1

This Curtis Generation 4 System is factory pre-set and ready to go right from the box.

Following are the factory settings for your G4 Coffee Brewing System:

• Brew Temperature = 200°F • Water Bypass = On for LARGE & MEDIUM Brew Only

• Brew Volume = Set to Vessel Requirement.

System Requirements:

•WaterSource20–90psi(minimumowrateof1gpm)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.com for your model.

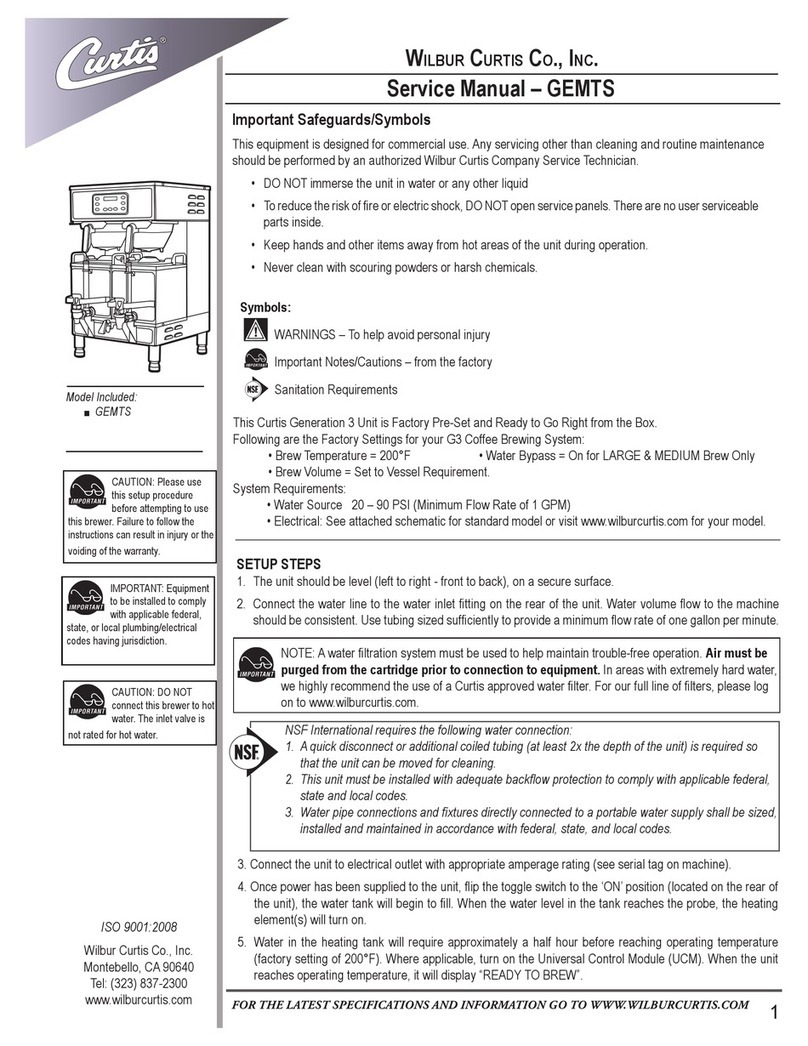

Model

G4GEMT

CAUTION: DO NOT

connect this brewer to hot

water. The inlet valve is

not rated for hot water.

CAUTION: Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions can result in injury or the

voiding of the warranty.

IMPORTANT: Equipment

to be installed to comply

with applicable govern-

mental plumbing/electrical codes

having jurisdiction.

ISO9001:2008REGISTERED

WILBUR CURTIS CO., INC.

6913WestAccoStreet

Montebello,CA90640-5403

For the latest information go to

www.wilburcurtis.com

Tel:800-421-6150

Fax:323-837-2410

Forthelatestspecicationsandinformationgotowww.wilburcurtis.com

TechnicalSupport:1-800-995-0417M-F5:30 a.m.- 4:00 p.m.PT

This equipment is designed for commercial use. Any servicing other than cleaning and routine maintenance

should be performed by an authorized Wilbur Curtis Company Service Technician.

• DO NOT immerse the unit in water or any other liquid

• Toreducetheriskofreorelectricshock,DONOTopenservicepanels.Therearenouserserviceable

parts inside.

• Keep hands and other items away from hot areas of the unit during operation.

• Never clean with scouring powders or harsh chemicals.

Important Safeguards/Symbols

Service Manual – G4 Gemini Twin Coffee Brewer

Wilbur Curtis Co., inC.

Symbols:

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

NSF International requires the following water connection:

1. Aquickdisconnectoradditionalcoiledtubing(atleast2xthedepthoftheunit)isrequiredso

that the unit can be moved for cleaning.

2. Thisunitmustbeinstalledwithadequatebackowprotectiontocomplywithapplicablefederal,

state and local codes.

3.Waterpipeconnectionsandxturesdirectlyconnectedtoaportablewatersupplyshallbesized,

installed and maintained in accordance with federal, state, and local codes.

3. Connect the unit to electrical outlet with appropriate amperage rating (see serial tag on machine).

4.Oncepowerhasbeensuppliedtotheunit,ipthetoggleswitchtothe‘ON’position(locatedontherearof

theunit),thewatertankwillbegintoll.Whenthewaterlevelinthetankreachestheprobe,theheating

element(s) will turn on.

5. Water in the heating tank will require approximately a half hour before reaching operating temperature

(factorysettingof200°F).Whereapplicable,turnontheuniversalcontrolmodule(UCM).Whentheunit

reachesoperatingtemperature,itwilldisplay“READYTOBREW”.

NOTE:Awaterltrationsystemmustbeusedtohelpmaintaintrouble-freeoperation.Air must be

purged from the cartridge prior to connection to equipment.Inareaswithextremelyhardwater,

wehighlyrecommendtheuseofaCurtisapprovedwaterlter.Forourfulllineoflters,pleaselog

on to www.wilburcurtis.com.

SETUP STEPS

1.Theunitshouldbelevel(lefttoright-fronttoback),onasecuresurface.

2. Connectthewaterlinetothewaterinletttingontherearoftheunit.Watervolumeowtothemachine

shouldbeconsistent.Usetubingsizedsufcientlytoprovideaminimumowrateofonegallonperminute.