8

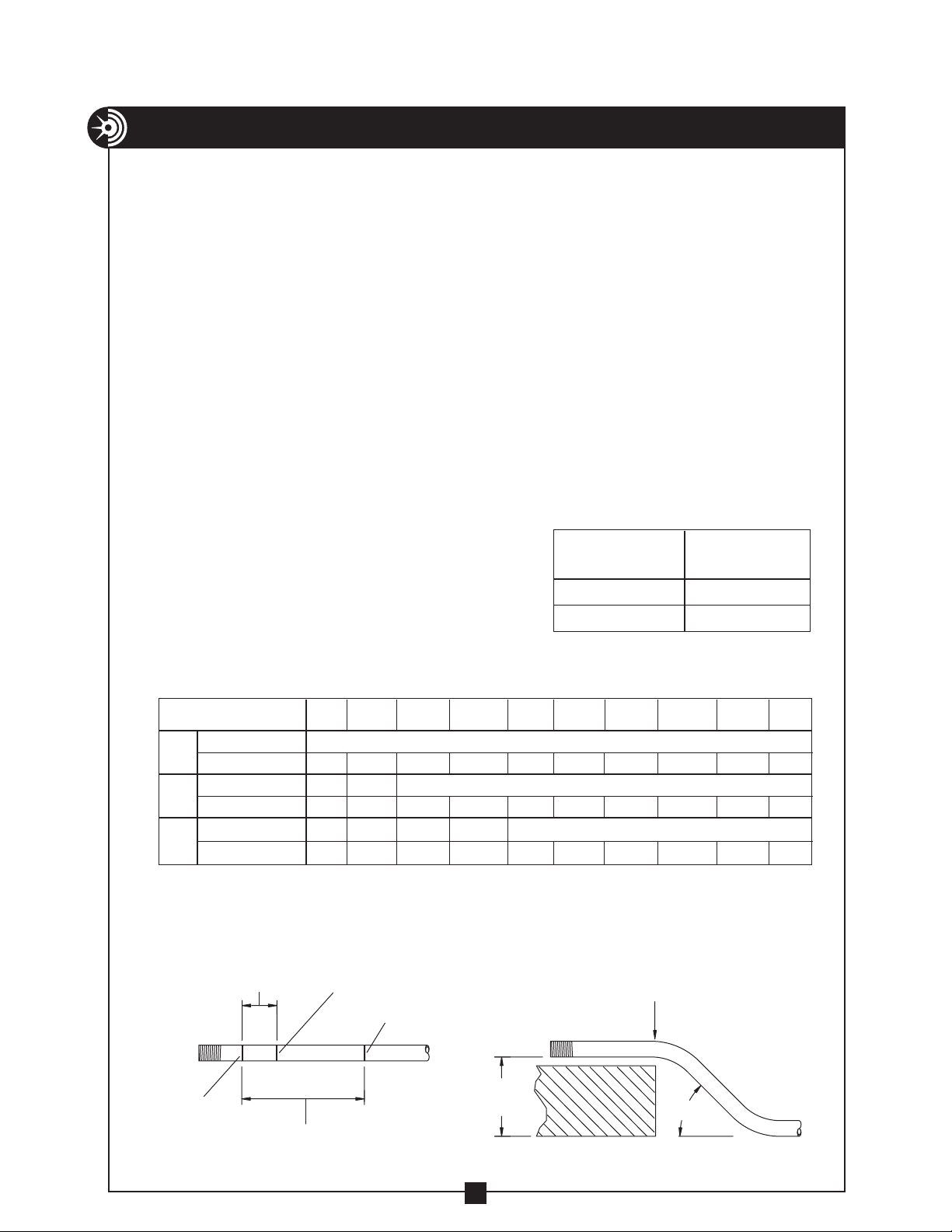

PARTS LIST — Model 751 Mechanical Bender

ITEM # PART # QTY DESCRIPTION

........1 ..............BENDING SHOE

........1 .............BENDER HOUSING

........1 ..............ROLLING STAND

. . . . . . . . 1 . . . . . . . . . . . WASHER – FLAT 7⁄8 SAE

........1 .............. RATCHET ARM

........1 ..............BENDING HOOK

........1 .............. RATCHET PAWL

........1 ...............RATCHET PIN

1 . . . . . . . . . . 751-458.

