this instruction manual for

proper use and set up. You also

must read the DeWalt DCD460

manual.

The use of this screed may be

hazardous. The screed has rotating

parts and lithium ion battery power.

Make sure anyone using the Batt

Screed 6000 understands the

proper way to set up and operate

the machine to avoid accidental

injury. Before each use make

sure the equipment has not been

damaged or altered.

As with any laborious job do not

operate the BATT Screed 6000 if

you are too tired or if you have a

medical condition that might be

aggravated by strenuous work.

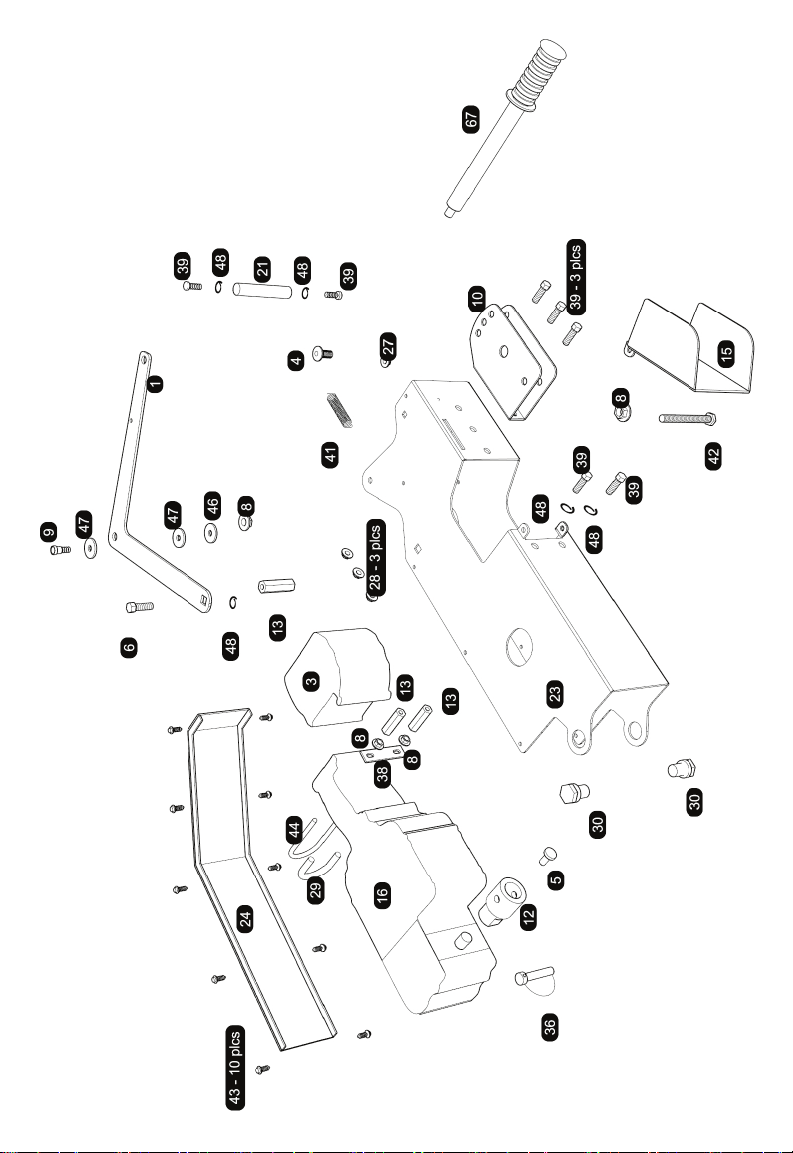

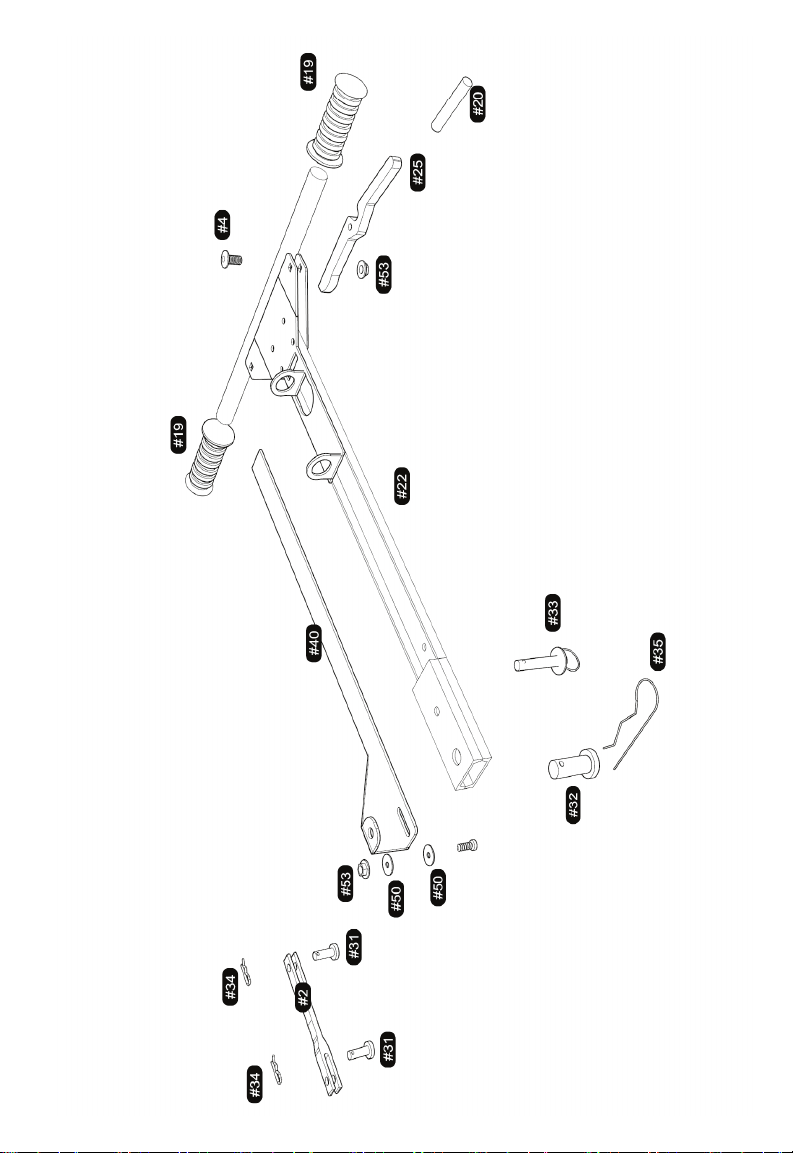

Minimal assembly is required for the

BATT Screed 6000.

After removing packaging, inspect

equipment for any damage that may

have occurred during shipping. If

any damage or defects are found

please stop and take photos. Email

photos to info@curbroller.com.

If you have safety concerns or

questions that are not addressed in

this manual please feel free to call

us at 785-467-3132 or email at

info@curbroller.com.

As the first battery powered roller

screed on the market, the BATT

Screed 6000 introduced the world

to a new level of roller screed

innovation and is the most versatile

roller screed on the market. Curb

Roller Mfg. constructed the BATT

Screed 6000 with the basics in

mind and it has been carefully

designed to protect the battery and

drill with an all steel housing for

longer life and durability.

Engineering Improvements and

Changes

Curb Roller Mfg. is constantly

improving on product quality

and eectiveness. As a result,

engineering changes and