2 . . . . . . . . . . 751-450.

3 . . . . . . . . . . 750-668.

4 . . . . . . . . . . . 750-13 .

5 . . . . . . . . . . 750-335.

6 . . . . . . . . . . . 751-2. .

7 . . . . . . . . . . 750-330.

8 . . . . . . . . . . 750-347.

9 . . . . . . . . . . . 750-10 . . . . . . . . . 1 . . . . . . . . . . . . . TORSION SPRING

........

........

........

........

........

........

........

........

.........

........

........

........

........

........

........

........

........

........

........

........

........

........

10. . . . . . . . . . . 750-9. .

11. . . . . . . . . . 751-420.

12. . . . . . . . . . . 504-1. .

13. . . . . . . . . . . 509-13 .

14. . . . . . . . . . . 77-016 .

15. . . . . . . . . . 750-349.

16. . . . . . . . . . . 750-18 .

17. . . . . . . . . . 751-440.

18 . . . . . . . . . . . 750-20.

19. . . . . . . . . . . 750-21 .

20. . . . . . . . . . . 750-22 .

21. . . . . . . . . . 750-394.

22. . . . . . . . . . . 751-8. .

23. . . . . . . . . . . 751-9. .

24. . . . . . . . . . . 2-1403 .

25. . . . . . . . . . . 281-2C .

26. . . . . . . . . . . 281-1F .

27. . . . . . . . . . .280-2G .

28. . . . . . . . . . . 751-10 .

29. . . . . . . . . . 751-419.

30. . . . . . . . . . . 751-11 .

31. . . . . . . . . . 751-389.

32. . . . . . . . . . 751-390. ........

33...........705-14 .........

1 . . . . . . . . . . . . .PRESSURE SPRING

1 . . . . . . . . . . . . . .PRESSURE PLUG

2 . . . . . . . . . . . . . . . . . . . GRIP

2 . . . . . . . . . . . . . . . . . . WHEEL

2 . . . . . . . . . . . . . . . .COTTER PIN

1 . . . . . . . . BENDING DEGREE INDICATOR

2 . . . . . . . . .7⁄8"-9" HEX LOCK NUT (THIN)

1 . . . . . . . . . . . . INDICATOR ARROW

1 . . . . . . . . . .¼"-20" X ½" HEX HD SCREW

2 . . . . . . . . . . . .RETAINING RING – ½"

1 . . . . . . . . . . . . RETAINING RING – 1"

1 . . . . . . . . . . . . . . . . . WASHER

1 . . . . . . . . . . ½"-13" X 5⁄16" JAM SCREW

1 . . . . . . 5⁄8" -11" X 2" SOC. HD. CAP SCREW

1 . . . . . . . . . . . . . . . . . BUSHING

4 . . . . . . . . . . . . . ½" LOCK WASHER

4 . . . . . . . . ½"-13" X 1½" HEX CAP SCREW

4 . . . . . . . . . . . . . . ½"-13" HEX NUT

1 . . . . ½"-13" X 1" SOC. SET SCREW (FLAT PT)

1 . . . . . . . . . . . . . SPACER – SPRING

1 . . . . . . . . . . .½" ROLL PIN X 2" LONG

1 . . . . . . . . . . . . . ROLLER - 1¼" (751)

1 . . . . . . . . . . . . . ROLLER - 1½" (751)

1 . . . . . . . . . SHOULDER SCREW, ½" X 2"

34..........2-1501-4 ........1 ...........3⁄8"-16 HEX NUT (LOCK)

35. . . . . . . . . . . 451-25 . . . . . . . . . 1 . . . . . . . . . . ½" FLAT WASHER (SAE)

36..........2-1401-4 ........1 .......5⁄8"-11" HEX NUT, NYLON INSERT

37. . . . . . . . . . . 751-12 . . . . . . . . . 1 . . . . . . . . . . . DECAL SET (3 PIECES)

38........... 88-39..........1 ..............GREASE FITTING

39. . . . . . . . . . . 77-017 . . . . . . . . . 2 . . . . . . . . . . .WASHER – FLAT, 3⁄4 SAE